Академический Документы

Профессиональный Документы

Культура Документы

Spirax Sarco TD62

Загружено:

JUANITOPYTАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Spirax Sarco TD62

Загружено:

JUANITOPYTАвторское право:

Доступные форматы

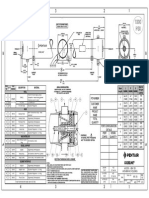

TD62LM and TD62M Thermodynamic Steam Trap

with replaceable seats

Description

The TD62LM and TD62M are maintainable high pressure thermodynamic steam traps with integral strainer

and a replaceable seat to ease maintenance. They have been specifically

designed for mains drainage applications up to 62 barg.

The TD62LM is specifically designed

for relatively small condensate loads

on superheat and mains drainage

applications. An insulating cover is fitted as standard to prevent the trap

being unduly influenced by excessive

heat loss when subjected to low outside temperatures, wind, rain etc.

Model

TD62LM and TD62M

900 psig

Sizes

1/2", 3/4", 1"

SW to ANSI B16.11 Class 3000

Construction

Alloy Steel

Options

8

14

7 & 15

13

1

4

NPT Connections

ANSI 300 / ANSI 600 Flanged

Blowdown Valve (SW and NPT only)

12

3

Blowdown

Valve

Option

Hot Condensate Flow

TD62LM

TD62M

#/hr.

kg.hr.

#/hr.

kg.hr

293

133

422

192

552

250

167

76

586

266

185

84

628

285

212

96

682

309

235

107

724

328

256

116

758

344

274

124

786

357

292

132

811

368

324

147

853

387

338

153

871

395

352

160

887

402

366

166

902

409

378

172

916

415

391

177

929

421

402

183

941

427

414

188

952

432

425

193

963

437

Operating Range

2

6

10

Connections

Capacities

Pressure

psig

barg

25

2

50

3

100

7

120

8

150

10

200

14

250

17

300

21

350

24

400

28

500

34

550

38

600

41

650

45

700

48

750

52

800

55

850

59

900

62

11

PMO

Materials

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

(SW Connection Only)

Part

Body

Cover

Strainer cap

Strainer screen

Insulating cover

Disc

Seat

Cover studs

Cover nuts

Cover gasket

Material

Steel

ASTM A217 Gr. WC 6

Steel

ASTM A217 Gr. WC 6

Steel

ASTM A217 Gr. WC 6

Stainless steel 100 mesh

316L

Aluminium

Chromium steel

Chromium steel

Steel

ASTM A193 Gr. B16

Steel

ASTM A194 Gr. 8M

Spirally wound stainless steel

with exfoliated graphite filler

Name-plate

Stainless steel

Strainer cap gasket Reinforced exfoliated graphite

Inner seat gasket Spirally wound stainless steel

with exfoliated graphite filler

Outer seat gasket Spirally wound stainless steel

with exfoliated graphite filler

Ferrule

Stainless steel

* Note: Item 15 (ferrule) is pressed into item 7 (seat).

Pressure barg

20

40

60 62*

80

100 barg

500

400

572

300

392

200

Steam

Saturation

Curve

212

100

32

0

290

580

870 900*

1160

1450

0

1500

Pressure psig

The product must not be used in this region

* PMO Max. operating pressure recommended

PMOB Max. operating back pressure 80% of upstream pressure

Temperature C

Temperature F

0

977

932

752

Limiting Conditions

Body design conditions ANSI 600

PMA Max. allowable pressure

1500 psig 103 barg

TMA Max. allowable temperature

977F 525C

Cold hydraulic test pressure

2250 psig 155 barg

TD62LM

Minimum pressure for satisfactory operation is

120 psig, 8 barg.

Maximum back pressure should not exceed 50% of the inlet pressure

under any conditions of operation, otherwise the trap may not shut.

TD62M

Minimum pressure for satisfactory operation is

20 psig, 1.4 barg.

Maximum back pressure should not exceed 80% of the inlet pressure

under any conditions of operation, otherwise the trap may not shut.

Local regulation may restrict the use of this product below the conditions quoted. Limiting conditions refer to standard connections only.

In the interests of development and improvement of the product, we reserve the right to change the specification.

TI-2-525-US

08.06

TD62LM and TD62M Thermodynamic Steam Trap

with replaceable seats

Socket Weld / NPT

Spare Parts

F withdrawal

distance

Socket Weld / NPT

Flanged

6

B

10

E withdrawal

distance

Dimensions

Size

A

3.1

1/2", 3/4" 79

3.3

1"

84

7+15

(nominal) in inches and millimeters

B

3.6

92

3.9

100

C

3.6

92

3.6

92

D D1*

2.0 3.3

51 84

1.8 3.1

46 79

E

0.8

20

0.8

20

F

2.0

51

2.0

51

14

Weight

4.6 lb

2.1 kg

5.3 lb

2.4 kg

13

8

* Traps with blowdown valve

withdrawal F

distance

Flanged

8A

12

9

D

Spare Parts

withdrawal

distance E

Dimensions

Size A

1/2" 3.2

82

3/4" 3.2

82

1"

3.2

82

The spare parts available are shown in solid outline. Parts shown in

broken line are not supplied a spares.

(nominal) in inches and millimeters

ANSI

600

ANSI

300

B1

5.9

150

5.9

150

6.3

160

B2

5.3

135

5.4

138

5.8

147

C

3.6

92

3.6

92

3.6

92

D

2.8

72

2.8

72

2.8

72

E

1.6

40

1.6

40

1.6

40

F

1.2

30

1.2

30

1.2

30

Weight

18.7 lb

8.5 kg

18.7 lb

8.5 kg

20.0 lb

9.1 kg

Available spares

Insulating cover

Set of cover studs and nuts (set of 8) on FCC

Seat and disc assembly

Strainer screen 100 mesh

Cover gasket (packet of 3 sets) Flanged

Set of gaskets (packet of 3 sets) SW, NPT

5

4 on other

8, 8A, 9

6, 7, 10, 13, 14, 15

4

10,13,14

10,12,13,14

How to order spares

Spirax Sarco TD62M ThermoDynamic steam trap, available in sizes

1/2", 3/4", and 1" socket weld connections to ANSI B16.11 Class 3000

(or NPT or ANSI 300 or 600 flanged connections). Alloy steel construction, suitable for operation from 20 to 900 psig at a maximum

operating temperature of 842F. An integral strainer and insulating

cover are standard. Traps to have replacement seats and disc.

Installation

The preferred trap installation is in a horizontal pipe with the insulcap

up. After 24 hours in service the cover nuts should be checked for

tightness and if necessary torqued to 33-37 ftlb. Full-port isolating

valves should be installed upstream and downstream of the trap.

Always order spares by using the description given in the column headed

Available spares and state the size and type of trap.

Example: 1- Strainer screen for a Spirax Sarco 1" TD62LM thermodynamic

steam trap (ASTM body)

Maintenance

This product can be maintained without disturbing the piping

connections. Complete isolation of the trap from both supply and

return line is required before any servicing is performed.

The trap should be disassembled periodically for cleaning of the

strainer screen and inspection and cleaning of the disc and seat.

Complete installation and maintenance instructions are given in

the IMI Sheet, which accompanies the product. (IM-P068-58)

Spirax Sarco, Inc., 1150 Northpoint Blvd, Blythewood, SC 29016

TI-2-525-US

Telephone: (803) 714-2000 FAX (803) 714-2222

Spirax Sarco, Inc. 2006

Sample Specification

08.06

Вам также может понравиться

- Steam TrapsДокумент2 страницыSteam Trapslaxmans20Оценок пока нет

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitОт EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitОценок пока нет

- TD62LM and TD62M Thermodynamic Steam Traps With Replaceable Seats (Screwed /socket Weld)Документ2 страницыTD62LM and TD62M Thermodynamic Steam Traps With Replaceable Seats (Screwed /socket Weld)Rupesh DesaiОценок пока нет

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsОт EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsРейтинг: 5 из 5 звезд5/5 (1)

- Trampa Socket WeldДокумент2 страницыTrampa Socket WeldOscar Nieves ZamoraОценок пока нет

- Steam TrapДокумент2 страницыSteam TrapJozsef MagyariОценок пока нет

- Trampa Termodinamica PDFДокумент2 страницыTrampa Termodinamica PDFriquelme0788Оценок пока нет

- Ti 2 516 UsДокумент2 страницыTi 2 516 Uswill_streetОценок пока нет

- Thermodynamic Steam TrapsДокумент12 страницThermodynamic Steam TrapsbuddhansamratОценок пока нет

- CS310AДокумент4 страницыCS310Arabacet2923Оценок пока нет

- Gestra Steam Trap - Thermostatic Steam Trap BK 29: Class Rating: ANSI 900 Available SizesДокумент2 страницыGestra Steam Trap - Thermostatic Steam Trap BK 29: Class Rating: ANSI 900 Available SizesdcarunchioОценок пока нет

- Harris 825Документ2 страницыHarris 825Riza SyahriОценок пока нет

- Series 826YD Specification SheetДокумент2 страницыSeries 826YD Specification SheetFEBCOОценок пока нет

- Steam TrapДокумент2 страницыSteam TrapAmpornchai PhupolОценок пока нет

- Air HeatersДокумент34 страницыAir HeatersNaveen KamatОценок пока нет

- DPSPDFДокумент6 страницDPSPDFNavneet SinghОценок пока нет

- Schmidt Bretten SIGMAWIGДокумент6 страницSchmidt Bretten SIGMAWIGUroš ČampragОценок пока нет

- PACSДокумент33 страницыPACSphilipnart100% (1)

- Endress+Hauser: RTD Thermometer Omnigrad TST11Документ4 страницыEndress+Hauser: RTD Thermometer Omnigrad TST11Pame CoronaОценок пока нет

- Watlow Air HeatersДокумент32 страницыWatlow Air HeatersEliasОценок пока нет

- A1200 Red Thread II PipingДокумент0 страницA1200 Red Thread II PipingjimmycabreraОценок пока нет

- SevereEnviroment CatalogДокумент8 страницSevereEnviroment CatalogSteven HungОценок пока нет

- SV97Документ2 страницыSV97nclogesh_1981Оценок пока нет

- Thermo-Dynamic Liquid Drain Trap TDA52: Typical ApplicationsДокумент2 страницыThermo-Dynamic Liquid Drain Trap TDA52: Typical ApplicationsbuddhansamratОценок пока нет

- Cd60 Low Leakage Control DamperДокумент3 страницыCd60 Low Leakage Control Dampermorucha_chicleОценок пока нет

- VAD Variable Area Desuperheaters: Desuperheater OverviewДокумент6 страницVAD Variable Area Desuperheaters: Desuperheater OverviewLucasZanaОценок пока нет

- MK25 2 2S En-Instr 1390296721Документ20 страницMK25 2 2S En-Instr 1390296721Erik RochaОценок пока нет

- Spirax Sarco PDFДокумент4 страницыSpirax Sarco PDFandresaroОценок пока нет

- Goodman GKS9 Spec Sheet 6.09Документ8 страницGoodman GKS9 Spec Sheet 6.09Rich KohliОценок пока нет

- Carrier38CKC 50HzДокумент20 страницCarrier38CKC 50HzAaron LeveyОценок пока нет

- Bryant 561CДокумент28 страницBryant 561Cspencer_lawrence_2Оценок пока нет

- Desuperheater That Combines Proven Technologies For Better Operational EconomyДокумент4 страницыDesuperheater That Combines Proven Technologies For Better Operational Economyhappale2002Оценок пока нет

- Nicholson Thermostatic Steam TrapsДокумент18 страницNicholson Thermostatic Steam TrapsAli Fanani100% (1)

- Automatic Air Vent Valve Spirax SarcoДокумент4 страницыAutomatic Air Vent Valve Spirax SarcosrshahОценок пока нет

- AMRI MAMMOUTwerrewrrH Type Series Booklet DataДокумент24 страницыAMRI MAMMOUTwerrewrrH Type Series Booklet Datarudiskw456Оценок пока нет

- Asco S V7394R5Документ16 страницAsco S V7394R5Jorge Jarpa VОценок пока нет

- Drawing 80H30Документ3 страницыDrawing 80H30kpranjal15Оценок пока нет

- At Temper at orДокумент8 страницAt Temper at orrobin_samuel88Оценок пока нет

- R401D-R402D 0425enДокумент2 страницыR401D-R402D 0425enwodrОценок пока нет

- Catalogo ChillerДокумент8 страницCatalogo ChillerJoan Sebastian DazaОценок пока нет

- 38eyg 3pdДокумент48 страниц38eyg 3pdBlueSkyMasterОценок пока нет

- HYD. PumpДокумент40 страницHYD. Pumprohitbhat2345Оценок пока нет

- Brosur Etanorm SYTДокумент24 страницыBrosur Etanorm SYTNovarОценок пока нет

- Big Blue Air Pak: The Power of BlueДокумент4 страницыBig Blue Air Pak: The Power of BlueRaul Izquierdo MoralesОценок пока нет

- b12cn PresostatДокумент1 страницаb12cn PresostatSandu VisanescuОценок пока нет

- CCIVALVE Desuper HeaterДокумент4 страницыCCIVALVE Desuper Heaterhappale2002Оценок пока нет

- 2010 Datasheet DMV 825Документ4 страницы2010 Datasheet DMV 825Roman BorovkovОценок пока нет

- Sauter B6R Three-Way Valve With Female Thread, PN 16Документ4 страницыSauter B6R Three-Way Valve With Female Thread, PN 16pitanje1991Оценок пока нет

- Watlow Immersion HeatersДокумент163 страницыWatlow Immersion HeatersEliasОценок пока нет

- Air Cooled Screw Chiller R134aДокумент12 страницAir Cooled Screw Chiller R134aamitbslpawar0% (1)

- Swagelok Medium Pressure Fittings Alloy 625Документ16 страницSwagelok Medium Pressure Fittings Alloy 625totcsabОценок пока нет

- Dryplus 3Документ10 страницDryplus 3sallehasanОценок пока нет

- Aks 38Документ8 страницAks 38Tran Ngoc HaОценок пока нет

- Si 83 - ENДокумент52 страницыSi 83 - ENBabis PapadopoulosОценок пока нет

- ImmersionДокумент164 страницыImmersionsvpd2006Оценок пока нет

- Gestra Catalog 2005Документ190 страницGestra Catalog 2005marioLhrОценок пока нет

- Yawmc 0442 Us YarwayДокумент20 страницYawmc 0442 Us YarwayGUZMANОценок пока нет

- HeaterДокумент12 страницHeaterErwin Paulian SihombingОценок пока нет

- (2012) Complete IELTS Bands 5-6.5 Student's BookДокумент3 страницы(2012) Complete IELTS Bands 5-6.5 Student's BookAhmed Hamdy0% (1)

- Pim Hnp006cДокумент2 страницыPim Hnp006cJUANITOPYTОценок пока нет

- Daily Thermetrics Turnaround Services (DT-TARS™)Документ1 страницаDaily Thermetrics Turnaround Services (DT-TARS™)JUANITOPYTОценок пока нет

- Ammonia-Syngas - Advanced Thermometry Solutions - DAILY THERMETRICSДокумент1 страницаAmmonia-Syngas - Advanced Thermometry Solutions - DAILY THERMETRICSHECTORОценок пока нет

- Richards Industries Product Line DivisionsДокумент2 страницыRichards Industries Product Line DivisionsJUANITOPYTОценок пока нет

- Addendum Manual FTДокумент77 страницAddendum Manual FTJUANITOPYTОценок пока нет

- Brochure FTДокумент6 страницBrochure FTJUANITOPYTОценок пока нет

- LGENTB0520 PosicДокумент12 страницLGENTB0520 PosicJUANITOPYTОценок пока нет

- Brochure FTДокумент6 страницBrochure FTJUANITOPYTОценок пока нет

- Instruction Manual FTДокумент28 страницInstruction Manual FTJUANITOPYTОценок пока нет

- Type 90 Air RegulatorДокумент2 страницыType 90 Air RegulatorJUANITOPYTОценок пока нет

- Installation and Operations Maintenance Manual Ball Valve: Valvtechnologies, IncДокумент20 страницInstallation and Operations Maintenance Manual Ball Valve: Valvtechnologies, IncJUANITOPYTОценок пока нет

- T RUNNIOPNДокумент4 страницыT RUNNIOPNJUANITOPYTОценок пока нет

- Spirax TD42Документ2 страницыSpirax TD42JUANITOPYTОценок пока нет

- List of Dielectric Figures enДокумент8 страницList of Dielectric Figures enJUANITOPYTОценок пока нет

- Boletin Actuador KämmerДокумент8 страницBoletin Actuador KämmerJUANITOPYTОценок пока нет

- بتول ماجد سعيد (تقرير السيطرة على تلوث الهواء)Документ5 страницبتول ماجد سعيد (تقرير السيطرة على تلوث الهواء)Batool MagedОценок пока нет

- Meta100 AP Brochure WebДокумент15 страницMeta100 AP Brochure WebFirman RamdhaniОценок пока нет

- Nominal GroupДокумент3 страницыNominal GroupSrourОценок пока нет

- Aashto M288-17 Product Selection GuideДокумент1 страницаAashto M288-17 Product Selection GuideDem DemОценок пока нет

- Department of Education: Consolidated Data On Learners' Grade Per QuarterДокумент4 страницыDepartment of Education: Consolidated Data On Learners' Grade Per QuarterUsagi HamadaОценок пока нет

- LG LFX31945 Refrigerator Service Manual MFL62188076 - Signature2 Brand DID PDFДокумент95 страницLG LFX31945 Refrigerator Service Manual MFL62188076 - Signature2 Brand DID PDFplasmapete71% (7)

- 2010 - Howaldt y Schwarz - Social Innovation-Concepts, Research Fields and International - LibroДокумент82 страницы2010 - Howaldt y Schwarz - Social Innovation-Concepts, Research Fields and International - Librovallejo13Оценок пока нет

- 2.a.1.f v2 Active Matrix (AM) DTMC (Display Technology Milestone Chart)Документ1 страница2.a.1.f v2 Active Matrix (AM) DTMC (Display Technology Milestone Chart)matwan29Оценок пока нет

- Unit 1 PrinciplesДокумент17 страницUnit 1 PrinciplesRohit YadavОценок пока нет

- Third Party Risk Management Solution - WebДокумент16 страницThird Party Risk Management Solution - Webpreenk8Оценок пока нет

- Design ProjectДокумент60 страницDesign Projectmahesh warОценок пока нет

- Sim Uge1Документ62 страницыSim Uge1ALLIAH NICHOLE SEPADAОценок пока нет

- Names of Planner(s) : Style of Experience: (Whole Class, Small Group, Etc.) Lab: KindergartenДокумент4 страницыNames of Planner(s) : Style of Experience: (Whole Class, Small Group, Etc.) Lab: Kindergartenapi-428128701Оценок пока нет

- Jinivefsiti: Sultan LorisДокумент13 страницJinivefsiti: Sultan LorisSITI HAJAR BINTI MOHD LATEPIОценок пока нет

- Eccentric FootingДокумент3 страницыEccentric FootingVarunn VelОценок пока нет

- AYUMJAДокумент1 страницаAYUMJASoumet Das SoumetОценок пока нет

- Expression of Interest (Eoi)Документ1 страницаExpression of Interest (Eoi)Mozaffar HussainОценок пока нет

- 'Causative' English Quiz & Worksheet UsingEnglish ComДокумент2 страницы'Causative' English Quiz & Worksheet UsingEnglish ComINAWATI BINTI AMING MoeОценок пока нет

- Darkle Slideshow by SlidesgoДокумент53 страницыDarkle Slideshow by SlidesgoADITI GUPTAОценок пока нет

- Maximum and Minimum PDFДокумент3 страницыMaximum and Minimum PDFChai Usajai UsajaiОценок пока нет

- Keeping Track of Your Time: Keep Track Challenge Welcome GuideДокумент1 страницаKeeping Track of Your Time: Keep Track Challenge Welcome GuideRizky NurdiansyahОценок пока нет

- Management PriniciplesДокумент87 страницManagement Priniciplesbusyboy_spОценок пока нет

- Designed For Severe ServiceДокумент28 страницDesigned For Severe ServiceAnthonyОценок пока нет

- Marking Scheme For Term 2 Trial Exam, STPM 2019 (Gbs Melaka) Section A (45 Marks)Документ7 страницMarking Scheme For Term 2 Trial Exam, STPM 2019 (Gbs Melaka) Section A (45 Marks)Michelles JimОценок пока нет

- Aditya Academy Syllabus-II 2020Документ7 страницAditya Academy Syllabus-II 2020Tarun MajumdarОценок пока нет

- 147 Amity Avenue Nampa, ID 81937 (999) 999-9999 William at Email - ComДокумент4 страницы147 Amity Avenue Nampa, ID 81937 (999) 999-9999 William at Email - ComjeyesbelmenОценок пока нет

- Moral GPS: A Positive Ethic For Our Multicultural WorldДокумент279 страницMoral GPS: A Positive Ethic For Our Multicultural WorldLeonard Bowman75% (4)

- Board of Technical Education (Student Marksheet)Документ2 страницыBoard of Technical Education (Student Marksheet)Manoj SainiОценок пока нет

- CE EVALUATION EXAM No. 4 - MGT, Fluid Properties, Hydrostatic Force (Answer Key)Документ6 страницCE EVALUATION EXAM No. 4 - MGT, Fluid Properties, Hydrostatic Force (Answer Key)Angelice Alliah De la CruzОценок пока нет

- Stability Analysis of Geocell Reinforced Slopes by Considering Bending EffectДокумент13 страницStability Analysis of Geocell Reinforced Slopes by Considering Bending EffectRakesh KapoorОценок пока нет

- University of Chicago Press Fall 2009 Distributed TitlesОт EverandUniversity of Chicago Press Fall 2009 Distributed TitlesРейтинг: 1 из 5 звезд1/5 (1)