Академический Документы

Профессиональный Документы

Культура Документы

Packing PDF

Загружено:

Kanishka PeellawattageИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Packing PDF

Загружено:

Kanishka PeellawattageАвторское право:

Доступные форматы

Apparel Packing Manual:

Issued: August 2002

Replaces: October 2001

Garment Folding Standards

Flat Packed Standards

Hanging Standards

Issued: August 2002

Replaces: October 2001

Apparel Packing Manual:

Issued: August 2002

Replaces: October 2001

1. INTRODUCTION

Background

As part of the General Merchandise & Apparel Group, Target and Kmart

(the Brands) are providing these Guidelines for the implementation of floor ready merchandise

flat packed in cartons and hanging in bags. These Guidelines are the minimum requirements

and standards to be applied to all apparel deliveries into Coles Brands Distribution Centres and

Stores.

Purpose

These Guidelines and standards have been compiled for information and use by Suppliers,

Quality Assurance, Buying Office and Third party Service Providers and have been developed

to maintain consistency and assist Suppliers in the rationalisation of standards and business

requirements.

Compliance

Your support and cooperation to comply with these Guidelines is essential to achieve quality of

clothing presentation and to ensure garments are handled and distributed efficiently and

economically throughout the supply chain. We are committed to Supplier partnerships. Such

partnerships will enable us to increase sales, improve profitability and provide our customers

with the best service and floor ready merchandise.

Presentation

Floor ready merchandise is a product that is ready for sale to the customer when it is delivered

to Stores. Garments must arrive in a merchantable condition with minimal creasing and fold

lines. The suggested floor ready standards are to be followed in all cases. It is the

responsibility of the garment manufacturers to ensure that all garments arrive in a

merchantable floor ready condition.

Presentation of merchandise should not be compromised.

In consultation with the

Buyer/Quality Assurance Departments and Coles Group Supply Chain, the General Merchandise

& Apparel Group has determined the most appropriate garment folding and packing methods for

floor ready merchandise delivery in cartons. The following suggested methods will provide the

best opportunity for garments to arrive in stores in the floor ready condition expected by our

customers.

Reference to Standards

Ongoing maintenance and amendments to this manual relating to the standards set in this

document will be updated via the Coles Internet site et.colesgroup.com.au

It is the Suppliers responsibility to ensure that they have the most upto date standards and

reference.

Apparel Packing Manual:

Issued: August 2002

Replaces: October 2001

TABLE OF CONTENTS

1. Introduction

2. Glossary of Terms

3. Flow Chart to Determine Packing Methods

4. Garment & Fabric Creasing Indicator

5. Local & Overseas Supplier Apparel Packaging & Packing Requirements

6. Packing Instructions

7. Carton Standards

8. Labelling and Marking

9. Weight Marking

10. Protective Poly Bag Standards

11. Garment Bags

12. Bag Ties

13. Garment Folding Standards

Pant (front hung)

Pant Larger Sizes (front hung)

Pant (side hung)

Jeans

Shorts (side hung)

Short Skirts

Long Skirts

Long A-Line Skirts

Singlets/Camisoles Regular & Larger Sizes

Crop Tops

Short Sleeve T-Shirts Regular & Larger Sizes

Long Sleeve T-Shirts Regular & Larger Sizes

Sleeveless Shirts

Short Sleeve Shirts

Long Sleeve Shirts Regular & Larger Sizes

Bomber Jacket

Shoestring Dress/Chemise

Sleeveless Dress/Nightie & A-Line Dress/Nightie

Short Sleeve Dress/Nightie Regular & Larger Sizes

Long Sleeve Dress/Nightie Regular & Larger Sizes

Short Sleeve Dressing Gown/Wraps

Long Sleeve Dressing Gowns/Jackets/Coats/Raincoats

2 Piece Short Sleeve Top & Skirt Sets

2 Piece Long Sleeve Top & Skirt Sets

Pyjama Sets Sleeveless Top/Singlets/Camisole Regular & Larger Sizes

Pyjama Sets Short Sleeve Top Regular & Larger Sizes

Pyjama Sets Sleeveless Top/Singlets/Camisole Regular & Larger Sizes

Pyjama Sets Short Sleeve Top Regular & Larger Sizes

Pyjama Sets Long Sleeve Top Regular & Larger Sizes

One Piece Bathing Suit/Leotard

14. Preferred Service providers

Cartons

Weight Marking Labels

Poly Bags

Advertised Line Stickers

2

Apparel Packing Manual:

Issued: August 2002

Replaces: October 2001

2. GLOSSARY OF TERMS

Floor Ready

Garments must arrive on hangers or folded as per Store

presentation requirements in a merchantable condition with minimal

creasing and fold lines

SCM

Shipping Container Marking

GM & A

General Merchandise and Apparel

DC

Distribution Centre

Folded

Refers to presentation at store - Product displayed on fixtures,

shelves or tables

Flat Pack

Product delivered folded in cartons with or without hangers in a

floor ready merchantable condition

GOH

Garments on hangers delivered hanging to stores in poly bags

Hung

Refers to presentation at store product delivered on hangers and

displayed hanging on fixtures

The Brands

Target and Kmart

Local

Australian based Suppliers

Overseas

Overseas based Suppliers

Apparel Packing Manual:

Issued: August 2002

Replaces: October 2001

3. FLOW CHART TO DETERMINE PACKING METHODS TO ENSURE MERCHANDISE IS FLOOR READY

In-store Presentation

Folded display

on shelf or table

Hanging display

on racks or fixturing

Garment Criteria

Delivery Method

If any/all of the criteria below

applies to the garment

The goods are delivered using the

following methods

Structured or Casual Garment

Knitted or Woven Fabric

Natural or Synthetic Fibre

Flat packed in cartons Floor

ready without hangers

Structured Garment .and / or

Delicate Fabric

.and / or

Prone to Creasing

(Refer to Garment & Fabric

Creasing Indicator)

Casual Garment

Knitted or Woven Fabric

50% > Synthetic Fibre

Flat packed in cartons - Floor

ready on hangers

Fully Fashioned Knitwear

Natural or Synthetic Fibre

Flat packed in cartons Floor ready

with hangers loose separated from

garments by a cardboard partition

GOH - Hanging in garment

bags, grouped or individually

bagged as required

Apparel Packing Manual:

Issued: August 2002

Replaces: October 2001

4. GARMENT & FABRIC CREASING INDICATOR

GARMENT TYPE

FIBRE TYPE

HANGING

FULL LENGTH WOVEN

LADIES DRESSES

WOVEN

HIGH CREASING

STRUCTURED

GARMENTS

SUITS/COATS/

JACKETS/PANTS

100% LINEN

100% COTTON

NATURAL FIBRE RICH BLENDS

50% OR GREATER

LINEN/COTTON/VISCOSE

100% VISCOSE RAYON

MENS & LADIES THREE

DIMENSIONAL

STRUCTURED ITEMS

BLOUSES, SKIRTS,

CASUAL SHIRTS

100% SILK

MODEL

LYOCELL

SYNTHETIC BLENDS

50% OR GREATER

POLYESTER / NYLON / ACRYLIC

CASUAL PANTS/SHORTS

ie. CARGO PANTS

JEANS / TRACKPANTS

KNITTED

CASUAL T-SHIRTS

POLO SHIRTS

SLOPPY JOES

LOW CREASING

UNDERWEAR,

SLEEPWEAR,

CORSETRY

100% POLYESTER

NYLON

ACRYLIC

FLATPACK

NOTE: This indicator is to be used as a guide only, ensure that you refer to the garment type in

conjunction with the fibre type when assessing how the merchandise is to be delivered.

5

Apparel Packing Manual:

Issued: August 2002

Replaces: October 2001

5. LOCAL & OVERSEAS SUPPLIER APPAREL PACKING & PACKAGING

REQUIREMENTS

Suppliers are to ensure they comply with the General Merchandise & Apparel Groups

packaging procedures as part of your contracted requirements.

This section gives you a general description of how to package goods.

When packaging merchandise in cartons, follow the guidelines below:

Ensure the carton is strong and secure enough to protect the contents in the normal

transport and distribution processes according to the standards

Ensure the contents of the carton are packed as per instructions

Ensure the labelling/marking are as per requirements

Eliminate the outer shipper carton where inners are the distribution unit

Ensure the carton does not display any misleading information or unrelated printed matter,

for example, brands or product names unrelated to the cartons content.

It is important to:

Use the correct size carton for the goods you need to pack to minimise free space in carton

Ensure that packages form a stable unit load

Ensure that cartons are adequately sealed to support the content

Do not use brown paper wrapping

DO NOT use any form of strapping

DO NOT use carton stapling

Maximum Weight

The maximum weight of cartons must not exceed 20 kilograms, except where a single product

item is contained in the carton (refer page 12), unless the appropriate lifting signage is on the

cartons. Use the following table as a guide when packaging merchandise in cartons.

Carton measurement

Height

Width

Length

Weight

Minimum dimension

100mm

150mm

200mm

2kg

Maximum dimension

760mm

860mm

1060mm

20 kg

It is the Suppliers responsibility to ensure that the above standards are adhered to.

In order to maximise carton size and capacity, it is at the Suppliers discretion to determine the

appropriate quantity of garments to be packed into a carton whilst at all times preserving

garment presentation. This will vary between different product types and Store allocations.

Under no circumstances are cartons to be over-packed leading to crushing/creasing of

garments or adversely affecting the floor ready presentation once garments are unpacked at

Store level. Similarly, under-packing a carton can result in excessive movement of the product

within during transit. To minimise damage in transit and avoid creasing and crushing,

cardboard inserts can also be placed between product, preferably every 5-7 units.

Large Bulky Merchandise

Are made of appropriate materials which can support the weight of the merchandise

Are securely fixed to the carton

Are positioned appropriately for carrying

Have appropriate room for hands to grasp them securely

6

Apparel Packing Manual:

Issued: August 2002

Replaces: October 2001

6. PACKING INSTRUCTIONS

Standard Packs or Pre Pack Deliveries

This instruction describes how garments must be packed for delivery into Distribution Centres

or Stores.

All garments to be folded as per garment folding methods described in attached standards

with no extra folds required

Garments to be placed into cartons by top tailing garments in lots of 5 or 6 depending on

the ratio quantity

If required hangers are to be secured at the end of the carton to minimise garment

movement within the box during transit

All garments to be placed in one large polybag unless otherwise instructed

All garments with placement print must have the barcode swing ticket placed inside of the

garment to ensure that tickets do not stick to the print. If the placement print garment also

has a rubber badge, ensure the garment is folded in such a way that the badge does not

come in contact with the print. This may mean you may need to pack each garment into a

separate polybag

Carton must be correct height/width/depth to fit ratio pack without placing stress on the

garments when packing and sealing the carton. Garment floor ready presentation must

be preserved at all times

Correct ratio and quantity only to be packed per carton, no multiple packs to be put into

cartons unless specified by Buying Quality Assurance or Shipping

Hangers

Please note the hangers drawn in the folding standards diagrams are indicative of the

folding requirement not of the hanger type to be used. All standards relating to the

Brands hanger types remain unchanged.

The Buying/Quality Assurance Department will specify the type of hanger to be used with each

garment. Any special packaging requirements, which may relate to a particular garment will

also be specified by Buyer/Quality Assurance. Eg. The use of plastic bags to package delicate

garments for their protection during transit in carton.

Only approved size system hangers for each Brand are to be used as specified by

Buyer/Quality Assurance. Hangers must be inserted into upper body garments and should be

pushed down partially into the garment for transport and distribution purposes as illustrated.

Hangers must never be included loose inside the carton.

However, there may be exceptions to allow hangers to be packed loose within the carton. This

may be the case with knitwear and delicate fabrics where specified. If hangers are to be

packed loose, a division is required between merchandise and hangers to avoid damage to the

garments. If instructions are unclear, Suppliers are to clarify with Buyer/Quality Assurance for

guidance before packing.

Apparel Packing Manual:

Issued: August 2002

Replaces: October 2001

6. PACKING INSTRUCTIONS

Standard Packs or Pre Pack Deliveries

All Apparel Suppliers and Third Party Service Providers are:

To ensure garments are clean and dry before packing and must be folded as per

illustrations included in this guideline.

To ensure that staff handling the garments have clean hands and that the general

environment is clean and dust free.

To ensure garments are firmly packed into cartons as some settling will occur during transit

To ensure Overseas only must be pre-packed into a clear plastic protective poly bag as

required/requested (individually or grouped) prior to packing and sealing in carton

To ensure, if packed in groups - garments must be pre-hung and the garment hangers

grouped and secured together (eg with an elastic band or bar lock), inside each bag as

specified

To ensure overseas only by exception - if packed individually - garments are to be flat

packed inside each protective bag and each bag laid flat inside the transit carton

To ensure that protective bags are sealed.

Apparel Packing Manual:

Issued: August 2002

Replaces: October 2001

7. CARTON STANDARDS

Transit Cartons

Cartons must be of sufficient strength and quality to be able to withstand double pallet

stacking without creasing or collapsing. Cartons must be stacked on their bases.

Carton size must be chosen to closely fit the volume of contents within. Merchandise must

not be crushed into cartons, over filling, and likewise empty spaces left in the top of the

cartons are not acceptable.

If various sized cartons are used they must be stacked from the largest and heaviest on the

bottom layer graduating up to the smallest and lightest at the top layer.

Second hand cartons are not permitted if the description on the outside of the carton would

be misleading as to the actual contents, or where the carton does not have sufficient

strength to support and protect the product.

Metal staples, metal strapping closures and polypropylene strapping must not be used to

seal cartons. Cartons may be glued or taped closed.

It is the Suppliers responsibility to ensure that merchandise is securely packed to ensure

no damage will occur during transit or sortation.

Board Grade

The minimum acceptable board grade for cartons is to be

Board grade 4

C flute (Flutes must run vertically to ensure box stacking strength is fully maximised)

Single wall

Inferior quality board should not be used

Maintain board grade standards where a division in cartons is required for hangers to be

packed loose in carton as per knitwear program.

Recommended Carton Size Range

Suggested sizes of cartons to use are as follows:

CODE

R1

R2

R3

R4

R5

R6

R7

R8

SIZE: Length X Width X Depth

560 X 360 X 100

560 X 360 X 150

560 X 360 X 225

680 X 460 X 100

680 X 460 X 150

680 X 460 X 225

480 X 330 X 100

680 X 460 X 280

Under no circumstances are cartons to be sealed with plastic or metal strapping or staples.

Heavy-duty tape is acceptable.

Apparel Packing Manual:

Issued: August 2002

Replaces: October 2001

7. CARTON STANDARDS

Cartons are to be marked with all the necessary handling instructions:

Special handling instructions where required should be displayed on cartons eg: This Way

Up, Do Not Drop, Merchandise with Hangers, Advertised Line etc

All cartons delivered either Direct to Store or through the Distribution Centre, which is for

an advertisement, must have the Fluoro Yellow Advertised Line Label. Suppliers to confirm

with individual Brands use of label.

ADVERTISED

LINES

10

Apparel Packing Manual:

Issued: August 2002

Replaces: October 2001

8. LABELLING /MARKING

DIRECT IMPORTS ONLY

(These Standards do not apply to indirect importers using third party packing agents)

Cartons or garment bags are to be externally clearly marked with:

Brand Name (ie MGB, Target, Kmart, etc)

Name of Country specific (ie Australia or New Zealand)

Port of Discharge (ie Melbourne)

Order Number

Keycode Number

Quantity per issue pack

Quantity per outer pack

Made in (Country of Origin)

Carton number (ie .of)

Gross carton weight

Cubic Metres

Cartons or garment bags to be marked consecutively for each consignment and where

appropriate for regions, ie Melbourne 1 of 50 2 of 50 etc. Sydney 1 of 45, 2 of 45 etc and so

on. The above also applies to Kmart New Zealand

Placement of label on cartons can be in 1 of 2 positions either top or front side of carton

KMART

AUSTRALIA

MELBOURNE

2 0F 50

o/No. 1234567

KEYCODE 123456789

QTY ISUE PACK 6

QTY SHIPPER PACK 24

MADE IN CHINA

GRS WGT:

CUBIC METRES

KG

The SCM label must be applied to the

right hand side of the bag (closed side

of Hanger hook), below the shoulder.

The bottom of the barcode must be no

less than 120mm from the shoulder.

11

Apparel Packing Manual:

Issued: August 2002

Replaces: October 2001

8. LABELLING / MARKING cont

LOCAL

Outlined below is the format for any SCM labels on cartons. To obtain further detail and

information on the fields on the labels visit the Coles Site of

et.colesgroup.com.au

NB. BELOW EXAMPLE IS A SAMPLE ONLY.

PLEASE REFER TO WEBSITE FOR THE CURRENT SPECIFICATIONS.

NB. Refer to relevant Freight manuals for guidance on specific Brands requirements for prepack labelling for non A.S.N. merchandise.

12

Apparel Packing Manual:

Issued: August 2002

Replaces: October 2001

9. WEIGHT MARKING - PACKAGING LABELS FOR HEAVY OR BULKY ITEMS

LOCAL AND OVERSEAS

In support of Government laws on employee Health, Safety and Welfare, All Coles Business

Groups have made the decision requiring suppliers to weight mark cartons of merchandise

weighing 10KG and over

Any single or packaged item or transit packaging carton containing more than one item in

excess of 10kg or is of a bulky nature, must carry one of the following approved Weight/Bulky

Marking Icons. Tickets must be attached to any individual product that weighs in excess of the

approved standards below as well as the outer packing carton or bag. Stickers must also be

applied to the outer bag where hanging garments are bagged together weighing in excess of

the approved standards

Purpose of Weight Warning Icons:

To minimise Weight Related workplace injuries and improve workplace safety by altering

person/s lifting packages of a heavy or bulky nature.

Heavy Weight Icon - for individual items or multi packed merchandise

packed in transit cartons 10kg up to 16kg

Note: 16kg is maximum weight for transit cartons through Coles

Distribution Centres

Bulky Icon - for individual items or multi packed

merchandise packed in transit cartons (weighing up to

16kg) where the carton size is larger than 0.4 cubic

metres, and must be lifted by 2 people to avoid injury.

Heavy Weight Icon - for items 17kg to 50kg

Extra Heavy Weight Icon - for items over 50kg. Use extreme caution. A

minimum of two people is required to lift items marked with this weight

warning or use a suitable lifting device if available.

All standards and guidelines relating to weight icon applicability, application, colours, location,

ordering can be accessed via the Coles Electronic Trading Internet Supplier Information Web

site http://et.colesgroup.com.au/

NOTE: Acrobat Reader is required to open and read the artwork files attached.

As the General Merchandise and Apparel group is committed to the principal of the health and

safety of its employees and customers it is important that all suppliers have a full

understanding and acceptance of this commitment. Coles Group Supply Chain

must approve any variations to artwork

13

Apparel Packing Manual:

Issued: August 2002

Replaces: October 2001

10. PROTECTIVE POLY BAG STANDARDS

FOR INDIVIDUAL FLAT PACK MERCHANDISE

LOCAL AND OVERSEAS

Suppliers are required to comply with the following polybag/carton liner standards.

Polybags/carton liners must be free of Butylated Hydrozyl/toluene (BHT). This agent will

create problems of yellowing product. The presence of only a few parts of BHT per million

will create garment discolouration or can cause other adverse reactions with the garment

contained therein.

Clear bag 15 um natural HDPE virgin material.

Poly bags that are being used to pack garments individually are required to have 4 holes

per side to expel excess air. We currently accept clean hole punched bags for ventilation.

These holes should not be ripped into the bag.

Garments must have no more than 6cm to 12cm excess at the bottom and should be heatsealed or taped closed.

Poly bags must be wide enough and long enough to cover the garment without wrinkling.

Warnings on Poly Bags and Carton Liners

All poly bags should have warnings printed on the back of the bag as follows:

CAUTION: PLASTIC BAGS CAN BE DANGEROUS. TO

AVOID DANGER OF SUFFOCATION KEEP THIS BAG

AWAY FROM BABIES AND CHILDREN.

The number of print repeats is optional

The font size should be at least 20 points.

14

Apparel Packing Manual:

Issued: August 2002

Replaces: October 2001

11. GARMENT BAGS

All hanging garments in bags delivered to General Merchandise and Apparel Distribution

Centres must comply with the following specifications:

Garment Bag Specifications

1. The base material and pigment used in the production of the bag film must not impart

odour, stain or cause any other adverse reaction with the garment contained there in.

2. Bags must be equipped with 6 star vents or 4 holes per side to expel excess air. We

currently accept clean hole punched bags for ventilation. These holes should not be ripped

into the bag.

3. Bags must be securely sealed at one end only so that the bag may be sealed at the other

end with cable tie.

4. Suppliers must ensure that an appropriate bag size is chosen to fit the needs of the

specified garment and pack size required.

5. Garments must hang freely inside the bag with the bottom edge of the garment remaining

above, (not touching), the bottom of the bag. A minimum clearance of 6cm to 12cm is

required.

Despatch Instructions

1. Ensure that garments are clean and dry before packing in a garment hang bag.

2. Ensure staff handling the garments have clean hands and that the general environment is

clean and dust free.

3. Ensure that the sealed bags are kept in a cool, dry place until ready for despatch. Bags

must not be left outdoors or exposed to adverse weather conditions.

4. Bags remain vertical; i.e. hanging at all times. Under no circumstances should bags be laid

flat or over fixturing.

5. Ensure garment bags are not crushed together unnecessarily at any time causing excess

garment creasing or crushing. This applies at the manufacturers, and in the transport

vehicle.

6. Garment quantities must not exceed the recommended units as specified by the Brands.

Maximum weight of finished hanging pack is 7kg. If the pack weighs in excess of this

weight the relevant Brand Buyer must be contacted to review pack size.

7. The length of the hanging pack as measured across the hangers should not exceed

18.5cm to ensure it fits through the bagging machine.

8. Nominated carriers are to provide clean and odour free vehicles

15

Apparel Packing Manual:

Issued: August 2002

Replaces: October 2001

11. GARMENT BAGS

If a supplier has access to an automatic garment-bagging machine, this is a suitable

alternative to manual bagging. The hangers must be secured with a cable tie. All film

specifications remain the same as for pre-made bags. The supplier must ensure that the heat

setting is adequate to seal the bags sufficiently without overheating and weakening the bag

strength.

Garments to hang loose in bags. Bottom edge of garment is to remain above bottom edge of

bag. Hanger opening is to face left.

NOTE:

Garments must have no more that 6cm to 12cm excess

at the bottom heat-sealed or taped closed.

16

Apparel Packing Manual:

Issued: August 2002

Replaces: October 2001

12. BAG TIES

Ladder-lock cable ties are the only fasteners to be used to secure bags. The ties are to be

either 7inch (17.5cm) or 11 inch (27.5cm) long YELLOW.

NOTE:

CLEAR AND BLACK TIES MUST NOT BE USED DUE TO OCCUPATIONAL

HEALTH AND SAFETY RISKS WHEN PROCESSING MERCHANDISE

If a longer tie is required two 7inch (17.5cm) ties can be joined to give added length.

Ties must be firmly secured around the outside of the garment hang bag at the base of the

hanger hooks. This will ensure hangers are kept secure and easy to handle. Ties must

however, not be secured too tightly causing hanger breakage.

When grouping garments ready for placing into a garment hang bag, the cable tie may be

placed through the die-mould hole in the centre of the hanger to hold hangers securely

together.

The ends of single ties must not be cut off or shortened.

Separate larger quantities of garments into batches with a separate ladder-lock cable tie per

batch.

Place bag around grouped garments

cable tie

Secure top of bag with a ladder-lock

17

Apparel Packing Manual:

Issued: August 2002

Replaces: October 2001

13. GARMENT FOLDING DIAGRAMS

NOTE. All diagrams are available separately via attached links to allow for easy

access to download specific folding requirements

All representations of folding methods are purely indicative according to the

product type.

Any specific queries can be clarified with the relevant Brands Quality Assurance

Representatives.

18

Apparel Packing Manual:

Issued: August 2002

Replaces: October 2001

14. PREFERRED SUPPLIERS

Cartons

Service Containers

1/800 Princes Highway

Springvale Victoria 3171

PH: 03 9549 8800

FAX: 03 9561 5715

Visy Board

13 Reo Crescent

Campbellfield Victoria 3061

PH: 03 9247 4300

FAX: 03 9247 4323

Weight Marking Labels Pre-printed weight marking icon stickers can be ordered from

Australia Hong Kong Roda Graphics

Kung Wo Brand Co.

13B Brougham Street

777 Yu Chan West Street

Eltham, Vic. 3095

2nd Floor, Block A, Wing Hong

PH: 03 9431 2043

Factory Building, Kowloon. HK

FAX: 03 9439 6964

PH: 2785 0011

Email: rodagraphics@bigpond.com

FAX: 2785 3840

Email: ada@kungwo.com.hk

Poly Bags

Cork International Pty. Ltd

105 Vanessa Street

Kingsgrove, NSW 2208

PH: 02 9370 8000

FAX: 02 9370 8090

Petex Trading Company

Unit 807 Kowloon Centre

29-43 Ashley Road T.S.T.

Kowloon, Hong Kong

PH: 2376 0813

FAX: 2376 1572

Advertised Lines Stickers

Norwil Ticket Printers

16 Temple Drive

Thomastown, Victoria 3074

PH: 03 9465 7255

FAX: 03 9465 0904.

NB. This list is not exclusive; Suppliers may source product from alternative service providers that meets

specifications and standards. Seek assistance from Coles Group Supply Chain for approval to alterations

or variations to the Coles Weight Marking Icons.

19

Вам также может понравиться

- Auto Repair Sample Business PlanДокумент8 страницAuto Repair Sample Business PlanAMAR265100% (3)

- McKiney-Associate HandbookДокумент91 страницаMcKiney-Associate HandbookGen Long92% (24)

- Global URBN Fabric and Apparel Testing Manual 2.25.2019Документ81 страницаGlobal URBN Fabric and Apparel Testing Manual 2.25.2019THYAGUОценок пока нет

- 3b.inspection Procedures in SEWING ROOMДокумент26 страниц3b.inspection Procedures in SEWING ROOMAlokKumarОценок пока нет

- Beautiful Kitchens 201409 PDFДокумент112 страницBeautiful Kitchens 201409 PDFBùi Thắng100% (2)

- Merchandising Process Product Development TAДокумент24 страницыMerchandising Process Product Development TANah-bel EhmedОценок пока нет

- 2 - Garment InspectionДокумент23 страницы2 - Garment Inspectionhridi147Оценок пока нет

- Garment Cutting Room ActivitiesДокумент11 страницGarment Cutting Room ActivitiesNaisargiОценок пока нет

- SM QA ChildrenswearДокумент58 страницSM QA Childrenswearnaveenerotex100% (1)

- Ann Taylor Manual 6-13-08Документ153 страницыAnn Taylor Manual 6-13-08Prasant Maharana86% (7)

- 20 Ways To Improve Productivity in Garment Production and Planning CapacityДокумент8 страниц20 Ways To Improve Productivity in Garment Production and Planning CapacityCucak RowoОценок пока нет

- Complete Quality Manual of Garments Factory PDFДокумент11 страницComplete Quality Manual of Garments Factory PDFGAURAV SHARMAОценок пока нет

- Matrix Quality Manual Fabric InspectionДокумент17 страницMatrix Quality Manual Fabric Inspectionbeeyesyem100% (3)

- 10 Apparel QamanualДокумент44 страницы10 Apparel QamanualRanjeetKamatОценок пока нет

- Aerie Inspection ManualДокумент40 страницAerie Inspection Manualzoomerfins2250% (4)

- Fabric Inspection ProcedureДокумент20 страницFabric Inspection ProcedureGarmentLearnerОценок пока нет

- Flipcart vs Amazon e-commerce reportДокумент68 страницFlipcart vs Amazon e-commerce reportBheeshm SinghОценок пока нет

- F-02 Fabric Inspection ManualДокумент13 страницF-02 Fabric Inspection Manualzoomerfins22100% (1)

- Quality Control Systems Used in Apparel IndustryДокумент61 страницаQuality Control Systems Used in Apparel IndustryKhuram Shah Engr100% (1)

- H&M Fabric Inspection Guideline English 2014Документ12 страницH&M Fabric Inspection Guideline English 2014Rashedul Alam100% (1)

- Fabric and Apparel Performance Testing ProtocolДокумент20 страницFabric and Apparel Performance Testing Protocolbeeyesyem100% (1)

- Fabric Inspection SystemДокумент14 страницFabric Inspection SystemVrinda GuptaОценок пока нет

- Testing procedures for fabrics and trims performanceДокумент48 страницTesting procedures for fabrics and trims performanceshivanift100% (1)

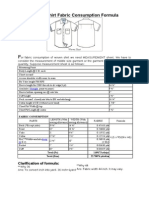

- Fabric Consumption FormulaДокумент6 страницFabric Consumption FormulaYeamin SufiОценок пока нет

- Quality Control in Garments ProductionДокумент22 страницыQuality Control in Garments Productioni_sonetОценок пока нет

- Garment InspectionДокумент93 страницыGarment InspectionShivalika Gupta100% (2)

- Production Planning and Control in the Garments IndustryДокумент2 страницыProduction Planning and Control in the Garments Industrykbalabala100% (1)

- Garment InspectionДокумент12 страницGarment Inspectionmohan smrОценок пока нет

- Materials Inspection Manual - NikeДокумент18 страницMaterials Inspection Manual - NikeNadia BeluzoОценок пока нет

- Del Monte Philippines, Inc. vs. AragoneДокумент1 страницаDel Monte Philippines, Inc. vs. AragoneLeizle Funa-FernandezОценок пока нет

- Tesco Textile Performance Standards Fabric Testing RequirementsДокумент21 страницаTesco Textile Performance Standards Fabric Testing RequirementsRezoanul Haque100% (1)

- Marker MakingДокумент12 страницMarker MakingsachipalОценок пока нет

- National Institute of Fashion Technology Course GuideДокумент17 страницNational Institute of Fashion Technology Course GuideKARISHMA RAJ100% (1)

- Garment Defects .Документ24 страницыGarment Defects .Anmol JainОценок пока нет

- Strategic Management Paper On PuregoldДокумент86 страницStrategic Management Paper On PuregoldRaraj61% (28)

- Apparel Packing Method Manual of Target AustraliaДокумент21 страницаApparel Packing Method Manual of Target AustraliaGarmentLearner100% (2)

- Sewing MachineДокумент243 страницыSewing MachineRAHUL1639840% (5)

- Processed Fabric InspectionДокумент5 страницProcessed Fabric InspectionTamrat TesfayeОценок пока нет

- SpreadingДокумент39 страницSpreadingPratik MinjОценок пока нет

- Study of Marketing Strategy On Reliance Retail: Content Page NoДокумент60 страницStudy of Marketing Strategy On Reliance Retail: Content Page NoPrateek Jena100% (1)

- Fashion Forecasting StagesДокумент27 страницFashion Forecasting StagesRavi SinghОценок пока нет

- Delivery Instructions v5Документ22 страницыDelivery Instructions v5SashenОценок пока нет

- Zigzag Alteration Data and Process Metrics ReportДокумент6 страницZigzag Alteration Data and Process Metrics ReportMd Majharul Islam100% (1)

- Business Project - Savoy Ice CreamДокумент24 страницыBusiness Project - Savoy Ice CreamUpomaAhmedОценок пока нет

- Process Flow Chart of Banswara Garment Kadaiya Unit AvinashДокумент23 страницыProcess Flow Chart of Banswara Garment Kadaiya Unit AvinashakashОценок пока нет

- Standardization of Apparel Manufacturing Industry Focusing On "Cutting Section"Документ8 страницStandardization of Apparel Manufacturing Industry Focusing On "Cutting Section"Anish RajОценок пока нет

- Care LabelДокумент21 страницаCare Labelmonisha100% (1)

- Spreading and Cutting of Apparel ProductsДокумент77 страницSpreading and Cutting of Apparel ProductskbalabalaОценок пока нет

- Fabric Finishing:: Finishing Faults/Defects - Different Types of Textile Finishing Faults/Defects With Their CausesДокумент31 страницаFabric Finishing:: Finishing Faults/Defects - Different Types of Textile Finishing Faults/Defects With Their CausesGemeda GebinoОценок пока нет

- Kohl's - Packing Requirment'sДокумент8 страницKohl's - Packing Requirment'sDebashishDolonОценок пока нет

- 1.2.1 - Triumph Global Quality Manual and Appendix - Edition Jan 2010Документ118 страниц1.2.1 - Triumph Global Quality Manual and Appendix - Edition Jan 2010LâmViên100% (1)

- Fabric Inspection Under 4-Point SystemДокумент5 страницFabric Inspection Under 4-Point Systemtexcons677150% (2)

- Carr and Latham's Technology of Clothing ManufactureОт EverandCarr and Latham's Technology of Clothing ManufactureDavid J. TylerРейтинг: 4 из 5 звезд4/5 (1)

- Loblaw Study Case NewДокумент6 страницLoblaw Study Case NewnORОценок пока нет

- Deed of Sale SampleДокумент3 страницыDeed of Sale Samplebarbiegirl9497Оценок пока нет

- KQATEX1 Apparel Textile Requirements 150310Документ17 страницKQATEX1 Apparel Textile Requirements 150310Ammar Maqsood100% (1)

- Traffic Light System in Garment IndustryДокумент11 страницTraffic Light System in Garment IndustryGopal Dixit0% (1)

- H&M QSR Part 01 - IntroductionДокумент7 страницH&M QSR Part 01 - IntroductionRashedul AlamОценок пока нет

- Apparel Quality Management Assignment 1-Care LabelsДокумент21 страницаApparel Quality Management Assignment 1-Care LabelsHarshita TiwariОценок пока нет

- Cut Order PlanningДокумент12 страницCut Order PlanningShirisha Bala100% (3)

- Fabric Inspection Process & Defect ClassificationsДокумент20 страницFabric Inspection Process & Defect ClassificationsHarrison Kan100% (1)

- Assignment 2: Understanding of Apparel QualityДокумент11 страницAssignment 2: Understanding of Apparel Qualitykashorina AgarwalОценок пока нет

- Quality System General HM GroupДокумент26 страницQuality System General HM GroupRafiqul Islam Sumon100% (1)

- IoT Machine Maintenance Using SensorsДокумент20 страницIoT Machine Maintenance Using SensorsGagan SinghviОценок пока нет

- Catalogue of Visual Textile Defects Aasim AhmedДокумент20 страницCatalogue of Visual Textile Defects Aasim AhmedAdi TtaОценок пока нет

- Sample Room DepartmentДокумент5 страницSample Room DepartmentRajib DasОценок пока нет

- QMS - F.02 Fabric Inspection Training ModuleДокумент22 страницыQMS - F.02 Fabric Inspection Training ModuleDebashishDolonОценок пока нет

- Cutting Room ProjectДокумент26 страницCutting Room ProjectSakshi Yadav100% (1)

- Target Packing ManualДокумент21 страницаTarget Packing ManualDebashishDolonОценок пока нет

- Shipping Platform Standards 2019 PDFДокумент32 страницыShipping Platform Standards 2019 PDFPaula CordobaОценок пока нет

- Product Zones: Zoning Defects and AppearanceДокумент24 страницыProduct Zones: Zoning Defects and AppearanceP. LakshmanakanthОценок пока нет

- Shipping and Routing Requirements: Box Content InformationДокумент7 страницShipping and Routing Requirements: Box Content InformationĐinh Đức ThiОценок пока нет

- Orient Garment in Sri LankaДокумент13 страницOrient Garment in Sri LankaKanishka PeellawattageОценок пока нет

- HR Training and DevelopmentДокумент25 страницHR Training and DevelopmentKanishka PeellawattageОценок пока нет

- Decision MakingДокумент25 страницDecision MakingMohammad Anisuzzaman83% (6)

- Swot Analysis PaperДокумент7 страницSwot Analysis Paperapi-310113385Оценок пока нет

- Introduction To E-Commerce: Dr. Noman IslamДокумент28 страницIntroduction To E-Commerce: Dr. Noman IslammoazzamОценок пока нет

- Batik Fabric Harbin China Using Original CottonДокумент3 страницыBatik Fabric Harbin China Using Original CottonAjeng Sito LarasatiОценок пока нет

- Financial Analysis - The Home DepotДокумент7 страницFinancial Analysis - The Home DepotbroetalzarmyОценок пока нет

- Objections To Planning Application 11-0104Документ4 страницыObjections To Planning Application 11-0104Tim DoddsОценок пока нет

- Chapter 5 - Strategies in ActionДокумент73 страницыChapter 5 - Strategies in ActionabmyonisОценок пока нет

- English Practice: I.E. N 80128 - Leoncio Prado - Huamachuco - 2011Документ25 страницEnglish Practice: I.E. N 80128 - Leoncio Prado - Huamachuco - 2011francavelezОценок пока нет

- Group4 - MiniCase - Nivea - Setting Product StrategyДокумент21 страницаGroup4 - MiniCase - Nivea - Setting Product StrategySitiAminahОценок пока нет

- BDJДокумент115 страницBDJAri cОценок пока нет

- Intl ProductДокумент16 страницIntl ProductMaddy ManojОценок пока нет

- Micromax MobilesДокумент72 страницыMicromax MobilesAshutoshSharmaОценок пока нет

- How To Apply These Ideas To BusinessДокумент19 страницHow To Apply These Ideas To Businessstuffyx100% (1)

- International Logistics ManagementДокумент8 страницInternational Logistics ManagementAby M DominicОценок пока нет

- Market Leader Progress TestДокумент3 страницыMarket Leader Progress TestBenGreenОценок пока нет

- Chapter - I Introduction and Design of The StudyДокумент21 страницаChapter - I Introduction and Design of The StudyUsha RavichandranОценок пока нет

- Economy broken into sectorsДокумент9 страницEconomy broken into sectorsAwais Muzaffar AliОценок пока нет

- RFID Implementation at METRO GroupДокумент6 страницRFID Implementation at METRO GroupAakash SahrawatОценок пока нет

- HUDCC Housing CategoriesДокумент1 страницаHUDCC Housing CategorieswrightwomanОценок пока нет

- Presentation AdДокумент40 страницPresentation Adtoqir_nwlОценок пока нет