Академический Документы

Профессиональный Документы

Культура Документы

Vma in Apshalt

Загружено:

Rakesh ParaliyaАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Vma in Apshalt

Загружено:

Rakesh ParaliyaАвторское право:

Доступные форматы

24

MID-CONTINENT TRANSPORTATION SYMPOSIUM 2000 PROCEEDINGS

VMA as a Design Parameter in Hot-Mix

Asphalt

WALTER P. HISLOP AND BRIAN J. COREE

Current research at Iowa State University on behalf of the Iowa

Department of Transportation has focused on the volumetric state of

hot-mix asphalt (HMA) mixtures as they transition from stable to

unstable configurations. This has traditionally been addressed during

mix design by a minimum voids in the mineral aggregate (VMA)

requirement, based solely upon the nominal maximum aggregate size.

The current research addresses three maximum aggregate sizes (19mm,

12.5mm, and 9.5mm), three gradations (coarse, fine, and dense), and

combinations of natural and manufactured coarse and fine aggregates.

Specimens are compacted using the Superpave Gyratory Compactor

(SGC), conventionally tested for bulk and maximum theoretical specific

gravities, and physically tested using the Nottingham Asphalt Tester

(NAT) under a repeated load confined configuration. The results

clearly demonstrate that the volumetric conditions of an HMA mixture

at the stable/unstable threshold are influenced by the maximum aggregate

size, gradation and aggregate shape and texture. The currently defined

VMA criterion, while significant, is seen to be insufficient by itself to

correctly differentiate sound from unsound mixtures. Under current

specifications, many otherwise sound mixtures are subject to rejection

solely on the basis of failing to meet the VMA requirement. The

results of the current research project suggest a new set of volumetric

design parameters that explicitly take into account such factors as

aggregate gradation, shape, and texture.

INTRODUCTION

The Asphalt Institute reinstated a VFA requirement in 1994 in conjunction with the minimum VMA requirement (4).

In Superpave, meeting McLeods minimum VMA requirement is

a deciding factor on whether or not an aggregate blend can be used.

In recent years, some researchers have presented concerns that these

minimum VMA requirements are too restrictive and may rule out

economical mixes with acceptable performance properties (5). Others point out that evaluating and selecting the aggregate gradation to

achieve VMA is the most difficult and time-consuming step in the

Superpave mix design process (6). Others suggest it is not applicable

to all asphalt mixtures and propose refinements to it (7).

TABLE 1 Superpave VMA Requirements

Nominal Maximum Aggregate Size

9.5 mm

12.5 mm

19 mm

25 mm

37.5 mm

Department of Civil and Construction Engineering, Iowa State University, Ames, Iowa 50011.

15.0

14.0

13.0

12.0

11.0

TABLE 2 Superpave VFA Requirements

Traffic, ESALs

In Superpave, the volumetric design of asphalt mixtures requires

consideration of air voids, voids in the mineral aggregate (VMA),

and voids filled with asphalt (VFA). The percent air voids is used as

the basis for selecting the asphalt binder content. VMA is defined as

the sum of the volumes of the air voids and the unabsorbed binder in

the compacted specimen. VFA is the percentage of VMA containing

asphalt binder. It is widely accepted that these volumetric properties

are useful in predicting hot-mix asphalt pavement performance. Excessive air voids or VFA and inadequate VMA suggest potential

durability problems. Insufficient air voids or excessive VFA indicate

potential rutting problems.

Over the years, mix designers have established standards of maximum and/or minimum limits on these volumetric properties to exclude poor performing asphalt mixes. The current Superpave guidelines are shown in Tables 1 and 2. The VFA requirements originated

with the Corps of Engineers in the late 1940s (1). The VMA requirements date back to 1959, when Dr. Norman W. McLeod first proposed a relationship between critical minimum VMA and nominal

maximum aggregate size for dense graded mixtures (2). In 1962, the

Asphalt Institute dropped the VFA requirements in favor of a minimum VMA requirement in their Marshall mix design guidelines (3).

Minimum VMA, %

<

<

<

<

<

<

<

3

1

3

1

3

1

3

x

x

x

x

x

x

x

105

106

106

107

107

108

108

Design VFA, %

7080

6578

6578

6575

6575

6575

6575

RESEARCH OBJECTIVES

The research objective was to determine the validity of the minimum

VMA requirement vs. nominal maximum aggregate size required in

Superpave volumetric mix design. The project sought to fulfill three

specific objectives:

1. To establish a laboratory method by which the transition of an

asphalt paving mixture from sound to unsound behavior may be

credibly identified and measured.

2. To use that method to identify and evaluate statistically the effects

of aggregate-related factors on the critical state of such mixtures.

3. To derive a predictive relationship relating critical state (e.g., critical VMA) to aggregate-related properties such as nominal maximum aggregate size, gradation, shape, and texture.

This paper presents the results of objectives 1 and 2. Work is in

progress on objective 3.

25

Hislop and Coree

TABLE 3 Experimental Matrix

Nominal Maximum Aggregate Size

9.5 mm

CA

FA

Crushed

Natural

50/50

Gravel

Manufactured

Manufactured

50/50

Natural

12.5 mm

19.0 mm

Fine

Dense

Coarse

Fine

Dense

Coarse

Fine

Dense

Coarse

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

EXPERIMENTAL TEST PROGRAM

Table 4 Superpave Test Properties of Asphalt Binder used in

Laboratory Testing.

Test Results

Experimental Design

Specification Requirements

Original Properties

The test matrix used in the study is presented in Table 3. As shown,

a total of 36 blends were studied; nine gradations comprised of four

different aggregate blends. The four blends selected were:

1. Manufactured: Each gradation is 100 percent crushed material.

2. 50-50 Blend: Each gradation is a blend of 50 percent crushed and

50 percent natural material on each sieve size.

3. Manufactured Fine-Natural Coarse (MFNC): The material passing the #4 sieve was 100 percent crushed and the material retained

100 percent natural. The coarse (natural) aggregate was washed to

make sure the P200 (75 mm) material was entirely from the crushed

aggregates.

4. Natural: Each gradation is 100 percent natural material.

Comparing these four blends should distinguish the effects of

gradation and shape for both the fine and coarse aggregates. For

example, comparing the manufactured with the MFNC would emphasize the effects of the coarse aggregate shape and texture. Comparing the MFNC with the natural blends would examine the shape

and texture effects of the fine aggregate to be examined.

For each blend, two specimens at 4, 5,6,7, and 8% asphalt content

were fabricated and tested to determine the critical state volumetric

properties. These properties were then compared with the values

shown in Tables 1 and 2 to validate the Superpave guidelines.

Flash Point Temperature 230+

C

Rotational Viscosity,

0.247

135 C

Dynamic Shear,

1.024@58 C

@ 10 rad/s kPa

230 minimum

3.0 maximum

1.0 minimum

Rolling Thin Film Oven (RTFO) Residue Properties

Mass Loss, %

Dynamic Shear

@ 10 rad/s kPa

O.248

2.515@58C

1.0 maximum

2.2 minimum

Pressure Aging Vessel (PAV) Residue Properties

Dynamic Shear,

@ 10 rad/s kPa

Creep Stiffness

@ 60 s, Mpa

m-value

4253@ 19C

5000 maximum

239@-18 C

300 maximum

0.303@-18 C

0.300 minimum

Aggregates

Materials

Asphalt Binder

While the binder was not intended to be a variable in the study, it was

important that it be of a typical performance grade used in Iowa.

Jebro, Inc., of Sioux City, Iowa supplied ten 5-gallon pails of a

conventional PG58-28 binder. The binder test results and specification requirements are listed in Table 4.

It was essential to differentiate the aggregates in as many ways as

possible to determine what properties contribute to critical VMA.

Ideally, it would have been desirable to select aggregates based on

specific (measured) test properties for comparison, but this is easier

said than done. Since gravel is not commonly used in asphalt mixtures, it was difficult to locate a source of natural coarse aggregates.

Automated Sand and Gravel of Fort Dodge, IA provided both the

coarse and fine natural aggregates used in the study. Martin-Marietta

Aggregates of Ames, IA supplied the manufactured aggregates used

in the study.

26

MID-CONTINENT TRANSPORTATION SYMPOSIUM 2000 PROCEEDINGS

TABLE 5 Aggregate Gradations

Percent Passing

Sieve

Number

(mm)

9.5 mm NMS

12.5 mm NMS

19.0 mm NMS

Fine

Dense

Coarse

Fine

Dense

Coarse

Fine

Dense

Coarse

19.0

12.5

9.5

100

100

95

100

100

95

100

100

95

100

95

86

100

95

73

100

95

65

100

87

78

100

74

65

100

65

55

4.75

2.36

1.18

80

60

45

65

47

34

55

36

25

65

50

37

54

39

29

45

32

22

59

45

33

47

34

25

40

28

20

0.600

0.300

0.150

0.075

32

22

9

4

26

19

9

4

17

12

9

4

27

18

9

4

21

15

9

4

15

10

9

4

25

18

9

4

18

13

9

4

14

10

9

4

Once the aggregates were selected and sufficient quantities were

obtained, each aggregate needed to be characterized using conventional tests. The aggregates were dried and sieved prior to testing.

Once this was done, the aggregate gradations used in the study could

be selected. For the project, three nominal maximum aggregate sizes

(19mm, 12.5mm, and 9.5mm) were used. For each nominal maximum aggregate size, fine, dense, and coarse gradations were carefully blended in the laboratory. The gradations used in the study are

shown in Table 5.

be omitted. The SGC compacted specimens were examined for

levelness and seemed adequate. Of course, prior to testing they

were liberally coated with a silicon-teflon grease to mitigate end

effects.

Mixing and compaction temperatures of 147C and 135 C were

used throughout the study. A two-hour short-term aging period was

used prior to compaction. All specimen tested were compacted to

Ndesign = 109, which corresponds to the heaviest traffic levels used in

Iowa.

LABORATORY TESTING

Specimen Preparation

For the most part, Superpave mix design procedures (AASHTO

TP4-93) and applicable British testing standards for the Nottingham

asphalt tester (NAT) were followed. However, to expedite testing

and conserve materials, two important changes were made.

1. Specimen size: The NAT equipment limits specimen height to

approximately 115120 mm in height, which would seem adequate for normal SGC specimens of 45004700 g. The Transport Research Laboratory (TRL) researchers who worked with the

NAT used specimen heights of 60 mm and 90 mm (8). The

Superpave specimens are considerably larger than these and would

require some care in mounting the linear variable displacement

transducers (LVDTs) used to measure axial deformation. Once

the decision was made to use smaller specimens, it was decided to

target a specimen height of 80 mm, which would also conserve

asphalt and aggregates. It was found that a batch weight of 3375

g would provide the right specimen geometry and optimize materials.

2. Unsawn/polished specimen ends: The TRL researchers recommend cutting and polishing the specimen ends prior to testing in

the NAT, as they will reduce end effects and can be specified and

reproduced by independent laboratories. However, since the same

specimens would be used to determine the theoretical maximum

specific gravity, it was determined that cutting and polishing would

FIGURE 1 Schematic of NAT triaxial apparatus

Testing Procedures

Repeated load triaxial tests were conducted using the Nottingham

asphalt tester (NAT). The NAT is widely used in Europe for testing

asphalt mixturesmost commonly in a repeated load axial configuration. It has recently been modified to apply a confining stress; this

is done through a vacuum as shown in Figure 1(8, 9). All tests were

conducted at 45 C.

The NAT repeated load triaxial test procedures are summarized as

follows:

1. Place specimen in environmental test chamber 130 minutes prior

to test to consistent test temperature.

27

Hislop and Coree

FIGURE 2 NAT results used for determining critical transition

FIGURE 3 Critical VMA vs. nominal maximum aggregate size

2. Grease top and base platen with silicon-teflon grease.

3. Place HMA specimen on base, slide rubber membrane over it, and

secure with O-ring.

4. Place top platen on specimen, roll membrane up over edge, and

secure with O-ring.

5. Place in center of load frame and lower load cell onto the ball

seating.

6. Place the LVDTs on the support arms and zero them out.

7. Enter in appropriate test data (e.g. specimen height, name, etc.) and

start test.

8. Begin the test after a two minute conditioning1800 cycles (one

second load duration, one second recovery) taking one hour at 300

kPa axial load, 17 kPa confining stress.

The repeated load triaxial test provides realistic loading conditions

in that it simulates traffic and confines the HMA laterally. Recent

improvements and innovations (such as the NAT equipment) have

made it user-friendly, expedient, and easily adaptable into a Superpave

based mix design program.

ANALYSIS OF RESULTS

The first step of the analysis was to determine the critical transition

asphalt content of the compacted HMA mixture based on a visual

analysis of the NAT results. To show how this was done, the test

results for the three 19 mm NMS crushed aggregate blends is shown

in Figure 2. Examining the plot the critical asphalt content of the

three mixes was estimated as 6.6 for the coarse, 6.3 for the dense, and

6.9 for the fine-graded mix. Five of the mixes did not become

unsound over the range of asphalt contents used in the study. For

28

MID-CONTINENT TRANSPORTATION SYMPOSIUM 2000 PROCEEDINGS

each of the 31 mixes that became plastic, the volumetric properties

were calculated at the critical point. Whereas McLeod specified

VMA at 5 percent air voids and Superpave at 4 percent air voids, the

critical VMA was defined at whatever air content the mix became

unstable.

TABLE 6 Comparison of Observed Critical VMA Values with

Superpave Requirements

Nominal

Maximum

Aggregate

Size

9.5 mm

12.5 mm

19 mm

Observed

VMA,

Average

Value

13.5

12.3

11.2

Observed

VMA,

Standard

Deviation

1.5

1.1

1.7

Minimum

Required

VMA

15

14

13

VMA & Nominal Maximum Size

The critical VMA values where the mixtures became unsound are

plotted in Figure 3. Table 6 compares the average values with

Superpaves minimum VMA requirements. As can be seen, the

minimum VMA requirements based on nominal maximum aggregate size appear to fit the data trend reasonably well, however it is

seen that the measured values are typically less than the Superpave

criteria.

Therefore, from a practical viewpoint, this gives credence to the

complaints that the VMA requirements are too restrictive, as is shown

in Figure 3, where only three mixes meet the Superpave VMA requirements. Given the difficulties in achieving Superpaves minimum VMA requirements, it is worth examining how other aggregate

properties, e.g., gradation and surface texture, effect critical VMA.

This involves using analysis of variance (ANOVA) to identify the

significant aggregate-related effects upon critical VMA.

In selecting what factors to include in the ANOVA analysis, it was

hypothesized that critical VMA would be determined not only by

nominal maximum aggregate size, but also by crushed coarse aggregate content, crushed fine aggregate content, and some indicator of

TABLE 7 ANOVA Results

the gradation curve. For the latter, the fineness modulus (ASTM C136), was selected.

The ANOVA results are presented in Table 7 and show that nominal maximum aggregate size becomes insignificant when the fineness modulus of the aggregate blend is included as a factor. This

makes sense as the fineness modulus encodes information about the

nominal maximum aggregate size of the blend.

Other Volumetric Properties

Air Voids

In Superpave, the design asphalt content is determined at 4 percent

air voids (Ndesign). Prior to Superpave, Marshall mix design allowed

a range of 35 % air voids. For the mixes tested, the results suggest

a lower limit of 2.6 % air voids (S.D. = 0.65) at the critical state.

Voids Filled with Asphalt

The mixes studied were compacted to Ndesign = 109 gyrations, which,

under Superpave (Table 2), corresponds to a traffic level of 310

million ESALs. Following Table 2, this limits VFA to 6575 percent. For the mixes tested, the critical VFA appears to occur at about

78 percent (S.D. = 5.8).

CONCLUSIONS

The results presented here are of a preliminary nature and based on

performance testing equipment that is still in the developmental stage.

Work is ongoing to develop an equation relating critical VMA to

aggregate properties to refine the Superpave requirements. Based on

the results achieved so far the following conclusions are presented:

1. Specifying a minimum VMA requirement for asphalt paving mixtures based on nominal maximum aggregate size may be unrealistic.

2. Fineness modulus (shape of gradation) and crushed coarse and

fine aggregate content (surface texture) appear to be much more

robust indicators of critical VMA.

3. Current minimum VMA requirements may rule out mixtures that

perform satisfactorily as some have suggested.

Type 1 Sum

of Squares

df

Corrected Model

Intercept

73.245

4184.617

11

1

6.659

4184.617

Fineness Modulus

Crushed Coarse

Aggregate Content

51.150

12.993

8

2

6.394

6.496

Crushed Fine

Aggregate Content

Nominal Maximum

Aggregate Size

9.103

9.103

FURTHER WORK

0

0.180

The next step in the research is to analyze the results statistically to

develop an equation

VMAcrit = f(FM (Gradation),% crushed coarse,% crushed fine)+ .

This equation will then need to be applied to field and laboratory

data, for both well and poorly performing mixes for validation.

Source

Error

Total

Corrected Total

2.887

4260.75

76.133

16

28

27

Mean Square

Hislop and Coree

ACKNOWLEDGEMENTS

This research was sponsored by the project Development Division

of the Iowa Department of Transportation and the Iowa Highway

Research Board (TR-415).The authors wish to express their gratitude to the Center for Transportation Research and Education (CTRE),

the Iowa Department of Transportation (IADOT), and the Asphalt

Paving Association of Iowa (APAI) for their support.

REFERENCES

1. McFadden, G. and W.G. Ricketts. Design and Field Control of

Asphalt Pavements for Military Installations. In Proceedings of the

Association of Asphalt Paving Technologists, Vol. 17, April 1948.

2. McLeod, N. W. Void Requirements for Dense-graded Bituminous

Paving Mixtures. American Society of Testing and Materials, STP252, 1959.

3. Mix Design Methods for Asphalt Concrete (MS-2). The Asphalt

29

Institute. Second Edition, Third Printing, May 1963.

4. Mix Design Methods for Asphalt Concrete and other Hot-Mix Types

(MS-2). The Asphalt Institute. Sixth Edition, March 1995.

5. Hinrichsen, J.A. and J. Heggen. Minimum Voids in Mineral Aggregate in Hot-Mix Asphalt Based on Gradation and Volumetric Properties. Transportation Research Record 1545, TRB, National Research Council, Washington, D.C., 1996, pp. 75-79.

6. Anderson, R.M. and H.U. Bahia. Evaluation and Selection of Aggregate Gradations for Asphalt Mixtures Using Superpave. Transportation Research Record 1583, TRB, National Research Council, Washington, D.C., 1997, pp. 91-97.

7. Mallick, R. B., M.S. Buchanan, P.S. Kandhal, R.L. Bradbury, and

W. McClay. A Rational Approach of Specifying the Voids in the

Mineral Aggregate for Dense-graded Hot Mix Asphalt. Presented

at the 79th Annual Meeting of the Transportation Research Board,

January, 2000.

8. Nunn, M.E., A.J. Brown, and S. J. Guise. Assessment of Simple

Tests to Measure Deformation Resistance of Asphalt, Transport

Research Laboratory Project Report PR/CE/92/98, March, 1998.

9. Brown, S.F. and T.V. Scholz. Permanent Deformation Characteristics of Porous Asphalt Determined in the Confined Repeated Load

Axial Test. Highways and Transportation Vol. 45, No. 12, Dec

1998.

Вам также может понравиться

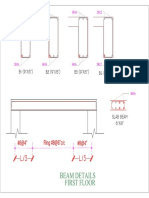

- Beam DetailsДокумент1 страницаBeam DetailsRakesh ParaliyaОценок пока нет

- Anchored Sheet Pile Walls in Sandy Soil CalculatorДокумент1 страницаAnchored Sheet Pile Walls in Sandy Soil CalculatorAnin Kuwi UpinОценок пока нет

- Corrige ND Um 16022018Документ11 страницCorrige ND Um 16022018Rakesh ParaliyaОценок пока нет

- Priced Bill of Quantities: Sl. No Description Qty Unit Amount (RS) in Figures in Words in Figures Rate (RS.)Документ9 страницPriced Bill of Quantities: Sl. No Description Qty Unit Amount (RS) in Figures in Words in Figures Rate (RS.)Rakesh ParaliyaОценок пока нет

- Class 9 - Road Infrastructure Development in India PDFДокумент102 страницыClass 9 - Road Infrastructure Development in India PDFRakesh Paraliya100% (1)

- C SSTSNJ Z2 TM Ibi 29Документ4 страницыC SSTSNJ Z2 TM Ibi 29Rakesh ParaliyaОценок пока нет

- Marble & Stones IndustriesДокумент12 страницMarble & Stones IndustriesRakesh Paraliya100% (1)

- Product Data: Beam Lintels LengthsДокумент2 страницыProduct Data: Beam Lintels LengthsRakesh ParaliyaОценок пока нет

- AP Cancellation Format With Fees Details (MCX & NCDEX)Документ4 страницыAP Cancellation Format With Fees Details (MCX & NCDEX)Rakesh ParaliyaОценок пока нет

- Alwer Railway TenderДокумент82 страницыAlwer Railway TenderRakesh ParaliyaОценок пока нет

- 29.sec.2900 (Pipe Culverts)Документ4 страницы29.sec.2900 (Pipe Culverts)Rakesh ParaliyaОценок пока нет

- 11.sec.1100 (Pile Foundations)Документ18 страниц11.sec.1100 (Pile Foundations)Rakesh ParaliyaОценок пока нет

- Methods of Measuring Brickwork: Brickwork Stone Masonry WallДокумент2 страницыMethods of Measuring Brickwork: Brickwork Stone Masonry WallRakesh Paraliya100% (1)

- Evaluation of Port Layout Alternatives: Pilbara Iron Ore and Infrastructure ProjectДокумент41 страницаEvaluation of Port Layout Alternatives: Pilbara Iron Ore and Infrastructure ProjectRakesh ParaliyaОценок пока нет

- Lithuanian Port: OuterДокумент15 страницLithuanian Port: OuterRakesh ParaliyaОценок пока нет

- A5 Runway ConstructionДокумент53 страницыA5 Runway ConstructionRakesh ParaliyaОценок пока нет

- Porch Construction DrawingsДокумент6 страницPorch Construction DrawingsRakesh ParaliyaОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Lesson 3 The Prodigal SonДокумент2 страницыLesson 3 The Prodigal Sonapi-241115908Оценок пока нет

- Complete PDFДокумент495 страницComplete PDFMárcio MoscosoОценок пока нет

- Creative Nonfiction 2 For Humss 12 Creative Nonfiction 2 For Humss 12Документ55 страницCreative Nonfiction 2 For Humss 12 Creative Nonfiction 2 For Humss 12QUINTOS, JOVINCE U. G-12 HUMSS A GROUP 8Оценок пока нет

- Review Questions Operational Excellence? Software WorksДокумент6 страницReview Questions Operational Excellence? Software WorksDwi RizkyОценок пока нет

- Grammar Reference With Practice Exercises: Unit 1Документ25 страницGrammar Reference With Practice Exercises: Unit 1violet15367% (3)

- Book of Dynamic Assessment in Practice PDFДокумент421 страницаBook of Dynamic Assessment in Practice PDFkamalazizi100% (1)

- In The World of Nursing Education, The Nurs FPX 4900 Assessment Stands As A PivotalДокумент3 страницыIn The World of Nursing Education, The Nurs FPX 4900 Assessment Stands As A Pivotalarthurella789Оценок пока нет

- Lite Touch. Completo PDFДокумент206 страницLite Touch. Completo PDFkerlystefaniaОценок пока нет

- Kurukku PadaiДокумент4 страницыKurukku PadaisimranОценок пока нет

- Klabin Reports 2nd Quarter Earnings of R$ 15 Million: HighlightsДокумент10 страницKlabin Reports 2nd Quarter Earnings of R$ 15 Million: HighlightsKlabin_RIОценок пока нет

- BedДокумент17 страницBedprasadum2321Оценок пока нет

- Strategic ManagementДокумент14 страницStrategic ManagementvishakhaОценок пока нет

- Chapter One Understanding Civics and Ethics 1.1.defining Civics, Ethics and MoralityДокумент7 страницChapter One Understanding Civics and Ethics 1.1.defining Civics, Ethics and Moralitynat gatОценок пока нет

- Becoming FarmersДокумент13 страницBecoming FarmersJimena RoblesОценок пока нет

- Fire Art Case StudyДокумент15 страницFire Art Case StudyKimberlyHerring100% (1)

- 38 Bayan Muna Vs MendozaДокумент3 страницы38 Bayan Muna Vs MendozaDavid Antonio A. EscuetaОценок пока нет

- IBM System X UPS Guide v1.4.0Документ71 страницаIBM System X UPS Guide v1.4.0Phil JonesОценок пока нет

- FJ&GJ SMДокумент30 страницFJ&GJ SMSAJAHAN MOLLAОценок пока нет

- Liver Disease With PregnancyДокумент115 страницLiver Disease With PregnancyAmro Ahmed Abdelrhman100% (3)

- Robot MecanumДокумент4 страницыRobot MecanumalienkanibalОценок пока нет

- MAT2355 Final 2002Документ8 страницMAT2355 Final 2002bojie_97965Оценок пока нет

- Kormos - Csizer Language Learning 2008Документ29 страницKormos - Csizer Language Learning 2008Anonymous rDHWR8eBОценок пока нет

- Panulaang FilipinoДокумент21 страницаPanulaang FilipinoKriza Erin B BaborОценок пока нет

- Brochure - Digital Banking - New DelhiДокумент4 страницыBrochure - Digital Banking - New Delhiankitgarg13Оценок пока нет

- GAJ Mod 18 Ace Your InterviewДокумент12 страницGAJ Mod 18 Ace Your InterviewAnjela SantiagoОценок пока нет

- Name Numerology Calculator - Chaldean Name Number PredictionsДокумент2 страницыName Numerology Calculator - Chaldean Name Number Predictionsarunamurugesan7Оценок пока нет

- Ghalib TimelineДокумент2 страницыGhalib Timelinemaryam-69Оценок пока нет

- SATURDAY - FIRST - PDF (1)Документ3 страницыSATURDAY - FIRST - PDF (1)Manuel Perez GastelumОценок пока нет

- Bakhtin's Chronotope On The RoadДокумент17 страницBakhtin's Chronotope On The RoadLeandro OliveiraОценок пока нет

- Thesis FulltextДокумент281 страницаThesis FulltextEvgenia MakantasiОценок пока нет