Академический Документы

Профессиональный Документы

Культура Документы

Ladder Logic

Загружено:

Cesar ChangИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Ladder Logic

Загружено:

Cesar ChangАвторское право:

Доступные форматы

IOSR Journal of Electrical and Electronics Engineering (IOSR-JEEE)

e-ISSN: 2278-1676,p-ISSN: 2320-3331, Volume 7, Issue 2 (Jul. - Aug. 2013), PP 61-67

www.iosrjournals.org

Automation of Tank Level Using Plc and Establishment of Hmi

by Scada

Rishabh Das1, Sayantan Dutta2, Anusree Sarkar3, Kaushik Samanta4

1

2-4

Department of Electrical Engineering UIT, BU, India

Department of Applied Electronics and Instrumentation Engineering UIT, BU, India

Abstract : Theproposed system provides an analysis of the simulation and components required for the

implementation of an automated level control system by the help of Programmable Logic Controller

(PLC).Supervisory Control And Data Acquisition(SCADA) was established and the HMI was created. The

proposed model can effectively supervise level control in multiple tanks. Three level sensors were used to

provide the level data to the PLC. PLC used this data to take the required decisions and thereby turning ON and

OFF a pump. A manual switch was also provided to override the automatic system. The SIMATIC S7-300

universal controller was used as the main decision making module. The system was implemented in SCADA to

create the required Human Machine Interface (HMI). Modifications can be made by using float sensors model

which would effectively provide the correct level but cost would increase and vibration of the sensor might

disrupt the result, our model effectively counters those shortcomings.

Keywords: Automation, SCADA, PLC,HMI, Tank-level Control.

I.

Introduction

A Programmable Logic Controller, PLC or Programmable Controller is a digital computer used for

automation of electromechanical processes [1]-[2]. Unlike general-purpose computers, the PLC is designed for

multiple inputs and output arrangements, extended temperature ranges, immunity to electrical noise, and

resistance to vibration and impact. Programs to control machine operation are typically stored in battery-backedup or non-volatile memory. In our project we used SIEMENS S7- 300 PLC [3].S.Ghosh et, al has effectively

designeda bottle filling plant using PLC [4] and A.Saha et, al gives a proposed system that efficiently controls a

cement factory using PLC[5]. A Centralized PLC Automation Control in Painting Line of Steel Plant is shown

byHao, L. and Ruilin[6].Our Proposed system can be divided into three main modules- sensing, decision

making and implementation. The PLC also communicates the status of the entire system through a Human

Machine Interface or virtual reality supervision. Four sensors are used to implement the system. These sensors

detect the presence of water. The readings of the sensors are used by the PLC to take the required decision.

Finally the decision is implemented by the PLC through a relay switch. The PLC communicates the

present status of the system through the IM port to the computer which is accessible by the HMI. The ladder

logic was implemented in SIMANTIC manager and the HMI was created by WINCC Explorer.

Fig.1 Block Diagram of the System

The proposed system will control and monitor the liquid level of the tank continuously and will ensure

that a sufficient level of water is maintained. This system can be used ubiquitously in industrial application. It

can be used to prevent industrial accident by overfilling of any open container, to prevent overfilling of any

closed container thereby creating overpressure condition. The high number of the input output port of the PLC

www.iosrjournals.org

61 | Page

Automation of Tank Level Using Plc and Establishment of Hmi by Scada

will enable this single system to control large number of tanks single handedly. Leakage can also be monitored.

Block diagram of the system is shown in Fig 1.

II.

System Component Description

The system can be divided into four main parts:2.1 Level Sensor

2.2 PLC(Programmable Logic Controller)

2.3 Relay and Motor

2.4 HMI(Human Machine Interface)

These are the four main modules of the system. The level sensor communicates the present level of the

tank to the PLC. The PLC decides whether to turn the motor ON or OFF. The status of the system is

communicated to the computer by MPI and is viewed and remotely controlled by the user through the HMI.

2.1 Level Sensor

Inductive proximity sensors were used to detect the presence of water in the tank. These sensors detect

magnetic loss due to eddy currents that are generated on a conductive surface by an external magnetic field. An

AC magnetic field is generated on the detection coil, and changes in the impedance due to eddy currents

generated on an object are detected. When the object enters this electromagnetic field which appears at the

active face of the switch, the field gets reduced and the switch turns ON or OFF. The main advantage of this

sensor is that it can sense the object without touching it, so this sensor can be fixed outside the water. The

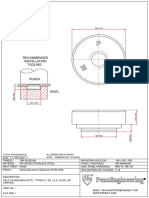

internal circuit diagram of the switch is shown in Fig.2.

Fig. 2 Proximity Sensor internal diagram

2.2 PLC (Programmable Logic Controller)

This serves as the main control unit of the system. The ladder logic is prewritten on a non- volatile

memory. The ladder logic was implemented in Siemens SIMANTIC manager. On basis of this logic the PLC

takes its decisions. In our project Siemens S7-300 was used. The S7-300 enables space-saving and modular

configurations.In a single-tiered configuration, S7-300 can support 256 I/O, and in multi-tiered configurations

up to 1024 I/O. In distributed configurations with PROFIBUS DP,65536 I/O connections are possible (up to 125

stations, such as ET 200M via IM 153) [7]. The slots are freely addressable, that is, there are no slot rules. So a

single S7-300 if deployed in an industry can automate and monitor a large number of tanks. The PLC was

interfaced by to the computer via IM

2.3 Relay and Motor

A relay is an electrically operated switch. The relay considered in our system uses an electromagnet to

operate a switching mechanism mechanically. Any compatible relay can be used with our system. The motor on

the other hand was used to pump the water from the underground tank to the overhead tank. The relay converts

the DC output of the PLC into a signal compatible to effectively control the motor being used.

2.4 HMI (Human Machine Interface)

The Human Machine Interface is the interface through which the user interacts with the system. The

current status of the system is communicated to the user by means of a GUI.

www.iosrjournals.org

62 | Page

Automation of Tank Level Using Plc and Establishment of Hmi by Scada

The user can also turn ON or OFF various functions from the interface. The HMI was created by

Siemens WINCC V5.5. Tags were used to enable communication between the WINCC and the SIMANTIC

Manger.

III.

Design And Implementation

The overhead Tank is to be filled by a Pump. The pump will automatically start when the water level of

Over Head Tank reaches below Low Level and stop when the level reaches High Level. Dry run is checked by

the Low Level sensor of the Under Ground Tank. In that case Pump will not run. Run time monitoring of the

pump in Second and minute is recorded and Reset Switch is also provided. Provision of Manual Start/Stop

switch is incorporated which will totally override the automatic system. Provisions are also made for various

alarms, such as Underground Tank Empty Alarmand Pump run time exceeded 10 Minutes (If pump runs

continuously for 10 Minutes).

The implementation is divided into four parts:3.1 Sensor Positioning

3.2 Circuit Design

3.3 Ladder Programing

3.4 HMI Creation

3.1. Sensor Positioning

Four inductive Proximity sensors were used to sense presence of water at required levels. The sensors

are UG_LL Low Level Sensor Underground tank (I 0.2), OH_LL Low Level Sensor Overhead tank (I 0.0),

OH_HL High Level Sensor Overhead tank (I 0.1) are placed as shown below in Fig 3.

(Theses sensors give open contact when they are inside water and they give close contact when they are outside

water.)

Fig. 3 The Schematic Design of the System

3.2Circuit Design

DI or Digital Input provides a volt-free contact to the controller from the sensors. While DO or Digital

Output provides the controller volt-free relay contact to control various equipment. One 16 bit DI and DO was

sufficient for the successful completion of the project. Dl 16x DC 24V (order no.-6ES7-321-1BH01-0AA0) was

used along with DO 16x DC 24V/0.5A (order no.-6ES7-322-1BH01-0AA0).PS 307 (order no.- 6ES7-3071BA00-0AA0) was used to power the PLC. The wiring diagrams of DI and DO are shown in Fig 4 and Fig 5

respectively.

www.iosrjournals.org

63 | Page

Automation of Tank Level Using Plc and Establishment of Hmi by Scada

MANUAL SWITCH

Fig.4 Wiring Diagram of 16 bit DI

Fig. 5Wiring Diagram of 16bit DO

3.3Ladder Programming

The Ladder programming for the Siemens S7-300 was done in Siemens Simantic manager [8]. The

symbol used in the ladder logic is shown in the symbol table in Fig 7.

Fig. 6 The ladder logic

www.iosrjournals.org

64 | Page

Automation of Tank Level Using Plc and Establishment of Hmi by Scada

The ladder logic shown in Fig 6 shows tank level control simulated for 1000 litre tank with a constant

flow rate of 125 litres per min. The flow rate of the drainage is also taken as 125 litres per minute. The Symbol

Table for the written ladder logic is shown above in Fig 6

Fig. 7 Symbol Table for the ladder logic

3.4 HMI Designing

The Human Machine Interface was created in WinCCExplorer[9]-[10]. Tags were used for the

communication of the PLC Ladder logic operation in the Simantic manger with the HMI. The created HMI is

shown in Fig 8 below. The whole project is shown along with the sensor positions.

Fig. 8SCADA Interface for the Tank Level Control

IV.

Results

The results were taken in four situations, and were represented in Variable Table (VAT). The situations

are

4.1 Empty tank

4.2 Filling tank

4.3 Full tank

4.4 Draining.

The variable description along with its status is shown. The manual override is turned OFF to enable

automatic operation.

www.iosrjournals.org

65 | Page

Automation of Tank Level Using Plc and Establishment of Hmi by Scada

4.1 Empty Tank

Fig. 9 Status of parameters when tank is empty

The Figure 9 shows the status of the various parameters when the tank is empty. The status of the level

indicators from Q5.0 to Q5.7 is all FALSE denoting absence of water. The drain valve is true showing that the

tank is being emptied. As drain valve is ON pump is switched OFF.

4.2 Filling Tank

Fig. 10 Status of parameters when tank is filling

The Figure 10 shows the status of the various parameters when the tank is being filled. Pump is ON

and Drain valve is OFF. The level of the increasing liquid is denoted by the indicators from Q5.0 to Q5.7.

4.3 Full Tank

Fig. 11 Status of parameters when tank is Full

The Figure 11 Shows TRUE value for all the level indicators denoting that liquid is present in every

level and tank is full. The pump is automatically turned OFF. The manual switch is kept OFF.

www.iosrjournals.org

66 | Page

Automation of Tank Level Using Plc and Establishment of Hmi by Scada

4.4 Draining

Fig. 12 Status of parameters when tank is Draining

During draining the drain valve shows TRUE value. The pump and the manual switch is kept OFF. The

level indicators (Q5.0-Q5.7) show decreasing level.

UG_LL Low Level Sensor Underground tank (I 0.2), OH_LL Low Level Sensor Overhead tank (I 0.0),

OH_HL High Level Sensor Overhead tank (I 0.1) status is denoted in each of the figures. They give FALSE

status when inside water.

V.

Conclusion

Our project readily achieved its aim of automating the level control process. No human supervision

was necessary. The system did not use float sensors yet denoted the accurate level. Hence the short coming of

the float sensors that is unwanted vibrations and high cost was easily overcome. The PLC Siemens SIMANTIC

S7-300 also offers many Input Output ports. Hence this single system can singlehandedly control as many as 50

tanks making it efficient and cost effective.

References

Books:

[1].

[2].

[7].

[8].

[9].

FestoDidactic ,Programmable Logic Controllers Basic Level(Textbook TP 301, GmbH & Co., D-73770 Denkendorf.)

Bolton, Programmable Logic Controllers.(4th ed.W. (2006). North Carolina: Elsevier Newnes.)

Siemens AG,Working with step 7 V5.2, Getting Started(edition- December 2012)

Siemens AG,Ladder Logic (LAD) for S7-300 and S7-400 Programming, Reference Manual, (edition-December 2012)

Axel Daniels & Wayne Salter, What is SCADA, (CERN-CNL-2000-003 Vol. XXXV, issue no 3.)

Journal Papers:

[3].

J.C.Chan, H.L.T.Dy, A.H.Fernando, R.L.Tiu, P.J.G.Viernes, Design, Fabrication, and Testing of a PLC Training Module Using

Siemens S7-300 PLC, DLSU Engineering e-Journal,Vol. 1 No. 1, March 2007, pp.43-54.

Proceedings Papers:

[4].

[5].

[6].

2002 S.Ghosh, S.Bairagya, C.Roy, S.Dey, S.Goswami, A.Ghosh, ET &TE-2008, Bottle Filling System using PLC

A.Saha, S.Kundu, A.Ghosh, MDCCT-2012, MINI CEMENT PLANT USING PLC, Conference proceedings, 6-7 february,2012,

Burdwan University

Hao, L. and Ruilin, P. (2005). Application of Centralized PLC Automation Control in Painting Line of Steel Plant. Proceeding of

the 4th Asian Conference on Industrial Automation and Robotics, Landmark Hotel, Thailand

Theses:

[10].

Tony Stafford, Taking Back A SCADA case study, Camrosa Water District, California, July 2002

www.iosrjournals.org

67 | Page

Вам также может понравиться

- CSWA Sample Exam Questions and Modeling ChallengesДокумент7 страницCSWA Sample Exam Questions and Modeling ChallengesPrathamesh BagweОценок пока нет

- PLC Wiring LaboratoryДокумент15 страницPLC Wiring LaboratoryEven OngОценок пока нет

- Modern Electrical Drive Systems and Power Electronic ConvertersДокумент9 страницModern Electrical Drive Systems and Power Electronic ConvertersGthulasi78Оценок пока нет

- SIMATIC S7-200: Simatic Hmi The Human Machine Interface SIMATIC S7-200Документ30 страницSIMATIC S7-200: Simatic Hmi The Human Machine Interface SIMATIC S7-200gaston100% (1)

- Humidity & Temperature Controller Pro.Документ41 страницаHumidity & Temperature Controller Pro.Amir WagdarikarОценок пока нет

- Logic AnalyzerДокумент27 страницLogic AnalyzerMohammad Umar RehmanОценок пока нет

- Pumping Stations Design Recommendations FlygtДокумент28 страницPumping Stations Design Recommendations FlygtjosegabrielrosasОценок пока нет

- CSWASample Exam 2010Документ14 страницCSWASample Exam 2010Rich Mack100% (1)

- Lab 10Документ5 страницLab 10Abdolkarim PahlianiОценок пока нет

- 8086 Microprocessors & Peripherals OverviewДокумент31 страница8086 Microprocessors & Peripherals OverviewAbdul Qadeer100% (4)

- Electrical Wiring DigramДокумент15 страницElectrical Wiring DigramSunilMurkikarОценок пока нет

- PLC K SaraswathiДокумент105 страницPLC K SaraswathiKoushik SgОценок пока нет

- STM32F30xx-31xx Standard Peripheral Library UM1581Документ584 страницыSTM32F30xx-31xx Standard Peripheral Library UM1581John LeungОценок пока нет

- 04 Ladder LogicДокумент17 страниц04 Ladder LogicNimsiri AbhayasingheОценок пока нет

- Here is the PLC ladder logic diagram to meet the given requirements:1 2 3 4 5 6 7 8| | | | | | | |K1-NO LED Green|K2-NO|LED Red|K1-NC|K2-NCДокумент116 страницHere is the PLC ladder logic diagram to meet the given requirements:1 2 3 4 5 6 7 8| | | | | | | |K1-NO LED Green|K2-NO|LED Red|K1-NC|K2-NCABHISHEK THAKURОценок пока нет

- CFD and Marine ApplicationsДокумент64 страницыCFD and Marine ApplicationsshahzОценок пока нет

- Lecture 1Документ39 страницLecture 1kasunweera100% (1)

- Introduction To Automation and Process Control - PLCДокумент38 страницIntroduction To Automation and Process Control - PLCrakeshlondonОценок пока нет

- LAB 10 Introduction To Ladder Logic ProgrammingДокумент10 страницLAB 10 Introduction To Ladder Logic ProgrammingNyanphyo AungОценок пока нет

- Simatic S7-200Документ30 страницSimatic S7-200Bui Hong PhongОценок пока нет

- S7-200 High Speed CountersДокумент27 страницS7-200 High Speed CountersasifОценок пока нет

- Simatic S7-300: The Universal, Small Control System Supplemented by New, Compact CpusДокумент18 страницSimatic S7-300: The Universal, Small Control System Supplemented by New, Compact CpusSunil SinghОценок пока нет

- Calog ManualДокумент34 страницыCalog Manualpatitay036817Оценок пока нет

- PLC Notes Unit 1Документ14 страницPLC Notes Unit 1126 N.EZHILARASAN EEERОценок пока нет

- Safety - Msr131rtpДокумент2 страницыSafety - Msr131rtpJose Hilario Rivera RezaОценок пока нет

- 2 Basic Ladder Instructions R1.1Документ19 страниц2 Basic Ladder Instructions R1.1Ahmed SamiОценок пока нет

- PLC Stepper Motor ControllerДокумент12 страницPLC Stepper Motor ControllerSibtain Ul Hassan100% (1)

- 2022 Iot Lab Mannual-R19Документ56 страниц2022 Iot Lab Mannual-R19Samyuktha DevarapalliОценок пока нет

- Danfoss OMMДокумент36 страницDanfoss OMMDi ScottОценок пока нет

- BEMO Roof Brochure en 2019Документ27 страницBEMO Roof Brochure en 2019Anonymous wzuyBcОценок пока нет

- PLC, PLC Ladder, PLC Ebook, PLC ProgrammingДокумент5 страницPLC, PLC Ladder, PLC Ebook, PLC ProgrammingAmar ThakurОценок пока нет

- PLC and Its Application Final-1Документ83 страницыPLC and Its Application Final-1Mohsin razaОценок пока нет

- ZKG IndiaДокумент36 страницZKG Indiajoe_kudo0% (1)

- PLC ProjectsДокумент12 страницPLC Projectssheraaz87Оценок пока нет

- Kinco HMIware User ManualДокумент522 страницыKinco HMIware User Manualrguzmanabundis100% (1)

- Manual Cutler HammerДокумент114 страницManual Cutler HammerMarcelo Palacios SantanaОценок пока нет

- Leseprobe - en Proportional Hydraulic Advance Workbook SampleДокумент50 страницLeseprobe - en Proportional Hydraulic Advance Workbook SamplePhuoc Tho TuongОценок пока нет

- 4th Term PLC Lab ManualДокумент8 страниц4th Term PLC Lab ManualOPIYO ONYANGOОценок пока нет

- Rashid Ch03 ImagesДокумент69 страницRashid Ch03 ImagesAtiq Ur RehmanОценок пока нет

- Visual LCD Studio Visual LCD Studio Visual LCD Studio: Unda TechДокумент54 страницыVisual LCD Studio Visual LCD Studio Visual LCD Studio: Unda TechIsmaelОценок пока нет

- Contactor Starter Relay PDFДокумент129 страницContactor Starter Relay PDFMohd Anas0% (1)

- Válvula Direcional RexRothДокумент22 страницыVálvula Direcional RexRothrfcardОценок пока нет

- Signalling Device SymbolДокумент1 страницаSignalling Device Symbolnooruddinkhan1Оценок пока нет

- Usingcontrol MatlabДокумент1 626 страницUsingcontrol MatlabGjergjiОценок пока нет

- Click PLC CommunicationДокумент30 страницClick PLC CommunicationHemesh Jain SuranaОценок пока нет

- PLC Stepper Motor Controller PDFДокумент12 страницPLC Stepper Motor Controller PDFVladimirОценок пока нет

- S7300ce 140903150130 Phpapp01Документ18 страницS7300ce 140903150130 Phpapp01Suhendri SaputraОценок пока нет

- Devices, Circuits, and ApplicationsДокумент55 страницDevices, Circuits, and ApplicationsAtiq Ur RehmanОценок пока нет

- Washing Machine Control Using 8051 MicrocontrollerДокумент4 страницыWashing Machine Control Using 8051 MicrocontrollerPrasath MurugesanОценок пока нет

- FBS-CMGSM Users Manual en v1-26Документ6 страницFBS-CMGSM Users Manual en v1-26naveedengineerОценок пока нет

- Devices, Circuits, and ApplicationsДокумент16 страницDevices, Circuits, and ApplicationsAtiq Ur RehmanОценок пока нет

- PLC Scada TrainingДокумент51 страницаPLC Scada TrainingPriya HadaОценок пока нет

- Zelio Brochure EngДокумент12 страницZelio Brochure EngCesar GutierrezОценок пока нет

- Robotic Sensors: Robot Actuators - Different TypesДокумент4 страницыRobotic Sensors: Robot Actuators - Different Typesmohan_rapaka100% (1)

- PLC Hardware, Software, Etc PDFДокумент268 страницPLC Hardware, Software, Etc PDFPacoGerEscoОценок пока нет

- General Machine Control - Automation Solutions For Industrial Machines - Catalogue 2014 PDFДокумент282 страницыGeneral Machine Control - Automation Solutions For Industrial Machines - Catalogue 2014 PDFRudy SikeОценок пока нет

- Development Kit For The CANBus Exercise BookДокумент60 страницDevelopment Kit For The CANBus Exercise Booksribodduna100% (3)

- Wiring Diagrams MICROLOGIX 1200 SERIE C PDFДокумент3 страницыWiring Diagrams MICROLOGIX 1200 SERIE C PDFEfren MarshalОценок пока нет

- RTC Based - Automatic College BellДокумент53 страницыRTC Based - Automatic College BellPgc VnbОценок пока нет

- Programmable Logic Controllers: Richard A. WyskДокумент49 страницProgrammable Logic Controllers: Richard A. WyskreliableplacementОценок пока нет

- Countersink Forming ToolДокумент1 страницаCountersink Forming ToolCesar ChangОценок пока нет

- Bystronics LaserДокумент5 страницBystronics LaserCesar ChangОценок пока нет

- Press Brake Set Up SheetДокумент1 страницаPress Brake Set Up SheetCesar ChangОценок пока нет

- CLS 256 1Документ1 страницаCLS 256 1Cesar ChangОценок пока нет

- Sheet FormingДокумент18 страницSheet FormingBachar FouadОценок пока нет

- Bystronic Tools OverviewДокумент88 страницBystronic Tools Overviewandre100% (1)

- CLS 256 1Документ1 страницаCLS 256 1Cesar ChangОценок пока нет

- Gantt ChartДокумент2 страницыGantt ChartCesar ChangОценок пока нет

- Cs WP Sample ExamДокумент2 страницыCs WP Sample ExamRamon Javier Villa MedinaОценок пока нет

- Pressure in Partitioned Tank (38Документ167 страницPressure in Partitioned Tank (38LoanFagetОценок пока нет

- Introduction To Fluid Mechanics - 6 Ed - Fox - Solution Manual Chapter 1Документ47 страницIntroduction To Fluid Mechanics - 6 Ed - Fox - Solution Manual Chapter 1Harun Yakut57% (7)

- Budynas SM ch04Документ45 страницBudynas SM ch04Na2ryОценок пока нет

- Secondary DatabasesДокумент21 страницаSecondary DatabasesDaljit SinghОценок пока нет

- Thermodynamics of Heating PDFДокумент19 страницThermodynamics of Heating PDFMatias MuñozОценок пока нет

- Relativistic Time Dilation and The Muon ExperimentДокумент6 страницRelativistic Time Dilation and The Muon ExperimentConexão Terra PlanaОценок пока нет

- Introduction To Logic (Worrall, J)Документ267 страницIntroduction To Logic (Worrall, J)Cindy Leung100% (1)

- ST Johns School QuestionsДокумент3 страницыST Johns School QuestionsGOOGLE NETОценок пока нет

- Rabin CryptosystemДокумент41 страницаRabin CryptosystemArkadev GhoshОценок пока нет

- Unit 4Документ76 страницUnit 4raghuram67Оценок пока нет

- CFD Application Tutorials 2Документ35 страницCFD Application Tutorials 2Jubril AkinwandeОценок пока нет

- Application of The Giroud - Han Design Method For Geosynthetic Reinforced Unpaved Roads With Tencate Mirafi GeosyntheticsДокумент7 страницApplication of The Giroud - Han Design Method For Geosynthetic Reinforced Unpaved Roads With Tencate Mirafi GeosyntheticsFaten Abou ShakraОценок пока нет

- Bullet Holes in PlasticДокумент7 страницBullet Holes in PlasticSonya PriceОценок пока нет

- Example of Two Group Discriminant AnalysisДокумент7 страницExample of Two Group Discriminant Analysisabcxyz7799Оценок пока нет

- Circle TheoryДокумент8 страницCircle Theoryapi-278074538100% (3)

- A VecFaraday1Документ10 страницA VecFaraday1zorrinОценок пока нет

- Dowf Rost: Engineering and Operating GuideДокумент44 страницыDowf Rost: Engineering and Operating GuidehamishlewisОценок пока нет

- Genetic Algorithms in OptimizationДокумент38 страницGenetic Algorithms in OptimizationssbhonsaleОценок пока нет

- (06b) C2 - 025 Project Specification RVSDДокумент90 страниц(06b) C2 - 025 Project Specification RVSDmohammeddashtiОценок пока нет

- PVT Experiment IndividualДокумент36 страницPVT Experiment IndividualnursyakirahrahimОценок пока нет

- FEA of RC Slab With OpeningДокумент4 страницыFEA of RC Slab With OpeningMelkamu DemewezОценок пока нет

- VTC 18MAT31 QP-Scheme-1Документ55 страницVTC 18MAT31 QP-Scheme-1Maithira HОценок пока нет

- B.Tech. 1st Term Q15 PDFДокумент10 страницB.Tech. 1st Term Q15 PDFDEBAPRASAD PALОценок пока нет

- Arduino Modules L298N Dual H Bridge Motor ControllДокумент7 страницArduino Modules L298N Dual H Bridge Motor ControllMarius DanilaОценок пока нет

- Thomeer Swanson Type Curve MatchingДокумент60 страницThomeer Swanson Type Curve MatchingDeepblue09Оценок пока нет

- JR Engg WAPDA (Civil)Документ16 страницJR Engg WAPDA (Civil)Hamza MujahidОценок пока нет

- Las 1-Earth Sci and LifeДокумент4 страницыLas 1-Earth Sci and LifeAlria CabugОценок пока нет

- EditДокумент2 страницыEditEvey HernándezОценок пока нет

- IAST Lect23 SlidesДокумент30 страницIAST Lect23 SlideskyleОценок пока нет