Академический Документы

Профессиональный Документы

Культура Документы

Carbonation-Related Microstructural Changes in Long-Term Durability Concrete

Загружено:

khoagleАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Carbonation-Related Microstructural Changes in Long-Term Durability Concrete

Загружено:

khoagleАвторское право:

Доступные форматы

Materials

Research,

2002.

Vol. 5, No.

3, 2002Vol. 5, No. 3, 287-293,

Carbonation-Related

Microstructural Changes in Long-Term Durability Concrete

2002

287

Carbonation-Related Microstructural Changes

in Long-Term Durability Concrete

Cludio A. Rigo da Silvaa*, Rubens J. Pedrosa Reisb, Fernando Soares Lameirasc

and Wander Luiz Vasconcelosd

a

Dep. of Materials Engineering and Civil Construction, Federal University of Minas Gerais,

Rua Esprito Santo, 35, 30160-030 Belo Horizonte - MG, Brazil

b

Dep. of Civil Engineering, FUMEC, Rua Cobre, 200

30310-190 Belo Horizonte - MG, Brazil

c

Nuclear Technology Development Center (CNEN/CDTN)

Av. Mrio Werneck, s/n Cidade Universitria, 31270-901 Belo Horizonte - MG, Brazil

d

Dep. of Metallurgical and Materials Engineering, Federal University of Minas Gerais

Rua Esprito Santo, 35, 2nd fl., 30160-030 Belo Horizonte - MG, Brazil

Received: September 27, 2001; Revised: July 10, 2002

This paper discusses the effects of carbonation on the microstructure of Portland cement concrete for long-term durability applications. A class C40 concrete (characteristic compression strength

between 40 MPa and 44 MPa on the 28th day, according to Brazilian standard NBR 8953) was

chosen for the experimental study of the carbonation effects, from which test samples were molded

for accelerated test under a 100%-CO2 atmosphere after physical and mechanical characterization.

It was observed that carbonation provoked a reduction of 5% to 12% of the concrete open porosity

accessible to water. Flexural strength values obtained after the carbonation tests revealed a decrease of 12% and 25% in relation to the values obtained before tests on the 28th and 91st days,

respectively.

Keywords: concrete, carbonation, microstructure, long-term durability

1. Introduction

The increasing concern for reinforced concrete structure durability is justified in many ways: concrete is cheap

and relatively easy to obtain anywhere in the world, in comparison to other building materials; the deterioration of concrete structures causes great losses to the world economy;

reinforced concrete deterioration mechanisms can be better

understood and prevented; this is an important field of study

which started to be better explored 20 years ago, enabling

the production of good concrete with specific physical properties, with the rational use of cement and the addition of

minerals, many a time from industrial wastes. In contrast,

the concern with world sustainable development has lead

to studies and economic and ecological decisions aiming to

optimize the use of natural resources in the manufacture of

the several types of cement, since cement world consump*e-mail: claudio@demc.ufmg.br

tion has increased unceasingly1.

In the recent years, it has been observed in many parts

of the world that one of the major causes of the deterioration of reinforced concrete structures is reinforcement corrosion2,3. The durability of the reinforced concrete structures depends basically on the microstructural properties of

the concrete, since the integrity of the steel bars is a direct

function of the capacity of the concrete to serve as a barrier

to aggressive agents. This is the reason why one comes

across truly discrepant cases side by side: a Roman Pantheon which has lasted more than 2000 years built with simple concrete of extremely low strength (around 10 MPa)

and the modern concrete structures with twice as much

strength and which is in critical state of deterioration little

older than ten years. The presence of the reinforcement

without sufficient protection is responsible for this discrepancy. Concrete carbonation is directly related to reinforce-

288

Rigo da Silva et al.

ment corrosion: it creates a chemical unbalance and lowers

the pH of concrete, which facilitates reinforcement

depassivation, and also enhances adverse chloride and

sulfide reactions.

The action of CO2 progresses from the outside to inside

in the form of a carbonation front, although some authors

point out that the penetration of carbon dioxide does not

necessarily produce a well defined front, and that punctual

advances may occur4 Whatever the case, it is necessary to

slow down this advance to the most to obtain durable reinforced concrete structures. Therefore, for the layer of concrete on the reinforcement (coating) to be an effective protection it is necessary that it present other characteristics

besides appropriate thickness: suitable microstructure density, low porosity and connectivity between the pores, which

leads to low permeability5. Such characteristics can be obtained from a concrete which presents low hydration heat,

small water/cement ratio, low exudation and plastic shrinkage2.

Most chemical reactions among the aggressive elements

and the concrete components occur in the water contained

in the pores. Therefore, for an adequate approach of the

durability of reinforced concrete structures, it is important

to know the material pore structure, the degree of saturation of these pores, that is, the volumetric fraction of the

pores of the material that contain gaseous and aqueous

phases, and the evolution of the concentration of the cement constituents which can be attacked with time6,7.

In the case of carbonation, air contains CO2, which reacts with cement hydrated compounds in the presence of

moisture. The carbonation reaction itself is not hazardous

to cement, except for the increase in shrinkage, which can

occur under certain conditions. The concern about carbonation increases when one considers reinforced concrete structures, because a reduction in the pH of the water in the pores

of concrete from 12.6-13.5 to values around 9 provokes the

depassivation of the reinforcements, exposing them to corrosion8-13.

2. Research Significance

The current work presents the results of a study, which

aims to clarify the effects of carbonation reaction on the

microstructure of concrete. The experimental strategy used

was the microstructural characterization of class C40 concrete, before and after accelerated carbonation tests. The

behavior of the material was evaluated by means of the

mechanical properties of tensile, by flexural and splitting

tests and axial compression. The microstructural parameters

considered were porosity, measured by means of two different methods; carbonation depth, given by the variation

of the material pH (phenolphthalein); and the identification

of carbonates by means of electronic scanning microscopy.

Materials Research

The correlation between the microstructure and the properties allowed the evaluation of the action of CO2 in concrete.

3. Experimental Program

The concrete selected, class C40, was made with cement CPII E 32 (composite cement added with 25% slag

and 10% limestone), washed sand, coarse gneiss aggregate

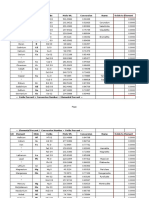

with maximum 25 mm diameter, and accelerating waterreducing admixture. Tables 1 and 2 show the main characteristics of the aggregates and the dosage used. Twenty-eight

cylindrical test samples ( 15 30 cm) and 14 prismatic

test samples (15 15 75 cm) were cast according to Brazilian standard NBR 5738. Table 3 presents the results of

the mechanical tests of axial compression, tensile and

Table 1. Characteristics of Main Aggregates.

Characteristics

Maximum Diameter (mm)

Fineness Modulus

Content of Powder Coating

Materials (%)

Dry Unitary Weight (kg/m3)

Wet Unitary Weight (kg/m3)

Real Specific Weight (kg/m3)

Clay Lumps Content (%)

Fine

Aggregate

2.4

2.62

0.35

Coarse

Aggregate

25

7.02

0.13

1419

1135

2604

0.021

1409

2682

Table 2. Typical Mix Proportions for Strength Group C40 Concrete.

Materials

Mix Proportions

3

Cement (kg/m )

430

Fine Aggregates (kg/m3)

605

1104

Coarse Aggregates (kg/m3)

Superplasticizer REAX 3000 A (kg/m3)

2.2

Water (l/m3)

178.94

A/C ratio

0.42

Air Content (%)

4.1

Slump test (mm)

85

Table 3. Mechanical Properties of C40 Concrete.

Age

(days)

3

7

28

91

Tensile

Strength

(MPa)

2.2

2.8

3.9

4.7

Flexural

Strength

(MPa)

4.7

5.0

5.9

6.9

Compressive

Strength

(MPa)

29.5

33.8

41.8

46.6

Vol. 5, No. 3, 2002

Carbonation-Related Microstructural Changes in Long-Term Durability Concrete

flexural strength up to the age of 91 days.

A special chamber was prepared for carbonation tests,

which allowed submitting the test samples to a controlled

atmosphere with relative moisture and temperature coinciding with those of the laboratory (around 60% and 20 C,

respectively). A composition of 100% CO2 was chosen for

the chamber atmosphere in agreement with experiments

reported in literature14,15.

4. Test Results

In the first stage, two prismatic test samples P40CC

and P40DC were submitted to the CO2 atmosphere for 28

days. After the tests, flexural strength and depth of carbonation by phenolphthalein in the rupture section were measured. These data are presented in Table 4.

Open porosity of the concrete samples was measured

according to the RILEM16 procedures to obtain the porosity

accessible to water. Eight cubic samples (two of each test

sample) with approximately 10 cm corners were cut from

four cylindrical test samples ( 15 30 cm) C40EC,

C40FC, C40GC and C40HC. The advantage of this procedure is obtaining a concrete sample, which was not carbonated in the practice. These samples were initially protected

from air with a plastic film, and later kept in oven at 65 C

Table 4. Flexural Strength and Depth of Carbonation.

Flexural

Strength

Specimen (MPa) Depth of Carbonation (mm)

P40CC

5.2

P40DC

5.1

Below Surface, without air contact:

Lateral Faces:

Surface with air contact:

Below Surface, without air contact:

Lateral Faces:

Surface with air contact:

0

1-3

8-10

0

2

2-3

289

for a period equal or superior to three weeks until the mass

remained constant. This mass was called dry mass. After

reaching this condition, the sample was submitted to vacuum

for 24 h, and later kept submersed in water for another 24 h

for hydrostatic and saturated mass measurements. The following parameters, presented in Table 6, were calculated

based on these values17:

a) Porosity: ratio between the volume of pores accessible to water and the apparent volume of the sample;

b) Real volumetric mass (Dr): volumetric mass of the

impermeable material, i.e., the ratio between dry sample mass and impermeable material volume;

c) Apparent volumetric mass (Da): ration between dry

sample mass and its apparent volume.

Of the eight samples mentioned above, six were submitted to a 100%-CO2 atmosphere for 25 days. The two remaining samples C40EC2 and C40FC1 were kept in air

for control. After the accelerated carbonation test period,

the RILEM procedure was repeated to obtain the porosity

accessible to water for the eight samples. The results are

also shown in Table 6.

From the carbonated samples, mortar involving the thick

aggregate portions was taken for mercury porosimetry using an AutoPore III 9420 (Micromeritics) capable of reaching pressures in the order of 414 MPa. The mortar portions

were taken near the sample surface, and an A index was

added to the sample name, and from the central region of

the sample, added with a B index. Figure 2 shows the mercury intrusion curves for the two carbonated samples

(C40EC1 and C40GC2) and of a control sample (C40EC2).

The parameters obtained from the mercury porosimetry are

presented in Table 7.

Figures 3 and 4 show aspects of the microstructure of

the concrete analyzed. The hydration products were formed

normally and the microstructure was compact and with few

voids (Fig. 3). Some carbonates were identified as light

particles and with smooth surface (Fig. 4).

Table 5. Mechanical Properties of Concrete After Carbonation Test.

Figure 1. Flexural Strength of C40 Concrete.

Specimen

C40EC1

C40EC2

C40FC1

C40FC2

C40GC1

C40GC2

C40HC1

C40HC2

Depth of

Carbonation (mm)

8 15

1

1

8 15

8 15

8 15

8 15

8 15

Load at Rupture in

Axial Compression

Test (ton)

57

32

35

52.5

54.5

49.2

49

43

290

Rigo da Silva et al.

Materials Research

Table 6. Porosity Accessible to Water, Before and After Carbonation Test.

Specimen

C40EC1

C40EC2

C40FC1

C40FC2

C40GC1

C40GC2

C40HC1

C40HC2

P (%)

9.0

8.6

8.8

8.6

7.5

8.4

8.4

9.4

Before Carbonation Test

Dr (kg/m3)

Da (kg/m3)

2781.1

2531.3

2790.4

2551.4

2572.7

2345.9

2819.7

2577.9

2564.4

2373.1

2778.3

2543.5

2790.0

2554.8

2829.8

2564.9

P (%)

7.9

8.1

9.7

7.9

7.3

7.8

7.8

7.6

After Carbonation Test

Dr (kg/m3)

Da (kg/m3)

2603.4

2398.5

2576.2

2368.5

2586.9

2336.5

2607.3

2400.3

2601.9

2412.1

2598.9

2396.0

2610.1

2407.2

2606.0

2407.1

Table 7. Parameters Obtained with Mercury Intrusion Porosimetry.

Specimen

C40EC1A

C40EC1B

C40EC2A

C40EC2B

C40GC2A

C40GC2B

Open

Porosity

(%)

13.0

11.8

13.4

12.5

8.9

9.2

Pore Surface

Area

(m2/g)

11.6

7.6

4.8

4.2

4.5

4.1

Retention

Factor R

(%)

77.5

75.2

54.8

56.5

71.9

71.2

Figure 2. Mercury Intrusion Curves of Carbonated and Control

Samples.

5. Discussion

The carbonated concrete seems to present diminished

flexural strength. This can be observed in Fig. 1 and also in

the comparison of Tables 3 and 4. The values of flexural

strength decreased by 12% and 25% in relation to the values in the previous 28 and 91 days, respectively. At least

one of the prismatic test samples (P40CC) had larger values of carbonation depth on the surface, which means that

the face was not protected by the metallic mold used in casting the test sample. It seems reasonable that the unprotected

Threshold

Diameter

(m)

0.0144

0.0144

0.1443

0.1441

0.0144

0.027

dV/dD at

Final Intrusion

(m2/g)

0.9081

1.579

0.776

0.9793

0.000

1.357

Dm

(m)

0.1238

0.2745

0.2123

0.2695

0.1322

0.2767

face of the test sample would be more porous than the others.

The cubic carbonated samples stood loads significantly

higher (22% to 78% higher) than the control sample up to

rupture did, as shown in Table 5. These results are a confirmation that, considering only simple concrete, carbonation

can be beneficial, improving some of the properties of concrete. Measurements of porosity accessible to water (Table 6) show that carbonation makes concrete more compact,

since 5% to 12% of the open porosity was closed. This can

be one of the reasons, which explain the increase in mechanical strength.

Mercury intrusion curves of carbonated samples developed in a more irregular way and presented a total intrusion

volume lower than those of control samples, indicating that

the pore structures were really closed. The parameters used

in this analysis (Table 7) were described in a previous work18.

The open porosity of all are comparable, and the results of

C40GC2A and C40GC2B, a little smaller than those of the

others, are in agreement with the tendency already observed

in the measurements of porosity accessible to water.

The pore surface area, threshold diameter, average and

derived distribution diameter values in the end of the intrusion highlight the significant differences between the carbonated region (surface) and the non-carbonated region of

the samples. The surface area of the pores is always larger

Vol. 5, No. 3, 2002

Carbonation-Related Microstructural Changes in Long-Term Durability Concrete

at the surface than inside the sample, even for the control

sample, which may be due to the fact that the superficial

regions are continually subject to interactions with the atmospheric elements, including natural carbonation of the

control samples (originating from air contact). The threshold diameter, inflexion point of the intrusion curve (corresponding to the maximum in the dV/dD curve) of the carbonated samples is smaller than that of the control sample.

Some authors19,20 suggest that the threshold diameter corresponds to the smallest diameter of the pores, among the

largest pores, which would constitute a percolation path into

the sample. Therefore, the sharp decrease in the threshold

diameter is an indicator of the closing of the pores as a result of carbonation. The average pore diameter (Dm) of the

inner regions of the samples was practically the same, but

the differences appear in the averages calculated for the

surface regions, for which Dm is significantly smaller for

the carbonated samples (about 60% smaller) as a result of

the closing of the microstructure.

The carbonated samples present a pore structure more

crooked than that of the reference sample. This conclusion,

which already seemed to be indicated by the irregular intrusion curve, is confirmed by the significantly higher value of

the retention factor (R), defined as being the ratio between

the retained mercury volume after the first intrusion-extrusion cycle and the total volume of mercury introduced18.

The slope of the tangent in relation to the intrusion curve

near the point of maximum pressure (dV/dD in the end of

the intrusion) indicates the existence of fine pores in the

microstructure into which mercury did not succeed to enter

291

and which must be identified and described by other techniques such as nitrogen adsorption, which was not used in

this work. In conclusion, the smaller this slant, the smaller

the existing fraction of fine pores. It can be noted from the

values presented that the measures of this tangent obtained

in the most superficial regions were always smaller than those

of the inside of the sample, including of the reference sample (C40EC2), which would indicate a possible effect of the

natural carbonation. However, the decrease in dV/dD in the

end of the intrusion between the surface and the inside is

much sharper for carbonated samples, reaching even the zero

tangent for sample C40GC2, evidencing that carbonation

promoted the closing of the fine pores to a large extent.

A last aspect, which must be considered in the analysis

of mercury porosimetry results, is the morphology presented

by the intrusion curves. Figure 2 reveals that the two curves

related to the control sample (C40EC2) are practically overlapped, indicating that the pore size distribution coincides

for the surface and the inside of the sample. Now, the carbonated samples present a much diverse behavior. Practically along all the distribution of the two samples analyzed,

the superficial region, therefore which suffered carbonation,

had always a mercury intrusion value lower than that of the

inner region. In this way, carbonation seems to promote the

closing of the pore structure in all the distribution of the

sizes presented by the structure.

The microstructure observed in the concrete samples by

SEM can be classified as compact, presenting few pores

and few fissures. In general, the microstructure was uniform. In Fig. 3, some cement hydration products can be

Figure 3. Photomicrographs of Concrete: a) region of formation of ettringite; b) portlandite and calcium silicates.

292

Rigo da Silva et al.

Materials Research

Figure 4. Photomicrographs of Concrete: a) presence of carbonates (C); b) several elements of the microstructure: carbonates (C), portlandite

(P), calcium silicates (C-S-H) and ettringite (Et).

observed, such as some ettringite agglomerates (Fig. 3a)

and C-S-H particles mixed with portlandite (Fig. 3b). Carbonates were also identified in some micrographs and are

presented in Fig. 4.

6. Conclusions

The main conclusions of this work are summarized below:

1. The values of flexural strength obtained after the carbonation test show a decrease of 12% and 25% in relation to the values previously obtained on the 28th

and 91st days, respectively. The carbonated concrete

seems to present a decrease in its flexural strength.

2. The carbonated samples submitted to the compression test reached rupture with loads significantly

higher (22 a 78%) than the control samples did.

3. Carbonation provoked a reduction of 5% to 12% of

the open porosity of concrete.

4. The analysis of the results of the mercury porosimetry

showed clearly the closing of the structure of the pores

of the material as a result of the carbonation effect:

a) The pore surface area is always larger in the surface than inside the sample, even for control samples;

b) The threshold diameter of the carbonated samples is an order smaller than that of the control

sample;

c) The average diameter of pore distribution (Dm)

of the superficial regions is significantly smaller

in carbonated samples (about 60% smaller);

d) The significantly higher value of the retention

factor (R) of the carbonated samples seems to

point to a pore structure more crooked than that

of the reference sample, which already seemed

indicated by the irregular intrusion curve;

e) The slope (dV/dD) measurement in the end of

the intrusion curve in the most superficial regions

were always smaller than those inside the sample, including that of the reference sample

(C40EC2), which would indicate for this sample

a possible natural carbonation effect. However,

the decrease in the value of dV/dD in the end of

the intrusion between the surface and the inside

is much sharper for carbonated samples, even

reaching the zero tangent for sample C40GC2,

demonstrating that the carbonation promoted the

closing of a large part of these finer pores.

f) Carbonation seems to promote the closing of the

pore structure in all the size distribution presented

by this structure.

5. The microstructure observed in the C40 concrete samples can be classified as compact, presenting few pores

and fissures.

Acknowledgments

The authors thank FAPEMIG financial support.

References

1. Mehta, P.K. In: Proceedings of II Intern. Conference on

Vol. 5, No. 3, 2002

Carbonation-Related Microstructural Changes in Long-Term Durability Concrete

High-performance Concrete and..., Gramado, RS, p. 114, 1999.

2. Swamy, R.N. In: Proceedings of Second CANMET/ACI

Intern. Conference on High-performance Concrete, ACI

SP-186, p. 765-788, 1999.

3. DaSilva, T.J.; Roca, P. In: Proceedings of Second

CANMET/ACI Intern. Conference on High-performance

Concrete, ACI SP-186, p. 525-533, 1999.

4. Parrott, L.J. Magazine of Concrete Research, v. 46, n.

166, p.23-28, 1994.

5. Rigo da Silva, C.A.; Lemos, F.L.; Vasconcelos, W.L.;

Lameiras, F.S. In: 43o Congresso Brasileiro de Cermica,

Florianpolis, SC, 1999.

6. Papadakis, V.G.; Vayenas, C.G.; Fardis, M.N. ACI Materials Journal, v. 88, n. 2, p. 186-196, 1991.

7. Mehta, P.K.; Monteiro, P.J.M. Concreto: estrutura,

propriedades e materiais, Editora Pini, SP, Brasil, 581

p., 1994.

8. Neville, A.M. Propriedades do Concreto, Editora Pini,

SP, Brasil, 828 p., 1998.

9. Rafai, N. et al., Cement and Concrete Research, v. 21, n.

2/3, p. 368-377, 1991.

10. Kazmierczak, C.S.; Lindenmeyer, Z. In: Proceedings

of Intern. Congress on High-performance and...,

Florianpolis, SC, p. 402-413, 1996.

11. Papadakis, V.G.; Vayenas, C.G.; Fardis, M.N. ACI Ma-

293

terials Journal, v. 88, n. 4, p. 363-373, 1991.

12. Kobayashi, K.; Suzuki, K.; Uno, Y. Cement and Concrete Research, v. 24, n. 1, p. 55-61, 1994.

13. Deloy, F.X. In: Proceedings of International Seminar,

Braslia, DF, p. 1-11, 1997.

14. Helene, P.R.L. In: Proceedings of II Intern. Conference

on High-performance Concrete and..., Gramado, RS,

p. 1-30, 1999.

15. Guimares, A.T.C.; Dias, C.R.R.; Recena, F.A.P.;

Helene, P.R.L. In: Proceedings of II Intern. Conference

on High-performance Concrete and..., Gramado, RS,

p. 1-18, 1999.

16. RILEM Commission 25 PEM, Test n. I.1 Porosity

accessible to water, Matriaux et Construction, RILEM,

v. 13, n. 75, p. 177-179, 1980.

17. Rigo da Silva, C.A.; Reis, R.J.P.; Vasconcelos, W.L.;

Lameiras, F.S. In: Anais do V Encontro Nacional de

Aplicaes Nucleares, Rio de Janeiro, RJ, p. 1-6,

2000.

18. Rigo da Silva, C.A.; Vasconcelos, W.L. In: I Simpsio

Brasileiro de Estruturologia, Belo Horizonte, MG, p.

1-10, 1998.

19. Katz, A.J.; Thompson, A.H. Physical Review B, v. 34, n.

11, p. 8179-8181, 1986.

20. Halamickova, P. et al., Cement and Concrete Research,

v. 25, n. 4, p. 790-802, 1995.

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Informational Reading Comprehension Invasive SpeciesДокумент4 страницыInformational Reading Comprehension Invasive Speciesapi-660640857100% (1)

- Singularity University SU RP The State of The Global Grand Challenges 2019 EN PDFДокумент89 страницSingularity University SU RP The State of The Global Grand Challenges 2019 EN PDFlaura zamoraОценок пока нет

- Protected Areas in PakistanДокумент36 страницProtected Areas in PakistanTauseef Ahmed100% (1)

- Layers in TimeДокумент4 страницыLayers in Timeteacher3506Оценок пока нет

- Causes of Crackle On Porcelain WareДокумент2 страницыCauses of Crackle On Porcelain WarekhoagleОценок пока нет

- Journal Paper IJAETДокумент8 страницJournal Paper IJAETvempada1942Оценок пока нет

- Lecture 2Документ4 страницыLecture 2khoagleОценок пока нет

- Useful PhrasesДокумент8 страницUseful PhraseswinnieXDОценок пока нет

- Homework 2 - SolutionДокумент3 страницыHomework 2 - SolutionkhoagleОценок пока нет

- Monitoring Sulfide-Oxidizing Biofilm Activity On Cement Surfaces Using Non-Invasive Self-Referencing MicrosensorsДокумент9 страницMonitoring Sulfide-Oxidizing Biofilm Activity On Cement Surfaces Using Non-Invasive Self-Referencing MicrosensorskhoagleОценок пока нет

- Generating Surface Crack PatternsДокумент11 страницGenerating Surface Crack PatternskhoagleОценок пока нет

- Hammer CrusherДокумент4 страницыHammer CrusherkhoagleОценок пока нет

- Electric Mortor For Ball MillДокумент2 страницыElectric Mortor For Ball MillkhoagleОценок пока нет

- Choosing The Right Motors For Your Mills: Alex Doll and Derek BarrattДокумент16 страницChoosing The Right Motors For Your Mills: Alex Doll and Derek Barrattavca65Оценок пока нет

- Optimisation of The Rotary KilnДокумент34 страницыOptimisation of The Rotary KilnSampathkumar Mtech100% (3)

- Airflex Grinding MillsДокумент6 страницAirflex Grinding MillskhoagleОценок пока нет

- Comparison Between Currently Applied Grinding TechnologiesДокумент28 страницComparison Between Currently Applied Grinding TechnologiesSai Sricharan Reddy100% (3)

- United States Patent (191: Andersen Et A1Документ5 страницUnited States Patent (191: Andersen Et A1khoagleОценок пока нет

- Properties of Metakaolin Geopolymer Hardened Paste Prepared by High-Pressure CompactionДокумент8 страницProperties of Metakaolin Geopolymer Hardened Paste Prepared by High-Pressure CompactionkhoagleОценок пока нет

- CA501Документ614 страницCA501Ignacio AntonioОценок пока нет

- FAG-Jaw Crusher BearingsДокумент38 страницFAG-Jaw Crusher BearingsJinto A J100% (2)

- Phu Luc 3Документ2 страницыPhu Luc 3khoagleОценок пока нет

- United States Patent (191: Andersen Et A1Документ5 страницUnited States Patent (191: Andersen Et A1khoagleОценок пока нет

- Electrostatic Precipitator - Mechanical DescriptionДокумент19 страницElectrostatic Precipitator - Mechanical Descriptionhozipek5599Оценок пока нет

- 1Документ6 страниц1basanth_712982Оценок пока нет

- Effect of Porosity On The Absorbed, Reemitted and Transmitted Light by A Geopolymer Metakaolin BaseДокумент4 страницыEffect of Porosity On The Absorbed, Reemitted and Transmitted Light by A Geopolymer Metakaolin BasekhoagleОценок пока нет

- Effect of Curing Temperature On The Development of Hard Structure of Metakaolin-Based GeopolymerДокумент8 страницEffect of Curing Temperature On The Development of Hard Structure of Metakaolin-Based GeopolymerkhoagleОценок пока нет

- PaulingДокумент4 страницыPaulingkhoagleОценок пока нет

- PREHEATER OptimizationДокумент2 страницыPREHEATER OptimizationsaeedhoseiniОценок пока нет

- ConvertДокумент8 страницConvertkhoagleОценок пока нет

- NDT NLU Detection Micro Cracks ConcreteДокумент7 страницNDT NLU Detection Micro Cracks ConcreteElango PaulchamyОценок пока нет

- Pauling RulesДокумент5 страницPauling RuleskhoagleОценок пока нет

- Calcium Carbonate Precipitation by Different Bacterial StrainsДокумент14 страницCalcium Carbonate Precipitation by Different Bacterial StrainskhoagleОценок пока нет

- Times and TidesДокумент3 страницыTimes and Tidesapi-81413736Оценок пока нет

- Lecture Note Ch-5 GVFДокумент27 страницLecture Note Ch-5 GVFyeshi janexoОценок пока нет

- Shrinkage Compensating Admixtures by Sunanda CoatingsДокумент2 страницыShrinkage Compensating Admixtures by Sunanda Coatingss.skumar10% (1)

- Book Review of Scott Barry Kaufman's Book Ungifted by Todd StarkДокумент6 страницBook Review of Scott Barry Kaufman's Book Ungifted by Todd StarkTodd Ian Stark100% (1)

- Human-Environment InteractionДокумент3 страницыHuman-Environment Interactionapi-299100358Оценок пока нет

- Kat-SL Enw PDFДокумент34 страницыKat-SL Enw PDFAlanAvtoОценок пока нет

- Unit - 4 FoundationsДокумент21 страницаUnit - 4 FoundationsTARANATH S DОценок пока нет

- Population Genetics and EvolutionДокумент19 страницPopulation Genetics and EvolutionLorenz Moises EnrickОценок пока нет

- Case Study of Micro Hydro Power Plant PDFДокумент79 страницCase Study of Micro Hydro Power Plant PDFMuhammad Ali100% (1)

- Bird Sanctuaries in India: Dr. Gaurav GargДокумент23 страницыBird Sanctuaries in India: Dr. Gaurav GargShubham ChaurasiaОценок пока нет

- Nov 2021 Notes From PresidentДокумент4 страницыNov 2021 Notes From Presidentapi-390529985Оценок пока нет

- Unit 2Документ5 страницUnit 2Jyoti SinghОценок пока нет

- API 571 Part 1Документ20 страницAPI 571 Part 1Bashu Poudel100% (4)

- Ecz Questions On ForestryДокумент6 страницEcz Questions On Forestrysydneymazuba2024Оценок пока нет

- Safe Work Method Statement - Formwork and ConcretingДокумент8 страницSafe Work Method Statement - Formwork and ConcretingAnonymous gmNTrHsОценок пока нет

- Personal and Professional Development Module 1 Bsoa 2CДокумент4 страницыPersonal and Professional Development Module 1 Bsoa 2CYram GambzОценок пока нет

- 4N252Документ8 страниц4N252Taumar MoraisОценок пока нет

- Rani Channamma University, Belgaum Question Papers of Different Subjects-1 PDFДокумент250 страницRani Channamma University, Belgaum Question Papers of Different Subjects-1 PDFmani_bushanОценок пока нет

- Fluval Manual 082002Документ32 страницыFluval Manual 082002datashifterОценок пока нет

- Forest School Activites One 1magic WandДокумент2 страницыForest School Activites One 1magic Wandgggabi100% (2)

- NGC2012 ProceedingsДокумент192 страницыNGC2012 ProceedingsMuh Darmawan BasokaОценок пока нет

- Monitoring Ecological ChangeДокумент411 страницMonitoring Ecological ChangeSylvain O' Marinier75% (4)

- Process Control SpinningДокумент25 страницProcess Control SpinningNessre Zeine100% (2)

- Plummer Block DskatkasndfmДокумент30 страницPlummer Block DskatkasndfmVivek AradhyaОценок пока нет

- Corus Prevention of Corrosion On Structural Steelwork PDFДокумент28 страницCorus Prevention of Corrosion On Structural Steelwork PDFvonipkoОценок пока нет

- The Story of The Aral Sea: Reading ComprehensionДокумент2 страницыThe Story of The Aral Sea: Reading ComprehensionGreceanu AlinaОценок пока нет