Академический Документы

Профессиональный Документы

Культура Документы

Prosedur Penangkal Petir

Загружено:

hendra silalahiИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Prosedur Penangkal Petir

Загружено:

hendra silalahiАвторское право:

Доступные форматы

INSPECTION PROCEDURE FOR LIGHNTING PROTECTON

1.

PURPOSE

To provide written instruction for inspection & certification of electrical equipment.

2.

SCOPE

This procedure describes the requirements and techniques for Lightning Protection

inspection and certification.

3.

RESPONSIBILITY

3.1

3.2

3.3

Inspector : verify, inspect, prepare report and certificate, sign

Head of department/branch deputy : verify report and certificate

Head of Unit/branch : sign certificate

4.

4.1.

PROCEDURE

Personnel qualification

Electrical Engineer

1 (one) year experience in electrical inspection for bachelor/master and or have

qualification certificate from recognized institution and 3 (three) years experience

in electrical inspection for diploma and or have qualification certificate from

recognized institution

4.2

Regulation, Code & Standard

Peraturan Menteri Tenaga Kerja No Per 02/Men/1989

PUIL 2000

NETA 2001

IEEE-STD-80 2000

NFPA 70

4.3

Scope of Work For Electrical Equipment Certification

4.3.1

4.3.2

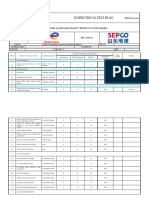

Review of Inspection & Testing Plan (ITP)

Review Design Document of Lightning Protection :

Technical data

General arrangement drawing

Cable tray, clamp and supporting drawing

Type and dimension of cable and BC wire

Type and dimension of electrode

Terminal box drawing and dimension

4.3.3 Physical Inspection

4.3.3.1.

Visual inspection of Lightning Protection in general.

Visual inspection of all parts of Lightning Protection system.

Range to protect of Lightning protection

Condition of Lightning Protection

Place and numbers of terminal box

4.3.3.2.

Inspection of electrode mast.

INSPECTION PROCEDURE FOR LIGHNTING PROTECTON

4.3.3.3.

4.3.3.4.

Visual inspection of damage, corrosion, tightening of bolt & nuts, terminal cable,

position of electrode and connection of cable

Inspection of Cable clamp and supporting.

Visual inspection of damage, corrosion, tightening of bolt & nuts, position of cable

& clamp and connection of cable.

Cable tray, clamp and supporting of cable should be inspected for any damage.

Condition of Cable, Clamp and Supporting

Inspection of Box Control Terminal and Cable Connection Terminal

Measure of dimension of Box Control Terminal

Visual inspection of damage, corrosion, tightening of bolt & nuts, position of Box

Control and connection of cable

Condition of Box Control Terminal and accessories (BC wire bolt & nuts)

Measure of dimension and condition of BC wire

4.3.4 Testing

Measure of earth ground test of electrode, according to PUIL standard shall be

less than 5 Ohm.

4.3.5 Non Conformity Report (If Available)

NCR to be issued if during inspection found parts not compliant with

standard/code/specification. NCR to be followed up with corrective action and closed

out accordingly.

4.4 Reporting

After satisfactory completion of design review/appraisal, site inspection and verification, BKI will

prepare report and recommendation.

5. RECORD

5.1 External Records

Requirement from Related Institution

Design Document (Specification of Terminal box, electrode, cable and BC wire).

As built drawings

History card (for existing)

5.2 Related documents :

Inspection record (inspectors log book)

Non Conformity Report

Certificate of Inspection

INSPECTION PROCEDURE FOR LIGHNTING PROTECTON

Вам также может понравиться

- PT TestingДокумент7 страницPT TestingNaveedОценок пока нет

- Cable Pulling Report (Instrument Cable) : Project Name CustomerДокумент3 страницыCable Pulling Report (Instrument Cable) : Project Name CustomerAldeline SungahidОценок пока нет

- ITP - Control PanelДокумент2 страницыITP - Control PanelHoras Canman Sianipar100% (1)

- Site Inspection and Test Plan For Tie-In Works: Subcontrac TorДокумент24 страницыSite Inspection and Test Plan For Tie-In Works: Subcontrac Torprabu palaniswamyОценок пока нет

- Commissioning Service Department Commissioning Standard Test Formats Description: MVAJ101 - TRIP RELAYДокумент2 страницыCommissioning Service Department Commissioning Standard Test Formats Description: MVAJ101 - TRIP RELAYtajudeenОценок пока нет

- MS Field Instrument InstallationДокумент11 страницMS Field Instrument InstallationMohammad Fazal KhanОценок пока нет

- Cable Tray InstallationДокумент1 страницаCable Tray InstallationNaeemОценок пока нет

- Cathodic Protection System MMO Grid of Tank Quality Control and Inspection Report FormДокумент5 страницCathodic Protection System MMO Grid of Tank Quality Control and Inspection Report Formjamal2877Оценок пока нет

- Right Factorz Projects PVT LTD Checklist For Cable InstallationДокумент9 страницRight Factorz Projects PVT LTD Checklist For Cable InstallationRajesh RaghunathanОценок пока нет

- ITP - Fiber Optic CableДокумент2 страницыITP - Fiber Optic CableRamy AiadОценок пока нет

- QAQC Form - ArchitechtureДокумент42 страницыQAQC Form - ArchitechtureMohammad Hadoumi SaldanОценок пока нет

- Fm-Ti-050 - Rev.0 Inspection Report Ultrasonic Examination - Eff.170107Документ1 страницаFm-Ti-050 - Rev.0 Inspection Report Ultrasonic Examination - Eff.170107Jindarat KasemsooksakulОценок пока нет

- KBR Inspection Test Plan For Bus Duct: NO. Inspection Activity 1 Pre-Inspection Meeting 2 Documentation ReviewДокумент2 страницыKBR Inspection Test Plan For Bus Duct: NO. Inspection Activity 1 Pre-Inspection Meeting 2 Documentation ReviewkamlОценок пока нет

- Battista Mondin, Saint Thomas Aquinas' Philosophy. in The Commentary To The Sentences (Inglés) PDFДокумент134 страницыBattista Mondin, Saint Thomas Aquinas' Philosophy. in The Commentary To The Sentences (Inglés) PDFFray Daniel Sisa NiñoОценок пока нет

- P0022 CS E 002 CableTrenchesДокумент1 страницаP0022 CS E 002 CableTrenchesnayumОценок пока нет

- Contoh ItpДокумент3 страницыContoh Itphafiz elektroОценок пока нет

- ITR For Electrical Instrument PDFДокумент4 страницыITR For Electrical Instrument PDFCokro YudhaОценок пока нет

- ITP - Fire Hydrant InstallationДокумент9 страницITP - Fire Hydrant InstallationGultom Juliana LiliesОценок пока нет

- PAUT Procedure ED - AMSYCO 500-8-2 Rev 00 PDFДокумент34 страницыPAUT Procedure ED - AMSYCO 500-8-2 Rev 00 PDFkbldam100% (3)

- Annual Fire Alarm Service ReportДокумент10 страницAnnual Fire Alarm Service ReportrisnaidiОценок пока нет

- ITP Transformer Testing and CommissioningДокумент1 страницаITP Transformer Testing and CommissioningguspriyОценок пока нет

- Electrical Distribution Board Inspection ChecklistДокумент2 страницыElectrical Distribution Board Inspection ChecklistBoluwatife ElishaОценок пока нет

- 415v Air Circuit Breaker-14Документ2 страницы415v Air Circuit Breaker-14Subhransu MohapatraОценок пока нет

- Itp Electrical CableДокумент2 страницыItp Electrical CablekamlОценок пока нет

- Checklist For UPS & Accessories InstallationДокумент1 страницаChecklist For UPS & Accessories InstallationguspriyОценок пока нет

- Vallorbs Guide Cut Vs Rolled ThreadsДокумент3 страницыVallorbs Guide Cut Vs Rolled ThreadsOrlando AriasОценок пока нет

- Instrumentation and ControlsДокумент2 страницыInstrumentation and ControlsTrí NguyễnОценок пока нет

- Method Statement For Installation of PVC PipesДокумент23 страницыMethod Statement For Installation of PVC Pipeschathura dharmasenaОценок пока нет

- Inspection and Test Plan (ITP) - Grounding WorksДокумент2 страницыInspection and Test Plan (ITP) - Grounding WorksElisco Pher SalmasanОценок пока нет

- Mov Specification PDFДокумент27 страницMov Specification PDFpl_arunachalam79Оценок пока нет

- 16950s01 HV Testing ProceduresДокумент1 страница16950s01 HV Testing ProceduresVICTOR JOSE VILORIAОценок пока нет

- Electrical Safety Audit Commissioning ServicesДокумент14 страницElectrical Safety Audit Commissioning ServicesNiroj Mohapatra100% (1)

- Dokgoro K1785 Method StatementДокумент6 страницDokgoro K1785 Method StatementJackie van SchalkwykОценок пока нет

- Unloading, Lifting and Install Panel r1Документ18 страницUnloading, Lifting and Install Panel r1Nurdin Sudrajat SasrabahuОценок пока нет

- DLP #7 Eng 7Документ2 страницыDLP #7 Eng 7Lenn Don50% (2)

- Itp FBSB Moc Fibreoptic 005 FinalДокумент6 страницItp FBSB Moc Fibreoptic 005 FinalVictor BiacoloОценок пока нет

- ITP Final PLPS 82336-43 - ITP 150kV KENDARI ANDOOLO SECT 1 Rev1 Baruga PDFДокумент3 страницыITP Final PLPS 82336-43 - ITP 150kV KENDARI ANDOOLO SECT 1 Rev1 Baruga PDFMuhammad YahdimanОценок пока нет

- FAT (Factory Acceptance Test)Документ4 страницыFAT (Factory Acceptance Test)MohamedОценок пока нет

- Quality Control Procedure For HVДокумент9 страницQuality Control Procedure For HVVIKRAM DESAIОценок пока нет

- ITP Socket Data and TelephoneДокумент6 страницITP Socket Data and TelephoneCosphiiiОценок пока нет

- ITP Work DownДокумент5 страницITP Work DownMuralimohan Pandian100% (1)

- DB ChecklistДокумент4 страницыDB ChecklistJabinОценок пока нет

- ITP For PV Mounting Structure and Module Installation-2023!05!19Документ3 страницыITP For PV Mounting Structure and Module Installation-2023!05!19Mohammad BayisОценок пока нет

- Installation of Panels, Cabinets and Field Junction Box: Method StatementДокумент8 страницInstallation of Panels, Cabinets and Field Junction Box: Method StatementRobe Caro100% (1)

- O&m Manual For Landscapeing LightДокумент104 страницыO&m Manual For Landscapeing Lightmukilanarul12Оценок пока нет

- Wrapping and Coating Inspection Report: Lanco Infratech Limited 2X600 MW Power Project MBMPL, Anuppur, M.PДокумент2 страницыWrapping and Coating Inspection Report: Lanco Infratech Limited 2X600 MW Power Project MBMPL, Anuppur, M.PSimbu ArasanОценок пока нет

- Minor Electrical Installation Works - RedДокумент2 страницыMinor Electrical Installation Works - RedSeby SebastianОценок пока нет

- Method Statement For Replacing of Existing MCCДокумент3 страницыMethod Statement For Replacing of Existing MCCsushanta chowdhuryОценок пока нет

- Pgcdc-40-003-089 Continuity and Insulation Resistance Test - 1660264288Документ6 страницPgcdc-40-003-089 Continuity and Insulation Resistance Test - 1660264288Manuel DizonОценок пока нет

- Installation of Fire & Gas Detectors (Flame - Toxic - Hydro Carbon) Check ListДокумент1 страницаInstallation of Fire & Gas Detectors (Flame - Toxic - Hydro Carbon) Check ListZulfequar R. Ali KhanОценок пока нет

- Radius Bending Pada KabelДокумент1 страницаRadius Bending Pada Kabeltwo travellerОценок пока нет

- Elec Foreman CVДокумент4 страницыElec Foreman CVhitanshu0% (1)

- Visual Inspection Checklist For Electrical Safety: Portable Electrical Equipment Yes NoДокумент2 страницыVisual Inspection Checklist For Electrical Safety: Portable Electrical Equipment Yes NoAhmed Zahran100% (1)

- Method Statement FOR Laying of LV Cables: M & E ContractorДокумент4 страницыMethod Statement FOR Laying of LV Cables: M & E ContractorJoe_AverageОценок пока нет

- Motors Solo Run TestДокумент2 страницыMotors Solo Run TestSureshYarlagaddaОценок пока нет

- 16126Документ13 страниц16126uddinnadeemОценок пока нет

- Hengxin RF Leaky Cable PDFДокумент16 страницHengxin RF Leaky Cable PDFculeros1Оценок пока нет

- E&I QAP's - Submitted To Contractor HZAДокумент33 страницыE&I QAP's - Submitted To Contractor HZASuraj ShettyОценок пока нет

- SAT Procedure DCI JK5 - Fire Fighting Rev. 2Документ14 страницSAT Procedure DCI JK5 - Fire Fighting Rev. 2Awaludin Angga WОценок пока нет

- 26may Testing Commissioning Electrical Equipment Rev2Документ39 страниц26may Testing Commissioning Electrical Equipment Rev2kpr_02161371Оценок пока нет

- 0610.1 - Shell and Tube Heat ExchangersДокумент30 страниц0610.1 - Shell and Tube Heat Exchangersvenkatrangan2003Оценок пока нет

- Emergency Lights Inspection ChecklistДокумент7 страницEmergency Lights Inspection ChecklistDemmy Rose NugasОценок пока нет

- Eal Qeta 015 DP 2 0114Документ45 страницEal Qeta 015 DP 2 0114Abdual abdualОценок пока нет

- CV - Pinki Arindra P&GДокумент6 страницCV - Pinki Arindra P&GPinqi Arindra PutraОценок пока нет

- Conductivity Type of Extrinsic Semiconducting Materials: Standard Test Methods ForДокумент6 страницConductivity Type of Extrinsic Semiconducting Materials: Standard Test Methods ForRob GridleyОценок пока нет

- Additional Instructions For Mailing Your Package: Drop Off LocatorДокумент2 страницыAdditional Instructions For Mailing Your Package: Drop Off LocatorEthanОценок пока нет

- Sternberg TheoryДокумент20 страницSternberg TheoryKhadijah ElamoreОценок пока нет

- Physiological, Anthropometric, and Motor Characteristics of Elite Chinese Youth Athletes From Six Different SportsДокумент12 страницPhysiological, Anthropometric, and Motor Characteristics of Elite Chinese Youth Athletes From Six Different SportsRafida I CОценок пока нет

- Energy TransportДокумент16 страницEnergy TransportainmnrhОценок пока нет

- 12 Chemistry Chapter 1 Assignment 2Документ2 страницы12 Chemistry Chapter 1 Assignment 2Mohd UvaisОценок пока нет

- Sex Quiz ResultsДокумент1 страницаSex Quiz Resultsapi-285789748Оценок пока нет

- ZXR10 8900 Series: Hardware Installation ManualДокумент109 страницZXR10 8900 Series: Hardware Installation ManualErnestoLopezGonzalezОценок пока нет

- THMT 3312: Research Methods For Tourism & Hospitality ManagementДокумент13 страницTHMT 3312: Research Methods For Tourism & Hospitality Managementmilrosebatilo2012Оценок пока нет

- Curriculum Vitae: Alex Gnanamani.KДокумент4 страницыCurriculum Vitae: Alex Gnanamani.KDIJUОценок пока нет

- Powerpoint TrainingДокумент22 страницыPowerpoint TrainingDenise SuОценок пока нет

- DS-KH6320-TE1 Video Intercom Network Indoor Station: Key FeatureДокумент3 страницыDS-KH6320-TE1 Video Intercom Network Indoor Station: Key FeatureDaniellMargaritОценок пока нет

- Family Tree Template With DetailsДокумент8 страницFamily Tree Template With DetailsJude WellsОценок пока нет

- Final Test 1 K 2 - KeyДокумент10 страницFinal Test 1 K 2 - KeyDuy HưngОценок пока нет

- Gep Primary Water Resource Aug12 NSWДокумент50 страницGep Primary Water Resource Aug12 NSWNitin AroraОценок пока нет

- Kinematics of A Novel Nine Degree of Freedom Configurable Gough-Stewart PlatformДокумент19 страницKinematics of A Novel Nine Degree of Freedom Configurable Gough-Stewart PlatformNeider NadidОценок пока нет

- Dynamic Modelling of Gas TurbinesДокумент8 страницDynamic Modelling of Gas TurbinesdannyОценок пока нет

- Model Rocketry Safety CodeДокумент2 страницыModel Rocketry Safety CodeAviation/Space History LibraryОценок пока нет

- Circuflow 5200 Operating InstructionsДокумент24 страницыCircuflow 5200 Operating InstructionsalexОценок пока нет

- University of Tehran Faculty of New Science & Technology Master's Thesis Proposal DefenseДокумент46 страницUniversity of Tehran Faculty of New Science & Technology Master's Thesis Proposal DefenseSoheilDarvishMotavalliОценок пока нет

- TEACHERS' ORGANIZATIONAL COMMITMENT, TEACHING EFFICACY BELIEF AND LEVEL OF PERFORMANCE in RELATION TO THEIR PUPILS' ATTITuDES Towards MathematicsДокумент8 страницTEACHERS' ORGANIZATIONAL COMMITMENT, TEACHING EFFICACY BELIEF AND LEVEL OF PERFORMANCE in RELATION TO THEIR PUPILS' ATTITuDES Towards MathematicsJay GalangОценок пока нет

- AMME4710 Chap5 ColourIPДокумент56 страницAMME4710 Chap5 ColourIPrajeevrajkumarОценок пока нет

- Ludo (Sorry) - Game StrategyДокумент8 страницLudo (Sorry) - Game Strategysuperyoopy100% (1)

- Ways To Measure Public Opinion 3Документ11 страницWays To Measure Public Opinion 3Mohamed Abd ELfattahОценок пока нет

- Modul Customer ServiceДокумент5 страницModul Customer ServiceFandy Bestario HarlanОценок пока нет