Академический Документы

Профессиональный Документы

Культура Документы

Occidental of Oman, Inc. Engineering Services Contract For Oman North OXY CONTRACT NO. SWL-CA-2013-24000039693-A

Загружено:

Sakthikumar ChandrasekaranОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Occidental of Oman, Inc. Engineering Services Contract For Oman North OXY CONTRACT NO. SWL-CA-2013-24000039693-A

Загружено:

Sakthikumar ChandrasekaranАвторское право:

Доступные форматы

OCCIDENTAL OF OMAN,INC.

TR ENGINEERING LLC

OCCIDENTAL OF OMAN,INC.

ENGINEERING SERVICES CONTRACT FOR OMAN NORTH

OXY CONTRACT NO. SWL-CA-2013-24000039693-A

DD FOR REPLACEMENT OF CRUDE HEATER H-102 AT SGP

TECHNICAL SPECIFICATION

FOR

HOT HYDROCARBON DRAIN VESSEL (01-V-169)

18/08/2014

Issued for Purchase

SUM

26/09/2013

Issued for Enquiry

SEE T&P DOCUMENT # 2181001

28/07/2014

Issued for Approval

SEE T&P DOCUMENT # 2181001

04/07/2013

First Issue

SEE T&P DOCUMENT # 2181001

REV

DATE

REASON FOR ISSUE

TR Engineering LLC

P O Box 1597,PC 112, Ruwi, Sultanate of Oman

Tel: +968 24642100, Fax: +968 24604 414

OXY Project No.: 1165425

PKU

DVS

PREPARED

CHECKED

APPROVED

APPROVED

DISCIPLINE

ENGINEER

DISCIPLINE

CHECK

LDE/DH

PM

W I No.: TRE-14-003

TRE Job No.: J66202

RPW

Document No.

Rev. No.

OMN-SAF-100-MEC-00003-001

This document is the property of TRE and OXY. It is not to be copied or shown to a third party without prior consent.

OMN-SAF-100-MEC-00003-001

Page 1 of 45

Revision: C

18/08/2014

OCCIDENTAL OF OMAN,INC.

TR ENGINEERING LLC

HOT HYDROCARBON DRAIN VESSEL (01-V-169)

CONTENTS

FRONT PAGE

CONTENTS

ABBREVIATIONS

HOLDS

1.0

2.0

INTRODUCTION

1.1

General

1.2

Intent of the enquiry

1.3

Definitions:

1.4

Broadguidelines:

1.5

Guarantee

APPLICABLE STANDARDS

2.1

General

2.2

Conflicting Requirements

2.3

Adherence to Specifications

2.4

Codes, Specifications and Standard drawing

3.0

GENERAL SITE CONDITIONS

12

4.0

VENDORS SCOPE OF SUPPLY

13

4.1

General

13

4.2

Scope of Supply of Equipment and Materials

13

4.3

Exclusions

15

5.0

DESIGN REQUIREMENTS

16

5.1

General

16

5.2

Design Guide lines

16

6.0

MATERIALS OF CONSTRUCTION

20

7.0

QUALITY ASSURANCE

21

7.1

21

Quality System Requirements

OMN-SAF-100-MEC-00003-001

Page 2 of 45

Revision: C

18/08/2014

OCCIDENTAL OF OMAN,INC.

TR ENGINEERING LLC

HOT HYDROCARBON DRAIN VESSEL (01-V-169)

7.2

8.0

9.0

10.0

11.0

Quality Assurance and Quality Assurance Plans

21

INSPECTION AND TESTING

22

8.1

22

General

INFORMATION TO BE SUBMITTED WITH THE TENDER

25

9.1

Technical Information

25

9.2

Separate Quotations

25

9.3

Unit Prices

25

DOCUMENTATION AND INFORMATION REQUIRED AFTER PLACEMENT ORDER 26

10.1

General

26

10.2

Drawings, Calculations and Procedures

26

10.3

Material and other Certificates

27

10.4

Spare Parts

27

SURFACE TREATMENT

28

11.1

External Painting

28

11.2

Internal Coating

28

12.0

PREPARATION FOR SHIPMENT

29

13.0

COMMISSIONING

30

13.1

Site Supervision

30

13.2

Manuals

30

13.3

Special Tools

30

14.0

APPENDICES

APPENDIX - A1 - LOCAL ENVIRONMENTAL CONDITIONS

APPENDIX- A2 - SELLER DOCUMENT REQUIREMENT LIST (SDRL)

APPENDIX - A3 - ALLOWABLE FORCES AND MOMENTS ON NOZZLES

APPENDIX - A4 -UNITS OF MEASUREMENT

OMN-SAF-100-MEC-00003-001

Page 3 of 45

Revision: C

18/08/2014

OCCIDENTAL OF OMAN,INC.

TR ENGINEERING LLC

HOT HYDROCARBON DRAIN VESSEL (01-V-169)

APPENDIX- B1

APPENDIX- B2 - P & ID

APPENDIX- B3CIVIL INPUT TO VENDOR

APPENDIX- C1- TABLE OF COMPLIANCE

OMN-SAF-100-MEC-00003-001

Page 4 of 45

Revision: C

18/08/2014

OCCIDENTAL OF OMAN,INC.

TR ENGINEERING LLC

HOT HYDROCARBON DRAIN VESSEL (01-V-169)

ABBREVIATIONS

TRE

- TECHNICAS REUNIDAS (TR) ENGINERING LLC.

SDRL

- SELLER DOCUMENT REQUIREMENT LIST

SPIR

- SPARE PARTS & INTERCHANGEABILITY REPORT

ITP

- INSPECTION TEST PLAN

CQP

- CONTRACT QUALITY PLAN

WPS

- WELDING PROCEDURE SPECIFICATION

PQR

- PROCEDURE QUALIFICATION RECORD

QA

- QUALITY ASSURANCE

QC

- QUALITY CONTROL

NDE

- NON DESTRUCTIVE EXAMINATION

TPIA

- THIRD PARTY INSPECTION AGENCY

AFC

- APPROVED FOR CONSTRUCTION

CPF

- CENTRAL PROCESSING FACILITIES

ASME

- AMERICAN SOCIETY OF MECHANICAL ENGINEERS

OXY

-OCCIDENTAL OF OMAN INC.

KM

- KILOMETER

KMPH

- KILOMETER PER HOUR

PO

- PURCHASE ORDER

DFT

- DRY FILM THICKNESS

WRC

- WELDING RESEARCH COUNCIL

ANSI

- AMERICAN NATIONAL STANDARD INSTITUTE

QCP

- QUALITY CONTROL PLAN

PWHT

- Post Weld Heat Treatment

NDT

- Non destructive Testing

OMN-SAF-100-MEC-00003-001

Page 5 of 45

Revision: C

18/08/2014

OCCIDENTAL OF OMAN,INC.

TR ENGINEERING LLC

HOT HYDROCARBON DRAIN VESSEL (01-V-169)

HOLDS

1. Vessel Boot dimensions.

2. Vessel Pump connection nozzle size.

OMN-SAF-100-MEC-00003-001

Page 6 of 45

Revision: C

18/08/2014

OCCIDENTAL OF OMAN,INC.

TR ENGINEERING LLC

HOT HYDROCARBON DRAIN VESSEL (01-V-169)

1.0

INTRODUCTION

1.1

General

This specification covers the minimum requirements for the detailed design,

engineering, material procurement, fabrication, assembly, inspection, PWHT, testing,

certification, painting, supply and transportation of below vessel for Safah for

Occidental of Oman Inc.

1.2

Hot Hydrocarbon Drain Vessel (01-V-169) as per attached data sheet AppendixB1.

Intent of the enquiry

The main objective of Replacement of Crude Heater H-102 at SGP project is to

replace existing Stabilizer Fired Heater Reboiler (H-102) with a new Fired Heater

packaged unit (H-168), new Hot Hydrocarbon Drain Vessel and transfer pump.

Intent of this enquiry is to install a new Hot Hydrocarbon Drain vessel (01-V-169) which

is required for liquid/vapor blowdown from heater and a transfer pump.

1.3

Definitions:

Purchaser

Vendor

Consultant

Company

1.4

:

:

:

:

EPC Contractor

Supplier of Equipments

TR Engineering LLC

Occidental of Oman Inc.

Broadguidelines:

The Vendor shall ensure that the Vessel fully complies with the applicable standards as

listed in section 2 and with the requirements of this specification.

The Vendor shall be responsible for:

Detailed design, engineering, material procurement, fabrication, assembly, coordination, inspection, testing, PWHT, certification, painting, transportation and

complete with all internals, ladders, platforms and gratings for vessel as

described in this specification, appendices, referred codes and standards. The

complete scope of vessel to be supplied is defined in subsequent section 4 &

section 5.

Mechanical and process hydraulic design, procurement, installation and

performance guarantee of all internals of the vessel.

Procurement and supply of spare parts for commissioning, start-up and two (2)

years operation and maintenance.

Installation and commissioning (Optional).

OMN-SAF-100-MEC-00003-001

Page 7 of 45

Revision: C

18/08/2014

OCCIDENTAL OF OMAN,INC.

TR ENGINEERING LLC

HOT HYDROCARBON DRAIN VESSEL (01-V-169)

The quality control of all sub-orders.

The Vendor shall have established a quality system that complies with ISO 9001:2008,

as described in section 7 of this specification.

This specification and its referenced standards shall in no way release the vendor from

final guarantee of the entire package as to mechanical design, materials, apparatus,

workmanship, control, operations, safeguarding and performance of the equipment

inspected/supplied.

1.5

Guarantee

The vendor shall guarantee the equipment as follows : Mechanical design, materials, apparatus, workmanship, control, operations,

safeguarding etc.

Guarantee period shall be 18 months from the date of delivery of equipment to site

or 12 months from the date of commissioning of equipment whichever is earlier. If

any defect is observed during guarantee period, vendor shall make all necessary

alteration, repair or replacement free of charges.

OMN-SAF-100-MEC-00003-001

Page 8 of 45

Revision: C

18/08/2014

OCCIDENTAL OF OMAN,INC.

TR ENGINEERING LLC

HOT HYDROCARBON DRAIN VESSEL (01-V-169)

2.0

APPLICABLE STANDARDS

2.1

General

This specification covers the minimum requirements for the detailed design,

engineering, material procurement, fabrication, assembly, inspection, PWHT, testing,

certification, painting, supply and transportation of one Hot Hydrocarbon Drain Vessel

(01-V-169) for Safah for Occidental of Oman Inc.

The Vessel shall be designed, manufactured, tested and supplied in accordance with

this specification, codes and standards referenced herein.

2.2

Conflicting Requirements

In case of conflict between documents relating to the inquiry or purchase order, the

following priority of documents shall apply.

First priority

Second priority

Third priority

Fourth priority

:

:

:

:

Purchase order and agreed variation thereto

Datasheet, drawing & Specification

Company standards, (if any)

International standards

Vendor shall seek clarification from Company and make a formal request with full

supporting information when a deviation from standard is required.

2.3

Adherence to Specifications

The vendor shall comply with this purchase specification and all standards, codes and

drawings listed in sub section 2.4.

The Vendor shall provide an itemized list of any comments or exceptions to this

specification and its appendices during technical submission phase. NO COMMENTS

AND/OR EXCEPTIONS WILL BE ACCEPTABLE DURING COMMERCIAL BIDS.

These shall be listed on the sheets provided in Appendix-C1, for review by the

Company. Unless referred to in these listings, it will be assumed that all specifications

will be adhered to and that they do not have any adverse implications with respect to

cost, delivery and integrity of the plant. The Company reserves the right to consider the

deviations on techno commercial ground.

2.4

Codes, Specifications and Standard drawing

The latest edition and addenda of the following Codes, standards and standard

drawings forms part of this requisition. The applicable editions shall be the revisions in

force at the time of the purchase order unless a specific revision has been defined. The

requirements stated therein shall be complied with.

OMN-SAF-100-MEC-00003-001

Page 9 of 45

Revision: C

18/08/2014

OCCIDENTAL OF OMAN,INC.

TR ENGINEERING LLC

HOT HYDROCARBON DRAIN VESSEL (01-V-169)

2.4.1

OXY Engineering Guidelines

EG-300

EG-305

EG-309

EG-310

EG-321

EG-322

SPEC-300

SPEC 406

MUK-FAC-150

MUK-FAC-153

MUK-FAC-154

MUK-FAC-155

MUK-FAC-255

MUK-FAC-256

MUK-FAC-200

MUK-FAC-251

MUK-FAC-318

MUK-FAC-253

MUK-FAC-300

2.4.2

General

Process Isolation and Emergency Shutdown

Facility Drainage and Sewer Systems

Pressure Relief System

Pressure Vessels and Boilers

Welding, Inspection and Testing

Specification for Oil Field Pressure Vessel

Piping Material Specification

Specification for General Instrumentation

Specification for ESD System and F&G System

Specification for Packaged Equipment Instrumentation

Specification for Basic Process Control System

Pressure Vessel Specification

Pressure Vessels for Sour Service Application

External Painting & Protective Coating

Protection of Goods during Shipment

External Painting & Protective Coating for Structural Steel

Pressure Vessel Welding Specification

Structural Design

International Standards

ASME Section VIII Div.1

ASME Section VIII Div.2

ASME Section IX

ASME Section V

ASME Section II Part A

ASME Section II Part C

ASME Section II Part D

Welding Research Council

ASME B 16.5

ASME B 30.20

ASME B 16.20

NACE MR 0175 / ISO 15156

OMN-SAF-100-MEC-00003-001

Rules for Construction of Pressure Vessel

Rules for Construction of Pressure Vessel

Welding and Brazing Qualifications

Non-destructive Examination

Ferrous Material Specifications

Specifications for Welding Rods, Electrodes

and Filler Metals

Material Properties

Local Stresses in Spherical and Cylindrical

Shells Bulletin No. 107 /297 due to External

Loadings

Pipe Flanges and Flanged Fittings

Below-The-Hook Lifting Devices

Metallic Gaskets for Pipe Flanges,

Ring-Joint, Spiral-Wound, and Jacketed

Materials for use in H2S containing

environments in oil & Gas production

Page 10 of 45

Revision: C

18/08/2014

OCCIDENTAL OF OMAN,INC.

TR ENGINEERING LLC

HOT HYDROCARBON DRAIN VESSEL (01-V-169)

ISO 10474 (1992)

ISO 9001:2000

ASCE-7-10

AISC-LRFD

OMN-SAF-100-MEC-00003-001

Steel & Steel Products Inspection Documents

Quality Systems

Wind Load

Steel Construction (Load Resistant Factor

Design)

Page 11 of 45

Revision: C

18/08/2014

OCCIDENTAL OF OMAN,INC.

TR ENGINEERING LLC

HOT HYDROCARBON DRAIN VESSEL (01-V-169)

3.0

GENERAL SITE CONDITIONS

The vessel shall be installed at Safah for Occidental of Oman Inc. Refer to Appendix-A1

for detailed data on the local environmental and meteorological conditions prevailing at

site.

OMN-SAF-100-MEC-00003-001

Page 12 of 45

Revision: C

18/08/2014

OCCIDENTAL OF OMAN,INC.

TR ENGINEERING LLC

HOT HYDROCARBON DRAIN VESSEL (01-V-169)

4.0

VENDORS SCOPE OF SUPPLY

4.1

General

The Vendors scope of supply includes all activities and deliverables required for the

execution of the design requirements as indicated in section 5.0 of this specification and

delivery to Safah for Occidental of Oman Inc, Sultanate of Oman.

The Vessel is to be Post Weld Heat Treated (PWHT).

The Vessel shall be supported on saddles as shown in respective data sheet. The

Vessel shall be completely assembled to the maximum possible extent to minimize the

installation time at site. Following items shall however, be supplied loose:

Ladders

Platforms (including gratings and handrails) shall be designed as per AISCLRFD.

Pipe supports

Pipe Guides

Platforms, ladders and gratings shall be shop fabricated in maximum dimensions within

shipping limits. Handrails shall be attached to platforms; cages shall be attached to

ladders. Ladders, platforms and gratings shall be trial assembled prior to shipment.

The Vendors scope of supply and services for Vessel, shall include, but not be

limited to the scope detailed below i.e. in section 4.2.

Refer Appendix- B3 for structural design of platforms & attached standard drawings of

platforms & attach standard drawings for handrail, ladders, Grating & anchor bolts.

4.2

Scope of Supply of Equipment and Materials

In addition to the bare Vessel complete in all respects with nozzles, supports, fittings and

appurtenances, the following are included in Vendors scope of supply:

Internal ladder rungs (if required)

External Stiffening Rings (if required)

Manholes complete with blind flange & davit

Blind flanges, bolts, nuts & gaskets for all spare nozzles and all other nozzles

wherever specified in data sheets

2 Nos. Earthing bosses

Complete fabrication, PWHT, NDT & hydrostatic test

OMN-SAF-100-MEC-00003-001

Page 13 of 45

Revision: C

18/08/2014

OCCIDENTAL OF OMAN,INC.

TR ENGINEERING LLC

HOT HYDROCARBON DRAIN VESSEL (01-V-169)

Lifting lugs to facilitate handling and erection

Pipe supports and Pipe Guides/Clips

Platform and ladder clips

Caged ladders and platforms with hand rail at all required locations (On unit price

basis)

SS Nameplate and bracket

Sizing of anchor bolts

Adjustable pads and shims (if required)

Assistance for field erection (if required)

Surface preparation, painting & internal coating

Quality assurance and control

Inspection and testing

Spare parts for commissioning, start-up and 2 years of operation

All documentation, drawings, calculations and reports

Packing & Preservation of Vessel internal surfaces not painted or cladded

Transportation from point of manufacture to Purchasers site

Special tools, if any.

Site erection/commissioning (Optional, if specified in Purchase Order)

OMN-SAF-100-MEC-00003-001

Page 14 of 45

Revision: C

18/08/2014

OCCIDENTAL OF OMAN,INC.

TR ENGINEERING LLC

HOT HYDROCARBON DRAIN VESSEL (01-V-169)

4.3

Exclusions

The Purchaser will provide:

Anchor Bolts (However sizing & details of anchor bolts by vendor)

Civil work / foundation

Instrumentation

Unloading at site

OMN-SAF-100-MEC-00003-001

Page 15 of 45

Revision: C

18/08/2014

OCCIDENTAL OF OMAN,INC.

TR ENGINEERING LLC

HOT HYDROCARBON DRAIN VESSEL (01-V-169)

5.0

DESIGN REQUIREMENTS

5.1

General

5.2

5.2.1

The design of Vessel shall essentially comply with all relevant International

Standards.

The Vessel shall have a minimum design life of 25 years.

Corrosion allowance of 3 mm is to be considered for all carbon steel surfaces

exposed to product.

Dimensional tolerance of the fabricated Vessel shall be in accordance with ASME

Section VIII Div.1.

Vessel shall be provided with at least two (2) earthing lugs welded to the Vessel

saddles support.

Design Guide lines

Mechanical Design

The mechanical design, fabrication and testing of the Vessel shall be carried out

in accordance with ASME Sec VIII Div.1.

The vessel shall be ASME U code stamped.

The nozzles load analysis in accordance with WRC bulletin 107/297 for the

allowable forces and moments on nozzles as per Appendix-A3. Vendor to

calculate the Final allowable nozzle loadings and shall be shown on General

Arrangement drawing.

Lifting lugs shall be designed for a total load of 1.5 times the lifted weight of the

Vessel to allow for dynamic effect.

The wind load shall be applied in accordance with Appendix-A1 of this

specification.

All equipment and materials must be new and not previously owned or used by

another party.

Reinforcement for nozzles and manways shall be in accordance with the

specified design code for the Maximum Allowable Pressure of the un-corroded

Vessel at test temperature and the Maximum Allowable Working Pressure of the

corroded Vessel at design temperature.

OMN-SAF-100-MEC-00003-001

Page 16 of 45

Revision: C

18/08/2014

OCCIDENTAL OF OMAN,INC.

TR ENGINEERING LLC

HOT HYDROCARBON DRAIN VESSEL (01-V-169)

The Vessel connections shall be flanged to ANSI B 16.5 WNRF smooth finish for

sizes DN 600 and less.

Bolt holes in flanges of nozzles and manways located in heads of Vessel shall

straddle the principal centerlines of the Vessel or lines parallel thereto. Bolt holes

in flanges of nozzles and manways located in shells shall straddle the vertical

centerline of the Vessel.

All nozzles shall be flushed with inside of the Vessel unless otherwise noted.

Nozzles with blind flanges shall be provided with gaskets, bolts and nuts.

All flanges not supplied with blind flanges shall be protected with wooden blanks.

These blanks shall be securely attached to the flanges with at least four bolts with

a neoprene gasket.

All machined surfaces and gasket facings shall be protected with an easy

removable anti-corrosion compound.

All sharp corners to be rounded off to smooth radius.

Gaskets and bolting used for hydro test shall be same type as service gaskets

and bolting.

Cathodic Protection (if required).

The minimum wall thickness of the nozzle shall be as follows:

Nozzle size

Pipe Schedule

2"

160

3", 4", 6", 8"

80

10"

5.2.2

Extra strong

Fabrication, Welding and Post Weld Heat Treatment

The fabrication, Welding and Post Weld Heat Treatment of Vessel as per applicable

code ASME Section VIII Div.1.

Fabrication :

When welding is completed, flux residues and weld spatter shall be- removed

mechanically using stainless steel tools.

Grinding wheels or belts used to remove excess weld metal has not been

previously used on other metals.

OMN-SAF-100-MEC-00003-001

Page 17 of 45

Revision: C

18/08/2014

OCCIDENTAL OF OMAN,INC.

TR ENGINEERING LLC

HOT HYDROCARBON DRAIN VESSEL (01-V-169)

Weld seams are to clear all nozzles and attachments.

Welding and Post Weld Heat Treatment:

The Vendor shall be responsible for developing the weld procedures necessary for

this contract, in accordance with relevant Company and ASME codes. All welders

shall be qualified to these procedures. Welding procedure specifications (WPS)

and supporting procedure qualification records (PQR) shall be subject to the

approval of the Company.

It is the responsibility of the Vendor to submit to the Purchaser all his sub-suppliers

fabrication and welding procedures and to ensure compliance with contract

requirements before submittal to the Purchaser.

No fabrication may commence until the Vendors Contract Quality Plan, related

fabrication drawings, weld procedures (WPS & PQR), NDE procedures,

Fabrication Repair Procedure, Hydro test Procedure, and all calculations have

been reviewed and approved by the Purchaser.

Post weld heat treatment (if required) shall be carried for the complete Vessel in

single furnace heat.

No welding or thermal cutting is permitted on stress relieved Vessels after

completion of final post weld heat treatment (PWHT).

5.2.3

Fabrication Repairs

The Vendor shall not proceed with the following repairs without Purchasers approval. If

parts/items/components are repaired without obtaining Purchasers prior approval, they

will be rejected by Purchaser.

a)

b)

c)

d)

5.2.4

Major Repairs.

Repairs to leaking pressure containing parts.

Rectification of fits/tolerances by the application of metal coatings or overlays.

Repairs necessitated by internal rubs for any reason.

Pressure Testing

The hydrostatic test procedure, test pressure and minimum pressurisation

temperature shall meet the requirements of the ASME Section VIII Div. 1

Upon completion of the hydro test, water shall be completely drained out. Wetted

surfaces shall be washed with potable water and completely dried. Particular

attention shall be given to low spots, crevices and similar areas. Hot air drying is

not permitted.

OMN-SAF-100-MEC-00003-001

Page 18 of 45

Revision: C

18/08/2014

OCCIDENTAL OF OMAN,INC.

TR ENGINEERING LLC

HOT HYDROCARBON DRAIN VESSEL (01-V-169)

All reinforcing pads shall be tested with 1 bar(g) air and soap suds solution after

completion of final post weld heat treatment.

OMN-SAF-100-MEC-00003-001

Page 19 of 45

Revision: C

18/08/2014

OCCIDENTAL OF OMAN,INC.

TR ENGINEERING LLC

HOT HYDROCARBON DRAIN VESSEL (01-V-169)

6.0

MATERIALS OF CONSTRUCTION

Materials of construction for the Vessel and internals shall be as specified in the

datasheet under Appendix-B1. The materials shall be suitable for Sour Service and

comply to standard MUK-FAC-256.

All materials shall be accordance with ASME Standards.

All materials for Vessel

vendors/manufacturers.

shall

be

procured

from

Company

approved

All attachments welded directly to the Vessel shall be the same grade of steel as that of

the Vessel.

All materials in contact with process fluid shall comply with NACE MR-0175/ISO 15156.

OMN-SAF-100-MEC-00003-001

Page 20 of 45

Revision: C

18/08/2014

OCCIDENTAL OF OMAN,INC.

TR ENGINEERING LLC

HOT HYDROCARBON DRAIN VESSEL (01-V-169)

7.0

QUALITY ASSURANCE

7.1

Quality System Requirements

The Vendor should be ISO 9001:2008 3rd Party certified and should submit a Quality

Plan with the quotation. These requirements apply equally to Vendors sub-contractors

and suppliers. The Vendor shall enforce these requirements accordingly.

Purchaser/Company reserves the right to audit the Vendors quality system (and/or

subcontractor/suppliers quality systems). Such audit may be carried out either by

Purchaser/Company or an appointed third party inspection agency.

7.2

Quality Assurance and Quality Assurance Plans

Vendor shall submit the following documentation with his tender, and also submit

updated documentation within 2 weeks of purchase order as a part of his contractual

obligations unless specified otherwise on the purchase order Appendix-A2 Seller

Document Requirement List:

Certification or evidence that the Quality system complies with ISO 9001:2008

Quality Manual

CQP - Contract Quality Plan

QCP - Quality Control Plan (Inspection and Test Plan)

All quality control plans shall be agreed, prior to commencement of fabrication.

OMN-SAF-100-MEC-00003-001

Page 21 of 45

Revision: C

18/08/2014

OCCIDENTAL OF OMAN,INC.

TR ENGINEERING LLC

HOT HYDROCARBON DRAIN VESSEL (01-V-169)

8.0

INSPECTION AND TESTING

8.1

General

Inspection and testing for the vessel shall be generally in line with the pressure vessel

code ASME Section VIII Div. 1 and attached data sheets.

The Vendor shall specify all the inspection and testing requirements in the quality

control plan which shall identify the activities requiring the Purchaser's/ Companys

approval, review, witnessing etc.

Purchaser / Company and his authorized representative reserve the right to inspect

every component or item, which will form part of the Equipment. The responsibility for

the inspection, certification, etc. of all materials lie with the Vendor.

Not withstanding the above, the Purchaser / Company or his authorized representative

shall have free access to all parts of the Vendor's and his sub-vendors works at all

times during the manufacturing period.

The Vendor shall be responsible for coordinating the inspection and testing of subvendor supplied equipment, and for ensuring that the Purchaser's/ Companys

representatives are given the necessary access for inspection, and adequate warning

of inspection and witness tests.

The Vendor (and all sub vendors) shall give the Purchaser/ Company, as required,

without charge, all reasonable facilities for the purpose of inspecting the equipment to

ensure that it is manufactured in accordance with the requisition, drawings and

technical specification and QA/QC procedures and practices.

The Purchaser/ Company shall be given a minimum of 10 working days notice prior to

carrying out any tests on the equipment covered by this specification.

All equipment shall be inspected for compliance with:

Approved for Construction drawings, latest revision.

Requirements of the Purchaser's requisition and correspondence thereafter.

Applicable standards, which shall also include the sub-referenced standards

therein.

Inspection and Test plans produced by the Vendor as part of the Contract Quality

Plan.

Except as approved by the Purchaser/ Company, all equipment shall be presented

for inspection in an unpainted condition.

OMN-SAF-100-MEC-00003-001

Page 22 of 45

Revision: C

18/08/2014

OCCIDENTAL OF OMAN,INC.

TR ENGINEERING LLC

HOT HYDROCARBON DRAIN VESSEL (01-V-169)

All measuring instruments required for shop testing shall be furnished by the Vendor,

and be supported by valid calibration certification.

All spare parts shall be subject to the same inspection standards and full material

certification as the main order.

Inspectors have the right to request additional inspections or tests to ensure that the

equipment complies with this specification and all relevant codes and standards.

Vendor shall furnish Inspection Test Plan specifying the responsibility scope of TPI &

TPIA. The minimum requirements of shop witnessed inspections are:

The verification of materials and certificates for conformity with the specification

requirement

The verification of welding procedures, welders qualifications, NDT results, heat

treatment charts.

The dimensional check of the equipment including internals as per approved

drawing.

Hydro test.

The surface preparation and painting and coating application.

The testing of the lifting frame for the transportation of the vessel. The lifting

frame shall be certified.

The completeness of shipment including checking of supply of spares and

accessories.

Material test certification in accordance with ISO 10474 and any additional

requirements of the requisition.

Mill and shop inspection shall not relieve the Vendor from his contractual responsibility

for replacing any defective material and for repairing any defective workmanship that

may be identified in the field.

Any defects found by the TPIA shall be rectified in his presence. Where this is not

possible or practical, checklists shall be prepared and signed by the TPIA stating all

'pending items'. Copies of these lists shall be sent to the Purchaser/ Company to enable

their subsequent checking.

The equipment shall not be tested or leave the factory before all identified defects have

been rectified.

OMN-SAF-100-MEC-00003-001

Page 23 of 45

Revision: C

18/08/2014

OCCIDENTAL OF OMAN,INC.

TR ENGINEERING LLC

HOT HYDROCARBON DRAIN VESSEL (01-V-169)

8.1.1

Site Acceptance Tests (SAT)

The Site Acceptance Test (SAT) shall be done to demonstrate that the equipment

performance is in accordance with the specification requirements.

After installation and commissioning at the Company's site, the SAT shall be executed

for at least 72 hours without any interruptions. Every interruption during the SAT will

result in restarting the SAT by resetting the elapsed time of the test to zero (0) hours.

The Companys confirmation of successful completion of the performance test shall be

mandatory for final acceptance of the system.

After satisfactory completion of the SAT the Company's authorized site representative

shall sign the 'System Acceptance Note, which shall mean acceptance of the system

for operation.

OMN-SAF-100-MEC-00003-001

Page 24 of 45

Revision: C

18/08/2014

OCCIDENTAL OF OMAN,INC.

TR ENGINEERING LLC

HOT HYDROCARBON DRAIN VESSEL (01-V-169)

9.0

INFORMATION TO BE SUBMITTED WITH THE TENDER

In addition to the documents required as per Appendix-A2 Seller Document

Requirement List, Vendor shall submit the following-

9.1

9.2

Technical Information

Completed Table of Compliance (Appendix-C1)

List of Proposed Materials

Location of Manufacturing Facility

Reference List of Vessel of Similar Design, Installed & Operating under

analogous conditions

List of Proposed Suppliers for Vessel Internals (if any)

Separate Quotations

The bidder shall furnish with the proposal the following separate quotations:

9.3

Two years operating spare part and other parts recommended by manufacturer

Special tools (if any)

Installation and commissioning (Optional)

Unit Prices

The bidder shall furnish the unit rates for the following:

Pipe Supports, Guides/Clips

Ladders, Platforms & Handrails and Gratings

Nozzles (each size and rating) including blind flange, gasket and bolting.

OMN-SAF-100-MEC-00003-001

Page 25 of 45

Revision: C

18/08/2014

OCCIDENTAL OF OMAN,INC.

TR ENGINEERING LLC

HOT HYDROCARBON DRAIN VESSEL (01-V-169)

10.0

DOCUMENTATION

AND

PLACEMENT ORDER

10.1

General

INFORMATION

REQUIRED

AFTER

All correspondence and documentation shall be in English. All measurements and

units shall be as per Attachment- A4.

Requirements on number of copies for approval and final submission shall be as per

Appendix-A2 Seller Document Requirement List. Vendor shall submit revised

documents incorporating the client/Contractor comments within 2 weeks after the

receipt of comments.

All drawings shall be drawn in AutoCAD version 2000 or higher. All documents shall be

Microsoft Word / Excel-2003. The final documentation shall include electronic copy of

all drawings and documents CDs.

Note: The documents shall be submitted in hard copy together with soft copy.

Submission of documents in soft copy only (i.e. without hard copy) is not

permitted.

10.2

Drawings, Calculations and Procedures

In addition to the documents required as per Appendix-A2 Seller Document

Requirement List, Vendor shall submit the following:

Detail Drawings / Layout:

-

Drawing for arrangement of Saddles, Stiffeners (if any), pipe supports and

guides, lifting lugs & associated weld details

Cross sectional drawing of nozzles & Internals with welding detail and bill of

material

Drawing for Weld location plan, Name plate / bracket and earthing details.

General arrangement and construction details of caged ladders and

platform.

Drawing showing arrangement of Vessel transportation & heavy lifting.

Sliding plate details for sliding support.

Vendor to provide anchor bolts showing dia., embedment, and projection

from top of concrete with grout thickness considered as per OXY standard

drawing.

Filled in Manufacturers Data report (MDR) form U-1 to be submitted by

vendor.

Calculations:

-

Mechanical Design Calculations

Nozzle Load Analysis

Mechanical & Process hydraulic calculations for internals (if any)

Wind and Vibration Analysis

OMN-SAF-100-MEC-00003-001

Page 26 of 45

Revision: C

18/08/2014

OCCIDENTAL OF OMAN,INC.

TR ENGINEERING LLC

HOT HYDROCARBON DRAIN VESSEL (01-V-169)

Procedures:

-

10.3

Load data for empty, operating, hydro test & wind case. Also vendor to

provide unbalanced dynamic loads with C.G with reference point.(Both

individual C.G & combined)

Welding Consumables & Handling Procedure

Lifting Procedures

Material and other Certificates

Material certificates shall be furnished for Vessel in accordance with the relevant

international standards. As a Minimum following certification shall include:

Chemical analysis

Mechanical Properties

10.4

: ISO 10474-3.1B

: ISO 10474-3.1B

Spare Parts

The Vendor shall include in his quotation a separate itemized price list of spare parts

for Commissioning, start-up and two (2) years normal operation and maintenance

spares.

OMN-SAF-100-MEC-00003-001

Page 27 of 45

Revision: C

18/08/2014

OCCIDENTAL OF OMAN,INC.

TR ENGINEERING LLC

HOT HYDROCARBON DRAIN VESSEL (01-V-169)

11.0

SURFACE TREATMENT

The surface preparation and application of the coating / painting material shall be done

by a qualified subcontractor duly approved by the painting material manufacturer.

11.1

External Painting

The external carbon steel surface of the Hot Hydrocarbon Drain Vessel (01-V-169)

shall be painted as per painting scheme -2 of Appendix- 2 std. MUK-FAC-200.

Stainless steel components shall not be painted

The external Surface preparation of the Vessel shall be as per SSPC-SP-10., SA 2.5

Coating System

Primer

Type:

DFT (mil):

Inorganic zinc-Rich

Ethyl Silicate

2-3

Mid Coat

Type:

DFT (mil):

Heat Resistant Aluminium (Air curing Type)

1

Finish Coat

Type:

Heat Resistant Silicone Aluminium (Air curing Type)

DFT (mil):

1

11.2

Internal Coating

Internal coating of the vessel shall be done by Belzona 1591.

OMN-SAF-100-MEC-00003-001

Page 28 of 45

Revision: C

18/08/2014

OCCIDENTAL OF OMAN,INC.

TR ENGINEERING LLC

HOT HYDROCARBON DRAIN VESSEL (01-V-169)

12.0

PREPARATION FOR SHIPMENT

The preparation for shipment of Vessel and its materials shall be in accordance with

Purchaser standards MUK-FAC-251. Special care should be taken for the packaging of

delicate equipment.

All the platforms and ladder shall be packed separately and supplied to site along with

equipment.

In general, within Oman, all items shall be transported to site by truck. The majority of

roads are rough, corrugated, dusty desert graded roads. The equipment and packing

must be able to withstand rougher than normal treatment, with greater use made of

shock absorbent materials.

As a part of this order, Vendor shall deliver the Vessel to Purchasers plant at Safah for

Occidental of Oman Inc.

The exterior of all crated parts shall be clearly identified in accordance with the

purchase order and a minimum shall include the following:

Project details such as:

Purchase order number, and Year of supply

Project name Replacement of Crude Heater H-102 at SGP

Destination, 01-V-169 at Safah, Occidental of Oman Inc.

Nearest Port

Country, Sultanate of Oman Muscat

Vessel dimensions and gross weight

Specific storage instructions

Package item x of y (for what unit package number)

OMN-SAF-100-MEC-00003-001

Page 29 of 45

Revision: C

18/08/2014

OCCIDENTAL OF OMAN,INC.

TR ENGINEERING LLC

HOT HYDROCARBON DRAIN VESSEL (01-V-169)

13.0

COMMISSIONING

13.1

Site Supervision

The Purchaser will install and commission the Vessel (if not included in Vendor scope).

The Vendor shall detail in his tender the extent of specialist supervision and

commissioning he deems necessary to satisfy himself that installation and operation of

the package meets the specification and warranty requirements.

13.2

Manuals

For field commissioning, the Vendor shall provide the results of all the shop tests

executed prior to shipment of Vessel.

The Vendor shall provide, as detailed in the Appendix-A2 Seller Document

Requirement List, complete instruction manual which shall include instructions for

installation, operation and maintenance along with all technical data and test results.

The Vendor shall provide to the Purchaser instructions on specific safety procedures for

the installation of the Vessel.

13.3

Special Tools

Special tools and fixtures for transport, installation, commissioning, operation and /or

maintenance:

Where specialist lifting equipment such as lifting or spreader beams are required,

Vendor shall supply all necessary slings (of correct length), pins, shackles or

turnbuckles etc. All lifting devices shall be designed, fabricated and certified in

accordance with ANSI/ASME B 30.20 and ON color code system.

OMN-SAF-100-MEC-00003-001

Page 30 of 45

Revision: C

18/08/2014

OCCIDENTAL OF OMAN,INC.

TR ENGINEERING LLC

HOT HYDROCARBON DRAIN VESSEL (01-V-169)

14.0

A.

APPENDICES

Supplementary Information and Data

A1

Local Environmental Conditions

1 Sheet

A2

Seller Document Requirement List

1 Sheet

A3

Allowable Forces and Moments on Nozzles

2 Sheets

A4

Units of Measurement

1 Sheet

B.

B1

Technical Datasheets

Data sheet for 2171001 Rev O Data sheet for Hot Hydrocarbon

Drain Vessel (01-V-169)

6 Sheets

B2

P & ID

1 Sheet

B3

Civil Input to Vendor

8 Sheets

C.

C1.

General

Table of Compliance

OMN-SAF-100-MEC-00003-001

2 Sheets

Page 31 of 45

Revision: C

18/08/2014

OCCIDENTAL OF OMAN,INC.

TR ENGINEERING LLC

HOT HYDROCARBON DRAIN VESSEL (01-V-169)

APPENDIX - A1 - LOCAL ENVIRONMENTAL CONDITIONS

OMN-SAF-100-MEC-00003-001

Page 32 of 45

Revision: C

18/08/2014

OCCIDENTAL OF OMAN,INC.

TR ENGINEERING LLC

HOT HYDROCARBON DRAIN VESSEL (01-V-169)

LOCAL ENVIRONMENTAL CONDITIONS

ENVIRONMENTAL DATA

The table below shall be used as the minimum environmental data required:

Site Conditions

Data

Elevation

Safah

Air Temperature

Max shade (summer)

Min shade (winter)

410 ft

130 F

41F

Max Black Bulb

Soil Temperature

Design Max

Design Min

Winter

Summer

Average

Max Incident Solar Radiation

Typical Incident Solar Radiation

180F

150F

41F

85F

104F

94F

385 BTU/hr ft

320 BTU/hr ft

Max Relative Humidity

Min Relative Humidity

Mean Relative Humidity

Rain Intensity

1hour

Annual Average

Seismic

98 %

30 %

74 %

Zone 0

Wind Speed

Basic wind speed

52.7 m/s

25 mm /hr

Neg

Typical Wind Direction

March-April

NW

May- June

SW

Remaining months

SE

Atmospheric Conditions a typical hot and dry climate prevails with frequent sand

storms. The particulate atmospheric dust can be as small as 2 microns. Rain is an

infrequent occurrence, but on such occasions is heavy.

High humidity is not the normal case. Use minimum humidity as the design case.

OMN-SAF-100-MEC-00003-001

Page 33 of 45

Revision: C

18/08/2014

OCCIDENTAL OF OMAN,INC.

TR ENGINEERING LLC

HOT HYDROCARBON DRAIN VESSEL (01-V-169)

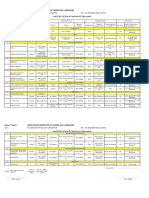

APPENDIX- A2 - SELLER DOCUMENT REQUIREMENT LIST (SDRL)

OMN-SAF-100-MEC-00003-001

Page 34 of 45

Revision: C

18/08/2014

OCCIDENTAL OF OMAN,INC.

TR ENGINEERING LLC

HOT HYDROCARBON DRAIN VESSEL (01-V-169)

APPENDIX - A3 - ALLOWABLE FORCES AND MOMENTS ON NOZZLES

OMN-SAF-100-MEC-00003-001

Page 35 of 45

Revision: C

18/08/2014

OCCIDENTAL OF OMAN,INC.

TR ENGINEERING LLC

HOT HYDROCARBON DRAIN VESSEL (01-V-169)

ALLOWABLE FORCES AND MOMENTS ON NOZZLES

(EXTERNALLY APPLIED NOZZLE LOADS)

Each nozzle shall be designed to withstand the forces and moments specified in the following

table. The effect on the shell or head due these externally applied loads shall be analyzed per

WRC107/297 for each vessel.

With regard to the radial load (FR), calculations shall be made firstly with the force acting radial

outwards in conjunction with the internal pressure and then with the force acting inwards. In the

second instance, the internal pressure shall not be used to oppose the compressive stresses

due to the force acting radial inwards; for this load condition a null pressure condition is to be

considered to exist.

For nozzles in spherical shells, the forces FL and FC and moments ML and MC shall be combined

algebraically to give resultant values.

Under vacuum condition, deflections () shall be derived at locations adjacent to the nozzle to

shell junction and shall be limited to: 0.0025 R

Nozzle

Size

(DN)

FR

lbf

(N)

FL

lbf

(N)

FC

lbf

(N)

Nozzle

Mark

Hot Hydrocarbon Drain Vessel (01-V-169) - Safah

N2/N5/N

278.8

197.8

197.8

50

8/N10

(1240)

(880)

(880)

1102.7

781.2

781.2

N3/N6

80

(4905)

(3475)

(3475)

1461.3

1033.9

1033.9

N7/ N9

100

(6500)

(4599)

(4599)

1072.3

757.6

757.6

N4

150

(4770)

(3370)

(3370)

1479.2

1045.4

1045.4

N1

200

(6580)

(4650)

(4650)

MT

lbf.ft

(Nm)

MC

lbf.ft

(Nm)

ML

lbf.ft

(Nm)

206.4

(280)

1220.2

(1655)

2260.6

(3066)

2492

(3380)

4350

(5900)

147.5

(200)

858.9

(1165)

1597

(2166)

1762.1

(2390)

3075.3

(4171)

147.5

(200)

858.9

(1165)

(1597)

2166

1762.1

(2390)

3075.3

(4171)

Where R is the shell or head radius.

FR = Radial Load

FL = Longitudinal Force

FC = Cirumferential Force

MT = Torsional Moment

ML = Longitudinal Moment

MC = Circumferential Moment

Nozzle loads and moments shall be as per MUK-FAC-255.

OCCIDENTAL OF OMAN,INC.

TR ENGINEERING LLC

HOT HYDROCARBON DRAIN VESSEL (01-V-169)

APPENDIX - A4 -UNITS OF MEASUREMENT

OMN-SAF-100-MEC-00003-001

Page 37 of 45

Revision: C

18/08/2014

OCCIDENTAL OF OMAN,INC.

TR ENGINEERING LLC

HOT HYDROCARBON DRAIN VESSEL (01-V-169)

UNITS OF MEASUREMENT

All documents and drawings shall contain customary units of measurement as indicated

in Table 1.

Table 1: Project Units

Parameter

Customary

SI

Pressure

psi

bar

Temperature

MMscf

sm3

USgal or bbl

m3 or liter (l)

lb/h

kg/h

MMscfd

sm /hr

BPD or GPM

l/min

Density

lb/ft3

kg/m3

Power

hp

kW

Length

in or ft

m or mm

Length pipeline

km

km

Force

lbf

Stress

lbf/in2

N/m2

Weight

lb

kg

Energy

Btu

kJ

Viscosity

cP

cP

Mol %

Mol %

Capacity gas

Capacity liquid

Flow (Weight)

Flow (Volume -gas)

Flow (Volume -liquid)

Composition

Note:

Pressures will be on gauge basis, unless noted otherwise.

OMN-SAF-100-MEC-00003-001

Page 38 of 45

Revision: C

18/08/2014

OCCIDENTAL OF OMAN,INC.

TR ENGINEERING LLC

HOT HYDROCARBON DRAIN VESSEL (01-V-169)

APPENDIX- B1

DATA SHEET FOR HOT HYDROCARBON DRAIN VESSEL

(01-V-169)(SAFAH)

OMN-SAF-100-MEC-00003-001

Page 39 of 45

Revision: C

18/08/2014

OCCIDENTAL OF OMAN,INC.

TR ENGINEERING LLC

HOT HYDROCARBON DRAIN VESSEL (01-V-169)

APPENDIX- B2 - P & ID

OMN-SAF-100-MEC-00003-001

Page 40 of 45

Revision: C

18/08/2014

OCCIDENTAL OF OMAN,INC.

TR ENGINEERING LLC

HOT HYDROCARBON DRAIN VESSEL (01-V-169)

APPENDIX- B3CIVIL INPUT TO VENDOR

OMN-SAF-100-MEC-00003-001

Page 41 of 45

Revision: C

18/08/2014

OCCIDENTAL OF OMAN,INC.

TR ENGINEERING LLC

HOT HYDROCARBON DRAIN VESSEL (01-V-169)

APPENDIX- C1- TABLE OF COMPLIANCE

OMN-SAF-100-MEC-00003-001

Page 42 of 45

Revision: C

18/08/2014

OCCIDENTAL OF OMAN,INC.

TR ENGINEERING LLC

HOT HYDROCARBON DRAIN VESSEL (01-V-169)

TABLE OF COMPLIANCE

The vendor shall confirm below that the offer complies with all the clauses contained in this

specification or otherwise highlight deviation / exceptions under the clarification column.

SPEC.

REF.

CONFORMS

ALTERNATIVE

PARAGRA

PH

Yes / No

Yes / No

CLARIFICATION

1.0

1.1

1.2

1.3

1.4

1.5

2.0

2.1

2.2

2.3

2.4

3.0

4.0

4.1

4.2

4.3

5.0

OMN-SAF-100-MEC-00003-001

Page 43 of 45

Revision: C

18/08/2014

OCCIDENTAL OF OMAN,INC.

TR ENGINEERING LLC

HOT HYDROCARBON DRAIN VESSEL (01-V-169)

5.1

5.2

6.0

7.0

7.1

7.2

6.

7.1

7.2

8.0

8.1

9.0

9.1

9.2

9.3

10.0

10.1

10.2

10.3

10.4

11.0

11.1

OMN-SAF-100-MEC-00003-001

Page 44 of 45

Revision: C

18/08/2014

OCCIDENTAL OF OMAN,INC.

TR ENGINEERING LLC

HOT HYDROCARBON DRAIN VESSEL (01-V-169)

12.0

13.0

13.1

13.2

13.3

Appendix A1

Appendix A2

Appendix A3

Appendix A4

Appendix B1

Appendix

B2

Appendix

B3

Appendix C1

OMN-SAF-100-MEC-00003-001

Page 45 of 45

Revision: C

18/08/2014

Вам также может понравиться

- General Technical Requirement For Mechanical - Piping (D 13Документ18 страницGeneral Technical Requirement For Mechanical - Piping (D 13Elias EliasОценок пока нет

- DPR 1Документ58 страницDPR 1MITHUNОценок пока нет

- ISO 15614-1 0 Bilfinger Salamis 19.11.2018. ISO 15614-1 N/A BIS-DK Form Number: BIS-DK-F 108Документ1 страницаISO 15614-1 0 Bilfinger Salamis 19.11.2018. ISO 15614-1 N/A BIS-DK Form Number: BIS-DK-F 108TomasPavlovicОценок пока нет

- Un 2004-02 - Ud-Au-000-Eb-0008 PDFДокумент4 страницыUn 2004-02 - Ud-Au-000-Eb-0008 PDFManjeet SainiОценок пока нет

- Tender SampleДокумент92 страницыTender SampleRajaramОценок пока нет

- Ring Wall & Foundation DsignFlow ChartДокумент1 страницаRing Wall & Foundation DsignFlow ChartsivaОценок пока нет

- Stratification OT 3536-22 ScrubberДокумент31 страницаStratification OT 3536-22 ScrubberbecemОценок пока нет

- MOV EIL Spec 2 PDFДокумент134 страницыMOV EIL Spec 2 PDFpl_arunachalam79Оценок пока нет

- Bleed Rings RTJДокумент1 страницаBleed Rings RTJAlessandro1975Оценок пока нет

- Combined Status of BoqmДокумент22 страницыCombined Status of Boqmhemant1284Оценок пока нет

- Code Ref.Документ155 страницCode Ref.Selvakpm06Оценок пока нет

- 2021.12.13 ITP - Concreting (5244.009) V.0Документ4 страницы2021.12.13 ITP - Concreting (5244.009) V.0huot phirunОценок пока нет

- IS, I I I: Name of ManufacturerДокумент1 страницаIS, I I I: Name of ManufacturercynideОценок пока нет

- Technical Data: 150x100 FS2KA 5 90Документ5 страницTechnical Data: 150x100 FS2KA 5 90infonetsmgОценок пока нет

- Jurassic Production Facility (JPF) at East Raudhatain: Supplier Document Cover SheetДокумент14 страницJurassic Production Facility (JPF) at East Raudhatain: Supplier Document Cover Sheettomj9104Оценок пока нет

- 7-13-0001 Rev 6Документ1 страница7-13-0001 Rev 6cynideОценок пока нет

- Proforma For Bidder'S Pre-Bid Queries / Clarifications - TechnicalДокумент4 страницыProforma For Bidder'S Pre-Bid Queries / Clarifications - TechnicalPanchdev KumarОценок пока нет

- 3 OEE 3 144 Mechanical Design Check ListsДокумент13 страниц3 OEE 3 144 Mechanical Design Check ListsAnonymous HDlK5cXc8Оценок пока нет

- Technical Data: 150x125 CNHA 5 18.5Документ5 страницTechnical Data: 150x125 CNHA 5 18.5سمير البسيونىОценок пока нет

- Technical Specification - LPG HeaterДокумент94 страницыTechnical Specification - LPG Heaterhbsheen100% (1)

- Epcc-04 Package - Delayed Coker Unit (Dcu) With Unsaturated LPG Treating UnitДокумент7 страницEpcc-04 Package - Delayed Coker Unit (Dcu) With Unsaturated LPG Treating UnitKunalОценок пока нет

- PipeClass NG 11.08.09 PDFДокумент138 страницPipeClass NG 11.08.09 PDFbadelitamariusОценок пока нет

- U StampДокумент5 страницU StampshifaОценок пока нет

- Purchase Spec. For Tubes (Sa789 S31803)Документ6 страницPurchase Spec. For Tubes (Sa789 S31803)Daison PaulОценок пока нет

- MRB IndexДокумент1 страницаMRB IndexVishnuGKОценок пока нет

- HT Chart For ASME Material-Sec IДокумент1 страницаHT Chart For ASME Material-Sec IMurugananthamParamasivamОценок пока нет

- Pmal 320 HD D 100 - BДокумент4 страницыPmal 320 HD D 100 - BraulgaldoОценок пока нет

- Calcs 4Документ19 страницCalcs 4Syariful Maliki NejstaršíОценок пока нет

- 01 PDFДокумент6 страниц01 PDFSherif AdelОценок пока нет

- Std-Ze-Itp-000001-Is00 - C.S. Shell and Tube Heat ExchangersДокумент16 страницStd-Ze-Itp-000001-Is00 - C.S. Shell and Tube Heat ExchangersAlexandru AsmarandeiОценок пока нет

- Avk Saudi National Price ListДокумент52 страницыAvk Saudi National Price Listshafeeqm3086Оценок пока нет

- Erg (1) T 01 378 07Документ58 страницErg (1) T 01 378 07nazar750Оценок пока нет

- Occpl: Hydro & Pneumatic Test ProcedureДокумент3 страницыOccpl: Hydro & Pneumatic Test ProcedureNupesh katreОценок пока нет

- Dry Bulk Storage Tank SpecificationДокумент7 страницDry Bulk Storage Tank SpecificationMohamed Mostafa IbrahimОценок пока нет

- Technical Bid RIMДокумент82 страницыTechnical Bid RIMpmcmbharat264Оценок пока нет

- Gas Pipeline SpecДокумент4 страницыGas Pipeline SpecA_bener100% (1)

- Valves Annexure - Ii Sotr GT25110000MДокумент92 страницыValves Annexure - Ii Sotr GT25110000MSrinivas KundrapuОценок пока нет

- Level WBS Code WBS NameДокумент2 страницыLevel WBS Code WBS NameAlwanОценок пока нет

- Yanbu: Export Refinery ProjectДокумент7 страницYanbu: Export Refinery ProjectJanakiraman MalligaОценок пока нет

- Plant Progress Tracker Rev1Документ3 страницыPlant Progress Tracker Rev1fcleong69Оценок пока нет

- 7-12-0037 Rev 3Документ1 страница7-12-0037 Rev 3cynideОценок пока нет

- QAP For Overall Mechanical ActivitiesДокумент2 страницыQAP For Overall Mechanical ActivitiesMaheshwar polepallyОценок пока нет

- Datasheet of Pig Indicator Rev 0Документ2 страницыDatasheet of Pig Indicator Rev 0toonaughty0% (1)

- DGS-2010-001 Design BasisДокумент19 страницDGS-2010-001 Design BasisJose ManjooranОценок пока нет

- HELIUM - LEAK TEST - Report PDFДокумент1 страницаHELIUM - LEAK TEST - Report PDFpl_arunachalam79Оценок пока нет

- Updated Equipment LotoДокумент6 страницUpdated Equipment LotoIsman UsomaruОценок пока нет

- Blasting Painting ReportДокумент1 страницаBlasting Painting ReportRafiqKuОценок пока нет

- J Ta .U : All Bin Sa'Ayid Al Shibli Rrad Co. L.L.CДокумент2 страницыJ Ta .U : All Bin Sa'Ayid Al Shibli Rrad Co. L.L.COmer WaheedОценок пока нет

- Boq of Ball Float ValveДокумент1 страницаBoq of Ball Float Valvem 418Оценок пока нет

- 11d Pms Rev00a Ongc 27jul15Документ3 страницы11d Pms Rev00a Ongc 27jul15abhiОценок пока нет

- Reservior Skid Assl Qap AlfaДокумент1 страницаReservior Skid Assl Qap AlfaajmainОценок пока нет

- 05 1 - Epc Ge PTC 3 La 00001 - Rev d1 SV Cow Job Card DetailsДокумент590 страниц05 1 - Epc Ge PTC 3 La 00001 - Rev d1 SV Cow Job Card DetailsHaianh PhamОценок пока нет

- PIG Handling TrollyДокумент1 страницаPIG Handling TrollyAnas Badar100% (1)

- Corrosion Inhibitor Injection System Data Sheet Surface Facility EPC Services Phase-4 Development ProjectДокумент11 страницCorrosion Inhibitor Injection System Data Sheet Surface Facility EPC Services Phase-4 Development ProjectNesrine MhedhbiОценок пока нет

- CV For Static Equipment Design EngineerДокумент4 страницыCV For Static Equipment Design EngineerKarthik AnandanОценок пока нет

- Crude Oil Stroage Tanks SpecsДокумент48 страницCrude Oil Stroage Tanks Specsmanish318Оценок пока нет

- AHU Design GuideДокумент37 страницAHU Design Guidesachin100% (1)

- RFQ 002Документ11 страницRFQ 002John EricksonОценок пока нет

- 038-Pro Welding Consumable Control Procedure PDFДокумент20 страниц038-Pro Welding Consumable Control Procedure PDFKöksal Patan100% (7)

- IELTS Advantage - Reading SkillsДокумент139 страницIELTS Advantage - Reading SkillsYashel Bartolome100% (9)

- Power BI BasicДокумент2 387 страницPower BI BasicSakthikumar Chandrasekaran100% (1)

- Academic Writing Task 2 PDFДокумент42 страницыAcademic Writing Task 2 PDFTôi Yêu Tiếng AnhОценок пока нет

- R For BeginnersДокумент76 страницR For BeginnersChiucheng LiuОценок пока нет

- Six Sigma PracticeДокумент4 страницыSix Sigma PracticeSakthikumar ChandrasekaranОценок пока нет

- BOB Check List For Education Loan PDFДокумент1 страницаBOB Check List For Education Loan PDFSakthikumar ChandrasekaranОценок пока нет

- Handbook of Mechanical Engineering TermsДокумент366 страницHandbook of Mechanical Engineering Termsjakejohns95% (44)

- Degree Enrollment Report 2013Документ65 страницDegree Enrollment Report 2013Sakthikumar ChandrasekaranОценок пока нет

- Lecture On MATLAB For Mechanical Engineers-LibreДокумент114 страницLecture On MATLAB For Mechanical Engineers-LibreKadiyam VijayОценок пока нет

- Static Equipment EngineerДокумент5 страницStatic Equipment EngineerSakthikumar ChandrasekaranОценок пока нет

- Static Equipment EngineerДокумент5 страницStatic Equipment EngineerSakthikumar ChandrasekaranОценок пока нет

- Lecture On MATLAB For Mechanical Engineers-LibreДокумент114 страницLecture On MATLAB For Mechanical Engineers-LibreKadiyam VijayОценок пока нет

- CAT 2015 - What The Changes Mean For StudentsДокумент2 страницыCAT 2015 - What The Changes Mean For StudentsSakthikumar ChandrasekaranОценок пока нет

- CAT 2015 - Salient FeaturesДокумент2 страницыCAT 2015 - Salient FeaturesSakthikumar ChandrasekaranОценок пока нет

- Pressure Vessel Specification PDFДокумент14 страницPressure Vessel Specification PDFSakthikumar ChandrasekaranОценок пока нет

- Sample Pressure Vessel DatasheetДокумент2 страницыSample Pressure Vessel Datasheetvofaith67% (3)

- AaaДокумент3 страницыAaaSakthikumar ChandrasekaranОценок пока нет

- Common Admission Test (CAT) 2015Документ1 страницаCommon Admission Test (CAT) 2015Sakthikumar ChandrasekaranОценок пока нет

- Kanthar Sashti KavasamДокумент26 страницKanthar Sashti KavasamSOWMYAОценок пока нет

- Piping PDFДокумент46 страницPiping PDFGORO43100% (1)

- BS5950 Load CasesДокумент46 страницBS5950 Load CasesthespecifierОценок пока нет

- Pressure Vessel & Process Equipment Design & EngineeringДокумент9 страницPressure Vessel & Process Equipment Design & EngineeringSakthikumar Chandrasekaran0% (1)

- Api 682 Mechanical Seal Data Sheet For Centrifugal and Rotary PumpsДокумент2 страницыApi 682 Mechanical Seal Data Sheet For Centrifugal and Rotary PumpsSakthikumar Chandrasekaran100% (3)

- Engineering Standards Manual ISD 341-2: Chapter 13, Welding & Joining Volume 2, Welding Fabrication ProcedureДокумент7 страницEngineering Standards Manual ISD 341-2: Chapter 13, Welding & Joining Volume 2, Welding Fabrication Proceduremabrouk2013Оценок пока нет

- Mod1 PDFДокумент41 страницаMod1 PDFAhmad Budiman100% (2)

- Tank Fabrication SpecsДокумент21 страницаTank Fabrication Specsjlcheefei9258100% (1)

- Fundamentals of Heat Exchanger Theory and DesignДокумент3 страницыFundamentals of Heat Exchanger Theory and DesignSakthikumar ChandrasekaranОценок пока нет

- HX Sizing GuideДокумент6 страницHX Sizing GuideSakthikumar ChandrasekaranОценок пока нет

- Seal Flushing PlansДокумент11 страницSeal Flushing PlansSakthikumar ChandrasekaranОценок пока нет

- RACMETДокумент54 страницыRACMETAthanasoulis KostasОценок пока нет

- Synthetic AdditivesДокумент5 страницSynthetic AdditivesJako MishyОценок пока нет

- Royal Military College of Science - Cranfield University: ReliabilityДокумент4 страницыRoyal Military College of Science - Cranfield University: ReliabilitySanjay MehrishiОценок пока нет

- Hydraulic Jet PumpДокумент3 страницыHydraulic Jet Pumpvictor javier nuñezОценок пока нет

- 3006-500A-DM281001 - Rev.1 - Standard Support DWG PDFДокумент199 страниц3006-500A-DM281001 - Rev.1 - Standard Support DWG PDFJoselyn LiraОценок пока нет

- Manual-Auto Grease System 自动打黄油操作手册Документ10 страницManual-Auto Grease System 自动打黄油操作手册Khowchae KunapatОценок пока нет

- Illustrated Parts Catalogue: Oi IsДокумент40 страницIllustrated Parts Catalogue: Oi IsDarren-Edward O'NeillОценок пока нет

- Vortex CNC Cooler System HBWДокумент7 страницVortex CNC Cooler System HBWHannan RizqiОценок пока нет

- 2013 Turbine Manufacture Pelton TurbineДокумент60 страниц2013 Turbine Manufacture Pelton TurbineAnonymous K48TgviОценок пока нет

- DKOM Lab ManualДокумент24 страницыDKOM Lab Manualaakash chakrabortyОценок пока нет

- Planer (Motor) (R921805375) (18 - ) (24 - ) - (S - N 341000655 & Above, 231611101 & Above, 721700342 & Above, 231711101 & Above) - PlanerДокумент3 страницыPlaner (Motor) (R921805375) (18 - ) (24 - ) - (S - N 341000655 & Above, 231611101 & Above, 721700342 & Above, 231711101 & Above) - PlanerPedro Alfonso PerezОценок пока нет

- Peugeot 408 Press Info EnglishДокумент19 страницPeugeot 408 Press Info Englishanthonykylim100% (1)

- 7 Overhaul Protocol COP 4050 - LR-ForMДокумент2 страницы7 Overhaul Protocol COP 4050 - LR-ForMChachou MohamedОценок пока нет

- 2.F2097Inspection MaintCheckList10302013Документ66 страниц2.F2097Inspection MaintCheckList10302013ArisОценок пока нет

- Spun PilesДокумент2 страницыSpun Pileshoetapea100% (1)

- IS 11999.2007 - R ValueДокумент9 страницIS 11999.2007 - R ValueSuvro ChakrabortyОценок пока нет

- ChE 122 Lecture Notes 03 II. Basic Concepts and The First Law (2.7-2.10)Документ4 страницыChE 122 Lecture Notes 03 II. Basic Concepts and The First Law (2.7-2.10)MarkVergelBorjaОценок пока нет

- Cummins - QSB4.5 CM2350Документ18 страницCummins - QSB4.5 CM2350bedoo54100% (2)

- Eto na-Uniform-Accelerated-Motion-lessonДокумент22 страницыEto na-Uniform-Accelerated-Motion-lessonJackiequeencess TentadoОценок пока нет

- 2000 KVA Caterpillar 3516 Gen Set Data SheetДокумент8 страниц2000 KVA Caterpillar 3516 Gen Set Data SheetMohamed Hamdallah100% (1)

- Steam InjectorДокумент5 страницSteam InjectorJannel TobongbanuaОценок пока нет

- Almera n16 Europa Ec-K9kДокумент214 страницAlmera n16 Europa Ec-K9kMARK llОценок пока нет

- Bearing Nomenclature Housing NomenclatureДокумент7 страницBearing Nomenclature Housing NomenclatureRajmohan KushwahaОценок пока нет

- Astm E23-2018Документ26 страницAstm E23-2018kavin100% (1)

- Waukesha Gas Engine Maintenance ManualДокумент7 страницWaukesha Gas Engine Maintenance Manualagusnnn56% (9)

- FM End-Sem Question Paper - 2021Документ1 страницаFM End-Sem Question Paper - 2021Anshu MeenaОценок пока нет

- Class 12 - 24Документ1 000 страницClass 12 - 24Sathish KumarОценок пока нет

- Simple Trusses, Zero-Force Members and The Method of SectionsДокумент33 страницыSimple Trusses, Zero-Force Members and The Method of SectionshaloОценок пока нет

- Layout: Rear View Front ViewДокумент14 страницLayout: Rear View Front ViewRms AutomotrizОценок пока нет

- 9600HDДокумент8 страниц9600HDRodyConnorОценок пока нет