Академический Документы

Профессиональный Документы

Культура Документы

Primary Liquid Mounted

Загружено:

VinayaKumarИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Primary Liquid Mounted

Загружено:

VinayaKumarАвторское право:

Доступные форматы

Specifications for Primary Seal- Liquid Mounted Type for External Floating Roof Tanks

1.0 GENERAL

This specifications cover requirements that shall be met as minimum for core foam and casing for

primary seals Liquid mounted type for External floating roof tanks (EFRT) and shall be read in

conjunction with other documents attached with the tender.

2.0 CORE FOAM

2.1 Core foam shall be of prime quality solid polyurethane foam and of octagon shape. Foam shall

be of light weight having appropriate elasticity, little permanent compressive strain and shall

have excellent resistance to oil and chemicals.

2.2 Core Foam shall have the following properties in accordance with ASTM D-3574

Specific Gravity- 0.018 to 0.022

Permanent strain due to compression- Not to exceed 10%

Load at 25% Deflection RMA value 6.81 +/- 1.36Kgs

2.3 Rim space of 150mm and 200mm shall be provided for tanks up to 30m dia. and above 30m dia.

respectively. Foam shall be of octagonal shape and of size 254mm and 305mm (across flat ends)

for rim space 150mm & 200mm respectively.

3.0 FOAM CASING

3.1 The casing material shall be oil and water resistant.

3.2 Material for foam casing shall be Nylon Fabric equally coated on both sides with Nitrile

Butadiene Rubber (NBR) and shall be compatible with petroleum products.

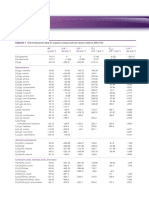

3.3 Casing shall have the following characteristics;

S No.

a

Characteristics

Thickness of Envelop

Values

2 mm

Original adhesion (ASTM D413)

80 Newtons /25mm

Adhesion after fuel ageing (*)

45 Newtons /25mm

Original tensile strength (ASTM D751)

1150 Newtons /25mm

Tensile strength after fuel ageing (*)

900 Newtons /25mm

Tensile strength after 50000 Flexes

1000 Newtons /25mm

g

h

Volumetric swelling (ASTM D471) (*)

25% maximum

Vapour Permeability

0.10 gms/Sq.m/hour

(*) Ageing in 75% Toluene, 25% Iso-octane for 7 days at 25 degree centigrade

Page 1 of 2

4.0 FABRICATION OF SEAL

4.1 EFRT shall be provided with double seal with minimum vapour recovery of 96%.

4.2 Maximum seal gap width shall be 4cm and maximum gap area will be 200cm2/m of tank

diameter.

4.3 Tests as specified above shall be carried out in a reputed laboratory and the results shall be

furnished for review/ approval.

4.4 Contractor shall use proper adhesive of approved quality. Contractor shall give complete

procedure for joining the pieces. The entire work shall be carried out in a clean, dry area, free of

heat, sparks of flame.

4.5 Minimum length of foam and casing for foam seal shall not be less than 3 meters. Total

circumferential length of foam seal shall be such that a compression of 150mm is achieved for

every 3 meters length of foam seal when installed.

5.0 APPROVED MAKES OF PRIMARY SEAL

a.

b.

c.

d.

e.

f.

g.

h.

M/s Petroleum Seals and Systems Ltd U.K.

M/s Motherwell Naylor, Scotland

M/s Mesa Insternational Corporation

M/s HMT Rubbaglass

M/s Sai Tools

M/s Veera Associates

M/s ITM Seals

M/s Maitree Industries

6.0 GUARANTEE

The primary seals shall have guarantee / warranty for its durability and satisfactory performance for

a minimum period of five years from the date of commissioning.

Page 2 of 2

Вам также может понравиться

- Refrigeration Cycle, HVAC System Basics and Refrigerant Charging PDFДокумент13 страницRefrigeration Cycle, HVAC System Basics and Refrigerant Charging PDFMurillo MendesОценок пока нет

- Insulation SpecДокумент16 страницInsulation Specsandesh100% (1)

- UNIT 4 Raman Spectroscopy 12309Документ24 страницыUNIT 4 Raman Spectroscopy 12309NathanianОценок пока нет

- Ace Your Food Science Projects PDFДокумент367 страницAce Your Food Science Projects PDFashqОценок пока нет

- EZ Torque: Hydraulic Cathead User's ManualДокумент35 страницEZ Torque: Hydraulic Cathead User's ManualJuan Garcia100% (1)

- Tarecpir Project Spec Inst GuideДокумент64 страницыTarecpir Project Spec Inst GuideFaizal YaacobОценок пока нет

- PR-1154 - Gas Testing ProcedureДокумент28 страницPR-1154 - Gas Testing ProcedureRAHULОценок пока нет

- Orthodontic Wires - Properties / Orthodontic Courses by Indian Dental AcademyДокумент226 страницOrthodontic Wires - Properties / Orthodontic Courses by Indian Dental Academyindian dental academy100% (1)

- Location Thickness Type of LiningДокумент7 страницLocation Thickness Type of LiningPaul PhiliphsОценок пока нет

- MasterSpec Consolidated TOCДокумент39 страницMasterSpec Consolidated TOCsheevesОценок пока нет

- WB 3 - Fireproofing IntumescentДокумент2 страницыWB 3 - Fireproofing Intumescentwafik.bassily100% (1)

- CES - Management - Oil Tanker - Correct AnswersДокумент87 страницCES - Management - Oil Tanker - Correct Answersboramir496793% (27)

- En12944Документ10 страницEn12944Rui MendesОценок пока нет

- 3 LayerДокумент4 страницы3 LayerArya Raditya100% (1)

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesОт EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesРейтинг: 3.5 из 5 звезд3.5/5 (3)

- 07 Technical Specification For Foam Seals of Floating Roof Tanks PDFДокумент6 страниц07 Technical Specification For Foam Seals of Floating Roof Tanks PDFvivekaramanaОценок пока нет

- QTN For Epoxy and ESD Flooring Dtd.28!2!2012Документ9 страницQTN For Epoxy and ESD Flooring Dtd.28!2!2012dox4printОценок пока нет

- BTT EB Specification Single Wall 08-07Документ12 страницBTT EB Specification Single Wall 08-07Alonso VillaОценок пока нет

- FRS Electrical Panel Spec EOIДокумент20 страницFRS Electrical Panel Spec EOITravis WoodОценок пока нет

- Rockwool Process Manual - p126-129Документ3 страницыRockwool Process Manual - p126-129isogulalebОценок пока нет

- Floline (3-W) Triple Wall Profiled Hdpe Culvert: Physical Properties Test Method Unit ValueДокумент3 страницыFloline (3-W) Triple Wall Profiled Hdpe Culvert: Physical Properties Test Method Unit Valuejerryruki71Оценок пока нет

- BTT EB Specification Double Wall 08-07Документ13 страницBTT EB Specification Double Wall 08-07Alonso VillaОценок пока нет

- Amerlock® 400 Voc: Product Data SheetДокумент8 страницAmerlock® 400 Voc: Product Data SheetCris gomezОценок пока нет

- Epoxy and ESD FlooringДокумент4 страницыEpoxy and ESD Flooringdox4printОценок пока нет

- Section 07430 Composite PanelsДокумент4 страницыSection 07430 Composite PanelsMØhãmmed ØwięsОценок пока нет

- Dm-dsi-SPEC09 - Corrosion PR & Odor CNTRLДокумент13 страницDm-dsi-SPEC09 - Corrosion PR & Odor CNTRLhardikОценок пока нет

- Certificate 032 96Документ9 страницCertificate 032 96ferdinandbataraОценок пока нет

- E 1605 SikaCor 255 277Документ6 страницE 1605 SikaCor 255 277emanuelluca@yahoo.comОценок пока нет

- Inter Therm 228Документ4 страницыInter Therm 228Mehman NasibovОценок пока нет

- General Concrete Requirements-WaterproofingДокумент5 страницGeneral Concrete Requirements-WaterproofingCire Lop CastroОценок пока нет

- Section Materilals (Book)Документ231 страницаSection Materilals (Book)ArifHadiОценок пока нет

- Self Adhering Sheet Waterproofing Bituthene 3000 and Bituthene Low Temperature GSWP 003A v2Документ5 страницSelf Adhering Sheet Waterproofing Bituthene 3000 and Bituthene Low Temperature GSWP 003A v2200365530Оценок пока нет

- Application of Exterior Insulation and Finish Systems Class PIДокумент7 страницApplication of Exterior Insulation and Finish Systems Class PIHumberto GutierrezОценок пока нет

- Spec Water Storage TanksДокумент5 страницSpec Water Storage TanksparthivОценок пока нет

- MORTH 1600 2 Acrylic Elastomeric CoatingДокумент4 страницыMORTH 1600 2 Acrylic Elastomeric CoatingRameshОценок пока нет

- ITCC in Riyadh Residential Complex J10-13300 07200-1 Building InsulationДокумент5 страницITCC in Riyadh Residential Complex J10-13300 07200-1 Building InsulationuddinnadeemОценок пока нет

- Techothane-Pu: High Build Elastomeric Bituminous Polyurethane Based Waterproofing MembraneДокумент5 страницTechothane-Pu: High Build Elastomeric Bituminous Polyurethane Based Waterproofing Membraneannayya.chandrashekar Civil EngineerОценок пока нет

- ITCC in Riyadh Residential Complex J10-13300 07500-1 RoofingДокумент8 страницITCC in Riyadh Residential Complex J10-13300 07500-1 RoofinguddinnadeemОценок пока нет

- Klambon Steel PipingДокумент5 страницKlambon Steel PipingshaunswanbyОценок пока нет

- TROSTEN Mechanical Specification - AHUДокумент6 страницTROSTEN Mechanical Specification - AHUBalaji JenarthananОценок пока нет

- Dampproofing (Revised)Документ29 страницDampproofing (Revised)masahinОценок пока нет

- Tape Coating StandardДокумент17 страницTape Coating StandardKaushik DuariОценок пока нет

- InsulationДокумент3 страницыInsulationjituahirОценок пока нет

- PAL Polyurethane Panel Spec 31102008Документ4 страницыPAL Polyurethane Panel Spec 31102008Mohd Fahmie Bin MustapaОценок пока нет

- Armaflex Insulation + Fire Rated DuctworkДокумент7 страницArmaflex Insulation + Fire Rated DuctworkGiải Pháp Cơ ĐiệnОценок пока нет

- Sectional TankДокумент4 страницыSectional TankGT2013Оценок пока нет

- 10 - Acoustic Insulation - 2Документ3 страницы10 - Acoustic Insulation - 2Anonymous BbZceWkVnОценок пока нет

- Repsol Oil Operations: Nc-115 Field DevelopmentДокумент11 страницRepsol Oil Operations: Nc-115 Field DevelopmentYangui AliОценок пока нет

- Self-Adhering Polymer Modified Bituminous Sheet Materials Used As Steep Roofing Underlayment For Ice Dam ProtectionДокумент5 страницSelf-Adhering Polymer Modified Bituminous Sheet Materials Used As Steep Roofing Underlayment For Ice Dam ProtectiondaovandongpktОценок пока нет

- Water Proof SpecДокумент2 страницыWater Proof SpecdjgiumixОценок пока нет

- ITCC in Riyadh Residential Complex J10-13300 07150-1 DampproofingДокумент3 страницыITCC in Riyadh Residential Complex J10-13300 07150-1 DampproofinguddinnadeemОценок пока нет

- SECTION 07 12 00 Built-Up Bituminous WaterproofingДокумент6 страницSECTION 07 12 00 Built-Up Bituminous WaterproofingMorris AlcantaraОценок пока нет

- DATA-URETHPOLY-ITW - TRYMER - Polyisocyanurate Pipe Insulation Refrigeration ApplicationsДокумент29 страницDATA-URETHPOLY-ITW - TRYMER - Polyisocyanurate Pipe Insulation Refrigeration ApplicationsAmir VoloderОценок пока нет

- EG Tech Bulletin ASTM C1695Документ3 страницыEG Tech Bulletin ASTM C1695AuburnMfgОценок пока нет

- Elastuff 102Документ3 страницыElastuff 102pravi3434Оценок пока нет

- Acp Alcolite Tds F 314Документ5 страницAcp Alcolite Tds F 314adjisetiaОценок пока нет

- Styrofoam (English)Документ21 страницаStyrofoam (English)Krish DoodnauthОценок пока нет

- Pyrocrete 241 PDSДокумент7 страницPyrocrete 241 PDSJorge Isaac Lara RamosОценок пока нет

- Pyrocrete 241 PDSДокумент6 страницPyrocrete 241 PDSOsama KheadryОценок пока нет

- 5.9. MBT Rubber CellsДокумент10 страниц5.9. MBT Rubber Cellshamada13Оценок пока нет

- Sec 1038Документ4 страницыSec 1038Lauren BowenОценок пока нет

- 020-130 - TB - CHEMOLINE 10 M - Revision - 1.00 - 13.03.2015Документ2 страницы020-130 - TB - CHEMOLINE 10 M - Revision - 1.00 - 13.03.2015Alejandra ZumaranОценок пока нет

- PN78HBCДокумент4 страницыPN78HBCLassadОценок пока нет

- U (1) .G Piping ProtectionДокумент5 страницU (1) .G Piping ProtectionAsad Bin Ala QatariОценок пока нет

- Thermazone Foilboard Insulation DatasheetДокумент3 страницыThermazone Foilboard Insulation DatasheetSuthirak SumranОценок пока нет

- 09875Документ10 страниц09875sethu1091Оценок пока нет

- Thermo Scientific Taq Dna Polymerase With KCL Buffer: DescriptionДокумент3 страницыThermo Scientific Taq Dna Polymerase With KCL Buffer: DescriptionCHIRANJEEVIОценок пока нет

- Seta Verification Materials: STVM MTVMДокумент2 страницыSeta Verification Materials: STVM MTVMdchyОценок пока нет

- Project Report On Pigment Print BinderДокумент4 страницыProject Report On Pigment Print BinderEIRI Board of Consultants and PublishersОценок пока нет

- Waste Management Write-UpДокумент5 страницWaste Management Write-UpGounassegaraneDuraisamy100% (1)

- Enviromental Toxicity and EvaluationДокумент25 страницEnviromental Toxicity and EvaluationSalma ShadОценок пока нет

- Experiment A Test For Lipid Result: Result When Added To WaterДокумент5 страницExperiment A Test For Lipid Result: Result When Added To WaterSuu Wan0% (2)

- Industrial ReportДокумент64 страницыIndustrial Reportfuad ullahОценок пока нет

- A Rapid Accurate Method For The Analysis of An Iron OreДокумент5 страницA Rapid Accurate Method For The Analysis of An Iron Oreilham_metallurgy6744Оценок пока нет

- LDP200 Series DatasheetДокумент6 страницLDP200 Series DatasheetReza RamadhanОценок пока нет

- Nafees Nastaleeq v1.02Документ2 страницыNafees Nastaleeq v1.02latifshaikh20Оценок пока нет

- Gen Bio W3-5Документ9 страницGen Bio W3-5Alyson EscuderoОценок пока нет

- 4 Different Ways To Use Hair Oils Curly Hair Care The Wild CurlДокумент1 страница4 Different Ways To Use Hair Oils Curly Hair Care The Wild CurlMaria jose MondragonОценок пока нет

- Omega 600S Manual PDFДокумент36 страницOmega 600S Manual PDFjosebernal_mzaОценок пока нет

- Model C-1 Electrostatic Airless Spray Gun: Customer Product Manual Part 104 326DДокумент50 страницModel C-1 Electrostatic Airless Spray Gun: Customer Product Manual Part 104 326DUlpianoxx19920% (1)

- Atkins & de Paula Elements of Physical Chemistry 5th TXTBK (Dragged) 2Документ7 страницAtkins & de Paula Elements of Physical Chemistry 5th TXTBK (Dragged) 2Roselle Mea EderОценок пока нет

- Assignment On: Textiles in Agriculture (Agrotech)Документ6 страницAssignment On: Textiles in Agriculture (Agrotech)AmirParvezОценок пока нет

- Dissolution TestДокумент5 страницDissolution TestAlecza Mae SavellaОценок пока нет

- Feasibility Study of Isononanol ProductionДокумент3 страницыFeasibility Study of Isononanol ProductionIntratec SolutionsОценок пока нет

- Carbon and Its Compounds - Shobhit NirwanДокумент17 страницCarbon and Its Compounds - Shobhit NirwanBhaskar 8287Оценок пока нет

- Fibc Type A B C D Classification SafetyДокумент2 страницыFibc Type A B C D Classification Safetydhineshbabu rОценок пока нет

- 51314-3985-Methanol-Induced Internal Stress CorrosДокумент18 страниц51314-3985-Methanol-Induced Internal Stress CorrosMahmoud GamalОценок пока нет

- Embedded Enzymatic Biomaterial Degradation: 6836 Macromolecules 2009, 42, 6836-6839Документ4 страницыEmbedded Enzymatic Biomaterial Degradation: 6836 Macromolecules 2009, 42, 6836-6839hhkkllОценок пока нет