Академический Документы

Профессиональный Документы

Культура Документы

Saudi Aramco Inspection Checklist

Загружено:

aamirapiИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Saudi Aramco Inspection Checklist

Загружено:

aamirapiАвторское право:

Доступные форматы

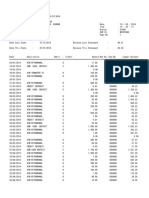

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - June 2008)

Rev 3

SAUDI ARAMCO INSPECTION CHECKLIST

SAIC NUMBER

In-Process Inspection of Pneumatically Applied (Gunned)

Refractory

PROJECT TITLE

SAIC-N-2025

WBS / BI / JO NUMBER

EQUIPMENT ID NUMBER(S)

EQUIPMENT DESCRIPTION

LAYOUT DRAWING NUMBER

REV. NO.

SCHEDULED INSPECTION DATE & TIME

ACTUAL INSPECTION DATE & TIME

PLANT NO.

EC / PMCC / MCC NO.

MH's SPENT

TRAVEL TIME

SAUDI ARAMCO USE ONLY

CONTRACTOR INSPECTION LEVEL

REFERENCE

General Requirements (SAES-N-110 procedure, Section 9)

A1

Checklist SAIC-N-2024 was completed & accepted for Pre-Application

requirements related to Pneumatic (Gunned application) refractory.

As Referenced

A2

Correct Material & Application Method is being used for equipment

with gunned refractory per SAES-N-100, Tables 2 & 3. See Note 1.

As Referenced

B.

Mixing Refractory for Pneumatic Applications (SAES-N-110 Procedure, Section 9)

B1

Mixing of refractory materials is done in a paddle type mixer.

SAES-N-110,

Para. 9.3.1

B2

Only full contents of refractory bags or drums are placed in the mixer.

Fractional parts of the bag or drum are not used.

SAES-N-110,

Para. 9.3.2

B3

Dry gunning application method is being used.

Note: Wet gunning application shall be approved by Saudi Aramco

Engineer.

SAES-N-110,

Para. 9.3.3

B4

When fiber reinforcement is used, the fibers were added to the mixer

through a wire mesh screen with approximately 12 mm openings.

SAES-N-110,

Para. 9.3.4

B5

Refractory is used within 15 minutes of mixing (time of water applied)

SAES-N-110,

Para. 9.3.5

C.

Application of Pneumatically Applied Refractory (SAES-N-110 Procedure, Section 9)

C1

Only qualified personnel who are thoroughly experienced with pneumatic

application of refractory lining are doing the work.

SAES-N-110,

Para. 9.4.1

C2

The proper minimum air pressure to assure adequate refractory

compaction is used (as determined by testing prior to application).

SAES-N-110,

Para. 9.4.2

C3

Gun nozzles are sized properly enabling "nozzleman" to control the

application and maneuver in confined spaces.

SAES-N-110,

Para. 9.4.3

C4

Refractory material is shot at right angles to the surfaces being lined.

SAES-N-110,

Para. 9.4.4

C5

Water supply & air pressure remain constant during application.

SAES-N-110,

Para. 9.4.5

C6

Refractory material rebounded ahead of "Nozzleman", is removed and

not included in the lining.

Note: Under no circumstances is rebound material reused.

SAES-N-110,

Para. 9.4.6

&

Para. 9.4.7

Page 1 of 5

MECH-

SYSTEM ID.

QUANTITY INSP.

SAUDI ARAMCO INSPECTION LEVEL

ACCEPTANCE CRITERIA

QR NUMBER

CONTRACTOR / SUBCONTRACTOR

PURCHASE ORDER NUMBER

SAUDI ARAMCO ACTIVITY NUMBER

A.

15-Dec-09

EQPT CODE

SAUDI ARAMCO TIP NUMBER

ITEM

No.

30-Jun-08

DATE APPROVED

WORK PERMIT REQUIRED?

PASS

FAIL

N/A

RE-INSP DATE

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - June 2008)

Rev 3

SAUDI ARAMCO INSPECTION CHECKLIST

In-Process Inspection of Pneumatically Applied (Gunned)

Refractory

PROJECT TITLE

SAIC NUMBER

SAIC-N-2025

WBS / BI / JO NUMBER

ITEM

No.

ACCEPTANCE CRITERIA

REFERENCE

C7

For each specific band all rebound & loose material is removed from the

surface before application of next band is started & no rebound material

is allowed to accumulate at any point where lining is already applied.

SAES-N-110,

Para. 9.4.8

C8

In vertical vessels & piping, lining is applied circumferentially in narrow

bands starting at bottom & proceeding upwards with full final thickness

permitted to develop in each band before the next band is applied.

SAES-N-110,

Para. 9.4.9

C9

In no case is a thickness applied that is less than the thickness that is

specified to allow the applied lining to develop into initial set.

The required thickness is not built up in layers.

SAES-N-110,

Para. 9.4.9

C10

In large vessels & piping, where height of the bands needed to provide

effective bonding is too small to be practical, sectionalizing or multiple

crews are used to meet Paragraph 9.4.9 (Item C10 item above).

SAES-N-110,

Para. 9.4.10

C11

Top of each band is cut back to shell with a steel trowel using a cut with

a right angle to the shell at a location where full refractory thickness is

applied with all refractory above this location removed & discarded.

SAES-N-110,

Para. 9.4.11

C12

The bottom of each successive band is securely bonded to the top of the

preceding band before the latter has developed an initial set.

SAES-N-110,

Para. 9.4.11

C13

Horizontal equipment utilizes the same general procedures unless the

horizontal equipment is rotated for casting or gunning in the flat position.

SAES-N-110,

Para. 9.4.12

C14

The lining is screeded to the final required thickness after placement &

any deficiencies are immediately corrected.

Smoothing, trowelling, and floating are not

permitted.

SAES-N-110,

Para. 9.4.13

C15

When application is interrupted before completion of entire lining, any

refractory applied at thickness less than full thickness is removed by

cutting back to shell with a steel trowel using a beveled cut into adjacent

lining by approximately 10 with all material above the line discarded.

SAES-N-110,

Para. 9.4.14

C16

During a period of interruption in application, the curing of the lining that

has already been applied may be completed.

SAES-N-110,

Para. 9.4.15

C17

Immediately prior to resuming application, the exposed surface of lining

to which a bond must be made is thoroughly wetted with a quality water.

SAES-N-110,

Para. 9.4.16

Page 2 of 5

30-Jun-08

DATE APPROVED

15-Dec-09

QR NUMBER

MECH-

CONTRACTOR / SUBCONTRACTOR

PASS

FAIL

N/A

RE-INSP DATE

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - June 2008)

Rev 3

SAUDI ARAMCO INSPECTION CHECKLIST

SAIC NUMBER

In-Process Inspection of Pneumatically Applied (Gunned)

Refractory

PROJECT TITLE

ITEM

No.

SAIC-N-2025

WBS / BI / JO NUMBER

ACCEPTANCE CRITERIA

30-Jun-08

DATE APPROVED

REFERENCE

D.

In-Process Inspection & Testing (COMPLETE SATR-N-2001)

D1

Inspection & Testing was performed per SAES-N-110 Procedure & SA

Inspection Requirement Form 175-328110.

See Attachment 1.

SAES-N-110,

Para. 11.1.1

D2

Two (2) Production test samples were taken once per shift or each

change of nozzleman/installer (1 sample to lab, 1 sample properly

stored/cured)

Refractory being gunned has samples cut from a gunned panel.

SAES-N-110,

Para. 11.3.1

D2

Samples taken during production are tested for cold crushing strength &

density per ASTM C133, ASTM C134 & ASTM C862 .

SAES-N-110,

Para. 11.3.2

D3

Refractory Installer keeps an accurate log of installation so that location

of refractory that is presented by the production samples can be

determined in case it becomes necessary to remove this refractory.

SAES-N-110,

Para. 11.3.5

QR NUMBER

15-Dec-09

MECH-

CONTRACTOR / SUBCONTRACTOR

PASS

FAIL

N/A

RE-INSP DATE

REMARKS:

REFERENCE DOCUMENTS:

1. SAES-N-100 -- Refractory Systems (30 Jan 2007)

2. SAES-N-110 -- Installation Requirements-Castable Refractories (30 Jan 2007)

3. SAES-N-120 -- Installation Requirements-Extreme Erosion Resistant Refractories (30 Jan 2007)

ATTACHMENTS: Attachment 1 -- SA INSP FORM 175-328110 (Refractories)

NOTES: 1. Use Table 2 & 3 Mandatory Refractory Systems of SAES-N-100 (Not Attached) for Pre-installation inspection checks of materials.

Contractor / Third-Party

Saudi Aramco

Construction Representative*

PMT Representative

Work is Complete and Ready for Inspection:

Name, Initials and Date:

T&I Witnessed

QC Record Reviewed

Work Verified

T&I Witnessed

QC Record Reviewed

Work Verified

T&I Witnessed

QC Record Reviewed

Work Verified

Name, Initials and Date:

QC Inspector

PID Representative

Performed Inspection

Work / Rework May Proceed

Name, Initials and Date:

Name, Initials and Date:

QC Supervisor

Proponent and Others

Quality Record Approved:

Name, Sign and Date:

Name, Organization,

Initials and Date:

*Person Responsible for Completion of Quality Work / Test

Y = YES

Page 3 of 5

N = NO F = FAILED

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - June 2008)

Rev 3

SAUDI ARAMCO INSPECTION CHECKLIST

In-Process Inspection of Pneumatically Applied (Gunned)

Refractory

SAIC NUMBER

SAIC-N-2025

30-Jun-08

DATE APPROVED

15-Dec-09

Attachment 1 -- SA INSP FORM 175-328110

Page 4 of 5

QR NUMBER

MECH-

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - June 2008)

Rev 3

SAUDI ARAMCO INSPECTION CHECKLIST

In-Process Inspection of Pneumatically Applied (Gunned)

Refractory

Page 5 of 5

SAIC NUMBER

SAIC-N-2025

30-Jun-08

DATE APPROVED

15-Dec-09

QR NUMBER

MECH-

Вам также может понравиться

- Saudi Aramco Inspection Checklist: Pre-Application Inspection of Castable & Brick Refractory SAIC-N-2024 15-Dec-09 MechДокумент12 страницSaudi Aramco Inspection Checklist: Pre-Application Inspection of Castable & Brick Refractory SAIC-N-2024 15-Dec-09 Mechaamirapi100% (1)

- Saic N 2033Документ5 страницSaic N 2033aamirapiОценок пока нет

- Saic N 2031Документ4 страницыSaic N 2031aamirapi100% (1)

- Saic N 2029Документ6 страницSaic N 2029aamirapi100% (1)

- Saic N 2028Документ4 страницыSaic N 2028aamirapi100% (1)

- Saudi Aramco Inspection ChecklistДокумент1 страницаSaudi Aramco Inspection Checklistaamirapi100% (1)

- Saudi Aramco Inspection ChecklistДокумент4 страницыSaudi Aramco Inspection Checklistaamirapi100% (2)

- Saudi Aramco Inspection Checklist: Post-Application Inspection of Fireclay Brick Installation SAIC-N-2041 15-Dec-09 MechДокумент5 страницSaudi Aramco Inspection Checklist: Post-Application Inspection of Fireclay Brick Installation SAIC-N-2041 15-Dec-09 MechaamirapiОценок пока нет

- Saudi Aramco Inspection Checklist: Inspection of Furnace Dryout SAIC-N-2030 25-May-05 MechДокумент4 страницыSaudi Aramco Inspection Checklist: Inspection of Furnace Dryout SAIC-N-2030 25-May-05 MechAnonymous S9qBDVky0% (1)

- Saudi Aramco Inspection ChecklistДокумент5 страницSaudi Aramco Inspection Checklistaamirapi100% (1)

- Saudi Aramco Inspection ChecklistДокумент6 страницSaudi Aramco Inspection Checklistaamirapi100% (1)

- Saic N 2037Документ5 страницSaic N 2037aamirapiОценок пока нет

- Saudi Aramco Inspection ChecklistДокумент2 страницыSaudi Aramco Inspection Checklistphilipyap100% (1)

- SKF Supergrip BoltДокумент29 страницSKF Supergrip BoltSahil KumarОценок пока нет

- Saudi Aramco Inspection Checklist: Review of Refractory Installation Procedure SAIC-N-2018 25-May-05 MechДокумент4 страницыSaudi Aramco Inspection Checklist: Review of Refractory Installation Procedure SAIC-N-2018 25-May-05 MechAnonymous S9qBDVky100% (1)

- SMS - 603 - UTZ - 001 - Sulzer SPEKTRA Rev.00.pdf (TTD) PDFДокумент24 страницыSMS - 603 - UTZ - 001 - Sulzer SPEKTRA Rev.00.pdf (TTD) PDFRosyidi danangОценок пока нет

- SABIC® LLDPE M500026: Linear Low Density Polyethylene For Masterbatch CompoundingДокумент2 страницыSABIC® LLDPE M500026: Linear Low Density Polyethylene For Masterbatch CompoundingAnas AbdoОценок пока нет

- Saudi Aramco Inspection Checklist: Storage & Preservation of Fireclay Bricks & Mortar SAIC-N-2038 15-Dec-09 MechДокумент1 страницаSaudi Aramco Inspection Checklist: Storage & Preservation of Fireclay Bricks & Mortar SAIC-N-2038 15-Dec-09 MechaamirapiОценок пока нет

- RSP - ALL - WI0573 - CC Permit To Work Management - Appendix 01Документ1 страницаRSP - ALL - WI0573 - CC Permit To Work Management - Appendix 01sani priadi100% (1)

- Stanvac 2Документ4 страницыStanvac 2Tamba PasaribuОценок пока нет

- Eagle Burgmann API PlanДокумент43 страницыEagle Burgmann API PlanONURОценок пока нет

- 04 AD 0042 Burner Maintenance FloorДокумент1 страница04 AD 0042 Burner Maintenance FloorPradip Tapan BanerjeeОценок пока нет

- 4.1 - ANX-1 Definition of Mechanical Completion PDFДокумент18 страниц4.1 - ANX-1 Definition of Mechanical Completion PDFLegend AnbuОценок пока нет

- Lesson Check Valves: Sub-ObjectiveДокумент7 страницLesson Check Valves: Sub-Objectivemister pogiОценок пока нет

- Boiler Hydrotest Procedure Boiler BDFB 350-1004Документ10 страницBoiler Hydrotest Procedure Boiler BDFB 350-1004Gunung A E SinamnbelaОценок пока нет

- Guard House Monkey Ladder 01Документ5 страницGuard House Monkey Ladder 01razi khanОценок пока нет

- Technical Specifications For 33 KV Xlpe Insulated Underground Cables 1. ScopeДокумент22 страницыTechnical Specifications For 33 KV Xlpe Insulated Underground Cables 1. Scopethumula.rameshОценок пока нет

- Aramco Balance Material Site IssuesДокумент12 страницAramco Balance Material Site IssuesVinay Yadav100% (1)

- 1.Cooling Tower Operation & Maintenance manual 冷却塔操作维护手册-ENДокумент15 страниц1.Cooling Tower Operation & Maintenance manual 冷却塔操作维护手册-ENNissar Hussain100% (2)

- Loctite Solutions For Power PlantsДокумент14 страницLoctite Solutions For Power PlantsHusen TaufiqОценок пока нет

- ControTrace Installation Checklist PipeДокумент1 страницаControTrace Installation Checklist PipeEnoch TwumasiОценок пока нет

- Pitting Repairs For High-Temperature/ High-Pressure Process VesselsДокумент8 страницPitting Repairs For High-Temperature/ High-Pressure Process VesselsRaghavanОценок пока нет

- Preservation of Coated Pipes For Long Term Storage in Tropical Environment PDFДокумент8 страницPreservation of Coated Pipes For Long Term Storage in Tropical Environment PDFNguyen Anh TungОценок пока нет

- EP 2 Grease PDFДокумент2 страницыEP 2 Grease PDFTayyab IftikharОценок пока нет

- 7EA Experience With Water Cooled Liquid FuelДокумент5 страниц7EA Experience With Water Cooled Liquid FuelJJОценок пока нет

- Scope of WorkДокумент75 страницScope of WorkPhong leОценок пока нет

- Complete Report Rla SWCC Ksa Phase 1 Unit5boilerДокумент149 страницComplete Report Rla SWCC Ksa Phase 1 Unit5boilerWaseem ArshadОценок пока нет

- Weld Built-Up ProcedureДокумент1 страницаWeld Built-Up ProcedureMohd Shafuaaz KassimОценок пока нет

- Equipment and ToolsДокумент15 страницEquipment and ToolsMathias OnosemuodeОценок пока нет

- Hts 2134981 RHM Bolting Proposal Yanbu 11.05.13Документ4 страницыHts 2134981 RHM Bolting Proposal Yanbu 11.05.13George ManuelОценок пока нет

- 8474L-000-JSD-2310-001-4-Protective Coatings PDFДокумент31 страница8474L-000-JSD-2310-001-4-Protective Coatings PDFDo Quynh100% (2)

- Turnaround Best Practices - Planning, Scheduling and Management of ShutdownsДокумент4 страницыTurnaround Best Practices - Planning, Scheduling and Management of ShutdownsAhmed Ibrahim ElaminОценок пока нет

- Steam Turbine Mechanical Overspeed Trip Devices: InsightДокумент2 страницыSteam Turbine Mechanical Overspeed Trip Devices: InsightManoj SinghОценок пока нет

- Heat Exchangers: Submitted To: Mr. AtifДокумент12 страницHeat Exchangers: Submitted To: Mr. Atifmak412Оценок пока нет

- Turbine Comm.Документ66 страницTurbine Comm.Abhishek TiwariОценок пока нет

- Water Wash Procedure For EconomizerДокумент3 страницыWater Wash Procedure For EconomizerRajendra100% (1)

- Dual Fuel Installation, Commissioning & Operation Manual REV IIIДокумент43 страницыDual Fuel Installation, Commissioning & Operation Manual REV IIIJuan Manuel Llorente VaraОценок пока нет

- Bare Plate Heat Exchanger IOДокумент33 страницыBare Plate Heat Exchanger IOCarlos SopasОценок пока нет

- SMP For Sealing Water Pump Multi Stage.Документ13 страницSMP For Sealing Water Pump Multi Stage.SonratОценок пока нет

- Ch7 G4010-R1Документ140 страницCh7 G4010-R1MoshОценок пока нет

- Saudi Aramco Inspection ChecklistДокумент2 страницыSaudi Aramco Inspection ChecklistaamirapiОценок пока нет

- Inspection Checksheet For The Gas TurbineДокумент12 страницInspection Checksheet For The Gas TurbineMax CuiОценок пока нет

- Commissioning Measures Form For Approval: Phase I of 2×330MW Project of Tengda Coal-Fired Power Plant in IndiaДокумент21 страницаCommissioning Measures Form For Approval: Phase I of 2×330MW Project of Tengda Coal-Fired Power Plant in IndiaParthiban KarunaОценок пока нет

- 2 Long Term OverheatingДокумент17 страниц2 Long Term OverheatingWalter RuedaОценок пока нет

- Sa e 001aДокумент7 страницSa e 001amahdi_gОценок пока нет

- Is 2062 - E250 Vs Is-1367 ComparisonДокумент2 страницыIs 2062 - E250 Vs Is-1367 ComparisonDevang JaniОценок пока нет

- Design Operation and Maintenance of CT PDFДокумент24 страницыDesign Operation and Maintenance of CT PDFHamid Ariz50% (2)

- Saic N 2034Документ4 страницыSaic N 2034aamirapiОценок пока нет

- Saic-W-2xxx-15 Pre Welding & Joint Fit-Up InspectionДокумент4 страницыSaic-W-2xxx-15 Pre Welding & Joint Fit-Up InspectionAnsuman Kalidas100% (1)

- SAIC N 2025 in ProcessInspPneumaticallyAppliedRefract EL RevДокумент3 страницыSAIC N 2025 in ProcessInspPneumaticallyAppliedRefract EL RevAnonymous S9qBDVkyОценок пока нет

- SATIP-X-400-01 Rev 5Документ3 страницыSATIP-X-400-01 Rev 5aamirapiОценок пока нет

- Saes N 140Документ10 страницSaes N 140aamirapiОценок пока нет

- Saudi Aramco Inspection ChecklistДокумент2 страницыSaudi Aramco Inspection ChecklistaamirapiОценок пока нет

- SAIC-X-3002 Rev 5Документ3 страницыSAIC-X-3002 Rev 5aamirapiОценок пока нет

- Refractory Dry-Out Procedure For SRU Train 5 (MC-P06) Rev-AДокумент107 страницRefractory Dry-Out Procedure For SRU Train 5 (MC-P06) Rev-Aaamirapi100% (2)

- Saic N 2037Документ5 страницSaic N 2037aamirapiОценок пока нет

- Saudi Aramco Inspection Checklist: Storage & Preservation of Fireclay Bricks & Mortar SAIC-N-2038 15-Dec-09 MechДокумент1 страницаSaudi Aramco Inspection Checklist: Storage & Preservation of Fireclay Bricks & Mortar SAIC-N-2038 15-Dec-09 MechaamirapiОценок пока нет

- Saudi Aramco Inspection Checklist: Post-Application Inspection of Fireclay Brick Installation SAIC-N-2041 15-Dec-09 MechДокумент5 страницSaudi Aramco Inspection Checklist: Post-Application Inspection of Fireclay Brick Installation SAIC-N-2041 15-Dec-09 MechaamirapiОценок пока нет

- Saic N 2036Документ6 страницSaic N 2036aamirapiОценок пока нет

- Saic N 2034Документ4 страницыSaic N 2034aamirapiОценок пока нет

- Saic N 2034Документ4 страницыSaic N 2034aamirapiОценок пока нет

- Saudi Aramco Inspection ChecklistДокумент6 страницSaudi Aramco Inspection Checklistaamirapi100% (1)

- Saudi Aramco Inspection ChecklistДокумент5 страницSaudi Aramco Inspection Checklistaamirapi100% (1)

- Saudi Aramco Inspection ChecklistДокумент1 страницаSaudi Aramco Inspection Checklistaamirapi100% (1)

- Saes N 120Документ13 страницSaes N 120aamirapi100% (1)

- Test - SHEM - 07.05 (ANSWER SHEET.) : Employ Name ID# Department SignДокумент1 страницаTest - SHEM - 07.05 (ANSWER SHEET.) : Employ Name ID# Department SignaamirapiОценок пока нет

- MD4 203 D 7150 340 9003 009 - AwcДокумент1 страницаMD4 203 D 7150 340 9003 009 - AwcaamirapiОценок пока нет

- Saes N 110Документ17 страницSaes N 110aamirapi100% (1)

- Saudi Aramco Inspection ChecklistДокумент7 страницSaudi Aramco Inspection ChecklistaamirapiОценок пока нет

- Saudi Aramco Inspection ChecklistДокумент4 страницыSaudi Aramco Inspection Checklistaamirapi100% (2)

- Plateform Deleted Hence This Gate Also Not RequiredДокумент1 страницаPlateform Deleted Hence This Gate Also Not RequiredaamirapiОценок пока нет

- Daelim: General NotesДокумент1 страницаDaelim: General NotesaamirapiОценок пока нет

- Saes N 100Документ16 страницSaes N 100aamirapiОценок пока нет

- EE1000 DC Networks Problem SetДокумент7 страницEE1000 DC Networks Problem SetAmit DipankarОценок пока нет

- A Comparison of Pharmaceutical Promotional Tactics Between HK & ChinaДокумент10 страницA Comparison of Pharmaceutical Promotional Tactics Between HK & ChinaAlfred LeungОценок пока нет

- DR-2100P Manual EspДокумент86 страницDR-2100P Manual EspGustavo HolikОценок пока нет

- Toa Valix Vol 1Документ451 страницаToa Valix Vol 1Joseph Andrei BunadoОценок пока нет

- Fletcher Theophilus Ato CVДокумент7 страницFletcher Theophilus Ato CVTHEOPHILUS ATO FLETCHERОценок пока нет

- Awais Inspector-PaintingДокумент6 страницAwais Inspector-PaintingMohammed GaniОценок пока нет

- Vice President Enrollment Management in Oklahoma City OK Resume David CurranДокумент2 страницыVice President Enrollment Management in Oklahoma City OK Resume David CurranDavidCurranОценок пока нет

- Conflict WaiverДокумент2 страницыConflict WaiverjlurosОценок пока нет

- Digital Documentation Class 10 NotesДокумент8 страницDigital Documentation Class 10 NotesRuby Khatoon86% (7)

- We Move You. With Passion.: YachtДокумент27 страницWe Move You. With Passion.: YachthatelОценок пока нет

- Test Bank For American Corrections Concepts and Controversies 2nd Edition Barry A Krisberg Susan Marchionna Christopher J HartneyДокумент36 страницTest Bank For American Corrections Concepts and Controversies 2nd Edition Barry A Krisberg Susan Marchionna Christopher J Hartneyvaultedsacristya7a11100% (30)

- Chat Application (Collg Report)Документ31 страницаChat Application (Collg Report)Kartik WadehraОценок пока нет

- Bismillah SpeechДокумент2 страницыBismillah SpeechanggiОценок пока нет

- EC2 406006 001 EFE 0121 - Controgen Generator Excitation System Description - Rev - AДокумент29 страницEC2 406006 001 EFE 0121 - Controgen Generator Excitation System Description - Rev - AAnonymous bSpP1m8j0n50% (2)

- Introduction To Wireless and Mobile Systems 4th Edition Agrawal Solutions ManualДокумент12 страницIntroduction To Wireless and Mobile Systems 4th Edition Agrawal Solutions Manualethelbertsangffz100% (34)

- In Partial Fulfillment of The Requirements For The Award of The Degree ofДокумент66 страницIn Partial Fulfillment of The Requirements For The Award of The Degree ofcicil josyОценок пока нет

- Research Proposal IntroductionДокумент8 страницResearch Proposal IntroductionIsaac OmwengaОценок пока нет

- ABB Price Book 524Документ1 страницаABB Price Book 524EliasОценок пока нет

- Bank Statement SampleДокумент6 страницBank Statement SampleRovern Keith Oro CuencaОценок пока нет

- Curamik Design Rules DBC 20150901Документ8 страницCuramik Design Rules DBC 20150901Ale VuОценок пока нет

- Aluminium Extrusion Industry in IndiaДокумент3 страницыAluminium Extrusion Industry in Indiakalan45Оценок пока нет

- Engagement Letter TrustДокумент4 страницыEngagement Letter Trustxetay24207Оценок пока нет

- Electrical Estimate Template PDFДокумент1 страницаElectrical Estimate Template PDFMEGAWATT CONTRACTING AND ELECTRICITY COMPANYОценок пока нет

- 88 - 02 Exhaust Manifold Gasket Service BulletinДокумент3 страницы88 - 02 Exhaust Manifold Gasket Service BulletinGerrit DekkerОценок пока нет

- Certification and LettersДокумент6 страницCertification and LettersReimar FerrarenОценок пока нет

- Soneri Bank Compensation PolicyДокумент20 страницSoneri Bank Compensation PolicySapii Mandhan100% (1)

- Hitt PPT 12e ch08-SMДокумент32 страницыHitt PPT 12e ch08-SMHananie NanieОценок пока нет

- Shopnil Tower 45KVA EicherДокумент4 страницыShopnil Tower 45KVA EicherBrown builderОценок пока нет

- Power For All - Myth or RealityДокумент11 страницPower For All - Myth or RealityAshutosh BhaktaОценок пока нет