Академический Документы

Профессиональный Документы

Культура Документы

Forging and Rolling

Загружено:

Anz JoyИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Forging and Rolling

Загружено:

Anz JoyАвторское право:

Доступные форматы

28/02/2015

ForgingWikipedia,thefreeencyclopedia

Forging

FromWikipedia,thefreeencyclopedia

Forgingisamanufacturingprocessinvolvingthe

shapingofmetalusinglocalizedcompressive

forces.Theblowsaredeliveredwithahammer

(oftenapowerhammer)oradie.Forgingisoften

classifiedaccordingtothetemperatureatwhichit

isperformed:coldforging(atypeofcold

working),warmforging,orhotforging(atypeof

hotworking).Forthelattertwo,themetalis

heated,usuallyinaforge.Forgedpartscanrange

inweightfromlessthanakilogramtohundredsof

metrictons.[1][2]Forginghasbeendonebysmiths

formillenniathetraditionalproductswere

kitchenware,hardware,handtools,edgedweapons,

Hotmetalingotbeingloadedintoahammerforge

andjewellery.SincetheIndustrialRevolution,

forgedpartsarewidelyusedinmechanismsand

machineswhereveracomponentrequireshighstrengthsuchforgingsusuallyrequirefurtherprocessing

(suchasmachining)toachieveafinishedpart.Today,forgingisamajorworldwideindustry.[3]

Contents

1History

2Advantagesanddisadvantages

3Processes

3.1Temperature

3.2Dropforging

3.2.1Opendiedropforging

3.2.2Impressiondieforging

3.2.2.1Designofimpressiondieforgingsandtooling

3.3Pressforging

3.4Upsetforging

3.5Automatichotforging

3.6Rollforging

3.7Netshapeandnearnetshapeforging

3.7.1Costimplications

3.8Inductionforging

4Equipment

4.1Forgingpresses

5Seealso

http://en.wikipedia.org/wiki/Forging

1/12

28/02/2015

ForgingWikipedia,thefreeencyclopedia

6References

6.1Bibliography

7Externallinks

History

Forgingisoneoftheoldestknownmetalworkingprocesses.[1]Traditionally,forgingwasperformedbya

smithusinghammerandanvil,thoughintroducingwaterpowertotheproductionandworkingofironin

the12thcenturydrovethehammerandanvilintoobsolescence.Thesmithyorforgehasevolvedover

centuriestobecomeafacilitywithengineeredprocesses,productionequipment,tooling,rawmaterials

andproductstomeetthedemandsofmodernindustry.

Inmoderntimes,industrialforgingisdoneeitherwithpressesorwithhammerspoweredbycompressed

air,electricity,hydraulicsorsteam.Thesehammersmayhavereciprocatingweightsinthethousandsof

pounds.Smallerpowerhammers,500lb(230kg)orlessreciprocatingweight,andhydraulicpressesare

commoninartsmithiesaswell.Somesteamhammersremaininuse,buttheybecameobsoletewiththe

availabilityoftheother,moreconvenient,powersources.

Advantagesanddisadvantages

Forgingcanproduceapiecethatisstrongerthananequivalentcastormachinedpart.Asthemetalis

shapedduringtheforgingprocess,itsinternalgraindeformstofollowthegeneralshapeofthepart.Asa

result,thegrainiscontinuousthroughoutthepart,givingrisetoapiecewithimprovedstrength

characteristics.[4]

Somemetalsmaybeforgedcold,butironandsteelarealmostalwayshotforged.Hotforgingprevents

theworkhardeningthatwouldresultfromcoldforging,whichwouldincreasethedifficultyof

performingsecondarymachiningoperationsonthepiece.Also,whileworkhardeningmaybedesirable

insomecircumstances,othermethodsofhardeningthepiece,suchasheattreating,aregenerallymore

economicalandmorecontrollable.Alloysthatareamenabletoprecipitationhardening,suchasmost

aluminiumalloysandtitanium,canbehotforged,followedbyhardening.

Productionforginginvolvessignificantcapitalexpenditureformachinery,tooling,facilitiesand

personnel.Inthecaseofhotforging,ahightemperaturefurnace(sometimesreferredtoastheforge)is

requiredtoheatingotsorbillets.Owingtothemassivenessoflargeforginghammersandpressesand

thepartstheycanproduce,aswellasthedangersinherentinworkingwithhotmetal,aspecialbuilding

isfrequentlyrequiredtohousetheoperation.Inthecaseofdropforgingoperations,provisionsmustbe

madetoabsorbtheshockandvibrationgeneratedbythehammer.Mostforgingoperationsusemetal

formingdies,whichmustbepreciselymachinedandcarefullyheattreatedtocorrectlyshapethe

workpiece,aswellastowithstandthetremendousforcesinvolved.[5]

Processes

Therearemanydifferentkindsofforgingprocessesavailable,howevertheycanbegroupedintothree

mainclasses:[1]

Drawnout:lengthincreases,crosssectiondecreases

http://en.wikipedia.org/wiki/Forging

2/12

28/02/2015

ForgingWikipedia,thefreeencyclopedia

Upset:lengthdecreases,crosssectionincreases

Squeezedinclosedcompressiondies:producesmultidirectionalflow

Commonforgingprocessesinclude:rollforging,swaging,cogging,opendieforging,impressiondie

forging,pressforging,automatichotforgingandupsetting.[1]

Temperature

Allofthefollowingforgingprocessescanbeperformedat

varioustemperatures,howevertheyaregenerallyclassifiedby

whetherthemetaltemperatureisaboveorbelowthe

recrystallizationtemperature.Ifthetemperatureisabovethe

material'srecrystallizationtemperatureitisdeemedhotforging

ifthetemperatureisbelowthematerial'srecrystallization

temperaturebutabove30%oftherecrystallizationtemperature

(onanabsolutescale)itisdeemedwarmforgingifbelow30%

oftherecrystallizationtemperature(usuallyroomtemperature)

thenitisdeemedcoldforging.Themainadvantageofhot

forgingisthatasthemetalisdeformedworkhardeningeffects

arenegatedbytherecrystallizationprocess.Coldforging

typicallyresultsinworkhardeningofthepiece.[6][7]

Dropforging

Dropforgingisaforgingprocesswhereahammerisraisedand

then"dropped"ontotheworkpiecetodeformitaccordingtothe

shapeofthedie.Therearetwotypesofdropforging:opendie

dropforgingandcloseddiedropforging.Asthenamesimply,

thedifferenceisintheshapeofthedie,withtheformernotfully

enclosingtheworkpiece,whilethelatterdoes.

Acrosssectionofaforged

connectingrodthathasbeenetchedto

showthegrainflow

Opendiedropforging

Opendieforgingisalsoknownassmithforging.[8]Inopendieforging,ahammerstrikesanddeforms

theworkpiece,whichisplacedonastationaryanvil.Opendieforginggetsitsnamefromthefactthat

thedies(thesurfacesthatareincontactwiththeworkpiece)donotenclosetheworkpiece,allowingitto

flowexceptwherecontactedbythedies.Thereforetheoperator,orarobot,needstoorientandposition

theworkpiecetogetthedesiredshape.Thediesareusuallyflatinshape,butsomehaveaspecially

shapedsurfaceforspecializedoperations.Forexample,adiemayhavearound,concave,orconvex

surfaceorbeatooltoformholesorbeacutofftool.[9]

Opendieforgingscanbeworkedintoshapeswhichincludediscs,hubs,blocks,shafts(includingstep

shaftsorwithflanges),sleeves,cylinders,flats,hexes,rounds,plate,andsomecustomshapes.[10]

Opendieforginglendsitselftoshortrunsandisappropriateforartsmithingandcustomwork.Insome

cases,opendieforgingmaybeemployedtoroughshapeingotstopreparethemforsubsequent

operations.Opendieforgingmayalsoorientthegraintoincreasestrengthintherequireddirection.[9]

AdvantagesofOpenDieForging

http://en.wikipedia.org/wiki/Forging

3/12

28/02/2015

ForgingWikipedia,thefreeencyclopedia

Reducedchanceofvoids

Betterfatigueresistance

Improvedmicrostructure

Continuousgrainflow

Finergrainsize

Greaterstrength[11]

Coggingissuccessivedeformationofabaralongitslengthusing

anopendiedropforge.Itiscommonlyusedtoworkapieceof

rawmaterialtotheproperthickness.Oncetheproperthicknessis

achievedtheproperwidthisachievedviaedging.[12]Edgingis

theprocessofconcentratingmaterialusingaconcaveshaped

opendie.Theprocessiscallededgingbecauseitisusually

carriedoutontheendsoftheworkpiece.Fulleringisasimilar

processthatthinsoutsectionsoftheforgingusingaconvex

shapeddie.Theseprocessespreparetheworkpiecesforfurther

forgingprocesses.[13]

Opendiedropforging(withtwo

dies)ofaningottobefurther

processedintoawheel

Edging

Fullering

Impressiondieforging

Impressiondieforgingisalsocalledcloseddieforging.Inimpressiondieforging,themetalisplacedin

adieresemblingamold,whichisattachedtotheanvil.Usually,thehammerdieisshapedaswell.The

hammeristhendroppedontheworkpiece,causingthemetaltoflowandfillthediecavities.The

hammerisgenerallyincontactwiththeworkpieceonthescaleofmilliseconds.Dependingonthesize

andcomplexityofthepart,thehammermaybedroppedmultipletimesinquicksuccession.Excess

metalissqueezedoutofthediecavities,formingwhatisreferredtoasflash.Theflashcoolsmore

rapidlythantherestofthematerialthiscoolmetalisstrongerthanthemetalinthedie,soithelps

preventmoreflashfromforming.Thisalsoforcesthemetaltocompletelyfillthediecavity.After

forging,theflashisremoved.[8][14]

Incommercialimpressiondieforging,theworkpieceisusuallymovedthroughaseriesofcavitiesina

dietogetfromaningottothefinalform.Thefirstimpressionisusedtodistributethemetalintothe

roughshapeinaccordancetotheneedsoflatercavitiesthisimpressioniscalledanedging,fullering,or

bendingimpression.Thefollowingcavitiesarecalledblockingcavities,inwhichthepieceisworking

intoashapethatmorecloselyresemblesthefinalproduct.Thesestagesusuallyimparttheworkpiece

http://en.wikipedia.org/wiki/Forging

4/12

28/02/2015

ForgingWikipedia,thefreeencyclopedia

withgenerousbendsandlargefillets.Thefinalshapeisforgedinafinalorfinisherimpressioncavity.If

thereisonlyashortrunofpartstobedone,thenitmaybemoreeconomicalforthedietolackafinal

impressioncavityandinsteadmachinethefinalfeatures.[4]

Impressiondieforginghasbeenimprovedinrecentyearsthroughincreasedautomationwhichincludes

inductionheating,mechanicalfeeding,positioningandmanipulation,andthedirectheattreatmentof

partsafterforging.[15]

Onevariationofimpressiondieforgingiscalledflashlessforging,ortruecloseddieforging.Inthis

typeofforging,thediecavitiesarecompletelyclosed,whichkeepstheworkpiecefromformingflash.

Themajoradvantagetothisprocessisthatlessmetalislosttoflash.Flashcanaccountfor20to45%of

thestartingmaterial.Thedisadvantagesofthisprocessincludeadditionalcostduetoamorecomplex

diedesignandtheneedforbetterlubricationandworkpieceplacement.[4]

Thereareothervariationsofpartformationthatintegrateimpressiondieforging.Onemethod

incorporatescastingaforgingpreformfromliquidmetal.Thecastingisremovedafterithassolidified,

butwhilestillhot.Itisthenfinishedinasinglecavitydie.Theflashistrimmed,thenthepartisquench

hardened.Anothervariationfollowsthesameprocessasoutlinedabove,exceptthepreformisproduced

bythesprayingdepositionofmetaldropletsintoshapedcollectors(similartotheOspreyprocess).[15]

Getrecommendationsfromyourfriends:

Facebook

Closeddieforginghasahighinitialcostduetothecreationofdiesandrequireddesignworktomake

workingdiecavities.However,ithaslowrecurringcostsforeachpart,thusforgingsbecomemore

economicalwithmorevolume.Thisisoneofthemajorreasonscloseddieforgingsareoftenusedinthe

automotiveandtoolindustry.Anotherreasonforgingsarecommonintheseindustrialsectorsisthat

forgingsgenerallyhaveabouta20percenthigherstrengthtoweightratiocomparedtocastormachined

partsofthesamematerial.[4]

Designofimpressiondieforgingsandtooling

Forgingdiesareusuallymadeofhighalloyortoolsteel.Diesmustbeimpactresistant,wearresistant,

maintainstrengthathightemperatures,andhavetheabilitytowithstandcyclesofrapidheatingand

cooling.Inordertoproduceabetter,moreeconomicaldiethefollowingrulesshouldbefollowed:[15]

Thediesshouldpartalongasingle,flatplaneifatallpossible.Ifnot,thepartingplaneshould

followthecontourofthepart.

Thepartingsurfaceshouldbeaplanethroughthecenteroftheforgingandnotnearanupperor

loweredge.

Adequatedraftshouldbeprovidedagoodguidelineisatleast3foraluminumand5to7for

steel.

Generousfilletsandradiishouldbeused.

Ribsshouldbelowandwide.

Thevarioussectionsshouldbebalancedtoavoidextremedifferenceinmetalflow.

Fulladvantageshouldbetakenoffiberflowlines.

Dimensionaltolerancesshouldnotbecloserthannecessary.

http://en.wikipedia.org/wiki/Forging

5/12

28/02/2015

ForgingWikipedia,thefreeencyclopedia

Thedimensionaltolerancesofasteelpartproducedusingtheimpressiondieforgingmethodare

outlinedinthetablebelow.Thedimensionsacrossthepartingplaneareaffectedbytheclosureofthe

dies,andarethereforedependentondiewearandthethicknessofthefinalflash.Dimensionsthatare

completelycontainedwithinasinglediesegmentorhalfcanbemaintainedatasignificantlygreater

levelofaccuracy.[14]

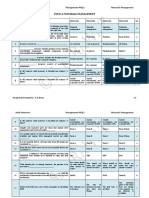

Dimensionaltolerancesforimpressiondieforgings[14]

Mass[kg(lb)] Minustolerance[mm(in)] Plustolerance[mm(in)]

0.45(1)

0.15(0.006)

0.46(0.018)

0.91(2)

0.20(0.008)

0.61(0.024)

2.27(5)

0.25(0.010)

0.76(0.030)

4.54(10)

0.28(0.011)

0.84(0.033)

9.07(20)

0.33(0.013)

0.99(0.039)

22.68(50)

0.48(0.019)

1.45(0.057)

45.36(100)

0.74(0.029)

2.21(0.087)

Alubricantisusedwhenforgingtoreducefrictionandwear.Itisalsousedasathermalbarrierto

restrictheattransferfromtheworkpiecetothedie.Finally,thelubricantactsasapartingcompoundto

preventthepartfromstickinginthedies.[14]

Pressforging

Pressforgingworksbyslowlyapplyingacontinuouspressureorforce,whichdiffersfromthenear

instantaneousimpactofdrophammerforging.Theamountoftimethediesareincontactwiththe

workpieceismeasuredinseconds(ascomparedtothemillisecondsofdrophammerforges).Thepress

forgingoperationcanbedoneeithercoldorhot.[14]

Themainadvantageofpressforging,ascomparedtodrophammerforging,isitsabilitytodeformthe

completeworkpiece.Drophammerforgingusuallyonlydeformsthesurfacesoftheworkpiecein

contactwiththehammerandanviltheinterioroftheworkpiecewillstayrelativelyundeformed.

Anotheradvantagetotheprocessincludestheknowledgeofthenewpart'sstrainrate.Wespecifically

knowwhatkindofstraincanbeputonthepart,becausethecompressionrateofthepressforging

operationiscontrolled.

Thereareafewdisadvantagestothisprocess,moststemmingfromtheworkpiecebeingincontactwith

thediesforsuchanextendedperiodoftime.Theoperationisatimeconsumingprocessduetothe

amountandlengthofsteps.Theworkpiecewillcoolfasterbecausethediesareincontactwith

workpiecethediesfacilitatedrasticallymoreheattransferthanthesurroundingatmosphere.Asthe

workpiececoolsitbecomesstrongerandlessductile,whichmayinducecrackingifdeformation

continues.Thereforeheateddiesareusuallyusedtoreduceheatloss,promotesurfaceflow,andenable

theproductionoffinerdetailsandclosertolerances.Theworkpiecemayalsoneedtobereheated.

Whendoneinhighproductivity,pressforgingismoreeconomicalthanhammerforging.Theoperation

alsocreatesclosertolerances.Inhammerforgingalotoftheworkisabsorbedbythemachinery,when

inpressforging,thegreaterpercentageofworkisusedintheworkpiece.Anotheradvantageisthatthe

operationcanbeusedtocreateanysizepartbecausethereisnolimittothesizeofthepressforging

http://en.wikipedia.org/wiki/Forging

6/12

28/02/2015

ForgingWikipedia,thefreeencyclopedia

machine.Newpressforgingtechniqueshavebeenabletocreateahigherdegreeofmechanicaland

orientationintegrity.Bytheconstraintofoxidationtotheouterlayersofthepart,reducedlevelsof

microcrackingoccurinthefinishedpart.[14]

Pressforgingcanbeusedtoperformalltypesofforging,includingopendieandimpressiondieforging.

Impressiondiepressforgingusuallyrequireslessdraftthandropforgingandhasbetterdimensional

accuracy.Also,pressforgingscanoftenbedoneinoneclosingofthedies,allowingforeasy

automation.[16]

Upsetforging

Upsetforgingincreasesthediameteroftheworkpiecebycompressingitslength.[16]Basedonnumberof

piecesproduced,thisisthemostwidelyusedforgingprocess.[16]Afewexamplesofcommonparts

producedusingtheupsetforgingprocessareenginevalves,couplings,bolts,screws,andotherfasteners.

Upsetforgingisusuallydoneinspecialhighspeedmachinescalledcrankpresses,butupsettingcanalso

bedoneinaverticalcrankpressorahydraulicpress.Themachinesareusuallysetuptoworkinthe

horizontalplane,tofacilitatethequickexchangeofworkpiecesfromonestationtothenext.Theinitial

workpieceisusuallywireorrod,butsomemachinescanacceptbarsupto25cm(9.8in)indiameter

andacapacityofover1000tons.Thestandardupsettingmachineemployssplitdiesthatcontain

multiplecavities.Thediesopenenoughtoallowtheworkpiecetomovefromonecavitytothenextthe

diesthencloseandtheheadingtool,orram,thenmoveslongitudinallyagainstthebar,upsettingitinto

thecavity.Ifallofthecavitiesareutilizedoneverycycle,thenafinishedpartwillbeproducedwith

everycycle,whichmakesthisprocessadvantageousformassproduction.[16]

Theserulesmustbefollowedwhendesigningpartstobeupsetforged:[17]

Thelengthofunsupportedmetalthatcanbeupsetinoneblowwithoutinjuriousbucklingshould

belimitedtothreetimesthediameterofthebar.

Lengthsofstockgreaterthanthreetimesthediametermaybeupsetsuccessfully,providedthatthe

diameteroftheupsetisnotmorethan1.5timesthediameterofthestock.

Inanupsetrequiringstocklengthgreaterthanthreetimesthediameterofthestock,andwherethe

diameterofthecavityisnotmorethan1.5timesthediameterofthestock,thelengthof

unsupportedmetalbeyondthefaceofthediemustnotexceedthediameterofthebar.

Automatichotforging

Theautomatichotforgingprocessinvolvesfeedingmilllengthsteelbars(typically7m(23ft)long)

intooneendofthemachineatroomtemperatureandhotforgedproductsemergefromtheotherend.

Thisalloccursrapidlysmallpartscanbemadeatarateof180partsperminute(ppm)andlargercanbe

madeatarateof90ppm.Thepartscanbesolidorhollow,roundorsymmetrical,upto6kg(13lb),and

upto18cm(7.1in)indiameter.Themainadvantagestothisprocessareitshighoutputrateandability

toacceptlowcostmaterials.Littlelaborisrequiredtooperatethemachinery.

Thereisnoflashproducedsomaterialsavingsarebetween20and30%overconventionalforging.The

finalproductisaconsistent1,050C(1,920F)soaircoolingwillresultinapartthatisstilleasily

machinable(theadvantagebeingthelackofannealingrequiredafterforging).Tolerancesareusually

0.3mm(0.012in),surfacesareclean,anddraftanglesare0.5to1.Toollifeisnearlydoublethatof

http://en.wikipedia.org/wiki/Forging

7/12

28/02/2015

ForgingWikipedia,thefreeencyclopedia

conventionalforgingbecausecontacttimesareontheorderof0.06second.Thedownsideisthatthis

processisonlyfeasibleonsmallersymmetricpartsandcosttheinitialinvestmentcanbeover$10

million,solargequantitiesarerequiredtojustifythisprocess.[18]

Theprocessstartsbyheatingthebarto1,200to1,300C(2,190to2,370F)inlessthan60seconds

usinghighpowerinductioncoils.Itisthendescaledwithrollers,shearedintoblanks,andtransferred

throughseveralsuccessiveformingstages,duringwhichitisupset,preformed,finalforged,andpierced

(ifnecessary).Thisprocesscanalsobecoupledwithhighspeedcoldformingoperations.Generally,the

coldformingoperationwilldothefinishingstagesothattheadvantagesofcoldworkingcanbe

obtained,whilemaintainingthehighspeedofautomatichotforging.[19]

Examplesofpartsmadebythisprocessare:wheelhubunitbearings,transmissiongears,taperedroller

bearingraces,stainlesssteelcouplingflanges,andneckringsforLPgascylinders.[20]Manual

transmissiongearsareanexampleofautomatichotforgingusedinconjunctionwithcoldworking.[21]

Rollforging

Rollforgingisaprocesswhereroundorflatbarstockisreducedinthicknessandincreasedinlength.

Rollforgingisperformedusingtwocylindricalorsemicylindricalrolls,eachcontainingoneormore

shapedgrooves.Aheatedbarisinsertedintotherollsandwhenithitsastoptherollsrotateandthebar

isprogressivelyshapedasitisrolledthroughthemachine.Thepieceisthentransferredtothenextsetof

groovesorturnedaroundandreinsertedintothesamegrooves.Thiscontinuesuntilthedesiredshape

andsizeisachieved.Theadvantageofthisprocessisthereisnoflashanditimpartsafavorablegrain

structureintotheworkpiece.[22]

Examplesofproductsproducedusingthismethodincludeaxles,taperedleversandleafsprings.

Netshapeandnearnetshapeforging

Thisprocessisalsoknownasprecisionforging.Itwasdevelopedtominimizecostandwasteassociated

withpostforgingoperations.Therefore,thefinalproductfromaprecisionforgingneedslittleornofinal

machining.Costsavingsaregainedfromtheuseoflessmaterial,andthuslessscrap,theoverall

decreaseinenergyused,andthereductionoreliminationofmachining.Precisionforgingalsorequires

lessofadraft,1to0.Thedownsideofthisprocessisitscost,thereforeitisonlyimplementedif

significantcostreductioncanbeachieved.[23]

Costimplications

Toachievealowcostnetshapeforgingfordemandingapplicationsthataresubjecttoahighdegreeof

scrutiny,i.e.nondestructivetestingbywayofadyepenetrantinspectiontechnique,itiscrucialthat

basicforgingprocessdisciplinesbeimplemented.Ifthebasicdisciplinesarenotmet,subsequent

materialremovaloperationswilllikelybenecessarytoremovematerialdefectsfoundatnondestructive

testinginspection.Hencelowcostpartswillnotbeachievable.

Exampledisciplinesare:dielubricantmanagement(Useofuncontaminatedandhomogeneousmixtures,

amountandplacementoflubricant).Tightcontrolofdietemperaturesandsurfacefinish/friction.

Inductionforging

http://en.wikipedia.org/wiki/Forging

8/12

28/02/2015

ForgingWikipedia,thefreeencyclopedia

Unliketheaboveprocesses,inductionforgingisbasedonthetypeofheatingstyleused.Manyofthe

aboveprocessescanbeusedinconjunctionwiththisheatingmethod.

Equipment

Themostcommontypeofforgingequipmentisthehammerand

anvil.Principlesbehindthehammerandanvilarestillusedtoday

indrophammerequipment.Theprinciplebehindthemachineis

simple:raisethehammeranddropitorpropelitintothe

workpiece,whichrestsontheanvil.Themainvariationsbetween

drophammersareinthewaythehammerispoweredthemost

commonbeingairandsteamhammers.Drophammersusually

operateinaverticalposition.Themainreasonforthisisexcess

energy(energythatisn'tusedtodeformtheworkpiece)thatisn't

releasedasheatorsoundneedstobetransmittedtothe

foundation.Moreover,alargemachinebaseisneededtoabsorb

theimpacts.[9]

Hydraulicdrophammer

Toovercomesomeshortcomingsofthedrophammer,the

counterblowmachineorimpactorisused.Inacounterblow

machineboththehammerandanvilmoveandtheworkpieceis

heldbetweenthem.Hereexcessenergybecomesrecoil.This

allowsthemachinetoworkhorizontallyandhaveasmallerbase.

Otheradvantagesincludelessnoise,heatandvibration.Italso

producesadistinctlydifferentflowpattern.Bothofthese

machinescanbeusedforopendieorcloseddieforging.[24]

Forgingpresses

Aforgingpress,oftenjustcalledapress,isusedforpress

forging.Therearetwomaintypes:mechanicalandhydraulic

presses.Mechanicalpressesfunctionbyusingcams,cranks

and/ortogglestoproduceapreset(apredeterminedforceata

(a)Materialflowofaconventionally

certainlocationinthestroke)andreproduciblestroke.Duetothe

forgeddisc(b)Materialflowofan

natureofthistypeofsystem,differentforcesareavailableat

impactorforgeddisc

differentstrokepositions.Mechanicalpressesarefasterthan

theirhydrauliccounterparts(upto50strokesperminute).Their

capacitiesrangefrom3to160MN(300to18,000shorttonsforce).Hydraulicpressesusefluidpressure

andapistontogenerateforce.Theadvantagesofahydraulicpressoveramechanicalpressareits

flexibilityandgreatercapacity.Thedisadvantagesincludeaslower,larger,andcostliermachineto

operate.[14]

Therollforging,upsetting,andautomatichotforgingprocessesallusespecializedmachinery.

http://en.wikipedia.org/wiki/Forging

9/12

28/02/2015

ForgingWikipedia,thefreeencyclopedia

Listoflargeforgingpresses,byingotsize[2][25]

Force Ingotsize

Company

Location

(tonnes) (tonnes)

16,000

600

ChinaNationalErzhongGroup[26]

Deyang,China

14,000

600

JapanSteelWorks

Japan

15,000

580

ChinaFirstHeavyIndustriesGroup[27] Heilongjiang,China

13,000

Doosan

SouthKorea

Listoflargeforgingpresses,byforce

Force Force Ingotsize

Company

(tonnes) (tons) (tonnes)

Location

80,000

(88,200) >150

ChinaErzhong[26]

Deyang,China

75,000

(82,690)

VSMPOAVISMA

Russia

65,000

(71,660)

Aubert&Duval[28][29]

Issoire,France

(45,350) 50,000

20

Alcoa,[30][31]WymanGordon[32][33] USA

40,000

(44,100)

Aubert&Duval[28]

Pamiers,France

30,000

(33,080) 8

WymanGordon[34]

Livingston,Scotland

30,000

(33,070)

WeberMetals,Inc.[35]

California,USA

30,000

(30,108)

FirthRixson[36]

Georgia,USA

Seealso

Casting

Coldsizing

Doublehammer

Milling(machining)

Semisolidmetalcasting

Forgingtemperature

References

1. ^abcdDegarmo,p.389

2. ^abHeavyManufacturingofPowerPlants(http://www.world

nuclear.org/info/inf122_heavy_manufacturing_of_power_plants.html)WorldNuclearAssociation,September

2010.Retrieved:25September2010.

3. ^"Forging:TheEarlyYears"(http://www.steelforge.com/literature/historyofforgings/).AllMetals&Forge

Group.Retrieved1October2013.

4. ^abcdDegarmo,p.392

5. ^GavinMoore1989

6. ^Degarmo,p.373

7. ^Degarmo,p.375

http://en.wikipedia.org/wiki/Forging

10/12

28/02/2015

ForgingWikipedia,thefreeencyclopedia

8. ^abDegarmo,p.391

9. ^abcDegarmo,p.390

10. ^"ForgingShapes"(http://www.steelforge.com/customforgedshapes/forgingcapabilitieschart/).AllMetals

&ForgeGroup.Retrieved1October2013.

11. ^"ForgedCrankshaftAdvantages"(http://www.glforge.com/crankshafts.html).GreatLakesForge.Retrieved

28February2014.

12. ^Caststeel:Forging(http://www.webcitation.org/5nxpp3qEi),archivedfromtheoriginal

(http://steel.keytometals.com/Articles/Art168.htm)on3March2010,retrieved3March2010

13. ^Kaushish,J.P.(2008),ManufacturingProcesses(http://books.google.com/?

id=1ZOXXV9LdcwC&pg=PA469),PHILearning,p.469,ISBN9788120333529

14. ^abcdefgDegarmo,p.394

15. ^abcDegarmo,p.393

16. ^abcdDegarmo,p.395

17. ^Degarmo,pp.395396

18. ^Degarmo,pp.396397

19. ^Degarmo,p.396

20. ^PrecisionHotForging(http://www.samtech.co.jp/e/precision_hot/index.html).Samtech.Retrieved22

November2007

21. ^PrecisionCompositeForging(http://www.samtech.co.jp/e/precision_composite/index.html).Samtech.

Retrieved22November2007

22. ^Degarmo,pp.397398

23. ^Degarmo,p.398

24. ^Degarmo,pp.392393

25. ^Kidd,Steve.Newnuclearbuildsufficientsupplycapability?(http://www.neimagazine.com/story.asp?

sectioncode=147&storyCode=2052302)NuclearEngineeringInternational,3March2009.Retrieved:25

September2010

26. ^ab"ChinaBuildingWorld'sLargestPressForge"(http://www.chinatechgadget.com/chinabuildingworlds

largestpressforge.html).ChinaTechGadget.27October2011.Retrieved12February2012.

27. ^"World'sLargest15000MNhydraulicforgingpress"(http://www.chinatechgadget.com/worldslargest

150mnhydraulicforgingpress.html).ChinaTechGadget.3November2011.Retrieved15May2012.

28. ^ab"Erametalloys"(http://www.eramet.fr/us/Site/Template/T1.aspx?SELECTID=119&ID=106).Retrieved

18May2012.

29. ^Altan,Taylan(1983).FeasibilityofUsingaLargePress(80,000200,000Ton)forManufacturingFuture

ComponentsonArmySystems(http://www.dtic.mil/cgibin/GetTRDoc?AD=ADA132398).p.12.

30. ^Heffernan,Tim(8February2012)."IronGiant"

(http://www.theatlantic.com/magazine/archive/2012/03/irongiant/8886/).TheAtlantic.Retrieved12February

2012.

31. ^50,000TonClosedDieForgingPress

(http://files.asme.org/asmeorg/communities/history/landmarks/5488.pdf).AmericanSocietyofMechanical

Engineers.1981.HistoryoftheMestaPressatAlcoa

32. ^TheWymanGordon50,000TonForgingPress

(http://files.asme.org/ASMEORG/Communities/History/Landmarks/5662.pdf).AmericanSocietyof

MechanicalEngineers.1983.HistoryoftheLoewyPressatWymanGordon

http://en.wikipedia.org/wiki/Forging

11/12

28/02/2015

ForgingWikipedia,thefreeencyclopedia

33. ^Edson,Peter(18April1952)."RevolutionaryMetalPressCutsCostofPlanesandGuns"

(http://news.google.com/newspapers?

id=8kIgAAAAIBAJ&sjid=J4oEAAAAIBAJ&pg=6350,424911&dq=forging+aircraft&hl=en).Sarasota

Journal.Retrieved12February2012.

34. ^"WymanGordonLivingston"(http://www.wymangordon.com/livingston.htm).Retrieved18May2012.

35. ^"WeberMetals"(http://www.webermetals.com).Retrieved18July2013.

36. ^"FirthRixson"(http://www.firthrixson.com).Retrieved18May2012.

Bibliography

Degarmo,E.PaulBlack,J.T.Kohser,RonaldA.(2003).MaterialsandProcessesin

Manufacturing(9thed.).Wiley.ISBN0471656534{{inconsistentcitations}}

Externallinks

HotForgingvs.ColdForging

(http://www.beyondrigging.com/2014/04/hotforgingvs

WikimediaCommonshas

mediarelatedtoForging.

coldforging/)

GlossaryofForgingTermsandDefinitions(http://www.qcforge.info)

VideoofRingRollingwithImpressionDieForging(http://www.youtube.com/watch?

v=y1Za7rpxqfk)

Retrievedfrom"http://en.wikipedia.org/w/index.php?title=Forging&oldid=647013191"

Categories: Metalforming

Thispagewaslastmodifiedon13February2015,at22:19.

TextisavailableundertheCreativeCommonsAttributionShareAlikeLicenseadditionalterms

mayapply.Byusingthissite,youagreetotheTermsofUseandPrivacyPolicy.Wikipediaisa

registeredtrademarkoftheWikimediaFoundation,Inc.,anonprofitorganization.

http://en.wikipedia.org/wiki/Forging

12/12

Вам также может понравиться

- Forging: Orging Is A Manufacturing ProcessДокумент3 страницыForging: Orging Is A Manufacturing ProcessAri Fajar RamdaniОценок пока нет

- Experiment 6Документ3 страницыExperiment 6Subhasis BiswalОценок пока нет

- Material ManufakturДокумент27 страницMaterial ManufakturNathanaelОценок пока нет

- Manufacturing Technology - MachiningДокумент61 страницаManufacturing Technology - Machiningviverefelice100% (1)

- Laboratory 5Документ10 страницLaboratory 5Andy BirdieОценок пока нет

- Forging WikipediaДокумент12 страницForging WikipediakrumpestarmarioОценок пока нет

- Expo IT2Документ8 страницExpo IT2CEci de RosalesОценок пока нет

- ForgingДокумент13 страницForgingstallone21Оценок пока нет

- A Foundry Is Found AДокумент11 страницA Foundry Is Found AJackson SichingaОценок пока нет

- Such As Aluminum or Zinc, Is Melted in The Furnace and Then Injected Into The Dies in The DieДокумент1 страницаSuch As Aluminum or Zinc, Is Melted in The Furnace and Then Injected Into The Dies in The DieKumarChirraОценок пока нет

- Technical Manual - The Blacksmith and the Welder - June 16, 1941От EverandTechnical Manual - The Blacksmith and the Welder - June 16, 1941Оценок пока нет

- Forging Is A: Manufacturing ProcessДокумент12 страницForging Is A: Manufacturing ProcessMuhammad ShahirОценок пока нет

- Introduction To Bulk-Forming ProcessesДокумент9 страницIntroduction To Bulk-Forming ProcesseslelixОценок пока нет

- MR Sunil Kumar Ojha: Assistant Professor Mechanical Engineering Department JRE Group of Institutions Greater NoidaДокумент61 страницаMR Sunil Kumar Ojha: Assistant Professor Mechanical Engineering Department JRE Group of Institutions Greater NoidaGurjinderSinghDoshanjhОценок пока нет

- Extrusion: Extrusion Is A Process Used To CreateДокумент62 страницыExtrusion: Extrusion Is A Process Used To CreateSwapnesh PatelОценок пока нет

- Extrusion: Navigation SearchДокумент12 страницExtrusion: Navigation SearchAbdullah Syfq DaudОценок пока нет

- Extrusion: Cross-Sectional Die Compressive ShearДокумент10 страницExtrusion: Cross-Sectional Die Compressive ShearCarlos BustamanteОценок пока нет

- Forging SДокумент14 страницForging SGowrisanthosh PalikaОценок пока нет

- Metal WorkingДокумент7 страницMetal WorkingJulio OchoaОценок пока нет

- Die Casting - Wikipedia, The Free EncyclopediaДокумент10 страницDie Casting - Wikipedia, The Free EncyclopediaSantanu MondalОценок пока нет

- Forging - Manual of Practical Instruction in Hand Forging of Wrought Iron, Machine Steel and Tool Steel; Drop Forging; and Heat Treatment of Steel, Including Annealing, Hardening and TemperingОт EverandForging - Manual of Practical Instruction in Hand Forging of Wrought Iron, Machine Steel and Tool Steel; Drop Forging; and Heat Treatment of Steel, Including Annealing, Hardening and TemperingРейтинг: 5 из 5 звезд5/5 (1)

- ForgingДокумент8 страницForgingAshwani KansaraОценок пока нет

- ExtrusionДокумент9 страницExtrusionOdebiyi StephenОценок пока нет

- Processes, Uses, Properties, MethodsДокумент93 страницыProcesses, Uses, Properties, MethodsMicho CalimaОценок пока нет

- Manufacturing Engineering Forming: Chapter 3: MetalДокумент98 страницManufacturing Engineering Forming: Chapter 3: MetalnunuОценок пока нет

- Sexton's Pocket-Book for Boiler-Makers and Steam Users: Comprising a Variety of Useful Information for Employer and Workmen, Government Inspectors, Board of Trade Surveyors, Engineers in Charge of Works and Ships, Foreman of Manufactories, and the General Steam-Using PublicОт EverandSexton's Pocket-Book for Boiler-Makers and Steam Users: Comprising a Variety of Useful Information for Employer and Workmen, Government Inspectors, Board of Trade Surveyors, Engineers in Charge of Works and Ships, Foreman of Manufactories, and the General Steam-Using PublicОценок пока нет

- A. LiteratureДокумент15 страницA. LiteratureA Senthil KumarОценок пока нет

- Mee 507 Mechanics of Metal FormingДокумент39 страницMee 507 Mechanics of Metal FormingALABI MUHAMMED OLUWATOSINОценок пока нет

- MFT NotesДокумент156 страницMFT NotesNihad AhmedОценок пока нет

- Asst. Professor University of Petroleum and Energy Studies: Nitin LohaniДокумент29 страницAsst. Professor University of Petroleum and Energy Studies: Nitin LohaniRavichandran GОценок пока нет

- His Article Is About The Metalworking Process. For Specific Hot Forging Hearth, See - For The Act of Counterfeiting, SeeДокумент15 страницHis Article Is About The Metalworking Process. For Specific Hot Forging Hearth, See - For The Act of Counterfeiting, SeeCheeragОценок пока нет

- InPlant Training at Bharat Forge Limited, Pune.: by Pritam Shahu PawarДокумент34 страницыInPlant Training at Bharat Forge Limited, Pune.: by Pritam Shahu PawarpritamspawarОценок пока нет

- Forging 2Документ39 страницForging 2ssukhmeet551Оценок пока нет

- Foundry &forging Viva 3&4th Sem VtuДокумент11 страницFoundry &forging Viva 3&4th Sem VtuMahesh B R Mysore100% (11)

- Takoradi Technical University Faculty of EngineeringДокумент5 страницTakoradi Technical University Faculty of EngineeringErnest ForsonОценок пока нет

- Forging FundamentalsДокумент23 страницыForging FundamentalsJoОценок пока нет

- ManualДокумент1 страницаManualEmilio RochaОценок пока нет

- Group 5 ScriptДокумент28 страницGroup 5 ScriptCarl Jay R. IntacОценок пока нет

- Sheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkОт EverandSheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkОценок пока нет

- Introduction To Industrial Arts Part 2Документ17 страницIntroduction To Industrial Arts Part 2Azura FuchОценок пока нет

- Steel Forging: What Is The Metal Forging Process?Документ11 страницSteel Forging: What Is The Metal Forging Process?Lobna CHEBBIОценок пока нет

- ECG Interpretation Made Incredibly Easy! (5th Edition)Документ29 страницECG Interpretation Made Incredibly Easy! (5th Edition)Freisan Chen0% (1)

- Advantages of ForgingДокумент14 страницAdvantages of Forgingrehan RNОценок пока нет

- Metal Fabrication ShopДокумент4 страницыMetal Fabrication ShopNormina AboОценок пока нет

- Performing Hand Forging: LO1: Analyze and Plan HandДокумент21 страницаPerforming Hand Forging: LO1: Analyze and Plan HandZimbelachew Emawoy100% (2)

- Rolling (Metalworking) : From Wikipedia, The Free EncyclopediaДокумент12 страницRolling (Metalworking) : From Wikipedia, The Free Encyclopediarhajtv100% (1)

- Cold Hot Working AnnealingДокумент40 страницCold Hot Working AnnealingNikesh KoliОценок пока нет

- Cold and Hot ForgingДокумент6 страницCold and Hot ForgingAnonymous vvO0nZWflrОценок пока нет

- ForgingДокумент38 страницForgingapi-26546070100% (2)

- Forging Is AДокумент5 страницForging Is ASahilОценок пока нет

- Metal FormingДокумент20 страницMetal FormingPrashant ShreshthaОценок пока нет

- Me 116 At12Документ4 страницыMe 116 At12jeremiahpsalms4Оценок пока нет

- Share Elements of TechnologyДокумент22 страницыShare Elements of TechnologyPriti DixitОценок пока нет

- Internship ReportДокумент28 страницInternship ReportCH.H.AWAIS RASOOLОценок пока нет

- Report On Material Used For Making Dies For Pressure Die Casting of Alluminium Alloys.2Документ21 страницаReport On Material Used For Making Dies For Pressure Die Casting of Alluminium Alloys.2Maroof Alam100% (2)

- ForgingДокумент38 страницForgingapi-26546070Оценок пока нет

- Forging PDFДокумент16 страницForging PDFloveguru2512Оценок пока нет

- Machining ProcessДокумент16 страницMachining ProcessPoonam MargajОценок пока нет

- R & B Forging PVT Ltd.Документ31 страницаR & B Forging PVT Ltd.Mohit Punani100% (1)

- Sheet Metalworking: ©2002 John Wiley & Sons, Inc. M. P. Groover, "Fundamentals of Modern Manufacturing 2/e"Документ34 страницыSheet Metalworking: ©2002 John Wiley & Sons, Inc. M. P. Groover, "Fundamentals of Modern Manufacturing 2/e"Himanshu GuptaОценок пока нет

- GLMS User Guide For Business Partners - Ver1.2Документ26 страницGLMS User Guide For Business Partners - Ver1.2Anz JoyОценок пока нет

- BJSTR MS Id 006919Документ22 страницыBJSTR MS Id 006919Anz JoyОценок пока нет

- Untitled Diagram (1) .DrawioДокумент1 страницаUntitled Diagram (1) .DrawioAnz JoyОценок пока нет

- Basic Mechanical Engineering Assignment No: 1: MarksДокумент1 страницаBasic Mechanical Engineering Assignment No: 1: MarksAnz JoyОценок пока нет

- University of Cambridge International Examinations General Certificate of Education Advanced Subsidiary Level and Advanced LevelДокумент4 страницыUniversity of Cambridge International Examinations General Certificate of Education Advanced Subsidiary Level and Advanced LevelAnz JoyОценок пока нет

- Visakha Duct Profile Industries: Manufacturer of HVAC Products & ServicesДокумент6 страницVisakha Duct Profile Industries: Manufacturer of HVAC Products & ServicesAnz JoyОценок пока нет

- University of Cambridge International Examinations General Certificate of Education Advanced Subsidiary Level and Advanced LevelДокумент4 страницыUniversity of Cambridge International Examinations General Certificate of Education Advanced Subsidiary Level and Advanced LevelAnz JoyОценок пока нет

- Scholarship and Fee Concession For FD ProgrammeДокумент3 страницыScholarship and Fee Concession For FD ProgrammeAnz JoyОценок пока нет

- Descriptive Phrases On SceneryДокумент6 страницDescriptive Phrases On SceneryKen Lim90% (20)

- Cambridge Administrative Guide 2013 International 2Документ92 страницыCambridge Administrative Guide 2013 International 2Anz JoyОценок пока нет

- TMP 35561Документ1 страницаTMP 35561Anz JoyОценок пока нет

- Guide To University Access To Cambridge Results OnlineДокумент5 страницGuide To University Access To Cambridge Results OnlineAnz JoyОценок пока нет

- Estimation and Costing PDFДокумент112 страницEstimation and Costing PDFØwięs MØhãmmed100% (1)

- Cad For Manufacturing: Dr. Sankha DebДокумент31 страницаCad For Manufacturing: Dr. Sankha Debkiran03pachpandeОценок пока нет

- Topic 6: Materials ManagementДокумент21 страницаTopic 6: Materials Managementcareermotions50% (2)

- HD BM - Operations Management - Sri5151 - st20208570Документ19 страницHD BM - Operations Management - Sri5151 - st20208570Kasun WijerathnaОценок пока нет

- Design of Production SystemДокумент31 страницаDesign of Production SystemaireencloresОценок пока нет

- Use of Plastic Waste in Road ConstructionДокумент28 страницUse of Plastic Waste in Road ConstructionKunreddy Naresh Reddy100% (2)

- (APQP) For Manufacturers: Advanced Product Quality PlanningДокумент26 страниц(APQP) For Manufacturers: Advanced Product Quality Planningpawar_kinjal110Оценок пока нет

- Quality AssuranceДокумент47 страницQuality AssuranceНаталя Нат100% (1)

- Cost AccountingДокумент47 страницCost AccountingCarlos John Talania 1923Оценок пока нет

- Process Theory The Principles of Operations Manage... - (2 The Process) PDFДокумент30 страницProcess Theory The Principles of Operations Manage... - (2 The Process) PDFSunny SouravОценок пока нет

- Finals - QuizzesДокумент10 страницFinals - QuizzesXyne FernandezОценок пока нет

- Lean Theory PDFДокумент29 страницLean Theory PDFEduardo GrandeОценок пока нет

- Customer AccomodationДокумент19 страницCustomer AccomodationSamantha Domingo100% (1)

- Specification Package Cover PageДокумент11 страницSpecification Package Cover PageAli ZaibОценок пока нет

- BSIT 54 ContentДокумент8 страницBSIT 54 ContentRoopa RoopaОценок пока нет

- Internship ReportДокумент12 страницInternship ReportChandrasekar ChithambaramОценок пока нет

- Omct 1Документ60 страницOmct 1AkhilGovindОценок пока нет

- Checkpoints v1.01 TPI-AutomotiveДокумент32 страницыCheckpoints v1.01 TPI-AutomotiveGuru PrasadОценок пока нет

- Zero DefectsДокумент16 страницZero DefectsZero DefectsОценок пока нет

- Lolp Supply Chain ManagementДокумент9 страницLolp Supply Chain Managementtotan_suri8060Оценок пока нет

- Vdocuments - MX Chapter 18 562906fc38da2Документ41 страницаVdocuments - MX Chapter 18 562906fc38da2KemerutОценок пока нет

- Product and Product MixДокумент28 страницProduct and Product MixPrashant Upashi SonuОценок пока нет

- Operations Management & Strategic Management: Study NotesДокумент332 страницыOperations Management & Strategic Management: Study NotesKunal MishraОценок пока нет

- 09 X07 C Responsibility Accounting and TP Variable Costing & Segmented ReportingДокумент8 страниц09 X07 C Responsibility Accounting and TP Variable Costing & Segmented ReportingAnnaОценок пока нет

- 00 Lean ManufacturingДокумент12 страниц00 Lean ManufacturingErnesto Rascon Basaldua0% (1)

- Just-In-Time Logistics in The Supply of Building MaterialsДокумент9 страницJust-In-Time Logistics in The Supply of Building MaterialsMelik Koray ÜsterОценок пока нет

- Operations Method of RFL Plastic LimitedДокумент13 страницOperations Method of RFL Plastic Limitedimranronybd60% (5)

- PMPДокумент99 страницPMPlaleye_olumideОценок пока нет

- Industrial Robot CNC Equipment Arm Tooling Toolholder Grippers Milling BitsДокумент8 страницIndustrial Robot CNC Equipment Arm Tooling Toolholder Grippers Milling BitsSalce SmithОценок пока нет