Академический Документы

Профессиональный Документы

Культура Документы

Cable Fire Behaviour (Compatibility Mode)

Загружено:

elvikaОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Cable Fire Behaviour (Compatibility Mode)

Загружено:

elvikaАвторское право:

Доступные форматы

BU Industrial Projects

The Quality Connection

Fire Behaviour of Cables

(Detlef Uerlings)

Fire Behaviour of Cables

Contents

- Introduction

- Classification

- Tests

- Cable Types with CI-Properties

LEONI Kerpen GmbH, September 2014

Fire Behaviour of Cables

Introduction

In recent years we had various fire disasters worldwide with

human victims and high amount of damages.

We could find fires in the industry (e.g. Refineries, petrochemical plants, power plants, offshore platforms), public

buildings (e.g. airports, subways, tunnels) and vehicles (e.g.

ships, trains, coaches, planes).

The reasons for these fire disasters were different. The

accidents were caused by natural disasters, human failure

or technical defects.

Summarising we can say that precautions must be taken to

avoid fire catastrophes. But we must note too that blasts are not

preventable in all cases.

LEONI Kerpen GmbH, September 2014

Fire Behaviour of Cables

Introduction

In consequence of this recognition, we have to do all efforts to

protect human lives and material assets in case of fire.

What does it mean for

cables

?

LEONI Kerpen GmbH, September 2014

Fire Behaviour of Cables

Introduction

Cables, if they are installed professionally, are under normal

circumstances never the source of a fire!

But cables are very often involved in fires.

Due to this fact we have more and more requirements for cables

concerning the fire behaviour.

LEONI Kerpen GmbH, September 2014

Fire Behaviour of Cables

Classification

CI Circuit Integrity (Fire Resistant) (+ DIN 4102-12)

CI Circuit Integrity (Fire Resistant) (+ IEC 60331-)

LSZH Low Smoke Zero Halogen

(+ IEC 61034-1 & -2)

FRNC Flame Retardant Non Corrosive ( + IEC 60754-2)

HCL

FRLS

RP

FR

Halogen Content

Flame Retardant Low Smoke

(+ IEC 60754-1)

(+ ASTM D 2843)

Reduced Flame Propagation

(IEC 60332-3-)

Flame Retardant

(IEC 60332-1)

LEONI Kerpen GmbH, September 2014

Fire Behaviour of Cables

We must differentiate into:

- Material Tests

- Cable Tests

LEONI Kerpen GmbH, September 2014

Fire Behaviour of Cables

Material Tests

Halogen Acid Gas (HCL-Emission)

Degree of Acidity of Gases (Zero Halogen)

Toxicity

Limiting Oxygen Index (LOI)

Flammability Temperature (FT)

Flame Retardant Low Smoke (FRLS)

LEONI Kerpen GmbH, September 2014

Fire Behaviour of Cables

Cable Tests

Flame Retardancy

Reduced Flame Propagation

Smoke Density

Circuit Integrity (Fire Resistance)

LEONI Kerpen GmbH, September 2014

Fire Behaviour of Cables

Material Tests

LEONI Kerpen GmbH, September 2014

10

Fire Behaviour of Cables

IEC 60754-1

Determination of the Amount of Halogen Acid Gas (HCL-Emission)

Halogen acid gas contains mainly following elements:

Fluorine, Chlorine, Bromine, Iodine, Astatine

0.5 1.0 g of a material is burnt at a test temperature of

800 C for 40 minutes (min. 20 minutes at max.

temperature)

Evaluation: Measured HCL-Emission in percentage

Not suitable for defining compounds described as

zero-halogen.

Furnace

Halogens

Comparable tests:

Gas Washing Bottles

EN 50267-2-1

DIN VDE 0472-267-2-1

Combustion boat

containing sample

Synth.

air

Thermo

Couple

LEONI Kerpen GmbH, September 2014

11

Fire Behaviour of Cables

IEC 60754-2

Determination of Degree of acidity of gases (Zero Halogen)

Halogen acid gas contains mainly following elements:

Fluorine, Chlorine, Bromine, Iodine, Astatine

1.0 g of a material is burnt at a test temperature of

935 C for 30 minutes.

Limit values:

pH-value 4.3 / Conductivity 10 S/mm

Furnace

Halogens

Comparable tests:

Gas Washing Bottles

EN 50267-2-3

DIN VDE 0482-267-2-3

Combustion boat

containing sample

Synth.

air

Thermo

Couple

LEONI Kerpen GmbH, September 2014

12

Fire Behaviour of Cables

Defence Standard 02-713 (NES 713)

Determination of Toxicity Index of Materials

Analytical data of certain small molecular gaseous species arising when the

material is completely burnt at a flame temperature of 1150 C for 5 minutes,

are mathematically computed, using the exposure level (in ppm) of each gas

to produce fatality in 30 minutes as a base, to derive a combined toxicity

index.

The concentration of gas considered fatal to man for a 30 minute exposure

time.

Typical limit values for the Toxicity Index (T.I.) are for e.g.

- marine applications: 5 8

- railway applications: < 5

That means the smaller the value the better

Comparable tests:

NF C 20-454

LEONI Kerpen GmbH, September 2014

13

Fire Behaviour of Cables

LEONI Kerpen GmbH, September 2014

14

Fire Behaviour of Cables

ASTM D 2863 / ISO 4589

Limiting Oxygen Index (LOI)

The oxygen index describes the minimum concentration of oxygen,

expressed as volume percentage, in a mixture of oxygen and nitrogen that

will just support combustion of a material / plastic / compound.

For information: LOI 23 combustible

24.28 conditional flame retardant

29.35 flame retardant

36 extra flame retardant

LEONI Kerpen GmbH, September 2014

15

Fire Behaviour of Cables

ISO 4589-3 annex A

Flammability Temperature (F.T.)

The flammability temperature (F.T.) is the temperature at which combustion

of a material / plastic / compound is just supported in air under specified test

conditions.

For information:

F.T. of compounds are e.g. 200C up to 300C

LEONI Kerpen GmbH, September 2014

16

Fire Behaviour of Cables

ASTM D 2843

Max. Smoke Density Rating (Flame Retardant Low Smoke (FRLS))

This test covers a laboratory procedure for measuring the relative amounts

of smoke obscuration produced by the burning of plastics.

The measurements are made in terms of the loss of light transmittance

through a collected volume of smoke produced under standardized

conditions.

Typical value is a Smoke Density of max. 60%

LEONI Kerpen GmbH, September 2014

17

Fire Behaviour of Cables

Cable Tests

LEONI Kerpen GmbH, September 2014

18

Fire Behaviour of Cables

IEC 60332-1-2

Test on a single core or a single cable (Flame Retardancy)

The wire or cable shall pass the test, if the distance between the lower

edge of the top support and the onset of charring is greater than 50 mm.

Time of flame application:

cable diameter 25 mm: 60 s

cable diameter 25 < D 50 mm: 120 s

cable diameter 50 < D 75 mm: 240 s

cable diameter > 75 mm: 480 s

Comparable tests:

EN 60332-1-2

DIN VDE 0482-332-1-2

LEONI Kerpen GmbH, September 2014

19

Fire Behaviour of Cables

IEC 60332-3-

Test on bunched cables (Reduced Flame Propagation)

The cable shall pass the test, if the created flames are selfextinguishing and the maximum extent of the charred portion

measured on the sample shall not have reached a height

exceeding 2.5 m above the bottom edge of the burner.

Samples / Time for flame application:

No. of the samples (each 3.5 m long) is

calculated as follows:

-22 (cat. A):

-23 (cat. B):

-24 (cat. C):

7 l / m, Time > 40 Min.

3.5 l / m, Time > 40 Min.

1.5 l / m, Time > 20 Min.

(Total volume of non-metal material in ...litre / meter)

Comparable tests:

VDE 0482-332-3-

EN 60332-3-

ANSI/IEEE 1202 (IEEE 383)

LEONI Kerpen GmbH, September 2014

20

Fire Behaviour of Cables

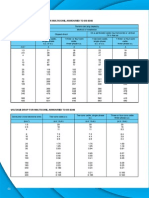

Test diagram of an unsuccessfull flame test

IEC 60332-3-24 (cat. C)

max. height of the charred portion

NOTE: The tested sample will pass IEC 60332-1 only

Burner

switched on

LEONI Kerpen GmbH, September 2014

Burner

switched off

21

Fire Behaviour of Cables

Test diagram of a successfull flame test

IEC 60332-3-24 (cat. C)

max. height of the charred portion

Burner

switched on

LEONI Kerpen GmbH, September 2014

Burner

switched off

22

Fire Behaviour of Cables

IEC 61034-2

Measurement of Smoke Density of Cables

1 litre of alcohol will be ignited in a closed test chamber. The light intensity will

be measured between the light source and the photocell. The test is

considered as ended when there is no decrease in light transmittance for 5

minutes after the fire source has extinguished or when

the test duration reaches 40 minutes. The test will be

passed, if the recorded light transmittance is min. 60%

(IEC recommendation).

Comparable tests:

VDE 0482-1034-2

EN 61034-2

LEONI Kerpen GmbH, September 2014

23

Fire Behaviour of Cables

LEONI Kerpen GmbH, September 2014

24

Fire Behaviour of Cables

IEC 60331-21 (Uo/U 0.6/1 kV)

Tests for electric cables under fire conditions - Circuit integrity CI

Conductors are connected to a separate

phase of a transformer output with a 2 A

fuse with the nominal voltage Uo/U.

After the test duration of 90 minutes

(flame temperature 750 C) the burner will

be switched off, but the cable sample shall

remain energised for further 15 min. The

total test duration shall be the flame

application time together with the 15 min

cooling period. The test will be passed, if during the course of the test no fuse

fails and a conductor does not rupture, i.e. the lamp is not extinguished.

Comparable tests:

BS 6387 B (750 C / 3 hours)

LEONI Kerpen GmbH, September 2014

25

Fire Behaviour of Cables

IEC 60331-1 and -2 (Uo/U 0.6/1 kV)

Tests for electric cables under fire conditions - Circuit integrity CI

(with mechanical shock)

Conductors are connected to a separate phase of a transformer output with a

2 A fuse with the nominal voltage Uo/U.

Flame temperature min. 830 C.

Flame application time 30 min, 60 min, 90 min or 120 min.

(pH 30, pH 60, pH 90 or pH 120 Cables)

The shock-producing device shall impact the wall after 5 min from activation

and subsequently at 5 min intervals.

The cable possesses circuit integrity characteristics, if the voltage is maintained

and a conductor does not

rupture.

Comparable tests:

BS 6387 C Z (950 C / 3 hours)

EN 50 200

IEC 60331-1 ( > 20 mm)

IEC 60331-2 ( 20 mm)

IEC 60331-3 (met. enclosure)

LEONI Kerpen GmbH, September 2014

26

Fire Behaviour of Cables

DIN VDE 4102 part 12

Tests for electric cables under fire conditions - Circuit integrity CI

(complete cable system with installation material)

Cables will be tested together with

fitting accessories like cable clamps and

cable tray from a defined supplier.

Test chamber temperature of

950 -1000 C following a temperature

curve.

Test voltage Uo/U, e.g. 400 V for

LV-cables, 110 V for TelecommunicationCables

Test duration 30 / 60 / 90 min.

(E30 / E60 / E90 Cables)

The cable possesses circuit integrity

characteristics, if the voltage is maintained

and a conductor does not rupture.

Comparable tests:

--LEONI Kerpen GmbH, September 2014

27

Fire Behaviour of Cables

Cable Types with CI-Properties

LEONI Kerpen GmbH, September 2014

28

Fire Behaviour of Cables

Cable Types with CI-Properties

All circuit integrity tests have one common ground:

Cables have to be checked for their electrical functionality!

All efforts concerning the cable construction have one common target:

to avoid a short circuit between the different cable elements.

LEONI Kerpen GmbH, September 2014

29

Fire Behaviour of Cables

Cable Types with CI-Properties

What are the methods to avoid these short circuits?

1.) Mineral insulated conductors in so-called MICC-Cables.

Mineral insulated cables are manufactured from completely inorganic

materials.

Solid copper conductors are inside of a sealed copper

tube packed with magnesium oxide as fireproof

insulator.

These kind of cables are very expensive and

only used for very special applications.

LEONI Kerpen GmbH, September 2014

30

Fire Behaviour of Cables

Cable Types with CI-Properties

What are the methods to avoid these short circuits?

2.) Mineral tapes, so-called MICA-tapes, which are

wrapped around the copper conductor

under halogen-free insulating

material.

The use of cables with MICA-Tape

wrapping is established since

many years in the market.

LEONI Kerpen GmbH, September 2014

31

Fire Behaviour of Cables

Cable Types with CI-Properties

What are the methods to avoid these short circuits?

3.) Silicone-rubber insulated conductors.

The special silicone-rubber does not

melt and forms a ceramic layer around

the conductor during fire.

This kind of insulating of CI-cables is the

latest compared to MICC-cables and

MICA-wrapped cables and can be called

as state-of-the-art.

LEONI Kerpen GmbH, September 2014

32

Fire Behaviour of Cables

Cable Types with CI-Properties

for common applications we find nowadays the cable versions with

MICA-Tape and with silicone-rubber.

In the overall view the CI-cable with silicone-rubber has the better

standing compared to a cable with MICA-wrapped conductors:

- silicone-rubber is suitable for +180 C

- thinner core diameter

- thinner cable diameter

- no additional wrapping of glass tape or similar over the twisted elements

necessary

- better performance profile in case of challenging fire tests

- better handling performance for installation

- lower smoke emission compared to standard PE and XLPE

- more economic than MICA-constructions (LEONI Kerpen)

LEONI Kerpen GmbH, September 2014

33

Fire Behaviour of Cables

Thank you very much for your attention!

Any further questions

?

LEONI Kerpen GmbH, September 2014

34

Вам также может понравиться

- Vde 0816 Part 2Документ28 страницVde 0816 Part 2VatsalОценок пока нет

- As 4435.4-2005 Insulators - Composite For Overhead Power Lines - Voltages Greater Than 1000V A.C. DefinitionsДокумент9 страницAs 4435.4-2005 Insulators - Composite For Overhead Power Lines - Voltages Greater Than 1000V A.C. DefinitionsSAI Global - APACОценок пока нет

- FirecelДокумент24 страницыFirecelapi-3803155Оценок пока нет

- Control Cable Termination Rev0Документ114 страницControl Cable Termination Rev0kahonarehaОценок пока нет

- No Smoke Without FireДокумент1 страницаNo Smoke Without FireArdi Do0% (1)

- 09 PDFДокумент19 страниц09 PDFHesham FandyОценок пока нет

- BS EN 60684-3-400 To 402-2002Документ14 страницBS EN 60684-3-400 To 402-2002FilipeFerreiraОценок пока нет

- GTP For DPDC HTДокумент2 страницыGTP For DPDC HTjamilОценок пока нет

- 10 MeV Electron Beam Cross-Linking of Plasticized PVCДокумент6 страниц10 MeV Electron Beam Cross-Linking of Plasticized PVCDuc Nguyen HuuОценок пока нет

- Is 10810 43 1984 PDFДокумент5 страницIs 10810 43 1984 PDFRushangОценок пока нет

- Specification For PVC Insulated (Heavy Duty) Electric CablesДокумент18 страницSpecification For PVC Insulated (Heavy Duty) Electric CablesPrashant TrivediОценок пока нет

- 2192Y / H03VVH2-F BS EN 50525-2-11 Flexible CableДокумент2 страницы2192Y / H03VVH2-F BS EN 50525-2-11 Flexible CableVictor Manayay ChamayaОценок пока нет

- Nhxmh-O-J 300-500VДокумент4 страницыNhxmh-O-J 300-500VA. HassanОценок пока нет

- Disclosure To Promote The Right To InformationДокумент24 страницыDisclosure To Promote The Right To InformationJitender Singh Tomar100% (1)

- Iec 61869 - 87 2009Документ16 страницIec 61869 - 87 2009Anonymous UbwGTAcKlsОценок пока нет

- List of IEC Codes For CableДокумент6 страницList of IEC Codes For CableGuha Arnab100% (1)

- h07rn F Bs en 50525 2 21 Flexible Rubber CableДокумент6 страницh07rn F Bs en 50525 2 21 Flexible Rubber CableManny DummyОценок пока нет

- TOPCABLE - RH5Z1-OL Al Eng - Rev7Документ4 страницыTOPCABLE - RH5Z1-OL Al Eng - Rev7apranaguptaОценок пока нет

- EMEA WC Sec 6Документ55 страницEMEA WC Sec 6andy175Оценок пока нет

- TempRise IEC61439 07112018Документ7 страницTempRise IEC61439 07112018Anonymous JDWNC4ZDMUОценок пока нет

- G81 - 2 Housing Materials PDFДокумент17 страницG81 - 2 Housing Materials PDFHassan SaeedОценок пока нет

- Compact Round Concentric-Lay-Stranded Aluminum 1350 ConductorsДокумент6 страницCompact Round Concentric-Lay-Stranded Aluminum 1350 ConductorsThanh DangОценок пока нет

- AS/NZS 1125:2001/amdt 1:2004, Conductors in Insulated Electric Cables and Flexible CordsДокумент7 страницAS/NZS 1125:2001/amdt 1:2004, Conductors in Insulated Electric Cables and Flexible CordsSAI Global - APAC100% (1)

- TDS, CSD - Iec 60502-2Документ4 страницыTDS, CSD - Iec 60502-2Ghiles AOUICHEОценок пока нет

- Usawire Cable CatalogДокумент242 страницыUsawire Cable CatalogRajОценок пока нет

- Strand Make-Up According To DIN VDE 0295, IEC 60228 and HD 383Документ1 страницаStrand Make-Up According To DIN VDE 0295, IEC 60228 and HD 383rocketvtОценок пока нет

- 600 / 1000v Stranded Copper Conductors PVC Insulated With Steel Wire Amour and PVC Sheathed Overall. (BS 6346: 1997)Документ8 страниц600 / 1000v Stranded Copper Conductors PVC Insulated With Steel Wire Amour and PVC Sheathed Overall. (BS 6346: 1997)Himdad TahirОценок пока нет

- Catalogo Cables Prysmian OffshoreДокумент86 страницCatalogo Cables Prysmian OffshoreJuanОценок пока нет

- High Conductive High Galvanized Round Steel WireДокумент2 страницыHigh Conductive High Galvanized Round Steel WirequycoctuОценок пока нет

- AEI LinkeX Cross-Linked Polyethylene Insulated Power CablesДокумент42 страницыAEI LinkeX Cross-Linked Polyethylene Insulated Power Cablesjohn9999999Оценок пока нет

- BS - EN - 60811-411 - 2012 - Electric&Optical Fibre - Cables - Test Methods For - Non-Metallic MaterialsДокумент12 страницBS - EN - 60811-411 - 2012 - Electric&Optical Fibre - Cables - Test Methods For - Non-Metallic MaterialsBehçet Serdal CanbazОценок пока нет

- Standard Test Methods For Crosslinked Insulations and Jackets For Wire and CableДокумент25 страницStandard Test Methods For Crosslinked Insulations and Jackets For Wire and CableLina Rocio Gutierrez BarraganОценок пока нет

- Current-Carrying Capacity For Multicore, Armoured To Bs 6346Документ1 страницаCurrent-Carrying Capacity For Multicore, Armoured To Bs 6346lkt_pestechОценок пока нет

- Cables and Wires: 3 Voltex Catalogue Voltex CatalogueДокумент48 страницCables and Wires: 3 Voltex Catalogue Voltex CatalogueChris MostertОценок пока нет

- Astm B830 97Документ3 страницыAstm B830 97Mary MaОценок пока нет

- Compact Round Concentric-Lay-Stranded Copper Conductors: Standard Specification ForДокумент3 страницыCompact Round Concentric-Lay-Stranded Copper Conductors: Standard Specification ForCarlos HerreraОценок пока нет

- BS en 60794-3-2015Документ22 страницыBS en 60794-3-2015Amer AmeryОценок пока нет

- Fire Resistant Fiber CablesДокумент43 страницыFire Resistant Fiber Cablesrose chenОценок пока нет

- Description: Cu/Mica/Xlpe/Oscr/Lszh/Gswa/LszhДокумент4 страницыDescription: Cu/Mica/Xlpe/Oscr/Lszh/Gswa/LszhTarek FawzyОценок пока нет

- BS en 50267-2-1-1999Документ8 страницBS en 50267-2-1-1999Djaffar SalahouiОценок пока нет

- Of Strand Diameter and Conductor Resistance As Per IS 694 and IS 8130 Are MetДокумент4 страницыOf Strand Diameter and Conductor Resistance As Per IS 694 and IS 8130 Are MetShubhranshu SumanОценок пока нет

- 27 HV XLPErformance Cable TechnologyДокумент6 страниц27 HV XLPErformance Cable TechnologyRanaSinhaОценок пока нет

- EDC-DTS-LV002 - Electrical Accessories For LV ABCДокумент34 страницыEDC-DTS-LV002 - Electrical Accessories For LV ABCJoe bilouteОценок пока нет

- Total Standard For CablesДокумент14 страницTotal Standard For CablesjamilОценок пока нет

- Prysmian PDFДокумент114 страницPrysmian PDFFeodor RadilovОценок пока нет

- EVS HD 629 1 S2 2006 en PreviewДокумент7 страницEVS HD 629 1 S2 2006 en PreviewSandra Milena Arias BetancourthОценок пока нет

- TAN DELTA PrincipleДокумент3 страницыTAN DELTA PrincipleRahul PhadakeОценок пока нет

- Is 9434 1992Документ26 страницIs 9434 1992Reza RhiОценок пока нет

- Compact Round Stranded Aluminum Conductors Using Single Input Wire ConstructionДокумент4 страницыCompact Round Stranded Aluminum Conductors Using Single Input Wire ConstructionHanh-Trang DangОценок пока нет

- As 60269.3.0-2005 Low-Voltage Fuses - Supplementary Requirements For Fuses For Use by Unskilled Persons (FuseДокумент8 страницAs 60269.3.0-2005 Low-Voltage Fuses - Supplementary Requirements For Fuses For Use by Unskilled Persons (FuseSAI Global - APAC0% (2)

- BS en 50368 Cable CleatДокумент27 страницBS en 50368 Cable CleatNima dawa SherpaОценок пока нет

- Contactor Selection: U R R R R U UДокумент3 страницыContactor Selection: U R R R R U UKISHAN PATELОценок пока нет

- Info Iec60445 (Ed4.0) enДокумент6 страницInfo Iec60445 (Ed4.0) enrio0% (1)

- Tracking in InsulatorsДокумент6 страницTracking in InsulatorsGaurav kumarОценок пока нет

- Doha Cables Profile 2015Документ15 страницDoha Cables Profile 2015Ahmed Farouk100% (1)

- Factors Affecting The Choice of Insulation System For Extruded HVDC Power Cables.Документ8 страницFactors Affecting The Choice of Insulation System For Extruded HVDC Power Cables.Just MagexОценок пока нет

- B115 PDFДокумент9 страницB115 PDFSanth v SaksenaОценок пока нет

- High-Voltage Bridge For Cable Fault Location, Sheath Testing, Sheath Fault Prelocation and PinpointingДокумент4 страницыHigh-Voltage Bridge For Cable Fault Location, Sheath Testing, Sheath Fault Prelocation and PinpointingPetru VirgilОценок пока нет

- Aluminum Cables For Power Distribution AECH - Chapter - 10Документ22 страницыAluminum Cables For Power Distribution AECH - Chapter - 10Anonymous XgX8kTОценок пока нет

- Optical and Microwave Technologies for Telecommunication NetworksОт EverandOptical and Microwave Technologies for Telecommunication NetworksОценок пока нет

- Industry Immersion ProjectДокумент16 страницIndustry Immersion ProjectArun kumara SОценок пока нет

- Bs 5422 GuideДокумент20 страницBs 5422 GuideGary ChanОценок пока нет

- FireClass Consultants GuideДокумент280 страницFireClass Consultants GuideJothimanikkam SomasundaramОценок пока нет

- Hazard Identification StudyДокумент16 страницHazard Identification StudyIqbal MuhammadОценок пока нет

- ACL Fire Rated Cables CatalogueДокумент52 страницыACL Fire Rated Cables CatalogueAsangaОценок пока нет

- Filtrex Brochure DustyДокумент4 страницыFiltrex Brochure Dustynarse8488Оценок пока нет

- Carbonizericehullproduction 150720142522 Lva1 App6891Документ23 страницыCarbonizericehullproduction 150720142522 Lva1 App6891gildesenganio100% (1)

- Office Health HazardsДокумент4 страницыOffice Health HazardsPlinio CabreraОценок пока нет

- Fire and Smoke CurtainsДокумент21 страницаFire and Smoke CurtainsNghia Huynh NgocОценок пока нет

- Perbedaan Status Gizi Antara Perokok Dan Bukan Perokok Pada Mahasiswa Politeknik Kesehatan Kemenkes AcehДокумент6 страницPerbedaan Status Gizi Antara Perokok Dan Bukan Perokok Pada Mahasiswa Politeknik Kesehatan Kemenkes AcehPutroe JamilahОценок пока нет

- Survey of Military PyrotechnicsДокумент40 страницSurvey of Military PyrotechnicsLuciana Amorim100% (1)

- Lech Walesa - The Struggle and The Triumph 32Документ1 страницаLech Walesa - The Struggle and The Triumph 32Ilie MapsОценок пока нет

- 09 Xtralis Osid Brochure A4 LoresДокумент2 страницы09 Xtralis Osid Brochure A4 LoresfndprojectОценок пока нет

- Script RoleplayДокумент2 страницыScript Roleplayshaa leenОценок пока нет

- Adhesive PDS & MSDS PDFДокумент25 страницAdhesive PDS & MSDS PDFsmartayaz1987Оценок пока нет

- L&TДокумент23 страницыL&TRam RamisettiОценок пока нет

- Detectomat Price List 2013: Prices Are Ex Works AhrensburgДокумент8 страницDetectomat Price List 2013: Prices Are Ex Works AhrensburgArslan KadıköyОценок пока нет

- Fire Detection and Alarm Systems - PresentationДокумент43 страницыFire Detection and Alarm Systems - PresentationKenneth100% (1)

- EDM1601 Manual A4 SingleДокумент17 страницEDM1601 Manual A4 SinglerndОценок пока нет

- MSDS PE Foam PDFДокумент4 страницыMSDS PE Foam PDFmamaze ilmania100% (1)

- EI1588 Vs EI1598 INTOPLANE JET FUEL FILTRATION TECHNOLOGIES - r3Документ5 страницEI1588 Vs EI1598 INTOPLANE JET FUEL FILTRATION TECHNOLOGIES - r3George GarciaОценок пока нет

- Indoor Environmental Quality - IДокумент18 страницIndoor Environmental Quality - Inikita chawlaОценок пока нет

- Fireproofing For Petrochemical FacilityДокумент12 страницFireproofing For Petrochemical FacilityJames Murray100% (4)

- EVS MCQ 25Документ4 страницыEVS MCQ 25shanesОценок пока нет

- Backdraft - How To Recognise It and Respond Safely. Part 1Документ7 страницBackdraft - How To Recognise It and Respond Safely. Part 1Shan RaffelОценок пока нет

- De Vries Et Al. (1998) and Bolman & de Vries (1998)Документ2 страницыDe Vries Et Al. (1998) and Bolman & de Vries (1998)Anonymous 8rsxG4Оценок пока нет

- TGS8100 Product InfomationДокумент10 страницTGS8100 Product Infomationbemxgm-1Оценок пока нет

- Olex-Flexs Brochure 21092017 3 21Документ9 страницOlex-Flexs Brochure 21092017 3 21Alkris SBОценок пока нет

- Artikel Bahasa Inggris Tentang Kesehatan LingkunganДокумент2 страницыArtikel Bahasa Inggris Tentang Kesehatan LingkunganYolanda SefraniОценок пока нет

- Lung Cap DataДокумент13 страницLung Cap DataAlberto ManastarlaОценок пока нет