Академический Документы

Профессиональный Документы

Культура Документы

Technical Data Sheet BD 004 Rev 4

Загружено:

debu1985Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Technical Data Sheet BD 004 Rev 4

Загружено:

debu1985Авторское право:

Доступные форматы

LAHMEYER INTERNATIONAL (INDIA) PVT. LTD.

CONSULTING ENGINEERS, INDIA

THIS APPROVAL STATUS SHALL NOT RELIEVE THE CONTRACTOR

FROM HIS CONTRACTUAL OBLIGATIONS.

STATUS

Approved

Approved subject to incorporation of comment/modifications as noted.

Resubmit revised drgs./docs after incorporating the comment

Not approved. Resubmit revised drgs/ Docs. Incorporating

comment/Modifications, as noted, for approval.

Date:22.05.12

04.07.2012

4A

For Information (with comments)

4B

For Information (without comments)

Transmittal

TransmittalRef:

RefLII/11119/CPL/404/037

: LII/11041/PLL/419/827

UNIQUE INDUSTRIAL HANDLERS PVT LTD

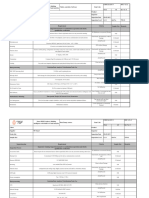

TECHNICALDATASHEETFOR85/25TTGHALLEOTCRANE

SLNo Description

Unit

Data

1.0

GENERAL

1.1

Manufacturer

UniqueIndustrialHandlersPvt.Ltd

1.2

Type/Model

DoubleGirderConstructionBox

typeEOTCrane

1.3

Quantity

Two(2)

1.4

Designaccordingtostandardservice

class/loadclass

OverallClassM5(ElectM7)asper

IS:31771999

1.5

SafeWorkingLoadcarryingcapacity

(SWL)

ForMainHoist

85

ForAuxiliaryHoist

25

B

1.6

Span(RailtoRailCentreLine)

25.492

1.7

HighestPositionofHook

MH:24.1AH:24.6

1.8

Lowestpositionofhook

MH:0.00AH:()3.5

1.9

TotalLiftprovided

MH:24.1AH:28.1

1.10

Operatingfloorelevation

12.6

1.11

Deflectionformaingirderwithload

atcentre(SWL+Crabweightwithout

consideringImpactFactor)

SPAN/900

2.0

SPEEDS

2.1

LongTravellingspeed

Normal

m/min

15

Creep

m/min

1.5

2.2

CrossTravellingspeed

Normal

m/min

10

Creep

m/min

1.0

2.3

HoistingSpeedMH

Normal

m/min

2.0

Creep

m/min

0.2

Sheet 2 of 9

UNIQUE INDUSTRIAL HANDLERS PVT LTD

2.4

HoistingSpeedAH.

Normal

m/min

5.0

Creep

m/min

0.5

3.0

ACCELERATION

3.1

CrossTravel

cm/sec2

3.2

LongTravel

cm/sec2

3.3

Location(Indoor/Outdoor)

Indoor

3.4

Clearancesandhookapproaches,as

pertender(ifno,specify)

ReferGAdrawingno.

BD/004/01/00.00&

BD/004/02/00.00

3.5

Typeofcontrolproposed

Fromopentypecabinthrough

MasterController&fromfloor

throughmovablePBPendantfor

Aandfromopentypecabin

throughMasterController&Radio

RemoteControlforcraneB

3.6

GantryRailSize

105Lbs/yd

4.0

CONSTRUCTIONALFEATURES

4.1

Weightofcompletecraneunladen

72

4.2

Weightoftrolleyunladen

23.5

4.3

WeightofBogie

1.0

4.4

Weightofgirder

15.5(includingCTRail)

4.5

Maximumwheelloadw/oimpact

32

5.0

HOISTINGSYSTEM

5.1

Rope

5.1.1

Ropediameter

5.1.2

Ropeconstruction

6x36

5.1.3

Ropequality(material)

Steelcore

5.1.4

RopeStrength

Kgf/mm2

200

5.1.5

WireRopeconformsto

IS:2266

5.1.6

BreakingStrength

72.9

5.1.7

NumberofRopefalls

mm

MH:32AH:18

23.1

Sheet 3 of 9

UNIQUE INDUSTRIAL HANDLERS PVT LTD

Formainhoist

ForAuxiliaryhoist

5.1.8

FactorofSafety

5.25

5.2

RopeDrum(mainhoist/aux.hoist)

5.2.1

Drumdiameterandlength

5.2.2

Drummaterial

5.2.3

Whetherstressrelieved

5.2.4

Bearingtype/make

5.2.5

Life

5.3

mm

MH:650diax4000Long

AH:500diax3600Long

SeamlessPipeASTM106GrBor

FabricatedFe410wtoIS:2062GrB

Yes/No

Yes,iffabricatedshellused.

AntifrictionRollerorBallbearing

Hrs

Min10000

Hook(mainhoist/auxhoist)

5.3.1

Hooktype

MH:Ramshorn

AH:PlainShankCtype

5.3.2

Hookmaterial

MH:Cl2IS1875

AH:Cl2GradeL,IS1875

5.3.3

ISStandardforhook

5.3.4

Safetylatchesprovided(bothmain

andaux.hook)

Yes/No

Yes

5.3.5

Swivellockpin(bothmainandaux.

hook)

Yes/No

Yes

5.4

Sheaves(main/aux.hoist)

5.4.1

Lowersheavediameter

5.4.2

Lowersheavematerial

5.4.3

No.ofSheavesforMH&AH

(Top/Bottom)

5.4.4

No.ofEq.sheavesforMH&AH

5.4.5

Equalisingsheavediameter

5.4.6

Equilisingsheavematerial

mm

D

IS15560AH

710

400

CSGr280520,IS1030/Fe410IS

2062

4/2

1

mm

IS5749MH

500

250

CSGr280520,IS1030/Fe410IS

2062

Sheet 4 of 9

UNIQUE INDUSTRIAL HANDLERS PVT LTD

5.5

HoistBrake(bothmainandaux)

5.5.1

Type

DCEM

EHT

DCEM

EHT

5.5.2

Make

BCH

SOC/Eq

BCH

SOC/Eq

5.5.3

Size

mm

300

300

300

250

5.5.4

Torque

Kgm

76

62

76

35

5.5.5

CoefficientofReserve

1.5

1.5

1.5

1.5

5.5.6

No.ofbrakes

Qty

5.5.7

BrakesareFailsafe

5.6

BrakeDrum(bothmainandaux)

5.6.1

5.6.2

MainHoist

AuxHoist

YES

Material

CastSteel/ForgedSteel/Rolled

Width

510mmgreaterthanShoewidth

LimitSwitch

5.7.1

Numbers

5.7.2

Type

PerHoist1no.Rotary+1no.

Gravitytype

5.7.3

Make

SOC/Omega/EMM

6.0

CROSSTRAVELMOVEMENT

6.1

CTBrake

6.2

Type

DCElectromagnetic+Electro

HydraulicThrustortype

6.3

Make

SOC/Omega/EMM/BCH

6.4

Size

mm

160

6.5

Torque

Kgm

DCEM:7.5EHT:9.00

6.6

No.ofbrakes

Qty

1noeach

6.7

BrakeDrum

6.7.1

Material

CastSteel/ForgedSteel/Rolled

6.7.2

Width

510mmgreaterthanShoewidth

6.8

Couplingtype

6.8.1

Gearboxinput

Flexiblegearedtype

6.8.2

Gearboxoutput

Drumgearedjoint

6.8.3

GearboxCasing

FabricatedFe410wIS:2062

6.8.4

Materialofgears

CastSteel/En9/C55Mn75

5.7

Sheet 5 of 9

UNIQUE INDUSTRIAL HANDLERS PVT LTD

6.5.5

Hardnessforgear

Min217BHN

6.8.6

Materialofpinion

En19/En24

6.8.7

Hardnessforpinion

Min266BHN

6.8.8

Differenceinhardnessforgear&

pinion

Min20BHN

6.8.9

Typeofgears/pinion

Helical/spur

6.8.10 No.ofGearStages

6.8.11

Lubrication

Splash

Wheels

6.9.1

Standardconformsto

3177:99

6.9.2

Materials

C55Mn75asperIS1570withnot

morethan0.06%ofSorP

6.9.3

Hardness

BHN

Min300

6.9.4

Type

DoubleFlangedtype

6.9.5

Diameter

mm

400

6.9.6

Wheelbearingtype/make

Antifrictionsphericalrollertype

2nos2waylevertype

6.10.2 Make

6.10.3 TypeofBuffers

Hydraulic

6.10.4 Numberofdrivenwheels

6.10.5 Numberoftotalwheels

7.0

LONGTRAVELMOVEMENT

7.1

Endcarriagelength

ReferGAdrawingBD/004/01/00.00

7.2

GearBoxinputSideCoupling

FlexibleGearedtype

7.3

GearBoxoutputSideCoupling

7.4

GearBoxcasing

7.5

Materialofgears

CastSteel/En9/C55Mn75

7.6

Materialofpinion

En19/En24

7.7

Typeofgears/pinion

Helical/Spur

7.8

LTBrakes

6.9

6.10

LimitSwitches

6.10.1 Number&Type

SOC/Omega/EMM

FabricatedFe410wIS:2062

Sheet 6 of 9

UNIQUE INDUSTRIAL HANDLERS PVT LTD

7.8.1

Type

DCElectromagnetic+Electro

HydraulicThrustortype

7.8.2

Make

SOC/Omega/EMM/BCH

7.8.3

Size

mm

160

7.8.4

Torque

Kgm

DCEM:7.5EHT:9.00

7.8.5

No.ofbrakes

7.9

Wheels

7.9.1

Materials

C55Mn75asperIS1570withnot

morethan0.06%ofSorP

7.9.2

Hardness

BHN

7.9.3

Type

7.9.4

Diameter

7.9.5

Wheelbearingtype/make

Antifrictionsphericalrollertype

7.10

LimitSwitches

7.10.1 Number&Type

2nos2waylevertype

7.10.2 Make

SOC/Omega/EMM

7.10.3 TypeofBuffers

Spring

7.10.4 Numberofdrivenwheels

7.10.5 Numberoftotalwheels

8.0

CraneLubrication

CentralizedGrease

9.0

MOTORMAIN

(CREEPSPEEDBYVVVFDRIVES)

Main

Hoist

9.1

GENERAL

9.1.1

Make

9.1.2

Type

SC

9.1.3

Number

9.1.4

Rating(consumedkw)

9.1.5

Qty

mm

2nosDC+2nosEHT+2nosEHT

ParkingBrakes

Min320

DoubleFlangedtype

400

Bridge

Travel

Trolley

Travel

SC

SC

SC

46.32

34.21

3.663

3.322

Rating:kwat50oC

47

39

4.6

4.6

9.1.6

Rating

40%CDF

9.1.7

PermissibleStarts/hr

150st/hr

Aux.

Hoist

KEC/CGL/ABB

Sheet 7 of 9

UNIQUE INDUSTRIAL HANDLERS PVT LTD

9.1.8

SuitableforInverterDuty

Yes

9.1.9

ClassofProtection/Enclosure/

ClassofInsulation

IP55/TEFC/ClassFwithtemp.

riselimitedtoclassB

9.1.10 MotorRPM

975

975

935

9.1.11 Voltagephase,frequency

9.1.12 Ratedcurrent

Aspermotordatasheet

9.1.13 Ratedtorqueinkg.m

46.90

i)Starting

ii)Braking

935

415V(+/10%,3Ph,50z(+/5%,

combinedVolt&frequency

variationof10%

38.92

4.79

4.79

150%ofratedtorque

150%ofratedtorque

9.1.14 10%marginormotorratings

considered

Yes

9.1.15 SpaceHeaters

Providedfor30KW&above.

9.2

CraneControl

9.2.1

Type

Fromopentypecabinthrough

MasterController&fromfloor

throughmovablePBPendantfor

Aandfromopentypecabin

throughMasterController&Radio

RemoteControlforcraneB

9.2.2

No.ofspeednotches

(MH/AH/CT/LT)

9.2.3

InchingSpeedControl

ThroughVVVFDrivearrangement

9.2.4

Type

Cabin+Pendant(forCraneA)And

Cabin+RadioRemote(forCraneB)

9.2.5

Inchingspeedin%fullloadspeed

10%

9.2.6

CT

Flexibletrailingcable

9.2.7

DSL

PVCcoppershrouded(bothPhases

&neutralbusbarsmadeofcopper

withnecessaryshrouding)forbay

lengthof169.5m

9.2.8

Detailedwriteupfurnishedon

inchingspeedcontrol

9.2.9

Individualcontrolpanelfurnished

Shallbefurnishedalongwith

Electricaldrawings&documents

Yes

Sheet 8 of 9

UNIQUE INDUSTRIAL HANDLERS PVT LTD

onforallcranemotors?

9.2.10 Detailedwriteuponspeedcontrol

furnished?

Shallbefurnishedalongwith

Electricaldrawings&documents

10.0

Operatorscabin

10.1

Mastercontrollerforallmotions

Provided

10.1

CabinSize

2.5X2X2(clearheight)

10.2

Emergencystoppushbutton

Provided

10.3

Switchesforlightingfixtures

Provided

10.4

FireExtinguisher

3KgCO2type(1no.incabin&3

nos.onbridge)

10.5

Insulatingmat&swingwaytype

operatorschair

Provided

10.6

Cabinlight

Provided

10.7

Cabinfan

Provided

10.8

Hooter

Provided

10.9

Annunciation

Provided

10.10 Ventilationfanwithguard

Provided

10.11 Maintenancetools&tackles

Provided

11

Painting

Asperpaintingprocedure

12

LoadTest&overloadtestat125%

SWLatworks&atsite

YES

13

MinimumThicknessofmetal

Forloadcarryingmembers,the

component,plates,bars,angles&

otherrolledsectionswillbe8mm

thick.Fortubeshavingbothends

sealed,themin.thicknesswillbe

4.9m.Forunsealedtubes,themin.

thicknesswillbe8mm.The

chequeredplates,min8mmthick.

14

Slendernessratio

Max120forcompressionmembers

&max.180forotherloadcarrying

members

15

Maintenancecageprovided

YES

Sheet 9 of 9

Вам также может понравиться

- SKH3-DS-20-007A-A4 Data Sheet Overhead Crane REV 0.1Документ31 страницаSKH3-DS-20-007A-A4 Data Sheet Overhead Crane REV 0.1kebarongan12Оценок пока нет

- PDF Created With Pdffactory Pro Trial Version: Pxd-767-Cal-02 23 MMДокумент24 страницыPDF Created With Pdffactory Pro Trial Version: Pxd-767-Cal-02 23 MMSISIR KR BARMAN0% (1)

- Valve and Speciality ListДокумент4 страницыValve and Speciality Listbandithaguru6338Оценок пока нет

- Tank Datasheet - CS-8000KL - RAДокумент1 страницаTank Datasheet - CS-8000KL - RASumantrra ChattopadhyayОценок пока нет

- Arocity-Water BOQ 2010Документ23 страницыArocity-Water BOQ 2010Hemn Rafiq TofiqОценок пока нет

- New Gravity Flow CalculationДокумент4 страницыNew Gravity Flow CalculationShiv GandhiОценок пока нет

- Project Report - THDCILДокумент36 страницProject Report - THDCILMukesh VermaОценок пока нет

- S.no Description Data For ApprovalДокумент2 страницыS.no Description Data For ApprovalVenkatОценок пока нет

- 8 Penstock BFV and AccessoriesДокумент6 страниц8 Penstock BFV and Accessoriespavankumar001Оценок пока нет

- Al-Khobar Seawater Reverse Osmosis 2 Desalination PlantДокумент4 страницыAl-Khobar Seawater Reverse Osmosis 2 Desalination PlantABAID ULLAHОценок пока нет

- Vol 2 Khep Rmu e MДокумент144 страницыVol 2 Khep Rmu e MMuhammed AnasОценок пока нет

- Pump Horsepower CalculationДокумент4 страницыPump Horsepower CalculationAbigail RuedaОценок пока нет

- Annexure - I Comments On Eot Cranes in Msds (Package - 087) (Make - Century Cranes)Документ2 страницыAnnexure - I Comments On Eot Cranes in Msds (Package - 087) (Make - Century Cranes)eagles1109Оценок пока нет

- 10070-C63-XX-XXXX-ENB-0001-024 RTP03M 44MPS-Old PoleДокумент1 страница10070-C63-XX-XXXX-ENB-0001-024 RTP03M 44MPS-Old PoleKrishna KnsОценок пока нет

- Static MixerДокумент1 страницаStatic Mixeraras aliОценок пока нет

- Dykewall CalculationДокумент4 страницыDykewall CalculationVipul GandhiОценок пока нет

- Check List - Water FillingДокумент1 страницаCheck List - Water Fillingsumit1975Оценок пока нет

- Vol 1 Khep Rmu e MДокумент45 страницVol 1 Khep Rmu e MMuhammed AnasОценок пока нет

- Is 1742 1983Документ55 страницIs 1742 1983Shobhit AcharyaОценок пока нет

- Specification or EOTДокумент8 страницSpecification or EOTMurthy NLNОценок пока нет

- BunkerHose DatasheetДокумент2 страницыBunkerHose Datasheetmohit_mg100% (1)

- Wilo Mather and Platt Pumps Pvt. LTD: Technical DatasheetДокумент3 страницыWilo Mather and Platt Pumps Pvt. LTD: Technical DatasheetViral ParmarОценок пока нет

- Gantry Cranes - Material Processing and Handling EquipmentДокумент49 страницGantry Cranes - Material Processing and Handling EquipmentGogyОценок пока нет

- Calc-Plum Fire IrtankДокумент6 страницCalc-Plum Fire IrtankAmro Metwally El HendawyОценок пока нет

- Void 004-Permeate Water Storage TankДокумент55 страницVoid 004-Permeate Water Storage TankUday UdmaleОценок пока нет

- 08572-Trht-Ms-Ppfm003-A06-003 - e General Arrangement Drawing Filtered Raw Water Storage TankДокумент3 страницы08572-Trht-Ms-Ppfm003-A06-003 - e General Arrangement Drawing Filtered Raw Water Storage TankSamer ArousОценок пока нет

- Approved: Pöyry EnergyДокумент2 страницыApproved: Pöyry Energytvpham123Оценок пока нет

- F0512 Manhole DatasheetДокумент2 страницыF0512 Manhole DatasheetAbrar HussainОценок пока нет

- Sluice Gates ExportДокумент20 страницSluice Gates ExportsaishankarlОценок пока нет

- Design of Incinerator Plant For Vasai-Virar RegionДокумент4 страницыDesign of Incinerator Plant For Vasai-Virar RegionVIVA-TECH IJRIОценок пока нет

- AEL Comments On STP Punch PointsДокумент14 страницAEL Comments On STP Punch PointsEphrem GizachewОценок пока нет

- Mechanical CommentsДокумент2 страницыMechanical CommentsMichael FaridОценок пока нет

- Perhitungan Anaerobik Digester, Floating Dome, Fixed DomeДокумент51 страницаPerhitungan Anaerobik Digester, Floating Dome, Fixed DomesehonoОценок пока нет

- Information of Terminated Work of M/s Gurinder Singh Contractor Kandi Canal Circle HoshiarpurДокумент8 страницInformation of Terminated Work of M/s Gurinder Singh Contractor Kandi Canal Circle HoshiarpurManjit SinghОценок пока нет

- Tender 43 Vol IIofIIДокумент58 страницTender 43 Vol IIofIIVeena S VОценок пока нет

- Motorised Valve: Instrument Datasheet Tag NoДокумент1 страницаMotorised Valve: Instrument Datasheet Tag Nokrishna kumarОценок пока нет

- VT4-YT01-P1LAC-120004 - RE - Technical Data Sheet For Main BFP& BFBPДокумент7 страницVT4-YT01-P1LAC-120004 - RE - Technical Data Sheet For Main BFP& BFBPNguyễn Hữu LượngОценок пока нет

- AL Hashemiah International Contracting Co.Документ3 страницыAL Hashemiah International Contracting Co.Ahmed SakrОценок пока нет

- Technical - Query - JIND - 2april2020 (Ed. LAPI)Документ1 страницаTechnical - Query - JIND - 2april2020 (Ed. LAPI)Nyayu SitimayaОценок пока нет

- Special Support in PipingДокумент6 страницSpecial Support in PipingAKHIL JOSEPHОценок пока нет

- 6261 - 4803 - 029 - Attachment-20 - Mandatory Spare Part List - XX PDFДокумент34 страницы6261 - 4803 - 029 - Attachment-20 - Mandatory Spare Part List - XX PDFharmlesdragon100% (1)

- Pipe Weight CalculationДокумент1 страницаPipe Weight CalculationtnasrevidОценок пока нет

- MOV EIL Spec 2 PDFДокумент134 страницыMOV EIL Spec 2 PDFpl_arunachalam79Оценок пока нет

- 00000-JDS-014 (Pressure Safety Valve) Rev 0Документ4 страницы00000-JDS-014 (Pressure Safety Valve) Rev 0sithulibra100% (1)

- 903-10004-SPC-M-001 Piping Material SpecificationДокумент15 страниц903-10004-SPC-M-001 Piping Material SpecificationChitradeep FalguniyaОценок пока нет

- Design SubmissionsДокумент46 страницDesign SubmissionsthisulaОценок пока нет

- Air Release VacuumДокумент7 страницAir Release VacuumsudjonoОценок пока нет

- 08572-Trht-Ms-Ppfm003-A06-001 - D General Arrangement Drawing Fire Water Storage TankДокумент3 страницы08572-Trht-Ms-Ppfm003-A06-001 - D General Arrangement Drawing Fire Water Storage TankSamer ArousОценок пока нет

- Syn CompressorДокумент23 страницыSyn CompressorManish GautamОценок пока нет

- Fuel Oil Dyke Size Calculation-R0Документ3 страницыFuel Oil Dyke Size Calculation-R0Amul AmnajeОценок пока нет

- Spreaer Beam&Lifting Line Beam p3Документ2 страницыSpreaer Beam&Lifting Line Beam p3Sabrang LorОценок пока нет

- 1639-U-008 R02 Data Sheet 16 Dec 18Документ16 страниц1639-U-008 R02 Data Sheet 16 Dec 18HEMANTОценок пока нет

- Calcs 4Документ19 страницCalcs 4Syariful Maliki NejstaršíОценок пока нет

- Asme Vert FilterДокумент27 страницAsme Vert FilterChaitanya Sai TОценок пока нет

- Epcc-04 Package - Delayed Coker Unit (Dcu) With Unsaturated LPG Treating UnitДокумент7 страницEpcc-04 Package - Delayed Coker Unit (Dcu) With Unsaturated LPG Treating UnitKunalОценок пока нет

- M.P. Projects STP Master Drawing List Sl. No. Drg. No - Drg. TitleДокумент7 страницM.P. Projects STP Master Drawing List Sl. No. Drg. No - Drg. TitleShubhankar SharmaОценок пока нет

- Bid Document of 4th B LiftДокумент670 страницBid Document of 4th B LiftSuresh Kumar100% (1)

- Ins PT003Документ1 страницаIns PT003faisal hajjОценок пока нет

- (EIFS) WMS-A-041 R.3 and ITP-A-041 R.3 For Field Installation of STO VENTEC System in DA and AG - RequestedДокумент58 страниц(EIFS) WMS-A-041 R.3 and ITP-A-041 R.3 For Field Installation of STO VENTEC System in DA and AG - RequestedLito VasquezОценок пока нет

- MSB SubmissionДокумент138 страницMSB SubmissionNatasha de SilvaОценок пока нет

- 02 111 AAP Foam Gear Pump PDFДокумент3 страницы02 111 AAP Foam Gear Pump PDFdebu1985Оценок пока нет

- CT Buffer InstallationДокумент1 страницаCT Buffer Installationdebu1985Оценок пока нет

- Technical Data: FoampakДокумент16 страницTechnical Data: Foampakdebu1985Оценок пока нет

- Remote Control Monitor: 1. General DescriptionДокумент3 страницыRemote Control Monitor: 1. General Descriptiondebu1985Оценок пока нет

- CT Buffer InstallationДокумент1 страницаCT Buffer Installationdebu1985Оценок пока нет

- CT Buffer InstallationДокумент1 страницаCT Buffer Installationdebu1985Оценок пока нет

- Inline Balance Pressure Foam Proportioner: HD Fire Protect Pvt. Ltd. Technical DataДокумент10 страницInline Balance Pressure Foam Proportioner: HD Fire Protect Pvt. Ltd. Technical Datadebu1985Оценок пока нет

- Created by - Vimal Fire Controls Pvt. LTDДокумент18 страницCreated by - Vimal Fire Controls Pvt. LTDdebu1985Оценок пока нет

- Oil Water SeparationДокумент2 страницыOil Water Separationdebu1985Оценок пока нет

- ISO 4301-5 CranesДокумент9 страницISO 4301-5 CranesMazhar Hussain75% (4)

- Painting procedure-BD-004 Rev. B PDFДокумент3 страницыPainting procedure-BD-004 Rev. B PDFdebu1985Оценок пока нет

- TECHNICAL DATA SHEET-BD-004-Rev 4 PDFДокумент9 страницTECHNICAL DATA SHEET-BD-004-Rev 4 PDFdebu1985Оценок пока нет

- Purpose of High Impedance Differential ProtectionДокумент1 страницаPurpose of High Impedance Differential Protectiondebu1985Оценок пока нет

- Pipe Chart PDFДокумент2 страницыPipe Chart PDFCarlos Rivera0% (1)

- Ee Gate'13Документ16 страницEe Gate'13menilanjan89nLОценок пока нет

- Gate 1991 EeДокумент15 страницGate 1991 EeParayatham ManasaОценок пока нет

- Flap Gate - Type - 3 (Fg-19) - Sht-1Документ1 страницаFlap Gate - Type - 3 (Fg-19) - Sht-1debu1985Оценок пока нет

- Requirement of Impact TestingДокумент1 страницаRequirement of Impact Testingdebu1985Оценок пока нет

- PDS of Flow MeterДокумент1 страницаPDS of Flow Meterdebu1985Оценок пока нет

- CHP PDFДокумент49 страницCHP PDFdebu1985Оценок пока нет

- PG ScheduleДокумент1 страницаPG Scheduledebu1985Оценок пока нет

- GA & Rebar Detail of StaircaseДокумент1 страницаGA & Rebar Detail of Staircasedebu1985Оценок пока нет

- Pipe Chart PDFДокумент2 страницыPipe Chart PDFCarlos Rivera0% (1)

- Eqpt ListДокумент19 страницEqpt Listdebu1985Оценок пока нет

- 43-6404 - Oil Spill PreventionДокумент2 страницы43-6404 - Oil Spill Preventiondebu1985Оценок пока нет

- Anchor BoltДокумент1 страницаAnchor Boltdebu1985Оценок пока нет

- 43-4002 - Fuel Oil SupplyДокумент4 страницы43-4002 - Fuel Oil Supplydebu1985Оценок пока нет

- GEA Ecoflex China Co., LTD PDFДокумент49 страницGEA Ecoflex China Co., LTD PDFdebu1985100% (1)

- 62-2610 - Oil PumpsДокумент3 страницы62-2610 - Oil Pumpsdebu1985Оценок пока нет

- 62-3602 - Field Erected Fuel Oil Storage TanksДокумент8 страниц62-3602 - Field Erected Fuel Oil Storage Tanksdebu1985Оценок пока нет

- 3-CHAPTER-1 - Edited v1Документ32 страницы3-CHAPTER-1 - Edited v1Michael Jaye RiblezaОценок пока нет

- Jurnal Direct and Indirect Pulp CappingДокумент9 страницJurnal Direct and Indirect Pulp Cappingninis anisaОценок пока нет

- Interceptor Specifications FinalДокумент7 страницInterceptor Specifications FinalAchint VermaОценок пока нет

- YS1700 Drum Level ControlДокумент2 страницыYS1700 Drum Level ControlIdriss BarçaОценок пока нет

- Quality Assurance Plan-75FДокумент3 страницыQuality Assurance Plan-75Fmohamad chaudhariОценок пока нет

- HSG 2023 KeyДокумент36 страницHSG 2023 Keyle827010Оценок пока нет

- Corporate Members List Iei Mysore Local CentreДокумент296 страницCorporate Members List Iei Mysore Local CentreNagarjun GowdaОценок пока нет

- SST Vs BBTДокумент7 страницSST Vs BBTFlaxkikare100% (1)

- EIL 6-51-0051-Rev 06 - 1.1kv-Xlpe - Dimension Cat - B Armour-BbpДокумент2 страницыEIL 6-51-0051-Rev 06 - 1.1kv-Xlpe - Dimension Cat - B Armour-BbpShubham BaderiyaОценок пока нет

- Vicente BSC2-4 WhoamiДокумент3 страницыVicente BSC2-4 WhoamiVethinaVirayОценок пока нет

- Excel Lesson 5 QuizДокумент5 страницExcel Lesson 5 Quizdeep72Оценок пока нет

- Fabric DefectsДокумент30 страницFabric Defectsaparna_ftОценок пока нет

- Using Ms-Dos 6.22Документ1 053 страницыUsing Ms-Dos 6.22lorimer78100% (3)

- How To Build Yam Chips Production PlantДокумент11 страницHow To Build Yam Chips Production PlantVu Thieu TuanОценок пока нет

- Opening Checklist: Duties: Monday Tuesday Wednesday Thursday Friday Saturday SundayДокумент3 страницыOpening Checklist: Duties: Monday Tuesday Wednesday Thursday Friday Saturday SundayAlven BlancoОценок пока нет

- Quality Assurance Plan - CivilДокумент11 страницQuality Assurance Plan - CivilDeviPrasadNathОценок пока нет

- 42ld340h Commercial Mode Setup Guide PDFДокумент59 страниц42ld340h Commercial Mode Setup Guide PDFGanesh BabuОценок пока нет

- Mastering American EnglishДокумент120 страницMastering American Englishmarharnwe80% (10)

- Refrigerador de Vacunas Vesfrost MKF 074Документ5 страницRefrigerador de Vacunas Vesfrost MKF 074Brevas CuchoОценок пока нет

- AJ IntroductionДокумент31 страницаAJ IntroductiontrollergamehuydkОценок пока нет

- Demand, Supply, and Market EquilibriumДокумент15 страницDemand, Supply, and Market EquilibriumAnonymous HBQ86kОценок пока нет

- 2015 Grade 4 English HL Test MemoДокумент5 страниц2015 Grade 4 English HL Test MemorosinaОценок пока нет

- Glory in The Cross - Holy Thursday - Schutte PDFДокумент1 страницаGlory in The Cross - Holy Thursday - Schutte PDFsharon0murphyОценок пока нет

- 7540 Physics Question Paper 1 Jan 2011Документ20 страниц7540 Physics Question Paper 1 Jan 2011abdulhadii0% (1)

- Cryptocurrency Research PDFДокумент59 страницCryptocurrency Research PDFAnupriyaОценок пока нет

- Body Temperature PDFДокумент56 страницBody Temperature PDFBanupriya-Оценок пока нет

- ETSI EG 202 057-4 Speech Processing - Transmission and Quality Aspects (STQ) - Umbrales de CalidaДокумент34 страницыETSI EG 202 057-4 Speech Processing - Transmission and Quality Aspects (STQ) - Umbrales de Calidat3rdacОценок пока нет

- Sel027 PDFДокумент9 страницSel027 PDFSmart BiomedicalОценок пока нет

- Service M5X0G SMДокумент98 страницService M5X0G SMbiancocfОценок пока нет

- Ryff's Six-Factor Model of Psychological Well-BeingДокумент7 страницRyff's Six-Factor Model of Psychological Well-BeingYogi Sastrawan100% (1)