Академический Документы

Профессиональный Документы

Культура Документы

An Overview of PH Sensors Based On Iridium Oxide-Fabrication and Application

Загружено:

saeid59Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

An Overview of PH Sensors Based On Iridium Oxide-Fabrication and Application

Загружено:

saeid59Авторское право:

Доступные форматы

International Journal of Material Science Innovations (IJMSI) 1 (1): 62-72, 2013

ISSN xxxx-xxxx

Academic Research Online Publisher

Review Article

An overview of pH Sensors Based on Iridium Oxide: Fabrication and

Application

Saeid Kakooei*, Mokhtar Che Ismail, Bambang Ari-Wahjoedi

Centre for Corrosion Research, Department of Mechanical Engineering, Universiti Teknologi PETRONAS,

Tronoh31750, Malaysia

* Corresponding author. Tel.: +60174958196;

E-mail address: skakooei59@hotmail.com

ARTICLE INFO

Article history

Received:01Feb2013

Accepted:10Feb2013

Keywords:

pH Sensor;

Iridium Oxide;

Electrodeposition;

Sputtering;

Sensor Fabrication

Abstract

In recent years, there has been an increasing interest in the adoption of

emerging sensing technologies for instrumentation within a variety of

structural systems. Iridium oxide as an stable and interesting material for pH

sensor in variuse temperature and pressure was paid attention by a lot of

researchers. In this study an overview of different methods for fabrication of

IrO2 pH sensors and their application are presented.

Academic Research Online Publisher. All rights reserved.

1. Introduction

During the past decades IrO2 became a superior material for reference electrode[1, 2] and pH

measurements in different fields such as biological media [3, 4], food industry [5], nuclear

field [6, 7], and oil and gas industry [8-10]. Iridium oxide can provide a rapid and stable

response in different media because of its high conductivity and low temperature coefficient.

Potentiometric response of the Iridium oxide to pH is a function of transition effect between

two oxidation states Ir(III) oxide and Ir(IV) oxide, which can be shown as follow[11]:

Ir(IV)oxide + qH+ + ne-

Ir(III)oxide + rH2O

In 1996, Roe et al.[12] measured dissolved oxygen, pH, and ion currents on mild steel

corroded surface using three closely spaced microelectrodes. They proposed a real time

mapping of the pH distribution on the mild steel corroded surface.

62 | P a g e

Kakooei S. et al. / International Journal of Material Science Innovations (IJMSI) 1 (1): 62-72, 2013

Two properties of biocompatibility and corrosion resistance of iridium oxide electrodes are

noticeable [13]. This fact made iridium oxide electrodes as a potential candidate for

Microbial induced corrosion investigation. A crystal structure of stoichiometric iridium oxide

is shown in Figure 1.

Figure 1: Crystal structure of IrO2 [14]

The difference between IrOx pH sensor and traditional glass pH sensor is related to their

mechanism for pH measuring. Glass pH electrode depends on solution-phase activities of the

relevant electrode whereas IrOx is dependent on H+ activity and oxidation state of IrOx. The

proposed reaction at the anhydrous Iroquois electrode shown as[15]:

2IrO2 + 2H+ + 2e-

Ir2O3 + H2O

(1)

And for a hydrous IrOx electrode as follows reaction:

2[IrO2 (OH)22H2O]2- + 3H+ + 2e-

[Ir2O3(OH)33H2O]3- + 3H2O

(2)

Hence the Nernstian response slopes for electrodes prepared by different methods can range

between 59 and 88.5 mV/pH. Moreover, proposed Nernst equations are as follows:

E=E0 - 2.3RT/2F log[Ir2O3]/[IrO2]2[H+]2

(3)

and

E = E0 - 2.3RT/2F log[Ir2O3]/[IrO2]2[H+]3

(4)

3+

It be proposed that any variation in the Ir /Ir

4+

ratio, IrOx electrode preparation, IrOx

electrodes age, and deliberate exposure to redox agents such as Fe(CN)63-/4- have been shown

to affect the pH response [15, 16].

Cathodic storage charge capacities (CSCC) of the test samples will be calculated by

integrating the cathodic area in cyclic voltammograms. The CSCC data generally be used in

the characterization of neural stimulation electrodes [17-19], although in some research work

CSCC calculated like this is approximately equal to the amount of Ir 4+ on the substrate in thin

63 | P a g e

Kakooei S. et al. / International Journal of Material Science Innovations (IJMSI) 1 (1): 62-72, 2013

electrodeposited layers. The calculated area above-mentioned is presented by the CV of an

EIROF on Au in Figure 2 [20].

Fig. 2. CV of iridium oxide in PBS at 50 mV/s showing the area used to calculate the CSC of the film [20].

2- Iridium oxide pH sensor fabrication:

It is clear that preparation methods play the main role in the pH response of the iridium

oxide-based electrodes. Anhydrous iridium oxides were achieved by thermal oxidation or

sputtering Methods which showed pH response of 59 mV/pH, whereas iridium oxides

fabricated by electrochemically technique are predominantly hydrated iridium oxides such as

IrO24H2O, Ir(OH)42H2O which present a super-Nerntian response 90 mV/pH unit [21].

2-1. Solgel processes

Sol-gel method was used to fabricated IrO2 pH sensor on flexible substrate [22, 23]. Three

different groups of pH sensors fabricated by the sol-gel process indicated similar near superNernstian response, good reversibility, and similar response times, which show better

reproducibility and repeatability in this fabrication technique.

The sol-gel technique is well-known as a cheap method for advance material fabrication. Da

Silva et al.[24] used a polymeric precursor approach to fabricate a low-cost pH sensor with

substitution of IrOx by TiO2. The best result was related to 70 % (IrOx)-30% (TiO2).

64 | P a g e

Kakooei S. et al. / International Journal of Material Science Innovations (IJMSI) 1 (1): 62-72, 2013

The challenge in sol-gel method is related to the drying process, which led to creating cracks

in iridium oxide film due to its dehydration. This phenomenon can be decreased by using

proper additives.

2-2. Electrochemical or thermal oxidation of iridium and iridium salts

Song et al. [13] fabricated an Ir/IrO2 pH sensor by using the potentiodynamically cycling

method on an Ir electrode in 0.5 M H2SO4 aqueous solution at a 50 mV/s scan rate with

different exposure time ( 2, 4, 8, and 24 hr). According to Figure 3, they found that pH

sensor fabricated by 2-hr and 4-hr treatment showed more drift than those fabricated by 8-hr

and 24-hr treatment.

Fig 3. Stacked voltammograms of iridium potentiodynamically cycled between 0.25 VSCE and 1.27 VSCE at 50

mV/s for 2, 4, 8, and 24 hr in deaerated 0.5 M H2SO4 aqueous solution [13].

Song et al. investigated the effect of bisulfite and thiosulfate ions on the Ir/IrO 2 pH sensor.

The calibration of pH sensor significantly changed when exposed in solution test containing

aforementioned ions.

2-3. Sputtering

Sputtering method was used in most IrO2 film fabrication for neural stimulation electrods

[17, 25-27]. Kreider [28] in 1991 used sputtered iridium oxide as pH-sensing electrodes in

high-temperature high-pressure saline solutions. Sputtered iridium oxide films was fabricated

in mixed Argon and oxygen environment in a 1:l ratio at a total pressure of ~0.40 Pa. The

thickness of 0.5-0.7 m thick depositions were made primarily on alumina circuit board at

65 | P a g e

Kakooei S. et al. / International Journal of Material Science Innovations (IJMSI) 1 (1): 62-72, 2013

30-40 C and at 240 C. He found that with increasing exposure time in saline solutions, pH

sensitivity decreased at high temperature. The main disadvantage of sputtering method is

expensive price of its target price which is not also available for some rare material.

2-4. Anodic or cathodic electrodeposition

Yamanaka [29] proposed electrodeposition of iridium oxide for the first time for fabrication

of display device. His suggested solution was based on a complex of IrCl4 and oxalate

component. After that a lot of researcher improved this solution or used it as described by

Yamanaka [18, 30-32].

Ryynnen et al. for first time used atomic layer deposition (ALD) for iridium oxide (IrOx)

fabrication as the pH sensitive layer with an average sensitivity of -67 mV/pH at 22 C. They

could coat 110 nm IrOx layer on a glass substrate consists of 300 nm thick titanium

electrodes. Their pH sensor was able to detect pH in a range from pH 4 to pH 10 [33].

Various metals have been used as substrate for IrO2 coating such as Au, Pt, Ir, PtIr, stainless

steel,

tin-doped indium oxide (ITO) [29, 34, 35]. Marzouk [36] in a valuable work

investigated various substrate pure metals such as Au, Ag, Ti, Cu, Ni, W, Zr, and Co and

some alloys such as nickel-chrome, Hastelloy and stainless steel. The blue layer of deposit,

proper adhesion of deposit to surface, and stability of the cyclic voltammogram were the

most important factor for substrates comparing. Mayorga et al. [35, 37] described a simple

pH sensor fabrication through IrO2 electrodeposition on stainless steel substrate. The

fabricated sensor had fast response time and good repeatability.

Most of researchers followed original Yamanaka solution[29], although some others

attempted the modification of his solution[38, 39].

Marzouk approved that using (NH4)2[IrCl6] instead of IrCl4 was wrong since the solution did

not develop to dark greenish-blue color for up to 7 days at room temperature [36]. Marzouk

was successful to reduce the development time of solution from 3 days to 10 minutes by

heating the solution to 90 C. Petit et al. [38] replaced IrCl4 with K3IrCl6. The required time

for solution development was 4 days at 35 C. This solution did not offer any highlighted

merit. Lu et al. [18] attempted to use H2IrCl6.6H2O for electrodeposition solution. Their

solution was developed from light yellow to dark blue after 5 days.

66 | P a g e

Kakooei S. et al. / International Journal of Material Science Innovations (IJMSI) 1 (1): 62-72, 2013

Table 1. Application and characterization of IrO2 electrodes fabricated by electrodeposition technique.

Substrate

Precursor

materials

Oxide

thickness

Sensitivity

(Nernstian

behavior

mV/pH)

70.2

Application

Platinum wire

---------

---------

Au, Pt, Ir, PtIr,

and

316LVM

stainless steel

wires

Tin-doped

indium oxide

(ITO)

IrCl4, oxalic

acid, and

K2CO3

100 nm

IrCl4, oxalic

acid, and

K2CO3

---------

---------

Electrochromic display

devices

[29]

Platinum

IrCl4, oxalic

acid, and

K2CO3

IrCl4, oxalic

acid, and

K2CO3

---------

-68 to -77

Glucose sensor

[1]

---------

-73

pH measurement

as a detector in a flow

injection analysis (FIA)

system

[36]

H2IrCl66H2O,

oxalic acid,

and K2CO3

IrCl4, oxalic

acid, and

K2CO3

K3IrC16,

oxalic acid,

and K2CO3

IrCl4, oxalic

acid, and

K2CO3

IrCl4, oxalic

acid, and

K2CO3

Na3IrCl6, HCl,

NaOH

---------

75.51

pH measurement as a

Neural sensor

[18]

20-30 nm

---------

pH measurement as a

biosensor

[35, 37]

--------

---------

---------

[38]

--------

77

pH measurement

in brain tissues

[40]

--------

64.5

----------

[11]

--------

---------

[41]

IrCl4, oxalic

acid, and

K2CO3

--------

-63.5

IrCl4, oxalic

acid, and

K2CO3

IrCl4, oxalic

acid, and

K2CO3

--------

77.6

--------

-68

Scanning

electrochemical

microscope (SECM)

pH measurement of

extracellular Myocardial

Acidosis during Acute

Ischemia

pH measurement of

microfluidic-based

microsystems

Monitoring of water

quality

--------

-73

Au, Ag, Ti, Cu,

Ni, W, Zr, Co,

nickel-chrome,

Hastelloy and

stainless steel

Platinum

Stainless steel

SnO2-coated

glass

Polyimide-CrAu

ITO-coated

glass

Carbon fiber

Sputtered

Platinum on

flexible

Kapton films

Platinum

Sputtered

Gold on Si

wafer

Stainless steel

IrCl4, oxalic

acid, and

K2CO3

---------

Interfacial pH

measurement

Neural stimulation and

recording

References

Corrosion monitoring

[39]

[34]

[42]

[32, 43]

[15]

[44]

Nguyen et al. [40] observed a 12 mV/pH as drift of sensitivity after 8 days sensitivity test

repeating. They explained that this change in sensitivity is due to dehydration phenomenon of

hydrated iridium oxide, which can be minimized by keeping IrO2 pH sensor in phosphate

buffered saline (PBS) solution.

67 | P a g e

Kakooei S. et al. / International Journal of Material Science Innovations (IJMSI) 1 (1): 62-72, 2013

Wipf et al.[41] produced a pH microelectrode via electrodeposition of IrO2 on carbon fiber.

They used this pH sensor in development of the scanning electrochemical microscope

(SECM). The fabricated pH sensor was able to measure pH near a surface. The result was

shown as a vertical pH map or image.

As Lu et al.[18] reported there is an optimum thickness for IrO2 electrodeposited coating.

Coating electrochemical performance increase when its CSCc and thickness increase, but

when CSCc approach to ~45mC/cm2 delamination of IrO2 coating was detected. Their

demonstarated iridium oxide electrode showed a pH sensitivity -75.51 mV/pH in broad pH

range of 1-13. More research works are presented in Table 1 with electrode application and

other characterization.

2-5. Other methods

A surface renewable IrO2 pH sensor or hydrogen ion-selective electrode can be made by

using composite electrode technique. Quan et al.[21] used carbon black, polyvinyl chloride

and ammonium hexachloroiridate to fabricate an IrO2 based composite electrode. Increasing

IrO2 content up to 40 wt% showed an increasing on the pH response. They also investigated

the effect of different ions on pH electrode efficiency that resulted that Fe(CN)63- , Fe(CN)64-,

I-, and H2O2 affected by electrode result. Similar results for IrO2 pH sensor were also reported

in other research [45].

Park et al.[46, 47] fabricated an iridium oxide-glass composite electrode by mixing

ammonium hexachloroiridate and glass powder, pressing, and sintering under oxygen

atmosphere. The mention electrode was renewable by using 2000 grit SiC emery paper

whenever it becomes fouled or deactivated. They observed many microscopic voids in the

electrode surface after sintering at high temperature. pH response in these electrodes was

dependent on the size and population of voids. Surface voids can be reduced by hot press

sintering technique.

3. Applications

3.1. Biomedical and Biological applications

Marzouk et al.[48] in 2002 measured extracellular pH in ischemic rabbit papillary muscle for

the first time. They used a pH sensor based on an IrO2 film electrodeposited on a planar

sputtered platinum electrode fabricated on a flexible Kapton substrate.

68 | P a g e

Kakooei S. et al. / International Journal of Material Science Innovations (IJMSI) 1 (1): 62-72, 2013

Fast response time of pH sensor is very important for biological application. Iridium oxide

pH microsensors were used to measure the acidification rate of CHO and fibroblast cells in a

cell culture with microfluidic control [32]. This approach can also be used in bioanalytical

filed or biosensor [32, 43].

Iridium oxide sensors are widely used in neural stimulation and recording electrodes

regarding to their low impedance, high charge storage capacity [34].

Iridium oxide based pH sensor is a reliable and robust approach for biological application.

OHare et al. [4] investigated application of IrO2 electrode fabricated by thermal oxidation

and anodization as a pH sensor in the cultured intervertebral disc. Their electrodes were

tending to be unstable in physiological media. Also dissolution of the hydrated oxide film

happened in higher concentrations of chloride. They reduced the effect of chloride by using

thermally annealed Nafion films. Although Nafion film caused an increase in response time,

it could protect iridium oxide film against the aggressive nature of biological media [32, 42].

3.2. Industrial applications

Zhang et al.[39, 49] used IrO2 pH sensor for measuring pH in electrode/solution interface in

electrodeposition process. They found that by increasing the applied potential, interfacial pH

increased. Marzouk [36] fabricated a tubular IrO2 pH sensor for using in a flow injection

analysis (FIA) system as a detector.

The pH of a solution is one of the most important parameters used for characterizing an

electrolyte during corrosion processes [5, 8, 10]. For this purpose, some researcher used

iridium oxide microelectrode to study the effect of local pH near the surface on corrosion on

steel surfaces [9, 50].

4. Conclusion

In this study various techniques for fabrication of IrO2 electrode was presented. Iridium oxide

pH sensor are able to measure pH changes in real-time which enablae researchers to use it in

variouse industrial field. More attention was paid to electrodeposition method due to cheaper

fabrication process, low-temperature process, potential for using cheaper substrates, and

versatility of sensor shapes and designs.

69 | P a g e

Kakooei S. et al. / International Journal of Material Science Innovations (IJMSI) 1 (1): 62-72, 2013

Acknowledgements

We are gratefully acknowledge the financial support from Ministry of Higher Education

(ERGS Grant No: 158200327) and Universiti Teknologi PETRONAS that has made this

work possible.

References

1.

Yang, H., S.K. Kang, D.H. Shin, H. Kim, and Y.T. Kim. 2003. IEEE.

2.

Franklin, R.K., S. Joo, S. Negi, F. Solzbacher, and R.B. Brown. 2009. IEEE.

3.

Macur, R.A., Iridium-Iridium oxide electrode for measuring pH of blood and other

fluids, 1973, US Patent 3,726,777.

4.

OHare, D., K.H. Parker, and C.P. Winlove, Metalmetal oxide pH sensors for

physiological application, Medical engineering & physics. 2006, 28(10): 982-988.

5.

Chiao, J.C. and W.D. Huang, Amorphous IrOx film pH sensor, US Patent App.

12/911,329, 2010.

6.

Huang, P. and K.G. Kreider, Electrochemical evaluation of solid state pH sensors for

nuclear waste containment, 1988, Nuclear Regulatory Commission, Washington, DC (USA).

Div. of Engineering; National Bureau of Standards, Washington, DC (USA). Center for

Chemical Engineering.

7.

Kreider, K., Iridium oxide thin-film stability in high-temperature corrosive solutions,

Sensors and Actuators B: Chemical. 1991, 5(14): 165-169.

8.

Prasad, R., Assessment and Control of MIC in the Oil Industry in the 20th Century,

CORROSION 2000. 2000.

9.

Lewandowski, Z., T. Funk, F. Roe, B.J. Little, J. Kearns, and B. Little, Spatial

distribution of pH at mild steel surfaces using an iridium oxide microelectrode, ASTM

SPECIAL TECHNICAL PUBLICATION. 1994, 1232: 61-61.

10.

Little, B.J., Z. Lewandowski, T. Funk, and F. Roe, Spatial Distribution of pH at Mild

Steel Surfaces Using an Iridium Oxide Microelectrode, 1994, DTIC Document.

11.

Kim, Y.J., Y.C. Lee, B.K. Sohn, J.H. Lee, and C.S. Kim, A novel pH microsensor

with a built-in reference electrode, Journal Korean Physical Society. 2003, 43(1): 769-772.

12.

Roe, F., Z. Lewandowski, and T. Funk, Simulating microbiologically influenced

corrosion by depositing extracellular biopolymers on mild steel surfaces, Corrosion. 1996,

52(10).

13.

Song, I., K. Fink, and J. Payer, Metal oxide/metal pH sensor: Effect of anions on pH

measurements, Corrosion. 1998, 54(01).

14.

Arikawa, T., Y. Takasu, Y. Murakami, K. Asakura, and Y. Iwasawa, Characterization

of the structure of RuO2-IrO2/Ti electrodes by exafs, The Journal of Physical Chemistry B.

1998, 102(19): 3736-3741.

15.

Carroll, S. and R.P. Baldwin, Self-Calibrating Microfabricated Iridium Oxide pH

Electrode Array for Remote Monitoring, Analytical chemistry. 2010, 82(3): 878-885.

16.

Kurzweil, P., Metal oxides and ion-exchanging surfaces as pH sensors in liquids:

State-of-the-art and outlook, Sensors. 2009, 9(6): 4955-4985.

70 | P a g e

Kakooei S. et al. / International Journal of Material Science Innovations (IJMSI) 1 (1): 62-72, 2013

17.

Thanawala, S.S., R.J. Baird, D.G. Georgiev, and G.W. Auner, Amorphous and

crystalline IrO2 thin films as potential stimulation electrode coatings, Applied Surface

Science. 2008, 254(16): 5164-5169.

18.

Lu, Y., T. Wang, Z. Cai, Y. Cao, H. Yang, and Y.Y. Duan, Anodically

electrodeposited iridium oxide films microelectrodes for neural microstimulation and

recording, Sensors and Actuators B: Chemical. 2009, 137(1): 334-339.

19.

Cogan, S., P. Troyk, J. Ehrlich, T. Plante, D. McCreery, and L. Bullara. 2003. IEEE.

20.

Ross D. Meyer, S.F.C., Member, Trung H. Nguyen, R. David Rauh, Electrodeposited

Iridium Oxide for Neural Stimulation and Recording Electrodes, IEEE TRANSACTIONS

ON NEURAL SYSTEMS AND REHABILITATION ENGINEERING. 2001, 9(1): 2-11.

21.

Quan, H., W. Kim, K. Chung, and J. Park, Surface renewable hydrogen ion-selective

polymeric composite electrode containing iridium oxide, Bulletin Korean Chemical Society.

2005, 26(10): 1565.

22.

Huang, W.D., J. Wang, T. Ativanichayaphong, M. Chiao, and J. Chiao. 2008. Society

of Photo-Optical Instrumentation Engineers.

23.

Huang, W.D., L.C. Hsu, J. Wang, T. Ativanichayaphong, S. Deb, M. Chiao, and J.

Chiao. 2008. Society of Photo-Optical Instrumentation Engineers.

24.

Da Silva, G., S. Lemos, L. Pocrifka, P. Marreto, A. Rosario, and E. Pereira,

Development of low-cost metal oxide pH electrodes based on the polymeric precursor

method, analytica chimica acta. 2008, 616(1): 36-41.

25.

Van Ooyen, A., G. Topalov, G. Ganske, W. Mokwa, and U. Schnakenberg, Iridium

oxide deposited by pulsed dc-sputtering for stimulation electrodes, Journal of

Micromechanics and Microengineering. 2009, 19(7): 074009.

26.

Lee, I.-S., C.-N. Whang, J.-C. Park, D.-H. Lee, and W.-S. Seo, Biocompatibility and

charge injection property of iridium film formed by ion beam assisted deposition,

Biomaterials. 2003, 24(13): 2225-2231.

27.

Wessling, B., A. van Ooyen, W. Mokwa, and U. Schnakenberg. Engineering in

Medicine and Biology Society, 2006. EMBS'06. 28th Annual International Conference of the

IEEE. 2006. IEEE.

28.

Kreider, K., Iridium oxide thin-film stability in high-temperature corrosive solutions,

Sensors and Actuators B: Chemical. 1991, 5(1): 165-169.

29.

Yamanaka, K., Anodically Electrodeposited Iridium Oxide Films(AEIROF) from

Alkaline Solutions for Electrochromic Display Devices, Japanese journal of applied physics.

1989, 28(part 1): 632-637.

30.

Pikulski, M. and W. Gorski, Iridium-based electrocatalytic systems for the

determination of insulin, Analytical chemistry. 2000, 72(13): 2696-2702.

31.

Terashima, C., T.N. Rao, B.V. Sarada, N. Spataru, and A. Fujishima,

Electrodeposition of hydrous iridium oxide on conductive diamond electrodes for catalytic

sensor applications, Journal of Electroanalytical Chemistry. 2003, 544: 65-74.

32.

Ges, I.A., B.L. Ivanov, D.K. Schaffer, E.A. Lima, A.A. Werdich, and F.J.

Baudenbacher, Thin-film IrOx pH microelectrode for microfluidic-based microsystems,

Biosensors and Bioelectronics. 2005, 21(2): 248-256.

33.

Ryynnen, T., K. Nurminen, J. Hmlinen, M. Leskel, and J. Lekkala, pH electrode

based on ALD deposited iridium oxide, Procedia Engineering. 2010, 5: 548-551.

71 | P a g e

Kakooei S. et al. / International Journal of Material Science Innovations (IJMSI) 1 (1): 62-72, 2013

34.

Meyer, R.D., S.F. Cogan, T.H. Nguyen, and R.D. Rauh, Electrodeposited iridium

oxide for neural stimulation and recording electrodes, Neural Systems and Rehabilitation

Engineering, IEEE Transactions on. 2001, 9(1): 2-11.

35.

Mayorga Martinez, C.C., R.E. Madrid, and C.J. Felice, Electrochemical and

geometrical characterization of iridium oxide electrodes in stainless steel substrate, Sensors

and Actuators B: Chemical. 2008, 133(2): 682-686.

36.

Marzouk, S.A.M., Improved electrodeposited iridium oxide pH sensor fabricated on

etched titanium substrates, Analytical chemistry. 2003, 75(6): 1258-1266.

37.

Martinez, C.C.M., R.E. Madrid, and C.J. Felice, A pH Sensor Based on a Stainless

Steel Electrode Electrodeposited With Iridium Oxide, Education, IEEE Transactions on.

2009, 52(1): 133-136.

38.

Petit, M.A. and V. Plichon, Anodic electrodeposition of iridium oxide films, Journal

of Electroanalytical Chemistry. 1998, 444(2): 247-252.

39.

Zhang, J.M., Q. Shi, C. Yang, and Q.F. Dong, In-situ pH measurement at the

electrode/solution interface, Chinese Chemical Letters. 2000, 11(7): 617-620.

40.

C. M. Nguyen, H.C., W. D. Huang, and J.-C. Chiao, An Electro-Deposited IrOx Thin

Film pH Sensor, in BMES Biomedical Engineering Society Annual Meeting2011: Hartford.

41.

Wipf, D.O., F. Ge, T.W. Spaine, and J.E. Baur, Microscopic measurement of pH with

iridium oxide microelectrodes, Analytical chemistry. 2000, 72(20): 4921-4927.

42.

Marzouk, S.A.M., S. Ufer, R.P. Buck, T.A. Johnson, L.A. Dunlap, and W.E. Cascio,

Electrodeposited iridium oxide pH electrode for measurement of extracellular myocardial

acidosis during acute ischemia, Analytical chemistry. 1998, 70(23): 5054-5061.

43.

Ges, I.A., B.L. Ivanov, A.A. Werdich, and F.J. Baudenbacher, Differential pH

measurements of metabolic cellular activity in nl culture volumes using microfabricated

iridium oxide electrodes, Biosensors and Bioelectronics. 2007, 22(7): 1303-1310.

44.

Kakooei, S., M.C. Ismail, and B.A. Wahjoedi, Electrochemical Study of Iridium

Oxide Coating on Stainless Steel Substrate, Int. J. Electrochem. Sci. 2013, 8: 3290-3301.

45.

Bezbaruah, A.N. and T.C. Zhang, Fabrication of anodically electrodeposited iridium

oxide film pH microelectrodes for microenvironmental studies, Analytical chemistry. 2002,

74(22): 5726-5733.

46.

Park, J., J. Kim, and H. Quan, A surface renewable iridium oxide-glass composite

hydrogen ion electrode, Microchemical Journal. 2010, 95(1): 102-106.

47.

Park, J.M. and J.Y. Kim, Surface Renewable Iridium Oxide-Glass or Ceramic

Composite Hydrogen Ion Electrode, US Patent App. 12/846,791, 2010.

48.

Marzouk, S.A.M., R.P. Buck, L.A. Dunlap, T.A. Johnson, and W.E. Cascio,

Measurement of extracellular pH, K+, and lactate in ischemic heart, Analytical biochemistry.

2002, 308(1): 52-60.

49.

Zhang, J., C. Lin, Z. Feng, and Z. Tian, Mechanistic studies of electrodeposition for

bioceramic coatings of calcium phosphates by an in situ pH-microsensor technique, Journal

of Electroanalytical Chemistry. 1998, 452(2): 235-240.

50.

Tanabe, H., K. Togashi, T. Misawa, and U. Kamachi Mudali, In situ pH

measurements during localised corrosion of type 316LN stainless steel using scanning

electrochemical microscopy, Journal of materials science letters. 1998, 17(7): 551-553.

72 | P a g e

Вам также может понравиться

- Solution Manual For Chemistry The Molecular Nature of Matter and Change 9th Edition Martin Silberberg Patricia AmateisДокумент26 страницSolution Manual For Chemistry The Molecular Nature of Matter and Change 9th Edition Martin Silberberg Patricia AmateisJenniferLarsonpsdc100% (40)

- Preparation of Cyclohexene From CyclohexanolДокумент7 страницPreparation of Cyclohexene From CyclohexanolDumile Nombasa100% (5)

- 52 CHEMISTRY OLYMPIAD ProblemsДокумент18 страниц52 CHEMISTRY OLYMPIAD ProblemsStephen PramatyaОценок пока нет

- Separation Process 1Документ86 страницSeparation Process 1hanisshi50% (4)

- Powder Technology: Prita Pant Sarangi, S.R. Vadera, M.K. Patra, N.N. GhoshДокумент6 страницPowder Technology: Prita Pant Sarangi, S.R. Vadera, M.K. Patra, N.N. Ghoshehagar60Оценок пока нет

- Mesoporous Zr-MCM-41 and Ti-MCM-41 As Solid Oxidation Catalysts in The Synthesis of EpichlorohydrinДокумент9 страницMesoporous Zr-MCM-41 and Ti-MCM-41 As Solid Oxidation Catalysts in The Synthesis of EpichlorohydrinAhmed Fouad MusaОценок пока нет

- CuCo2O4 Nanobricks As Electrode For Enhanced ElectДокумент13 страницCuCo2O4 Nanobricks As Electrode For Enhanced ElectPrasath JKОценок пока нет

- Nanomaterials 13 00048Документ14 страницNanomaterials 13 00048safiaОценок пока нет

- Mercury Removal Using Fe - Fe Electrodes by ElectrocoagulationДокумент8 страницMercury Removal Using Fe - Fe Electrodes by ElectrocoagulationIJMERОценок пока нет

- Ultrasonic Preparation and Nanosheets Supported Binary Metal Oxide NanocompositesДокумент9 страницUltrasonic Preparation and Nanosheets Supported Binary Metal Oxide Nanocompositesmasum.sОценок пока нет

- Indium Tin Oxide Coated Conducting Glass Electrode For Electrochemical Destruction of Textile ColorantsДокумент6 страницIndium Tin Oxide Coated Conducting Glass Electrode For Electrochemical Destruction of Textile Colorantsapi-3828788100% (1)

- Copper ECSAДокумент7 страницCopper ECSANusrat RashidОценок пока нет

- Evergreen WirДокумент12 страницEvergreen WirAisyah Putri OktavianiPendidikan KimiaОценок пока нет

- Electrochimica Acta: Yue-E Miao, Sixin He, Yunlan Zhong, Zhe Yang, Weng Weei Tjiu, Tianxi LiuДокумент7 страницElectrochimica Acta: Yue-E Miao, Sixin He, Yunlan Zhong, Zhe Yang, Weng Weei Tjiu, Tianxi LiuvinsmnОценок пока нет

- 2019 (Cat) NP Dielectric Barrier Discharge With NiMo Sulfide SemiConductorДокумент13 страниц2019 (Cat) NP Dielectric Barrier Discharge With NiMo Sulfide SemiConductorKin Wai CheahОценок пока нет

- A Novel One-Step Electrochemical Method To Obtain Crystalline Titanium Dioxide Films at Low TemperatureДокумент6 страницA Novel One-Step Electrochemical Method To Obtain Crystalline Titanium Dioxide Films at Low TemperatureTony HerreraОценок пока нет

- Electrochimica Acta: Xiaoli Xiong, Chao You, Xiaoqin Cao, Linfeng Pang, Rongmei Kong, Xuping SunДокумент5 страницElectrochimica Acta: Xiaoli Xiong, Chao You, Xiaoqin Cao, Linfeng Pang, Rongmei Kong, Xuping SunLoga NathanОценок пока нет

- (2019-11p) IOP MSE - Subcritical Water...Документ7 страниц(2019-11p) IOP MSE - Subcritical Water...ClearyОценок пока нет

- Amperometric Glucose Sensor Based On The Ni (OH) 2al (OH) 4 ElectrodeДокумент7 страницAmperometric Glucose Sensor Based On The Ni (OH) 2al (OH) 4 ElectrodeĐỗ MinhОценок пока нет

- Electrocatalysis of The Hydrogen Evolution Reaction by Rhenium Oxides Electrodeposited by Pulsed-Current 2015 A. VargasДокумент9 страницElectrocatalysis of The Hydrogen Evolution Reaction by Rhenium Oxides Electrodeposited by Pulsed-Current 2015 A. VargasCristianОценок пока нет

- 2022 Setyoputra, The Characterisation of MWCNT-rGO-TiO2 Nanocomposite As Potential ElectrodeДокумент10 страниц2022 Setyoputra, The Characterisation of MWCNT-rGO-TiO2 Nanocomposite As Potential Electrodeheri rustamajiОценок пока нет

- Anodo - ElectroquímicaДокумент8 страницAnodo - ElectroquímicaWade HarrisОценок пока нет

- Ag ZnOДокумент10 страницAg ZnORobeul AwalОценок пока нет

- LI 2021 Electrochemical Determination (VOR)Документ21 страницаLI 2021 Electrochemical Determination (VOR)Irwan Ibn HasanОценок пока нет

- 5.sensors 20 05992 v2Документ16 страниц5.sensors 20 05992 v2ARSALAN AHMADОценок пока нет

- Sensor Oxigenio CuOДокумент9 страницSensor Oxigenio CuOJeff SalesОценок пока нет

- Activity and Stability of Electrochemically and Thermally Treated Iridim For The Oxygen Evolution ReactionДокумент8 страницActivity and Stability of Electrochemically and Thermally Treated Iridim For The Oxygen Evolution Reaction응오황타이바오/환경·기후기술트랙Оценок пока нет

- Analysis of The Electrodeposition Process of Rhenium and Rhenium Oxides in Alkaline Aqueous Electrolyte 2013 A. VargasДокумент8 страницAnalysis of The Electrodeposition Process of Rhenium and Rhenium Oxides in Alkaline Aqueous Electrolyte 2013 A. VargasCristianОценок пока нет

- SEP1Xx-16-final Version PDFДокумент8 страницSEP1Xx-16-final Version PDFijasrjournalОценок пока нет

- Removal of Lead Ions by Nife2o4 NanoparticlesДокумент9 страницRemoval of Lead Ions by Nife2o4 NanoparticlesesatjournalsОценок пока нет

- Corrosion Inhibition of Mild Steel by Nettle (Urtica Dioica L.) Extract: Polarization, EIS, AFM, SEM and EDS StudiesДокумент14 страницCorrosion Inhibition of Mild Steel by Nettle (Urtica Dioica L.) Extract: Polarization, EIS, AFM, SEM and EDS StudiesAhmedAbdelZaherОценок пока нет

- Alcohol Sensor Based On ZnOДокумент6 страницAlcohol Sensor Based On ZnOArun KumarОценок пока нет

- NANV03I02P0084Документ9 страницNANV03I02P0084nano_journalОценок пока нет

- Electrochemical Investigation On Effect of Sodium Thiosulfate (Na S O) and Ammonium Chloride (NH CL) On Carbon Steel CorrosionДокумент13 страницElectrochemical Investigation On Effect of Sodium Thiosulfate (Na S O) and Ammonium Chloride (NH CL) On Carbon Steel Corrosionestiven ValderramaОценок пока нет

- Analytica Chimica Acta:, Mohamad Reza Ganjali, Mashaalah ZareДокумент8 страницAnalytica Chimica Acta:, Mohamad Reza Ganjali, Mashaalah ZareCaio SilvaОценок пока нет

- Corrosion Behavior of Copper at Elevated Temperature: Int. J. Electrochem. Sci., 7 (2012) 7902 - 7914Документ13 страницCorrosion Behavior of Copper at Elevated Temperature: Int. J. Electrochem. Sci., 7 (2012) 7902 - 7914idanfriОценок пока нет

- Adsorption and Corrosion Inhibition of New Synthesized Pyridazinium-Based Ionic Liquid On Carbon Steel in 0.5 M H SOДокумент9 страницAdsorption and Corrosion Inhibition of New Synthesized Pyridazinium-Based Ionic Liquid On Carbon Steel in 0.5 M H SOHyd BenОценок пока нет

- 557 Subardi OKДокумент8 страниц557 Subardi OKPemuda BekaryaОценок пока нет

- Moustafa Et Al. - 2020 - Titanium Dioxide-Decorated RGO As An Effective EleДокумент25 страницMoustafa Et Al. - 2020 - Titanium Dioxide-Decorated RGO As An Effective EleHuỳnh Tuấn KiệtОценок пока нет

- Gridded Gate Pt-SiO2-Si MOS Sensor For Detection of HydrogenДокумент8 страницGridded Gate Pt-SiO2-Si MOS Sensor For Detection of HydrogenKashif NabiОценок пока нет

- Ruengpirasiri 2016Документ10 страницRuengpirasiri 2016Şebnem Gül İlarslanОценок пока нет

- Paper IchzanДокумент5 страницPaper IchzanLintannisa RahmatiaОценок пока нет

- Synthesis and Characterisations of SnO2 Nanorods Via Low Temperature Hydrothermal MethodДокумент22 страницыSynthesis and Characterisations of SnO2 Nanorods Via Low Temperature Hydrothermal MethodPhú VõОценок пока нет

- 520-Article Text-2594-2-10-20200521Документ14 страниц520-Article Text-2594-2-10-20200521Barathan RajandranОценок пока нет

- The Study and Invention of Portable Voltammetry For Detecting Contamination Heavy MetalДокумент5 страницThe Study and Invention of Portable Voltammetry For Detecting Contamination Heavy MetalOmar ReynosoОценок пока нет

- Accepted Manuscript: Applied Surface ScienceДокумент20 страницAccepted Manuscript: Applied Surface ScienceMaharghya BiswasОценок пока нет

- Report ScientificoДокумент6 страницReport ScientificoDaniele GuastaferroОценок пока нет

- Electroanalysis - 2021 - Esmail Tehrani - Hydrogen Peroxide Detection Using Prussian Blue Modified 3D Pyrolytic CarbonДокумент13 страницElectroanalysis - 2021 - Esmail Tehrani - Hydrogen Peroxide Detection Using Prussian Blue Modified 3D Pyrolytic CarbonArya Zimmar Sant'AnnaОценок пока нет

- 10 1149@2 0131912jesДокумент7 страниц10 1149@2 0131912jesmarko.rukavinaОценок пока нет

- Functionalised MWCNT PDFДокумент7 страницFunctionalised MWCNT PDFBogdan MoneaОценок пока нет

- Turan 2020Документ9 страницTuran 2020ERICK JESUS MUÑOZ HERNANDEZОценок пока нет

- Bahadori 2020Документ14 страницBahadori 2020Flori DediuОценок пока нет

- SEMINAR On NanocompositesДокумент30 страницSEMINAR On NanocompositesRama GaurОценок пока нет

- PSL 2014-Vol07-No02-P372-375 PalisocДокумент4 страницыPSL 2014-Vol07-No02-P372-375 PalisocOmar ReynosoОценок пока нет

- SN CorrosionДокумент7 страницSN CorrosionrossooОценок пока нет

- 1 s2.0 S0360319906001868 MainДокумент8 страниц1 s2.0 S0360319906001868 MainJohn WickОценок пока нет

- EddddДокумент11 страницEddddBRYAN ARIEL CRUZADO CARPIOОценок пока нет

- Removal of Copper (II) Ion From Aqueous Solution by High-Porosity Activated CarbonДокумент8 страницRemoval of Copper (II) Ion From Aqueous Solution by High-Porosity Activated Carbonjuan perezОценок пока нет

- Tugas KatalisДокумент8 страницTugas KatalisJohanis DjawaОценок пока нет

- Sensing 5Документ6 страницSensing 5Sudip SinhaОценок пока нет

- Carbon Film Electrodes As Support of Metallic Particles: Int. J. Electrochem. Sci., 7 (2012) 150 - 166Документ17 страницCarbon Film Electrodes As Support of Metallic Particles: Int. J. Electrochem. Sci., 7 (2012) 150 - 166FelpnilОценок пока нет

- Sensors: Hydrogen Sensing With Ni-Doped Tio NanotubesДокумент10 страницSensors: Hydrogen Sensing With Ni-Doped Tio NanotubesiprateekОценок пока нет

- The Electrochemistry and Characteristics of Embeddable Reference Electrodes for ConcreteОт EverandThe Electrochemistry and Characteristics of Embeddable Reference Electrodes for ConcreteОценок пока нет

- CONBUILDMATДокумент8 страницCONBUILDMATsaeid59Оценок пока нет

- Numerical Investigation and Comparison With Experimental Characterisation of Side Gate P-Type Junctionless Silicon Transistor in Pinch-Off StateДокумент5 страницNumerical Investigation and Comparison With Experimental Characterisation of Side Gate P-Type Junctionless Silicon Transistor in Pinch-Off Statesaeid59Оценок пока нет

- Controlling The Shape and Gap Width of Silicon Electrodes Using Local Anodic Oxidation and Anisotropic TMAH Wet EtchingДокумент12 страницControlling The Shape and Gap Width of Silicon Electrodes Using Local Anodic Oxidation and Anisotropic TMAH Wet Etchingsaeid59Оценок пока нет

- Tech Sessions ICPER2012Документ20 страницTech Sessions ICPER2012saeid59Оценок пока нет

- Technology Supplement Paper Apas and PCCPДокумент4 страницыTechnology Supplement Paper Apas and PCCPsaeid59Оценок пока нет

- Observations and CalculationsДокумент5 страницObservations and CalculationsMian GulshadОценок пока нет

- Electropure EDI Engr OEM Manual v3.5.0 (CE)Документ81 страницаElectropure EDI Engr OEM Manual v3.5.0 (CE)Fábio GomesОценок пока нет

- ThermodynamicsДокумент72 страницыThermodynamicsarthey FriendОценок пока нет

- Physical Properties of Fluids: Ppendix BДокумент5 страницPhysical Properties of Fluids: Ppendix BYan MelloОценок пока нет

- End Term ALLДокумент31 страницаEnd Term ALLJulie Anne CristalesОценок пока нет

- Blushing of Amines in Coal Tar Epoxy (Amine Adduct)Документ7 страницBlushing of Amines in Coal Tar Epoxy (Amine Adduct)Nuwan RanaweeraОценок пока нет

- Grade 4 SCIENCE QUIZ BEE QUESTIONNAIREДокумент2 страницыGrade 4 SCIENCE QUIZ BEE QUESTIONNAIREMa Isabella T Ballesteros93% (14)

- Explanation To Report in RACДокумент2 страницыExplanation To Report in RACPaulDenver Villafuerte DoloresОценок пока нет

- Thesis On Doped ZnoДокумент6 страницThesis On Doped Znoameliarichardsonsouthbend100% (1)

- Properties of SteamДокумент27 страницProperties of SteamVishal DhimanОценок пока нет

- Chem DiagnosticДокумент3 страницыChem DiagnosticHeather Nicole BelinoОценок пока нет

- Acids Bases 1Документ40 страницAcids Bases 1api-508592459100% (1)

- Solutions Set 6Документ19 страницSolutions Set 6Augustine BrockОценок пока нет

- Ruthenium-Catalyzed Azide-Alkyne Cycloaddition (Ruaac)Документ4 страницыRuthenium-Catalyzed Azide-Alkyne Cycloaddition (Ruaac)MinhОценок пока нет

- Molecular Mass Spectroscopy:: HistoryДокумент43 страницыMolecular Mass Spectroscopy:: Historyramesh pokhrelОценок пока нет

- Properties of Air and Other GasesДокумент52 страницыProperties of Air and Other GasesNereo SpenglerОценок пока нет

- Numerical Analysis and Experimental Validation of Heat Transfer During Solidification of Phase Change Material in A Large DomainДокумент14 страницNumerical Analysis and Experimental Validation of Heat Transfer During Solidification of Phase Change Material in A Large DomainN96Оценок пока нет

- Diagnostic-Results ScienceДокумент1 страницаDiagnostic-Results ScienceJay Rostata TuraОценок пока нет

- Compound Vapor System2Документ1 страницаCompound Vapor System2kdpmansi100% (1)

- Seaweed Polysaccharides (Agar, Alginate Carrageenan) : January 2018Документ12 страницSeaweed Polysaccharides (Agar, Alginate Carrageenan) : January 2018Dwi PerbriyantiОценок пока нет

- AnaChem Conjugate Acid Base Pairs 3Документ3 страницыAnaChem Conjugate Acid Base Pairs 3Jei HernandezОценок пока нет

- PhysicsДокумент25 страницPhysicsNeerav KumarОценок пока нет

- Design and Analysis of Experiments - Melting IceДокумент18 страницDesign and Analysis of Experiments - Melting IceGreg VoloshenkoОценок пока нет

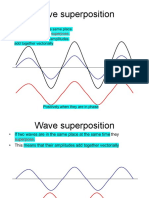

- Wave SuperpositionДокумент29 страницWave SuperpositionAndrei Allen GonzalesОценок пока нет

- 126 EXAM Common 1 Chem 126Документ7 страниц126 EXAM Common 1 Chem 126Ezequiel OrellanaОценок пока нет