Академический Документы

Профессиональный Документы

Культура Документы

2 - To Study The Speed Control of DC Shunt Motor by Armature Control and Field Control Method

Загружено:

bhavesh1863Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

2 - To Study The Speed Control of DC Shunt Motor by Armature Control and Field Control Method

Загружено:

bhavesh1863Авторское право:

Доступные форматы

PARUL INSTITUTE OF ENGINEERING & TECHNOLOGY

Department of Electrical Engineering

Electrical Machine-I

PRACTICAL NO: 02

AIM: To study the speed control of dc shunt motor by armature control and

field control method.

APPARATUS:

Sr.

No.

Apparatus

Type

Range

Quantity

Volt meter

MC

0-300 volt

01

Ammeter

MC

0-5amp

01

Rheostat

53,10amp

01

Rheostat

245,2amp

01

Tachometer Digital

0-2000 rpm

01

Single

tube

Single

tube

THEORY:

The equation governing the speed of a D.C. shunt motor is

V Ia Ra

N ------------

Where,

N = Speed of the machine

V = Armature voltage

Ia =Current through armature

Ra=Armature resistance

= Field flux.

PARUL INSTITUTE OF ENGINEERING & TECHNOLOGY

Department of Electrical Engineering

Electrical Machine-I

Out of the four parameters on the right hand side of the above equation Ra is

constant. We can control the speed of the motor in two ways. Firstly, by

changing the field flux . Secondly, by changing the armature voltage. First of

these alternatives is accomplished by introducing a rheostat in the field circuit

of the machine. By varying the rheostat we can get different values of field

current or field flux , and therefore, the different speeds of the motor.

Similarly, the second alternative can be accomplished by introducing a rheostat

in the armature circuit. This rheostat helps in changing the voltage across the

armature of the machine. This gives us different speeds.

PRECAUTIONS:

1) All the connections should be neat and tight.

2) Before switching off the supply, the armature rheostat should be moved to

the maximum position.

3) The range of the instruments should be carefully selected.

4) The zero setting of the instruments should be checked in the beginning.

PROCEDURE:

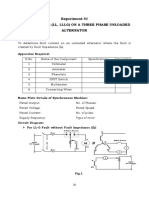

1) Connect the dc motor as per the circuit diagram shown in fig. 2.1

2) Ensure that the external resistance in the armature circuit is at maximum.

3) Ensure that the external resistance in the field circuit is at minimum.

4) After ensuring step 2 and 3, switch on the dc supply, as a result motor will

start running at a low speed.

5) Cut out the external resistance in the armature circuit and adjust the field

current, so that the speed of the motor becomes rated speed.

PARUL INSTITUTE OF ENGINEERING & TECHNOLOGY

Department of Electrical Engineering

Electrical Machine-I

6) The field current is kept constant to the above value. Very the voltage

applied to the armature by varying the external resistance in the armature

circuit. Record the applied voltage and the corresponding speed.

7) Repeat step 6 for various values of applied voltage to the armature, till the

rated Voltage of the motor.

8) Keep the applied voltage to the armature constant at its rated value. Vary the

speed of the motor by inserting external resistance in the field circuit. Record

the field current and the corresponding speed of the motor.

9) Repeat step 8 for various values of field current, till the speed of the motor is

about 1.4 times the rated speed of the motor. It is not advisable to increase the

speed beyond 1.4 times the rated speed, otherwise mechanical stresses will be

high, which may damage the motor.

10) Switch off the main supply to stop the motor.

OBSERVATIONS:

Armature voltage control

method

Field current control method

Sr.

Applied

Speed,

Sr.

No.

voltage, volt

rpm

No.

Applied

voltage,

volt

Speed,

rpm

PARUL INSTITUTE OF ENGINEERING & TECHNOLOGY

Department of Electrical Engineering

Electrical Machine-I

GRAPH: ( Plot it in graph paper for both methods )

CONCLUSION:

Fig. 2.1 speed control of dc shunt motor by armature control and field control

method

Вам также может понравиться

- Speed Control of DC Shunt MotorДокумент7 страницSpeed Control of DC Shunt MotorAakash0% (1)

- Electric Drive Lab Laboratory Manual: Dev Bhoomi Institute Chakrata Road, Navgaoun Manduwala, UttarakhandДокумент15 страницElectric Drive Lab Laboratory Manual: Dev Bhoomi Institute Chakrata Road, Navgaoun Manduwala, Uttarakhandjaya mishraОценок пока нет

- Experiment 2 - Iduction Motor Drive Using Slip Power RecoveryДокумент6 страницExperiment 2 - Iduction Motor Drive Using Slip Power RecoveryDeepak BansalОценок пока нет

- Brake Test On 3 Phase Slip Ring Induction MotorДокумент5 страницBrake Test On 3 Phase Slip Ring Induction MotorRajeev Sai0% (1)

- Voltage Regulation of 3-Phase Alternator by ZPF and ASA MethodsДокумент6 страницVoltage Regulation of 3-Phase Alternator by ZPF and ASA Methods61EEPrabhat Pal100% (1)

- Single Phase Half Controlled Converter With R LoadДокумент3 страницыSingle Phase Half Controlled Converter With R LoadB ANIL KUMARОценок пока нет

- Retardation TestДокумент5 страницRetardation TestAnkit Shetty100% (1)

- Hopkinson Test On DC Shunt MotorДокумент5 страницHopkinson Test On DC Shunt MotorVarun VadluriОценок пока нет

- DC to AC Conversion with Single Phase Series & Parallel InvertersДокумент19 страницDC to AC Conversion with Single Phase Series & Parallel Invertersmazza23467% (3)

- Speed Control of Three Phase Slip Ring Induction Motor at Variable Load ConditionДокумент3 страницыSpeed Control of Three Phase Slip Ring Induction Motor at Variable Load Conditionhi100% (1)

- Closed Loop Control of Separately Excited DC MotorДокумент13 страницClosed Loop Control of Separately Excited DC MotorJAIRAJ MIRASHIОценок пока нет

- Gate Firing Circuits For SCR'S R-C Triggering CircuitДокумент3 страницыGate Firing Circuits For SCR'S R-C Triggering CircuitB ANIL KUMARОценок пока нет

- Swinburne'S Test: AIM: To Pre-Determine The Efficiency of A D.C Shunt Machine by PerformingДокумент6 страницSwinburne'S Test: AIM: To Pre-Determine The Efficiency of A D.C Shunt Machine by PerformingAshutosh SharmaОценок пока нет

- Load Test On DC Shunt MotorДокумент6 страницLoad Test On DC Shunt Motorsanju0% (1)

- V and Inverted V Curves of Synchronous MotorДокумент7 страницV and Inverted V Curves of Synchronous Motorkarthikeyan249Оценок пока нет

- Four Quadrant Operation of DC Drives: - Dual ConvertersДокумент12 страницFour Quadrant Operation of DC Drives: - Dual ConvertersDr.K.Krishna Veni ProfessorОценок пока нет

- Load Test On Three Phase Induction Motor: Experiment No: 1Документ4 страницыLoad Test On Three Phase Induction Motor: Experiment No: 1Bodhayan PrasadОценок пока нет

- Injection of EMF in The Rotor CircuitДокумент3 страницыInjection of EMF in The Rotor CircuitAbhishekGuptaОценок пока нет

- Unit-4 Static Relays (Switchgear and Protection)Документ54 страницыUnit-4 Static Relays (Switchgear and Protection)sujithОценок пока нет

- EEP305 Electric Drives Laboratory PDFДокумент14 страницEEP305 Electric Drives Laboratory PDFAmit Singh100% (1)

- Study of StartersДокумент6 страницStudy of StartersGANESH KUMAR B eee2018Оценок пока нет

- MP Electrical Drives Lab ManualДокумент37 страницMP Electrical Drives Lab ManualSoumiya Srinivasan100% (1)

- Government Polytechnic Muzaffarpur: Name of The Lab: Power Electronics & DrivesДокумент18 страницGovernment Polytechnic Muzaffarpur: Name of The Lab: Power Electronics & DrivesVK DОценок пока нет

- Magnetization Characteristics of A D.C. Shunt Generator: Exp. No: DateДокумент60 страницMagnetization Characteristics of A D.C. Shunt Generator: Exp. No: DateSuyash SinghОценок пока нет

- Experiment:-7 Aim: To Study The Operation of Resistance Firing Circuit Using R, RC & UJT Firing Module. ApparatusДокумент6 страницExperiment:-7 Aim: To Study The Operation of Resistance Firing Circuit Using R, RC & UJT Firing Module. ApparatusNikhil BindalОценок пока нет

- 6.fault Analysis (LL, LLLG) On A Three Phase Unloaded AlternatorДокумент4 страницы6.fault Analysis (LL, LLLG) On A Three Phase Unloaded Alternatorarjuna4306Оценок пока нет

- Synchronous Motor Drive Control MethodsДокумент17 страницSynchronous Motor Drive Control MethodssidharthОценок пока нет

- Drives Manual Final EeeДокумент60 страницDrives Manual Final EeenandhakumarmeОценок пока нет

- Drives and Control Lab ManualДокумент36 страницDrives and Control Lab ManualKabilanОценок пока нет

- MA-415 Industrial Drives Lab IndexДокумент19 страницMA-415 Industrial Drives Lab IndexMayankJainОценок пока нет

- Chapter Thirteen: DC Drives Using Controlled RectifiersДокумент38 страницChapter Thirteen: DC Drives Using Controlled Rectifiersyemane gebremichal100% (2)

- Electrical Machines II Lab ManualДокумент28 страницElectrical Machines II Lab ManualAnith Krishnan83% (6)

- Tutorial EDДокумент10 страницTutorial EDPavan KhetrapalОценок пока нет

- VTU Guide Measures Resistance Using Wheatstone BridgeДокумент18 страницVTU Guide Measures Resistance Using Wheatstone Bridgevnyshreyas100% (2)

- DC Machines Lab ManualДокумент56 страницDC Machines Lab ManualRockstar RichОценок пока нет

- Solid State Controller of Drives - ExperimentДокумент37 страницSolid State Controller of Drives - ExperimentRakesh Singh LodhiОценок пока нет

- Determine regulation and efficiency of transformer using OC and SC testsДокумент45 страницDetermine regulation and efficiency of transformer using OC and SC testsrkadiraj701150% (4)

- On AC Voltage ControllersДокумент25 страницOn AC Voltage ControllersSahil ChoudharyОценок пока нет

- Lab ReportДокумент26 страницLab Reportsanjana972Оценок пока нет

- Experiment - 12: Power Angle Curve of Syncronous MachineДокумент3 страницыExperiment - 12: Power Angle Curve of Syncronous MachinesanjuОценок пока нет

- Special Electrical Machines Ee2403 PDFДокумент16 страницSpecial Electrical Machines Ee2403 PDFsamyramu100% (3)

- BrakingДокумент19 страницBrakingMohammad Umar RehmanОценок пока нет

- Speed Control of DC MotorДокумент4 страницыSpeed Control of DC MotorjitbakОценок пока нет

- Power Electronics Controlled RectificationДокумент13 страницPower Electronics Controlled Rectificationkibrom atsbhaОценок пока нет

- DC Motor Speed Control MethodsДокумент53 страницыDC Motor Speed Control MethodsKuhaanProОценок пока нет

- Single Phase and Three Phase Rectifiers NumericalsДокумент71 страницаSingle Phase and Three Phase Rectifiers Numericalsaryan singhОценок пока нет

- Operation of Generator Connected to Infinite BusДокумент6 страницOperation of Generator Connected to Infinite BuspremameОценок пока нет

- Synchronizing 3-Phase AlternatorДокумент5 страницSynchronizing 3-Phase AlternatorHaritha RkОценок пока нет

- Anderson Bridge: User ManualДокумент12 страницAnderson Bridge: User Manualaa_nilawarОценок пока нет

- SSSC PPT (Autosaved)Документ14 страницSSSC PPT (Autosaved)shubham bansalОценок пока нет

- Lecture 03 - CycloconvertersДокумент29 страницLecture 03 - CycloconvertersdaudiОценок пока нет

- Ed Lab ManualДокумент27 страницEd Lab ManualBonnieОценок пока нет

- EM-I Lab Viva Questions Updated OnДокумент6 страницEM-I Lab Viva Questions Updated OnNagamohan BilluОценок пока нет

- Ac Machines Lab ManualДокумент102 страницыAc Machines Lab ManualAshwin Gopinath100% (3)

- Ec-I Lab MannualДокумент30 страницEc-I Lab Mannualsmaran247017Оценок пока нет

- DC Machines Lab ManualДокумент153 страницыDC Machines Lab ManualdaluОценок пока нет

- DC Machines Lab ManualДокумент72 страницыDC Machines Lab ManualPuneeth PuniОценок пока нет

- 3 Speed Control of DC Shunt Motor PDFДокумент2 страницы3 Speed Control of DC Shunt Motor PDFRedwan Ahmad MuidОценок пока нет

- Voltage Regulation of alternator-EMF, MMF - ZPF-Expt-7Документ7 страницVoltage Regulation of alternator-EMF, MMF - ZPF-Expt-7Gingka HaganeОценок пока нет

- Electromechanical Energy Conversion Lab ManualДокумент61 страницаElectromechanical Energy Conversion Lab Manualprathyush srinivasanОценок пока нет

- 8044 PrintДокумент10 страниц8044 PrintOleg AshmarovОценок пока нет

- Agrirobot PDFДокумент103 страницыAgrirobot PDFMuhamad Azlan ShahОценок пока нет

- Potential Divider Student Worksheet: TheoryДокумент4 страницыPotential Divider Student Worksheet: TheoryMaha sidОценок пока нет

- WEG Regulador de Tensao Analogico Avr A Opt 03 03 B 03 C Mwml00516 Manual Portugues Ingles EspanholДокумент62 страницыWEG Regulador de Tensao Analogico Avr A Opt 03 03 B 03 C Mwml00516 Manual Portugues Ingles EspanholDEYNERОценок пока нет

- 8484.sensor CEM Diagnostic Tests User Manual v3.1.0Документ28 страниц8484.sensor CEM Diagnostic Tests User Manual v3.1.0Edgar FuentesОценок пока нет

- Avc63 12 PDFДокумент4 страницыAvc63 12 PDFZinou ZizouОценок пока нет

- Control System Lab ManualДокумент105 страницControl System Lab Manualshiva shakthyОценок пока нет

- 7 PVG ActuatorsДокумент87 страниц7 PVG ActuatorsJose Manuel Barroso PantojaОценок пока нет

- Rotary Encoder LED Ring User GuideДокумент5 страницRotary Encoder LED Ring User GuidekinolabОценок пока нет

- Multimeter TutorialДокумент36 страницMultimeter TutorialkshvsrmaОценок пока нет

- VOITH I To H ManualДокумент23 страницыVOITH I To H ManualPaulo Godinho67% (3)

- Sun Tracking System (#324534) - 319362 PDFДокумент6 страницSun Tracking System (#324534) - 319362 PDFRonnie Mere JuárezОценок пока нет

- Operation Manual: CMCP575-XXX-XXX Speed TransmitterДокумент8 страницOperation Manual: CMCP575-XXX-XXX Speed TransmitterYeral PobleteОценок пока нет

- Sensors and Actuators FundamentalsДокумент45 страницSensors and Actuators FundamentalsKedir MohammedОценок пока нет

- CrashCourseElectronicsMasterOutline 01 PDFДокумент39 страницCrashCourseElectronicsMasterOutline 01 PDFDinesh PanickerОценок пока нет

- ADVR-16-400Hz Universal Hybrid Voltage Regulator ManualДокумент6 страницADVR-16-400Hz Universal Hybrid Voltage Regulator ManualangelОценок пока нет

- Transducers, Pressure and Differential, Pressure, Electrical and Fiber-OpticДокумент31 страницаTransducers, Pressure and Differential, Pressure, Electrical and Fiber-OpticEduardoОценок пока нет

- BujiiДокумент3 страницыBujiilumasОценок пока нет

- 533 02827 0 X9C103Документ12 страниц533 02827 0 X9C103mikeОценок пока нет

- Operator and Maintenance Manual Spare Parts Lists Included: Serial Number: 1016387 & Up Printed in CanadaДокумент47 страницOperator and Maintenance Manual Spare Parts Lists Included: Serial Number: 1016387 & Up Printed in CanadaDavid OrtizОценок пока нет

- JS120 Single Axis Fingertip Joystick: Features and Options Mobile Machine ManagementДокумент2 страницыJS120 Single Axis Fingertip Joystick: Features and Options Mobile Machine ManagementStelian CrisanОценок пока нет

- Engine ControlДокумент30 страницEngine ControlAndi RusHmana100% (2)

- Potenciômetro Burns 10K T15% L3% 1V Sem LimiteДокумент4 страницыPotenciômetro Burns 10K T15% L3% 1V Sem Limiteitamar BarbosaОценок пока нет

- R450 AVR Manual From Macfarlane Generators PDFДокумент20 страницR450 AVR Manual From Macfarlane Generators PDFAnonymous 3RS6JNcОценок пока нет

- 2013-FYP-18 (Full Report)Документ51 страница2013-FYP-18 (Full Report)Mohsin AhsanОценок пока нет

- Instruction Manual Fisher 4200 Electronic Position Transmitters en 124158Документ44 страницыInstruction Manual Fisher 4200 Electronic Position Transmitters en 124158Peter RhoadsОценок пока нет

- Proportional Throttle Valves Technical SpecificationsДокумент15 страницProportional Throttle Valves Technical Specificationsabuzer1981Оценок пока нет

- Pulse Generator With 1 C/o (SPDT) Contact: Electronic Timer CT-TGD.12Документ9 страницPulse Generator With 1 C/o (SPDT) Contact: Electronic Timer CT-TGD.12DARKO RADICEVICОценок пока нет

- M03 Testing CompДокумент132 страницыM03 Testing CompGizaw TadesseОценок пока нет

- FV500HДокумент15 страницFV500HpinojazzОценок пока нет