Академический Документы

Профессиональный Документы

Культура Документы

Saes N 110

Загружено:

aamirapiОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Saes N 110

Загружено:

aamirapiАвторское право:

Доступные форматы

Engineering Standard

SAES-N-110

30 January 2007

Installation Requirements Castable Refractories

Heat Transfer Equipment Standards Committee Members

Anizi, Salamah Salem, Chairman

Bagawi, Jamil Jarallah, Vice Chairman

Hamam, Ibrahim Hassan

Fernandez, Gabriel Thomas

Gahtani, Moraya Saif

Dossary, Musfir Abdullah

Rumaih, Abdullah Mohammad

Naffaa, Mahmoud Youniss

Moore, Mark Andrew

Anezi, Mohammed Ali

Saudi Aramco DeskTop Standards

Table of Contents

1

2

3

4

5

6

7

8

9

10

11

Scope............................................................. 2

Conflicts and Deviations................................. 2

References..................................................... 2

Definitions...................................................... 4

Responsibilities.............................................. 5

Welding.......................................................... 5

Storage and Handling at Site......................... 6

Surface Preparation....................................... 6

Installation...................................................... 7

Curing and Dryout........................................ 12

Inspection, Testing and Repairs.................. 13

Previous Issue: 30 November 2004 Next Planned Update: 30 January 2012

Revised paragraphs are indicated in the right margin

Primary contact: Anizi, Salamah Salem on 966-3-8746139

CopyrightSaudi Aramco 2007. All rights reserved.

Page 1 of 17

Document Responsibility: Heat Transfer Equipment

Issue Date: 30 January 2007

Next Planned Update: 30 January 2012

SAES-N-110

Installation Requirements Castable Refractories

Scope

1.1

This standard establishes the minimum mandatory requirements for installation,

testing and inspection of hydraulic-setting refractory systems for pressure

vessels, boilers, process heaters, heat exchangers, flare tips, sulfur recovery unit

equipment and piping.

1.2

For equipment and refractory systems not covered by this standard, the Saudi

Aramco Engineer is to be contacted for guidance in determining the extent to

which this standard is applicable.

1.3

This entire standard may be attached to and made a part of purchase orders.

1.4

This standard covers the installation of new hydraulic-setting castable refractory

and the repair of existing hydraulic-setting castable refractory.

Conflicts and Deviations

2.1

Any conflicts between this standard and other applicable Saudi Aramco

Engineering Standards (SAESs), Materials System Specifications (SAMSSs),

Standard Drawings (SASDs), or industry standards, codes, and forms shall be

resolved in writing by the Company or Buyer Representative through the

Manager, Consulting Services Department of Saudi Aramco, Dhahran.

2.2

Direct all requests to deviate from this standard in writing to the Company or

Buyer Representative, who shall follow internal company procedure SAEP-302

and forward such requests to the Manager, Consulting Services Department of

Saudi Aramco, Dhahran.

References

The selection of material and equipment, and the design, construction, maintenance, and

repair of equipment and facilities covered by this standard shall comply with the latest

edition of the references listed below, unless otherwise noted.

3.1

Saudi Aramco References

Saudi Aramco Engineering Procedure

SAEP-302

Instructions for Obtaining a Waiver of a

Mandatory Saudi Aramco Engineering

Requirement

Saudi Aramco Engineering Standards

SAES-N-100

Refractory Systems

Page 2 of 17

Document Responsibility: Heat Transfer Equipment

Issue Date: 30 January 2007

Next Planned Update: 30 January 2012

SAES-W-010

SAES-N-110

Installation Requirements Castable Refractories

Welding Requirements for Pressure Vessels

Saudi Aramco Standard Drawings

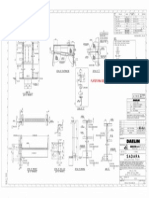

AB-036396

Hexsteel Details

AC-036397

Anchoring Details for Castable Refractory

AB-036914

Support Details at Nozzles and Manways for

Castable Refractory

AD-036916

Refractory Repairs and Terminations

Commentary Note:

The Saudi Aramco Drawings listed above and referenced in this standard shall be

used for the generation of detailed refractory system drawings, specific for each

application.

Saudi Aramco Inspection Requirement

Form 175-328110

3.2

Refractories: Hydraulic-Setting, Castable Systems

Industry Codes and Standards

American Society of Mechanical Engineers Boiler and Pressure Vessel Codes

ASME SEC IX

Welding and Brazing Qualifications

American Society for Testing and Materials

ASTM C20

Standard Test Methods for Apparent Porosity,

Water Absorption, Apparent Specific Gravity

and Bulk Density of Burned Refractory Brick

and Shapes by Boiling Water

ASTM C24

Standard Test Method for Pyrometric Cone

Equivalent (PCE) of Fireclay and High

Alumina Refractory Materials

ASTM C113

Standard Test Method for Reheat Change of

Refractory Brick

ASTM C133

Test Methods for Cold Crushing Strength and

Modulus of Rupture of Refractories

ASTM C134

Test Methods for Size and Bulk Density of

Refractory Brick and Insulating Firebrick

ASTM C860

Standard Practices for Determining and

Measuring Consistency of Refractory

Concretes

Page 3 of 17

Document Responsibility: Heat Transfer Equipment

Issue Date: 30 January 2007

Next Planned Update: 30 January 2012

ASTM C862

SAES-N-110

Installation Requirements Castable Refractories

Practice for Preparing Refractory Concrete

Specimens by Casting

Steel Structures Painting Council

SSPC SP 6

Commercial Blast Cleaning

SSPC SP 7

Brush Blasting

Definitions

Anchors: "V" or "Y" shaped hardware that supports and holds castable refractory in

place.

Curing: The initial ambient temperature holding period following refractory

placement. Curing is required to displace all free water prior to dryout.

Dryout: The initial controlled heating of refractory linings raised to temperatures near

their service temperature after curing. Dryout is to achieve the required physical

properties of the lining at its service temperature.

Equipment Manufacturer: The company that is responsible for the fabrication of

process heaters, pressure vessels, heat exchangers, piping and flare tips to which

refractory is installed.

Hexsteel and "S" bars: Metal supports for extreme erosion-resistant castable

refractory.

Metal Fiber Reinforcement: Stainless steel needles added to monolithic refractory

castables to increase strength.

MSDS: Material Safety Data Sheets for refractory material, supplied by the Refractory

Manufacturer

Refractory Inspector: The person or company authorized by the Saudi Aramco

Inspection Department to inspect refractory installations to the requirements of this

standard.

Refractory Installer: The company that is responsible for the installation of refractory

systems.

Refractory Manufacturer: The company that manufactures refractory products from

raw materials.

Refractory Systems: A lining system that is designed to high temperatures, hot gases,

and the action of erosive materials. Components include anchors, reinforcement, vapor

barriers, and refractory materials needed for complete installation.

Page 4 of 17

Document Responsibility: Heat Transfer Equipment

Issue Date: 30 January 2007

Next Planned Update: 30 January 2012

SAES-N-110

Installation Requirements Castable Refractories

Saudi Aramco Engineer: The Supervisor of the Piping and Valves Unit, Consulting

Services Department, Dhahran.

Vapor Barrier: A high-temperature coating that is applied to the shell of equipment to

protect the steel from condensing corrosive gases. For Refractory Ceramic Fibers

(RCF), the vapor barrier consists of a metal foil imbedded in RCF and high temperature

coating on the shell.

Vapor Stops: A metal ring that is welded to the shell of equipment to prevent gas

bypassing.

Vibration Casting: Castable installation technique where by refractory is mixed with

water and placed in a formed enclosure with the aid of which causes the refractory to

become "fluid like" and thereby flow and consolidate to the desired shape of the formed

enclosure.

5

Responsibilities

5.1

The Refractory Installer is responsible for installing refractory systems in

accordance with the requirements of this standard and of the specific

requirements of the Refractory Manufacturer and the Equipment Manufacturer.

5.2

The Refractory Installer is also responsible for preparing a complete installation

procedure in accordance with the requirements of the Refractory Manufacturer,

the Equipment Manufacturer, and this standard.

5.3

The Equipment Manufacturer is responsible for preparing fully detailed

engineering drawings of the refractory system. As a minimum, the drawings

shall include anchorage design including spacing and orientation, refractory

thickness, all materials, surface preparation, and welding details.

Welding

6.1

General

6.1.1

All refractory anchor welding shall be in accordance with the requirements

of ASME SEC IX, QW-190, as appropriate, for fillet welds or QW-192

for stud welding, and with the requirements of SAES-W-010.

6.1.2

All refractory anchors, stud supports, vapor stops, and edging bars for

the support of castable refractory materials on pressure vessels and

pressure piping are to be made only with the shielded metal arc welding

(SMAW) or gas tungsten arc welding (GTAW) welding processes and

shall be welded all around. For anchors, stud welding is an acceptable

alternative.

Page 5 of 17

Document Responsibility: Heat Transfer Equipment

Issue Date: 30 January 2007

Next Planned Update: 30 January 2012

6.2

SAES-N-110

Installation Requirements Castable Refractories

6.1.3

The Equipment Manufacturer shall submit Welding Procedure

Specifications and Performance Qualification Records to the Refractory

Inspector for review and approval prior to welding.

6.1.4

The Equipment Manufacturer shall prepare and have available the

detailed anchor welding procedure(s) that is to be used. This

procedure(s) shall include results of the procedure qualification tests.

6.1.5

For anchors welded by SMAW or GTAW, the procedure qualification

test shall include tension tests to failure on three anchors that have been

welded according to the procedure and on materials that will be used for

production welds. One welded anchor shall be bent through 90 and

shall show no evidence of failure in the weld.

Welding Details

6.2.1

Refractory anchorage, including anchors, studs, supports and similar

items shall not be welded within 12.5 mm of circumferential and

longitudinal seams of pressure vessels and piping. Anchors of edging

bars type shall not be welded less than 50 mm parallel to circumferential

or longitudinal seams of pressure vessels and piping.

6.2.2

If equipment is to be post weld heat treated, all anchors are to be welded

prior to heat treatment.

Storage and Handling at Site

7.1

Prior to placement, all refractory shall be protected from water and moisture.

7.2

Materials shall be stored off the ground and covered with tarps to protect against

water or moisture damage.

7.3

The Refractory Manufacturer's precautions, as specified on the MSDS sheets,

must be strictly followed.

Surface Preparation

8.1

All surfaces shall be clean, dry, and free from oil, grease, weld slag, and mill

scale prior to installation of refractory.

8.2

Prior to the application of refractory, all metallic surfaces shall be grit-blasted in

accordance with SSPC SP 6, "Commercial Blast Clean".

8.3

Surfaces that were previously coated with a vapor barrier or that are heavily

corroded shall be brush blasted in accordance with SSPC SP 7, "Brush

Page 6 of 17

Document Responsibility: Heat Transfer Equipment

Issue Date: 30 January 2007

Next Planned Update: 30 January 2012

SAES-N-110

Installation Requirements Castable Refractories

Blasting".

9

Installation

9.1

General

9.1.1

Application of hydraulic-setting refractory shall be by gunning, casting,

or vibration casting.

9.1.2

Test panels must be made prior to the application of castable refractory.

The testing procedures are to be performed in accordance with the

requirements of paragraph 11.

9.1.3

Surfaces to be lined shall be inspected prior to refractory installation.

Lining shall not be applied without prior approval of Saudi Aramco's

authorized Refractory Inspector.

9.1.4

Linings shall not be applied when the temperature of the backing surface

exceeds 32C.

9.1.5

Linings must be protected from heat-induced accelerated setting by

maintaining the temperature of the backing surface, a maximum of 32C

for a minimum of 24 hours after installation.

9.1.6

In order to achieve the temperature limitations specified in paragraphs

9.1.4 and 9.1.5, the backing surface may be shaded from direct sunlight,

the refractory lining may be applied indoors, or apply refractory lining at

night with proper illumination. Cooling by use of water spraying is

prohibited.

9.1.7

Linings shall not be applied in freezing weather unless all materials are

kept above 10C during the lining application and for a period 24 hours

after the lining application.

9.1.8

Linings shall be applied in a manner that will ensure minimal shrinkage.

All cracks are subject to repairs.

9.1.9

The water used to mix refractory shall comply with the following:

(1)

The pH shall be within a range of 5.8-8.6.

(2)

The quality of the water shall be within the following limits:

Total Impurity Level

< 1000 ppm

Calcium

< 300 ppm

Magnesium

< 300 ppm

Page 7 of 17

Document Responsibility: Heat Transfer Equipment

Issue Date: 30 January 2007

Next Planned Update: 30 January 2012

SAES-N-110

Installation Requirements Castable Refractories

Chlorine

< 200 ppm

Iron

< 500 ppm

Sulfur

< 200 ppm

9.1.10 Admixtures shall not be used.

9.1.11 The water ratios as specified by the Refractory Manufacturer shall be

used.

9.1.12 The temperature of the water and refractory shall be controlled so that

the mixed refractory is between 10C and 32C.

9.1.13 Additives to linings shall not be used unless approved by Saudi Aramco

Engineer.

9.1.14 Piping and equipment shall be adequately supported to prevent distortion

during lining.

9.1.15 Threaded attachments on equipment shall be protected from the lining

during application. Protection shall not interfere with the application of

the lining.

9.1.16 Equipment nozzle extensions shall be coated with grease to prevent

refractory from bonding to them.

9.1.17 All openings in equipment shall be closed by means of tapered hardwood

plugs or sheet metal sleeves that are long enough to extend beyond the

final thickness of the lining. These plugs or sleeves shall be coated with

grease, shall be snugly fitted into openings, and shall not be removed

until the refractory has set.

9.1.18 Refractory that shows signs of having set (lumps or hardness throughout)

prior to installation shall be rejected. All refractory shall be placed

within the Refractory Manufacturer's recommended time limits.

Refractory that is not used within specified time limit shall be discarded.

9.1.19 If refractory is installed in piping or vessel sections prior to their being

connected by welding a minimum gap of 100 mm at the ends of each

section shall be left unlined until the sections have been welded.

9.1.20 The second layer in double-layer linings shall not be applied until the

first layer has been cured for a minimum of 24 hours. Immediately prior

to applying the second layer, the first layer must be thoroughly wetted

with water of a quality as outlined in 9.1.9.

Page 8 of 17

Document Responsibility: Heat Transfer Equipment

Issue Date: 30 January 2007

Next Planned Update: 30 January 2012

SAES-N-110

Installation Requirements Castable Refractories

9.1.21 Linings of each type of refractory shall be installed to the full thickness

in a single application and shall not be built up in layers. If it is

necessary to apply lining in sections to achieve full thickness in single

application, edge forms shall be beveled 10 to provide for keying of

adjoining sections. Appropriate provisions shall be made for

construction joints.

9.2

9.3

9.4

Installation of Anchors and Supports

9.2.1

Anchors and T studs shall be installed in accordance with AC-036397.

9.2.2

Details of nozzle and manway openings in refractory lined pressure

vessels and piping shall be in accordance with AB-036914.

9.2.3

Hexsteel shall be installed in accordance with AB-036396.

Mixing Refractory for Pneumatic Applications

9.3.1

Mixing of refractory materials shall be done in a paddle type mixer.

9.3.2

Only full contents of refractory bags or drums shall be placed in the

mixer. Fractional parts of a bag or drum shall not be used.

9.3.3

Dry gunning application method shall be used. Wet gunning application

requires approval of Saudi Aramco Engineer.

9.3.4

When fiber reinforcement is used, the fibers shall be added to the mixer

through a wire mesh screen approximately 12 mm openings to obtain

proper fiber distribution.

9.3.5

The refractory shall be used within 15 minutes of mixing.

Application of Pneumatically Applied Refractory

9.4.1

Only qualified personnel who are thoroughly experienced with

pneumatic application of refractory lining shall be employed for this

work.

9.4.2

Minimum air pressure, consistent with adequate compaction of the

refractory, shall be used. The air pressure is to be determined by test

prior to application.

9.4.3

Gun nozzles are to be sized to enable the "nozzleman" to maintain

effective control of the application and to allow maneuverability in

confined spaces.

Page 9 of 17

Document Responsibility: Heat Transfer Equipment

Issue Date: 30 January 2007

Next Planned Update: 30 January 2012

SAES-N-110

Installation Requirements Castable Refractories

9.4.4

The "nozzleman" shall shoot at right angles to the surface that is being

lined.

9.4.5

The water supply and air pressure must remain constant during

application.

9.4.6

All rebound material ahead of the "nozzleman" shall be removed to

prevent inclusion in the lining.

9.4.7

Under no circumstances shall rebound material be reused.

9.4.8

For a specific band all rebound and loose material shall be removed from

the surface before application of the next band is started. No rebound

material shall be allowed to accumulate at any point where the lining has

already been applied.

9.4.9

In vertical vessels and piping, the lining shall be applied

circumferentially in narrow bands. Application is to start at the bottom

and is to proceed upwards. The full final thickness shall be permitted to

develop in each band before the next band is applied. In no case shall a

thickness be applied that is less than the thickness that is specified to

allow the applied lining to develop into initial set. The required

thickness shall not be built up in layers.

9.4.10 In large vessels and piping, where the height of the bands needed to

provide effective bonding would be too small to be practical, multiple

crews or sectionalizing may be used.

9.4.11 The top of each band shall be cut back to the shell with a steel trowel.

The cut shall be made at right angles to the shell, at a location where the

full thickness of the refractory has been applied. All refractory above

this location shall be removed and discarded. The bottom of each

successive band shall be securely bonded to the top of the preceding

band before the latter has developed an initial set.

9.4.12 The same general procedures shall be used for horizontal equipment with

the exception that horizontal equipment can be rotated for either casting

or gunning in the flat position.

9.4.13 The lining shall be screeded to the final required thickness after

placement and any deficiencies shall be immediately corrected.

Smoothing, trowelling, and floating are not permitted.

9.4.14 When application is interrupted before completion of the entire lining,

any refractory that is applied at a thickness less than the full thickness

shall be removed by cutting back to the shell with a steel trowel. The cut

Page 10 of 17

Document Responsibility: Heat Transfer Equipment

Issue Date: 30 January 2007

Next Planned Update: 30 January 2012

SAES-N-110

Installation Requirements Castable Refractories

shall be beveled into the adjacent lining by approximately 10 and all

material above the line shall be discarded.

9.4.15 During a period of interruption in application, the curing of the lining

that has already been applied may be completed.

9.4.16 Immediately prior to resuming application, the exposed surface of lining

to which a bond must be made shall be thoroughly wetted with water of a

quality as outlined in 9.1.9.

9.5

9.6

Mixing Refractory for Casting Applications

9.5.1

Mixing of refractory materials shall be done in a paddle type mixer.

9.5.2

Only full contents of refractory bags or drums shall be placed in the

mixer. Fractional parts of a bag or drum shall not be used.

9.5.3

When fiber reinforcement is used, the fibers shall, in order to obtain

proper fiber distribution, be added to the mixer through a wire mesh

screen with approximately 12 mm openings.

9.5.4

The quantity of refractory material that is mixed in one mixing shall not

be greater than the quantity that can be placed prior to initial set or 15

minutes after addition of water, whichever is shorter. Materials not used

within this time shall be discarded. Precautions shall be made to prevent

the separation of aggregates and cement prior to placement.

9.5.5

The amount of water that is used shall be the minimum amount that will

give the proper consistency for placement. This amount is not to exceed

the Refractory Manufacturer's specified amount.

9.5.6

The "ball in hand" test described in ASTM C860 shall be used to

determine the correct consistency.

Application of Cast Refractory

9.6.1

Only qualified personnel who are thoroughly experienced with cast

application of refractory lining shall be employed for this work.

9.6.2

Forms shall be s rigidly constructed and sufficiently tight to prevent

excessive leakage. The surface that are in contact with the lining shall be

uniform, reasonably smooth, and suitably coated to prevent bonding of

refractory to the forms. Forms shall be designed to facilitate their

removal without damage to the refractory.

Page 11 of 17

Document Responsibility: Heat Transfer Equipment

Issue Date: 30 January 2007

Next Planned Update: 30 January 2012

9.7

10

SAES-N-110

Installation Requirements Castable Refractories

9.6.3

Refractory shall be applied in a manner that will minimize section

segregation.

9.6.4

Refractory shall be compacted by spading or vibrating. Compacting

shall be done with care to avoid segregation of materials, damage to

previously applied portions of the lining, or damage to the equipment.

9.6.5

Work shall not be terminated until a panel or section is complete. When

work is resumed, the contact surface of the lining that is in place shall be

thoroughly cleaned, roughened, and wetted with water of a quality as

outlined in 9.1.9. Any excess water shall be removed.

9.6.6

Curing shall be carried out whenever the application is interrupted.

Application of Vibration Casting

9.7.1

The refractory materials to be used shall be manufactured specifically for

vibration casting and shall be fine grain and evenly distributed.

9.7.2

Additives used to promote flow shall be used in strict accordance with

the Refractory Manufacturer's instructions.

9.7.3

Forms used shall be made of steel sheet and shall be rigidly constructed.

Curing and Dryout

10.1

General

10.1.1 All new linings shall be cured and dried out in accordance with the

Refractory Manufacturer's recommendations and/or the standard

procedures as defined in 10.2 and 10.3 below.

10.1.2 During dryout, the equipment must be properly supported to prevent

damage to the lining and equipment.

10.2

Curing

10.2.1 Castables shall be cured after an initial set of 1 to 3 hours. All exposed

lining shall be cured by means of a fine water spray or by the application

of a membrane-curing compound. If a water spray is used, the surface

shall be kept damp for a minimum of 24 hours.

10.2.2 If forms were used during placement, these forms shall remain in place

for a minimum of 24 hours.

Page 12 of 17

Document Responsibility: Heat Transfer Equipment

Issue Date: 30 January 2007

Next Planned Update: 30 January 2012

SAES-N-110

Installation Requirements Castable Refractories

10.2.3 During the curing period, the temperature of the shell and refractory

material shall be maintained between 4C and 32C.

10.2.4 Lined equipment shall not be moved during curing.

10.3

Dryout

10.3.1 Adequately calibrated temperature measuring devices shall be installed

to monitor the temperature. When dryout is by auxiliary burners,

temperature monitoring must be provided on the gas outlet and burner

areas.

10.3.2 The maximum dryout temperature must be controlled so as not to reduce

the mechanical properties or chemical composition of the materials of

the lined equipment.

10.3.3 When dryout is done in a furnace, the temperature measuring devices

shall be installed on the refractory side and on the external surfaces of

equipment to indicate differentials between metal and refractory

temperatures.

10.3.4 Unless otherwise specified by the Refractory Manufacturer, the

minimum holding times during dryout shall be 1 hour per 25 mm of

refractory thickness.

11

Inspection, Testing and Repairs

11.1

General

11.1.1 All inspection shall be carried out in accordance with Saudi Aramco

Inspection Requirement Form 175-328110 and the requirements of this

standard.

11.1.2 All testing shall be done in accordance with the ASTM standards as

referenced in this standard.

11.1.3 All testing shall be conducted by a fully qualified independent

laboratory.

11.2

Prequalification Testing

11.2.1 Procedure and crew prequalification testing shall be carried out by the

Refractory Installer prior to any lining. This requirement shall apply to

gunning, casting or vibration casting a panel to the production thickness.

Page 13 of 17

Document Responsibility: Heat Transfer Equipment

Issue Date: 30 January 2007

Next Planned Update: 30 January 2012

SAES-N-110

Installation Requirements Castable Refractories

11.2.2 Documented evidence of the application crew's prequalification shall be

made available to the Refractory Inspector prior to production.

11.2.3 If material is to be gunned, each "nozzleman" shall "gunnite" a test panel

that is 1 m x 1 m and that is equal in thickness to the production

thickness of lining. The panel position shall be the same as the

equipment position during production application (e.g., for a vertical

wall application, the test panel shall be in the vertical position).

11.2.4 For vibration cast refractory, a mock up test employing the same

prequalified refractory materials, vibrating equipment, and mixing

procedure shall be performed prior to placement.

11.2.5 A test panel shall be constructed so that the back may be removed for

visual examination of the sample.

11.2.6 The cast or gunned test panels shall be cured for 24 hours and shall then

be hammer tested and inspected for correct curing and for voids,

cracking, deformation, or honeycombing.

11.2.7 If refractory is metallic-fiber reinforced, the test panel shall be cut into

four pieces. The cut edges will be examined for dispersion of metallic

fibers, laminations, inclusions, and voids.

11.2.8 Satisfactory results shall qualify both the crew and the application

technique.

11.3

Production Testing

11.3.1 Production tests shall be conducted during refractory application as

specified by the Refractory Inspector. However, two production samples

shall be taken at least once per shift or with each change of the

"nozzleman" or the installer. One sample shall be sent to a laboratory,

and the other sample shall remain on the job site or in the shop for

possible future testing.

11.3.2 Samples taken during production shall be tested for cold crushing

strength and density in accordance with ASTM C133, ASTM C134 and

ASTM C862. Samples from materials being cast shall be taken from the

mixer and shall be cast into molds. Samples from refractory being

gunned shall be cut from a gunned panel.

11.3.3 Test results shall be compared with the Refractory Manufacturer's

product data sheet. Test values that indicate cold crushing strength that

is less than 90% of the Refractory Manufacturer's minimum value shall

be cause for rejection.

Page 14 of 17

Document Responsibility: Heat Transfer Equipment

Issue Date: 30 January 2007

Next Planned Update: 30 January 2012

SAES-N-110

Installation Requirements Castable Refractories

11.3.4 Test values for density shall be within 81 kg/m (5 lbs/ft) of the

Refractory Manufacturer's published values. Test values outside this

range shall be cause for rejection.

11.3.5 The Refractory Installer shall keep an accurate log of installation so that

location of refractory that is presented by the production samples can be

determined in case it becomes necessary to remove this refractory.

11.3.6 At the completion of curing and drying, the lining shall be randomly

checked for voids or damaged areas. The check shall be conducted by

lightly tapping with a 1-pound hammer. It shall be sounded at random

by lightly striking the surface with a one-pound ball-peen hammer and

by audibly noting the presence of voids and insufficient hardness. If the

refractory is questionable or defective, it will produce a dead dull sound.

The size of dull sounding areas shall be investigated, and samples test

results shall be compared before a decision is made on removal of the

refractory. Visual examination and hammer testing shall be repeated

after furnace dryout. Hammer testing shall not replace refractory sample

testing.

11.3.7 Any refractory that is found to be defective due to presence of voids,

honeycombing, insufficient curing, or construction damage shall be

totally removed to the full thickness of the layer and shall be relined to

comply with this standard.

11.4

Inspection of Anchors and Supports

11.4.1 The strength of each anchor and stud attachment shall be checked with a

hammer blow.

11.4.2 All refractory anchors and their attachment welds shall be visually

inspected for complete fusion around the base of the anchor and at the

"T" stud plate. Any anchor that is not straight or that shows incomplete

fusion shall be subjected to a bend test as described in paragraphs 11.4.3

and 11.4.4.

11.4.3 A total of 5% of all anchor welds shall be subjected to a bend test. If any

of these samples shows cracks or failure at the weld, they shall be

rejected. Succeeding and preceding anchors in the same course shall be

bend tested until five consecutive welds in each direction are found to be

acceptable.

11.4.4 Bend testing shall be accomplished through use of a method that will

bend the anchor through approximately 30 and back to the normal

position.

Page 15 of 17

Document Responsibility: Heat Transfer Equipment

Issue Date: 30 January 2007

Next Planned Update: 30 January 2012

11.5

SAES-N-110

Installation Requirements Castable Refractories

Repairs

11.5.1 The method of repair, curing and retesting shall be in accordance with

the original installation procedure. Any part of a single layer lining,

except hexmesh or S-bar linings, which is defective, shall be removed

for the full thickness of the refractory material. The minimum area

removed shall be approximately one square foot. The surface shall be

cleaned of all refuse and pre-wet prior to refractory replacement. Saudi

Aramco Inspector shall determine the extent of the repair.

11.5.2 Where needed, additional refractory anchors shall be installed in

accordance with AD-036916.

11.5.3 Refractory that is under repair shall have exposed surfaces of the joint

thoroughly wetted with water of a quality as outlined in 9.1.9 prior to

placement of refractory.

11.5.4 Refractory lining cracks with a width of 3 mm (1/8") and larger and a

depth of more than 20% of refractory thickness shall be repaired.

11.6

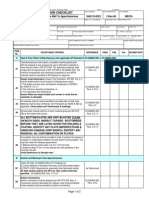

Checklist for Refractory Installation

Figure 1 is a checklist of activities that shall be used by the Refractory Installer

for the installation of castable refractory.

30 January 2007

Revision Summary

Revised the "Next Planned Update". Reaffirmed the contents of the document, and

reissued with no other changes.

Page 16 of 17

Document Responsibility: Heat Transfer Equipment

Issue Date: 30 January 2007

Next Planned Update: 30 January 2012

SAES-N-110

Installation Requirements Castable Refractories

Figure 1 Refractory Installation Checklist

A.

Prior To Installation

Materials

( )

Verify the types of

materials supplied,

data sheets and]

mixing instructions

( )

Verify availability of

MSDS sheets

Weather Protection

( )

Verify that materials

are properly stored

( )

Verify that equipment

to be lined is prepared

for inclement weather

conditions

Vibrators

( )

Number of vibrators

( )

Type

( )

Attachment method

( )

Operating condition

( )

Backup

Documents

( )

Verify approved

detail drawings

Equipment - Mixers

( )

Verify number and type

are adequate

( )

Back up mixer is available

( )

Location relative to work

( )

Cleanliness

Curing Compound Applicators

( )

Type and size

( )

Cleanliness

( )

Number

( )

Working conditions

Inspection

( )

( )

( )

B.

Inspect surface

preparation

Inspect anchor

layout and welding

Review welding

procedures

Gunnite Rig

( )

Number of Rigs

( )

Type

( )

Operating Condition

( )

Cleanliness

( )

Sufficient Hose

( )

Nozzle type

Air Compressors

( )

Size

( )

Operating Condition

( )

Contingencies

Sample Molds

( )

Cubes

( )

Gunnited

Installation

Condition

( )

Ambient

( )

Weather protection

Forming

( )

Strength

( )

Form release

( )

Position of forms

for proper thickness

( )

Sealed

( )

Bracing

( )

Secured

Mixing

( )

Water source

( )

Storage container

( )

Introduction of metallic

fiber reinforcement

( )

Percentage of metallic

fibers

( )

Cleanliness

( )

Method of adding water

( )

Water quality

( )

Water temperature

( )

Mixing time

( )

Mix temperature

( )

Water percentage

Inspection after Dryout

( )

Cracking

( )

hammer testingnats

Surface Preparation

and Anchorage

( )

Surface preparation

meets spec

( )

Welding procedures

( )

Anchor welds. Bend

tests, cracks

( )

Squaring of old refractory

( )

Anchor layout

( )

Hammer testing

Gunniting

( )

Competence of operator

( )

Pre-qualification of

gun operator

( )

Material feed rate

( )

Sampling

( )

Rebound

( )

Curing compound

application

( )

Maintenance of gun

( )

Gunning technique

( )

Air pressure

( )

Thickness

( )

Cut back

( )

Construction joints

( )

Prewet

Inspection after Curing

( )

Cracking

( )

Construction joints

( )

Hammer testing

Casting and Vibration Casting

( )

Vibrator frequency

( )

Movement of material

( )

Time between mixing

and placement

( )

Mixing per checklist

( )

Forms per checklist

( )

Curing compound applied

( )

Total casting time

( )

Water content

( )

Vibration arrangement

( )

Batch size

( )

Anchor loss

Production Sampling

( )

Proper molds and size

( )

Frequency of samples

( )

Sampling procedure

matches installation

procedure

( )

Curing

( )

Handling

Dryout

( )

Firing equipment

( )

Burner locations

relative to refractory

( )

Dryout schedule

( )

Thermocouple locations

( )

Recording equipment

Page 17 of 17

Вам также может понравиться

- Saes N 120Документ13 страницSaes N 120aamirapi100% (1)

- Saes N 100Документ16 страницSaes N 100aamirapiОценок пока нет

- 32 Samss 007Документ38 страниц32 Samss 007naruto256Оценок пока нет

- Saes D 008Документ21 страницаSaes D 008Shajin Mohammed ShamsudhinОценок пока нет

- 32 Samss 036Документ33 страницы32 Samss 036naruto256Оценок пока нет

- Saes H 204Документ33 страницыSaes H 204Rei Lizardo100% (1)

- Saep 317Документ22 страницыSaep 317brecht1980100% (1)

- SAES-W-014 - Old SpecДокумент12 страницSAES-W-014 - Old SpecMichael TayactacОценок пока нет

- Saudi Aramco Inspection Checklist: Review of Refractory Installation Procedure SAIC-N-2018 25-May-05 MechДокумент4 страницыSaudi Aramco Inspection Checklist: Review of Refractory Installation Procedure SAIC-N-2018 25-May-05 MechAnonymous S9qBDVky100% (1)

- Saic N 2031Документ4 страницыSaic N 2031aamirapi100% (1)

- Saes H 204Документ34 страницыSaes H 204heartbreakkid132Оценок пока нет

- 130087-PO-M-B-501-VP-0351 - Rev.B (Refractory)Документ22 страницы130087-PO-M-B-501-VP-0351 - Rev.B (Refractory)มิตร อันมาОценок пока нет

- Saudi Aramco Inspection ChecklistДокумент3 страницыSaudi Aramco Inspection ChecklistAbdul HannanОценок пока нет

- SAIC N 2023 PreQualTestApplicator&AppProcCastRefract EL Rev2Документ3 страницыSAIC N 2023 PreQualTestApplicator&AppProcCastRefract EL Rev2Anonymous S9qBDVkyОценок пока нет

- Saudi Aramco Inspection ChecklistДокумент5 страницSaudi Aramco Inspection ChecklistManoj Kumar100% (1)

- SAIC-S-4056 Rev 7Документ3 страницыSAIC-S-4056 Rev 7Eswari AnandОценок пока нет

- Saudi Aramco Inspection Checklist: Installation of Fired Heaters and Its Components SAIC-F-2006 25-May-05 MechДокумент10 страницSaudi Aramco Inspection Checklist: Installation of Fired Heaters and Its Components SAIC-F-2006 25-May-05 MechAnonymous S9qBDVkyОценок пока нет

- SAIC-A-2016 Pneumatic Test of Reinf Pad, Weld+EndsДокумент2 страницыSAIC-A-2016 Pneumatic Test of Reinf Pad, Weld+EndsAnonymous S9qBDVkyОценок пока нет

- Saic N 2029Документ6 страницSaic N 2029aamirapi100% (1)

- Saudi Aramco Inspection ChecklistДокумент22 страницыSaudi Aramco Inspection ChecklistAhdal NoushadОценок пока нет

- Saes W 016 PDFДокумент10 страницSaes W 016 PDFRaj AryanОценок пока нет

- Saudi Aramco Inspection Checklist: Post-Application Inspection of Fireclay Brick Installation SAIC-N-2041 15-Dec-09 MechДокумент5 страницSaudi Aramco Inspection Checklist: Post-Application Inspection of Fireclay Brick Installation SAIC-N-2041 15-Dec-09 MechaamirapiОценок пока нет

- Saudi Aramco Inspection ChecklistДокумент4 страницыSaudi Aramco Inspection Checklistaamirapi100% (2)

- Saes W 011Документ2 страницыSaes W 011hendraox3996Оценок пока нет

- SAIC-D-2023 Rev 2Документ2 страницыSAIC-D-2023 Rev 2ரமேஷ் பாலக்காடுОценок пока нет

- Saep 355 PDFДокумент20 страницSaep 355 PDFRami ElloumiОценок пока нет

- Saes H 200Документ9 страницSaes H 200راجہ شہزاد انورОценок пока нет

- Saes H 101V PDFДокумент389 страницSaes H 101V PDFQA QCОценок пока нет

- SAIC-L-2074 Rev 0Документ1 страницаSAIC-L-2074 Rev 0philipyapОценок пока нет

- Sabp A 022Документ40 страницSabp A 022Muhammad Awais100% (3)

- Saep 1146Документ11 страницSaep 1146Anonymous 4IpmN7On100% (1)

- SAIC-M-1018 Leak Proof Testing-Final InspectionДокумент1 страницаSAIC-M-1018 Leak Proof Testing-Final InspectionLegend AnbuОценок пока нет

- Saic N 2028Документ4 страницыSaic N 2028aamirapi100% (1)

- 175 010700 PDFДокумент2 страницы175 010700 PDFAbu Anas M.SalaheldinОценок пока нет

- 01 Samss 010Документ12 страниц01 Samss 010Ahmed Shaban KotbОценок пока нет

- Varun CBT QuestionДокумент7 страницVarun CBT Questionmedication abbasОценок пока нет

- Refractory Method Statement of Refractory Liquid Burn PitДокумент22 страницыRefractory Method Statement of Refractory Liquid Burn PitSaragadam Dilsri100% (4)

- 16 JRTP 02 ITP - Rev01Документ13 страниц16 JRTP 02 ITP - Rev01khsaeed100% (1)

- 00 Saip 74Документ8 страниц00 Saip 74balajiОценок пока нет

- Inspection Procedure: 00-SAIP-81 23 July 2017Документ37 страницInspection Procedure: 00-SAIP-81 23 July 2017John BuntalesОценок пока нет

- Reformer RepairДокумент11 страницReformer RepairNishant Kumar ThakurОценок пока нет

- 01 Samss 031Документ3 страницы01 Samss 031Awais CheemaОценок пока нет

- 175 091300Документ2 страницы175 091300Abu Anas M.SalaheldinОценок пока нет

- I Object: Repair Procedure For Tank BottomДокумент6 страницI Object: Repair Procedure For Tank BottomZouhair BenmabroukОценок пока нет

- Other NDT TechniquesДокумент12 страницOther NDT TechniquesabyОценок пока нет

- API-571 Reference CardДокумент7 страницAPI-571 Reference CardLaith SalmanОценок пока нет

- 00 Saip 75Документ72 страницы00 Saip 75bazresifanniОценок пока нет

- Saudi Aramco Inspection Checklist: Review of Welding Procedure Specification SAIC-W-2001 25-May-05 WeldДокумент13 страницSaudi Aramco Inspection Checklist: Review of Welding Procedure Specification SAIC-W-2001 25-May-05 WeldAnonymous S9qBDVky100% (1)

- Saic N 2037Документ5 страницSaic N 2037aamirapiОценок пока нет

- SATIP H 002 08 Rev 4.unlockedДокумент2 страницыSATIP H 002 08 Rev 4.unlockedMohamed Farhan B PositiveОценок пока нет

- Titanium Cladded Sheet Welding ProcedureДокумент4 страницыTitanium Cladded Sheet Welding ProcedureNaveenОценок пока нет

- Saudi Aramco Inspection ChecklistДокумент1 страницаSaudi Aramco Inspection Checklistaamirapi100% (1)

- Saudi Aramco Typical Inspection Plan: Fireproofing Concrete SATIP-B-006-01 14-May-18 CivilДокумент11 страницSaudi Aramco Typical Inspection Plan: Fireproofing Concrete SATIP-B-006-01 14-May-18 CivilKhurram ShehzadОценок пока нет

- 01-SAMSS-005 - Shop Applied, Internal Cement Mortar Lining of Steel PipeДокумент5 страниц01-SAMSS-005 - Shop Applied, Internal Cement Mortar Lining of Steel PipebalajiОценок пока нет

- 01 Samss 010Документ11 страниц01 Samss 010doyenofcastleОценок пока нет

- Ayari Maher: Qualified Welder I.D.CardДокумент10 страницAyari Maher: Qualified Welder I.D.CardZouhair BenmabroukОценок пока нет

- 32 Samss 028Документ28 страниц32 Samss 028naruto256Оценок пока нет

- 32 Samss 028Документ28 страниц32 Samss 028biplabpal2009Оценок пока нет

- 32 Samss 027Документ30 страниц32 Samss 027naruto256Оценок пока нет

- 32 Samss 019Документ17 страниц32 Samss 019Moustafa BayoumiОценок пока нет

- SATIP-X-400-01 Rev 5Документ3 страницыSATIP-X-400-01 Rev 5aamirapiОценок пока нет

- Refractory Dry-Out Procedure For SRU Train 5 (MC-P06) Rev-AДокумент107 страницRefractory Dry-Out Procedure For SRU Train 5 (MC-P06) Rev-Aaamirapi100% (2)

- SAIC-X-3002 Rev 5Документ3 страницыSAIC-X-3002 Rev 5aamirapiОценок пока нет

- Saudi Aramco Inspection Checklist: Post-Application Inspection of Fireclay Brick Installation SAIC-N-2041 15-Dec-09 MechДокумент5 страницSaudi Aramco Inspection Checklist: Post-Application Inspection of Fireclay Brick Installation SAIC-N-2041 15-Dec-09 MechaamirapiОценок пока нет

- Saudi Aramco Inspection ChecklistДокумент2 страницыSaudi Aramco Inspection ChecklistaamirapiОценок пока нет

- Saic N 2036Документ6 страницSaic N 2036aamirapiОценок пока нет

- Saudi Aramco Inspection Checklist: Storage & Preservation of Fireclay Bricks & Mortar SAIC-N-2038 15-Dec-09 MechДокумент1 страницаSaudi Aramco Inspection Checklist: Storage & Preservation of Fireclay Bricks & Mortar SAIC-N-2038 15-Dec-09 MechaamirapiОценок пока нет

- Saic N 2034Документ4 страницыSaic N 2034aamirapiОценок пока нет

- Saic N 2034Документ4 страницыSaic N 2034aamirapiОценок пока нет

- Saes N 140Документ10 страницSaes N 140aamirapiОценок пока нет

- Saic N 2037Документ5 страницSaic N 2037aamirapiОценок пока нет

- Saudi Aramco Inspection ChecklistДокумент6 страницSaudi Aramco Inspection Checklistaamirapi100% (1)

- Saudi Aramco Inspection ChecklistДокумент5 страницSaudi Aramco Inspection Checklistaamirapi100% (1)

- Saic N 2031Документ4 страницыSaic N 2031aamirapi100% (1)

- Saic N 2033Документ5 страницSaic N 2033aamirapiОценок пока нет

- Saic N 2029Документ6 страницSaic N 2029aamirapi100% (1)

- Saudi Aramco Inspection ChecklistДокумент5 страницSaudi Aramco Inspection Checklistaamirapi100% (1)

- Saic N 2028Документ4 страницыSaic N 2028aamirapi100% (1)

- Saudi Aramco Inspection Checklist: Pre-Application Inspection of Castable & Brick Refractory SAIC-N-2024 15-Dec-09 MechДокумент12 страницSaudi Aramco Inspection Checklist: Pre-Application Inspection of Castable & Brick Refractory SAIC-N-2024 15-Dec-09 Mechaamirapi100% (1)

- Saudi Aramco Inspection ChecklistДокумент1 страницаSaudi Aramco Inspection Checklistaamirapi100% (1)

- Saudi Aramco Inspection ChecklistДокумент7 страницSaudi Aramco Inspection ChecklistaamirapiОценок пока нет

- Saudi Aramco Inspection ChecklistДокумент4 страницыSaudi Aramco Inspection Checklistaamirapi100% (2)

- Daelim: General NotesДокумент1 страницаDaelim: General NotesaamirapiОценок пока нет

- Plateform Deleted Hence This Gate Also Not RequiredДокумент1 страницаPlateform Deleted Hence This Gate Also Not RequiredaamirapiОценок пока нет

- Test - SHEM - 07.05 (ANSWER SHEET.) : Employ Name ID# Department SignДокумент1 страницаTest - SHEM - 07.05 (ANSWER SHEET.) : Employ Name ID# Department SignaamirapiОценок пока нет

- MD4 203 D 7150 340 9003 009 - AwcДокумент1 страницаMD4 203 D 7150 340 9003 009 - AwcaamirapiОценок пока нет

- Lesson Plan 3Документ3 страницыLesson Plan 3api-547884261Оценок пока нет

- INERT-SIEX 200-300 IG-100: Design ManualДокумент54 страницыINERT-SIEX 200-300 IG-100: Design ManualSaleh Mohamed0% (1)

- 00capítulo - The Routledge Handbook of Henri Lefebvre, The City and Urban SocietyДокумент12 страниц00capítulo - The Routledge Handbook of Henri Lefebvre, The City and Urban SocietyJeronimoОценок пока нет

- ?????Документ89 страниц?????munglepreeti2Оценок пока нет

- Elementary Statistics A Step by Step Approach 9th Edition Bluman Solutions ManualДокумент23 страницыElementary Statistics A Step by Step Approach 9th Edition Bluman Solutions Manuala305894328100% (3)

- Exam Materials ScienceДокумент10 страницExam Materials ScienceChimzoe CatalanОценок пока нет

- CO Q1 TLE EPAS 7 8 Module 4 Preparing Technical DrawingsДокумент47 страницCO Q1 TLE EPAS 7 8 Module 4 Preparing Technical DrawingsNicky John Doroca Dela MercedОценок пока нет

- Physics Assessment 1 - Lab Report: Jessica Yam Year 10 Peace MR - SlosbergДокумент19 страницPhysics Assessment 1 - Lab Report: Jessica Yam Year 10 Peace MR - Slosbergapi-36149866550% (2)

- BBMP C&D Draft Notice 2014 (Updated)Документ10 страницBBMP C&D Draft Notice 2014 (Updated)PriankMathurОценок пока нет

- Chapter 8 - Nervous ReviewerДокумент18 страницChapter 8 - Nervous Reviewerchristian anchetaОценок пока нет

- ISO 13920 - Tolerâncias para Juntas SoldadasДокумент7 страницISO 13920 - Tolerâncias para Juntas SoldadasRicardo RicardoОценок пока нет

- Astm D6321-98-2004Документ3 страницыAstm D6321-98-2004Thyagu LingamurthyОценок пока нет

- B.ing Wajib - XI IPA1-2Документ3 страницыB.ing Wajib - XI IPA1-2iwan fals NurjaniОценок пока нет

- Thru Tubing Catalog PDFДокумент43 страницыThru Tubing Catalog PDFchubby_hippoОценок пока нет

- MiniNova GuideДокумент41 страницаMiniNova GuideBob FredОценок пока нет

- Object: Annex A, B, C DДокумент74 страницыObject: Annex A, B, C DfjsdОценок пока нет

- Namma Kalvi 12th English Slow Learners Study MaterialДокумент28 страницNamma Kalvi 12th English Slow Learners Study MaterialSTANLEY RAYEN100% (1)

- What Is Kpag?: Table of ContentsДокумент2 страницыWhat Is Kpag?: Table of Contentsangelito bernalОценок пока нет

- Designing New Vanillin Schiff Bases and Their Antibacterial StudiesДокумент4 страницыDesigning New Vanillin Schiff Bases and Their Antibacterial StudiesAvinash PurohitОценок пока нет

- 螳螂拳七長八短 - Tanglangquan Qi Chang Ba Duan - Tanglangquan's Seven Long & Eight Short - Lessons Learned in the World of Martial ArtsДокумент2 страницы螳螂拳七長八短 - Tanglangquan Qi Chang Ba Duan - Tanglangquan's Seven Long & Eight Short - Lessons Learned in the World of Martial ArtsGianfranco MuntoniОценок пока нет

- Basic Mechanical Engineering Btkit Dwarahat: Attempt All Questions. Q. 1. Attempt Any Four Parts: 5 X 4 20Документ2 страницыBasic Mechanical Engineering Btkit Dwarahat: Attempt All Questions. Q. 1. Attempt Any Four Parts: 5 X 4 20anadinath sharmaОценок пока нет

- Origami - Playing CardsДокумент6 страницOrigami - Playing Cardsapi-3709851Оценок пока нет

- Constructing 30deg AngleДокумент4 страницыConstructing 30deg AngleArthur ChewОценок пока нет

- The Singapore Engineer - September 2018 IssueДокумент27 страницThe Singapore Engineer - September 2018 Issuekrpt0tytОценок пока нет

- Teff Type-I Sourdough To ProduДокумент21 страницаTeff Type-I Sourdough To ProdudanaОценок пока нет

- THESISДокумент44 страницыTHESISRowena Shaira AbellarОценок пока нет

- Pid 14 MT23 160412Документ20 страницPid 14 MT23 160412Amol ChavanОценок пока нет

- Taenia SoliumДокумент40 страницTaenia SoliumBio SciencesОценок пока нет

- MHR PreCal 12 Textbook CH 1 SolutionsДокумент57 страницMHR PreCal 12 Textbook CH 1 SolutionsBryan LowОценок пока нет

- Practice Test 1 + 2Документ19 страницPractice Test 1 + 2yếnОценок пока нет