Академический Документы

Профессиональный Документы

Культура Документы

06 - Major Alarm& Safety of 50DF With UNIC (DNV)

Загружено:

dassi99Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

06 - Major Alarm& Safety of 50DF With UNIC (DNV)

Загружено:

dassi99Авторское право:

Доступные форматы

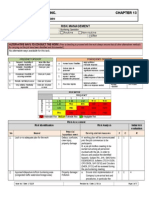

W50DF MAJOR SAFETY for

f Ship

Shi Power

P

UNIC

U

C C3

WRTSIL W50DF

For Training Use Only

Wrtsil 12 July 2012 WLSA-Korea Rev. 03

100 Fuel System

GS172 Mech overspeed trip released

Safety action

Set point

Delay

Engine mode

Fuel mode

Remark

SP emergency

stop

true

01s

0.1

Start, Run

Start

Shutdown

all

Emergency stop if tripped during run

run.(18%

(18% over

nom.)

SP start block

true

0s

Stop, Standby

all

Start blocking in stop/standby mode.

IS1741 Overspeed shutdown 1 status (Generated in ESM20)

IS1742 Overspeed shutdown 2 status (Generated in ESM20)

Safety action

Set point

Delay

Engine mode

Fuel mode

SP emergency stop

true

(15% over

nom. in

ESM20)

0.1 s

except Emergency

stop

all

Remark

Redundant overspeed protection actuation

handled in ESM20. Status signal connected to

MCM, for activation of em. stop mode.

For training use only

2

Wrtsil 12 July 2012 WLSA-Korea Rev. 03

100 Fuel System

PT125 Pilot fuel press, pump outlet

Safety action

Set point

Delay

Engine mode

Fuel mode

Remark

SF pilot

il t trip

ti

t

true

01s

0.1

allll

Diesel,l Gas,

Di

G

Transfer

SF generated

t d in

i MCM

MCM.

SF alarm

true

0.1 s

all

all

SF generated in MCM.

SP pilot trip

75 bar from

reference

5s

Start, Run

Diesel, Gas,

Transfer

Pilot trip from pilot fuel pressure swing. Pressure

has swung both over and under the reference with

75 bar, more than 2 times in 5 seconds.

SP pilot trip

100 bar from

reference

5s

Run

Diesel, Gas,

Transfer

High deviation from reference.

VSP pilot trip

mapped

0.5 s

Run

Diesel, Gas,

Transfer

Low press. pilot trip acc. to below mapping.

W50DF:

Press [bar]

0

600

650

700

Speed [rpm] 0

120

300

480

VSP pilot trip

mapped

0.5 s

Run

Diesel, Gas,

Transfer

High press. pilot trip acc. to below mapping.

W50DF:

Press [bar]

1200

1200

1200

1200

Speed [rpm]

0

120

300

480

For training use only

3

Wrtsil 12 July 2012 WLSA-Korea Rev. 03

200 Lube oil system

TE201 LO temp, engine inlet

Safety action

Set point

Delay

Engine mode

Fuel mode

Remark

SF alarm

l

t

true

3s

allll

allll

SF generated

t d in

i MCM

MCM.

SP alarm

70 C

5s

Run

all

High temp. alarm.

SP load reduction

(Relative -20%)

80 C

5s

Run

(CB close)

all

High

g temp.

p load red. 20 %

IS2011(PTZ201) LO press, shutdown

h td

status

t t (Generated

(G

t d in

i ESM20)

Safety action

SP shutdown

Set point

Delay

Engine mode

Fuel mode

Remark

2.5 bar

0.1 s

Run

all

Low pressure shutdown actuation handled in ESM20.

Status signal connected to MCM, for activation of

shutdown mode in MCM.

(in ESM20)

For training use only

4

Wrtsil 12 July 2012 WLSA-Korea Rev. 03

300 Compressed air system

PT312 Instrument air press (for wastegate v/v)

Safety action

Set point

Delay

Engine mode

Fuel mode

Remark

SF alarm

true

3s

all

all

SF generated in MCM.

SP alarm

5.0 bar

5s

Start, Run

all

Low pressure alarm.

SP gas trip

5.0 bar

10 s

Start, Run

Gas,

Transfer

Low pressure gas trip.

NZ331 Slow turning (if applicable)

Safety action

Set point

Delay

Engine mode

Fuel mode

SP shutdown

true

0s

Stop,

Standby,

Start

all

Remark

Slow turning failed.

For training use only

5

Wrtsil 12 July 2012 WLSA-Korea Rev. 03

400 Cooling water system(HT & LT)

IS4011 (TEZ402/TEZ403) HT water temperature shutdown status(Generated in ESM20)

Safety action

SP shutdown

Set point

Delay

Engine mode

Fuel mode

true

+110 C

(in ESM20)

01s

0.1

Run

all

Remark

High temperature shutdown actuation handled in

ESM20. Info signal connected

to MCM, for activation of shutdown mode in MCM.

TE432 HT water temp, HT CAC outlet

Safety action

SF alarm

Set point

Delay

Engine mode

Fuel mode

true

3s

all

all

Remark

Measurement only. SF generated in MCM.

For training use only

6

Wrtsil 12 July 2012 WLSA-Korea Rev. 03

500 Exhaust system

TE50##A/B Exh gas temp, cylinder ## A/B

Safety action

Set point

Delay

Engine mode

Fuel mode

Remark

SF alarm

true

3s

all

all

SF gas trip

true

3s

all

Gas,

Transfer(D to G)

SP alarm

540 C

C

5s

Run

all

Cyl temp.

Cyl.

temp too high

high.

SP load reduction

(Relative -20%)

550 C

10 s

Run

(CB Close)

all

High cyl. temp. load reduction. 20 %

SP gas trip

560C

5s

Run

Gas,

Transfer(D to G)

VSP pilot trip

mapped

60 s

Start,

Run

Diesel,

Gas

SP shutdown

580 C

3s

Run

all

generated in CCM. Value not used in exh.

SF g

gas temp. average calculation.

SF generated in CCM.

High temp gas trip.

Exhaust gas temp. min. level for all cylinders,

at pilot system check during start. Pass levels

for succeeded start in g

gas- or diesel mode acc.

to below mapping with TE402.

W50DF:

Exh. temp. [C] 60 80 100 110

HT temp. [C]

40 60

90 100

High cyl. temp. shutdown. Only for PP

For training use only

7

Wrtsil 12 July 2012 WLSA-Korea Rev. 03

500 Exhaust system

TY5##7A/B Exh gas temp deviation, cylinder ## A/B

Safety action

Set point

Delay

Engine mode

Fuel mode

Remark

g exhaust temp

p deviation from average.

g

High

VSP alarm

mapped

10 s

Run

all

Exh. temp. dev. [C]

Exh. temp. ave. [C]

90 C 50 C

250 C 500 C

NOTE! Alarm activated when average temperature is

above 250C.

VSP gas trip

mapped

3s

Run

Gas,

Transfer(D to G)

Gas trip for maximum exhaust temp. deviation (low) fr

om average, acc. to below

mapping:

Exh. temp. dev. [C] -170C -70C

Engine load [%]

0

100

For training use only

8

Wrtsil 12 July 2012 WLSA-Korea Rev. 03

600 Combution air system

PT601 Charge air pressure, engine inlet

Safety action

Set point

Delay

Engine mode

Fuel mode

SF alarm

true

3s

all

all

SF generated in MCM

MCM.

SF gas trip

true

1s

all

Gas,

Transfer(D to G)

SF generated in MCM.

3.5 bar

5s

Run

Backup,

Diesel

SP alarm

Remark

High pressure alarm in diesel & backup mode.

For training use only

9

Wrtsil 12 July 2012 WLSA-Korea Rev. 03

600 Combution air system

SE6##4A/B Knock, cyl ## A/B

Safety action

Set point

Delay

Engine mode

Fuel mode

Remark

SF alarm

True

3s

Run

(CB close)

all

SF load reduction

True

3s

Run

(CB close)

Gas,

Transfer(D to G)

Load reduction / Load reduction request to 80 % in

case of sensor failure.

SF load

l d reduction

d ti

t

true

3s

R

Run

(CB close)

G

Gas,

Transfer(D to G)

Load

L

d reduction

d ti / L

Load

d reduction

d ti requestt tto 80 % iin

case of sensor failure.

SP gas trip

Status 0

30 s

Run

Gas,

Transfer(D to G)

Gas trip if the system can not eliminate light knock.

SP alarm

Status = 1

0s

Run

Gas,

Transfer(D to G)

Light knock.

SP load reduction

(Relative -20%)

Status = 2

0s

Run

Gas,

Transfer(D to G)

Heavy knock.

SP gas trip

Status = 3

0s

Run

Gas,

Transfer(D to G)

Secondary heavy knock .

SF generated in MCM

MCM.

For training use only

10

Wrtsil 12 July 2012 WLSA-Korea Rev. 03

700 Miscellaneous system

NS700, QS700, QS701 Oil mist detector

Safety action

Set point

Delay

Engine mode

Fuel mode

SF alarm

(NS700)

SP alarm

(QS700)

true

3s

all

all

SF generated in oil mist detector.

detector

true

1s

Run

all

High oil mist concentration alarm

true

0.1

Run

all

High oil mist concentration shutdown by ESM20

(delay set in ESM20)

SP shutdown

(QS701)

Remark

For training use only

11

Wrtsil 12 July 2012 WLSA-Korea Rev. 03

700 Miscellaneous system

OS7305 External shutdown #4 (remote emergency stop)

Safety action

Set point

Delay

Engine mode

Fuel mode

SP emergency

stop

true

0s

all except

Emergency

stop

all

Remark

Emergency stop from remote emergency stop

button/input.

OS7309,, OS7310,, OS7311 External shutdowns #1,, #2,, #3

Safety action

SP shutdown

Set point

Delay

Engine mode

Fuel mode

true

0.1 s

all except

Shutdown,

Emergency

stop

all

Remark

Shutdown from ext. shutdown inputs.

OS7312, OS7313, OS7314 External start blocking #1, #2, #3

Safety action

SP start block

Set point

Delay

Engine mode

Fuel mode

true

0s

Stop,

Standby

all

Remark

Start blocking in stop/standby mode.

For training use only

12

Wrtsil 12 July 2012 WLSA-Korea Rev. 03

700 Miscellaneous system

OS7332 External gas trip #1 status

Safety action

SP gas trip

Set point

Delay

Engine mode

Fuel mode

true

01s

0.1

all

all

Remark

External gas trip status signal

signal.

UA793 Engine load over max. transfer level to gas

Safety action

Set point

Delay

Engine mode

Fuel mode

SP alarm

80 %

0s

Run

(CB Close)

Diesel

SP gas trip

80 %

0s

Run

(CB Close)

Transfer(D to G)

Remark

High load alarm (alarm only active if transfer to

gas is initiated). Transfer prohibited.

High load alarm. Transfer interrupted.

For training use only

13

Wrtsil 12 July 2012 WLSA-Korea Rev. 03

700 Miscellaneous system

UT793 Engine load feedback

Safety action

Set point

Delay

Engine mode

Fuel mode

Remark

SF gas trip

S

p

true

ue

0.1 s

0

Run

u

Gas,

Transfer

SF ge

S

generated

e a ed in MCM.

C

SF alarm

true

0.1 s

all

Backup,

Diesel

SF alarm.

SP alarm

(GTY1623)

mapped

mapped

Run

(CB Close)

Backup,

Backup

Diesel

Overload alarm acc

acc. to below mapping:

Delay [s]

5

3

1

0

Load [%]

102

104

106

108

SP gas trip

(GTY1623)

mapped

mapped

Run

(CB Close)

Gas,

Transfer

Overload gas trip acc. to below mapping:

Delay [s]

5

3

1

0

Load [%]

102

104

106

108

SP gas trip

(GQY793)

true

0s

Run

(CB Close)

Gas,

Transfer

High load oscillation level. 2 positive and 2 negative

peaks in 5 seconds. *) 10 % of rated engine output in

kW.

For training use only

14

Wrtsil 12 July 2012 WLSA-Korea Rev. 03

900 Gas system

PT901 Main gas press

Safety action

Set point

Delay

Engine mode

Fuel mode

Remark

SF alarm

true

3s

all

all

SF generated in MCM

MCM.

SF gas trip

true

0s

all

Gas,

Transfer

SF generated in MCM.

PDY901 Main gas press deviation

Safety action

Set point

Delay

Engine mode

Fuel mode

Remark

VSP alarm

mapped

10 s

Run

Gas

High abs deviation between reference- and actual

gas pressure. High

Hi h diff

diff. pressure alarm

l

acc. tto b

below

l

mapping:

Press. [bar]

0.3

0.3

0.3

0.3

Load [mbar]

0 8000 16000 20000

VSP gas trip

mapped

0.5 s

Run

Gas,

Transfer

High abs deviation between reference- and actual

gas pressure. High diff. pressure gas trip acc. to

below mapping:

Press. [bar]

0.5 0.5

0.5

0.5

Load [mbar]

0 8000 16000 20000

For training use only

15

Wrtsil 12 July 2012 WLSA-Korea Rev. 03

900 Gas system

IS901 Main gas press build up time elapsed

Safety action

SP gas trip

Set point

Delay

Engine mode

Fuel mode

true

0s

Start, Run

Diesel

Remark

Gas trip due to failing gas pressure

PDY940 High press diff, PT901-PT601

S f t action

Safety

ti

S t point

Set

i t

D l

Delay

E i mode

Engine

d

F l mode

Fuel

d

R

Remark

k

SP alarm

1.3 bar

0s

Run

Gas

High abs dP between gas pressure and charge air

pressure. (PT901 PT601)

SP gas ttrip

i

13b

1.3

bar

2s

R

Run

G

Gas

High

Hi

h abs

b dP between

b t

gas pressure and

d charge

h

air

i

pressure. (PT901 PT601)

For training use only

16

Wrtsil 12 July 2012 WLSA-Korea Rev. 03

Вам также может понравиться

- Unic PDFДокумент4 страницыUnic PDF11yudhaОценок пока нет

- 01 - Automation For W50DFДокумент33 страницы01 - Automation For W50DFarunkudagi100% (1)

- 3 4 Wecs8000 Functions w34sg V00r07cb0809a001l 01enДокумент5 страниц3 4 Wecs8000 Functions w34sg V00r07cb0809a001l 01enShahadat Hossain100% (1)

- 04 CCM10Документ11 страниц04 CCM10Mohamed AshfaqОценок пока нет

- Injection Valve Test RigДокумент4 страницыInjection Valve Test Rigmichael_forra0% (1)

- 08 Unic C3Документ49 страниц08 Unic C3Gloria HamiltonОценок пока нет

- User ManualS99E en 1.4Документ143 страницыUser ManualS99E en 1.4Nikita NezhelskoyОценок пока нет

- WFI0032 DF Conversion PresentationДокумент36 страницWFI0032 DF Conversion PresentationDesri TandiОценок пока нет

- WECS4Документ17 страницWECS4shahin gholamiОценок пока нет

- UG 40 Governor: Lever or Dial Type Speed Setting With Adjustable DroopДокумент4 страницыUG 40 Governor: Lever or Dial Type Speed Setting With Adjustable DroopPhilippe DAVIDОценок пока нет

- Training Programme CatalogueДокумент39 страницTraining Programme CatalogueSatyabrat Gaan100% (1)

- Napier NT1 BrochureДокумент16 страницNapier NT1 Brochureairtupas100% (2)

- 12 W34SGAutomationДокумент34 страницы12 W34SGAutomationmohamed100% (2)

- WS23P257 FGL 1363 Inductive Sensor PDFДокумент3 страницыWS23P257 FGL 1363 Inductive Sensor PDFmohamed0% (1)

- 08 AUTOMATION SYSTEM W3208L00BTM10A Rev 01Документ42 страницы08 AUTOMATION SYSTEM W3208L00BTM10A Rev 01John Earl TejamoОценок пока нет

- Engine W50DF Operation AdvancedДокумент1 234 страницыEngine W50DF Operation AdvancedAsif100% (1)

- Wartsila Slow SteamingДокумент6 страницWartsila Slow SteamingNapoleon MpОценок пока нет

- MAN - Power Plants PDFДокумент100 страницMAN - Power Plants PDFBárbara LeitãoОценок пока нет

- 04 RT - Flex4 Course D Control Systems 9500Документ56 страниц04 RT - Flex4 Course D Control Systems 9500Franky D'costa100% (1)

- Engine Characteristics: UEC33LSE-Eco-C2 Technical Data 1.4 Eco-Engine SystemДокумент6 страницEngine Characteristics: UEC33LSE-Eco-C2 Technical Data 1.4 Eco-Engine Systembritties69Оценок пока нет

- Electronic Fuel Viscosity Controller New Model English Tib 771 GB 0215Документ50 страницElectronic Fuel Viscosity Controller New Model English Tib 771 GB 0215irfanWPK100% (2)

- Boiler Setting ProceduresДокумент19 страницBoiler Setting Proceduressumit100% (1)

- 050 - RT-Flex Training FV104 Rev005Документ90 страниц050 - RT-Flex Training FV104 Rev005Laurian Ştefan100% (2)

- 07 - Engine Safety ModuleДокумент36 страниц07 - Engine Safety ModuleGloria Hamilton75% (4)

- Pneumatic Maneuvering SystemДокумент65 страницPneumatic Maneuvering Systemminhankyaw100% (3)

- Wartsilla Power Plant 6.3MW X 3Документ38 страницWartsilla Power Plant 6.3MW X 3Cvita CvitićОценок пока нет

- Cam Effects PDFДокумент6 страницCam Effects PDFGiovanniJara100% (6)

- Viscochief EVT-10C Viscosity Transducer: Marine & Diesel EquipmentДокумент18 страницViscochief EVT-10C Viscosity Transducer: Marine & Diesel EquipmentИван ПарлапановОценок пока нет

- 23 Instrumentation and AutomationДокумент42 страницы23 Instrumentation and AutomationAdrianzzzzОценок пока нет

- Wärtsilä 46DF: Product GuideДокумент242 страницыWärtsilä 46DF: Product GuideLyoshaZabarenkoОценок пока нет

- Pdfs Level DaticДокумент6 страницPdfs Level DaticJamal28100% (1)

- ERS Brochure PreviewДокумент14 страницERS Brochure PreviewVictor EugenОценок пока нет

- MДокумент36 страницMmajdi2013100% (1)

- Wärtsilä 50Df Engine TechnologyДокумент16 страницWärtsilä 50Df Engine TechnologyCésaire Aimé NdjemОценок пока нет

- Oil Mist Detector Testing ProcedureДокумент7 страницOil Mist Detector Testing Procedureavm4343Оценок пока нет

- Compact Gas Ramp - Product Manual - enДокумент38 страницCompact Gas Ramp - Product Manual - enSalman Khalid ChauhanОценок пока нет

- Instrumentation Systems: Wärtsilä V50Df Standard EngineДокумент30 страницInstrumentation Systems: Wärtsilä V50Df Standard Enginelarina20049273100% (1)

- SXD-12PC2 MaintenancesManualsДокумент488 страницSXD-12PC2 MaintenancesManualssilviaОценок пока нет

- Wartsila W28SG 1Документ5 страницWartsila W28SG 1hadОценок пока нет

- Wartsila Fuel Pump - MaintenanceДокумент15 страницWartsila Fuel Pump - MaintenanceAbhishek Singh Chauhan0% (1)

- Wecsplorer Software ToolДокумент5 страницWecsplorer Software ToolMank UduyОценок пока нет

- Wartsila Unic Engine Control System For Gas and Dual Fuel Engines PDFДокумент4 страницыWartsila Unic Engine Control System For Gas and Dual Fuel Engines PDFAries Shaqueena La PamasiОценок пока нет

- Wartsila Tools Guide TCSPC PDFДокумент159 страницWartsila Tools Guide TCSPC PDFcengiz kutukcu50% (2)

- W34SG-V00TMCB005L - 01 Engine W34SG Operation AdvancedДокумент861 страницаW34SG-V00TMCB005L - 01 Engine W34SG Operation Advancedhendrazulian0% (1)

- Wartsila 32Документ177 страницWartsila 32ivan paul ponayoОценок пока нет

- Wartsila 38-F-S-D-BOOKДокумент151 страницаWartsila 38-F-S-D-BOOKEgor Xlebnikov88% (8)

- Spemos System Wartsila ManualДокумент192 страницыSpemos System Wartsila ManualGeorgios MariolisОценок пока нет

- Man BWДокумент24 страницыMan BWDhanie KhruxzОценок пока нет

- W46 Adjustment of Fuel Valve Opening Pressure 4616Q006 - 01gbДокумент2 страницыW46 Adjustment of Fuel Valve Opening Pressure 4616Q006 - 01gbDP100% (1)

- Cooling Water Treatment - Bulletins - WartsilaДокумент9 страницCooling Water Treatment - Bulletins - WartsilaAfsanul TanveerОценок пока нет

- Paae221519spc en PDFДокумент600 страницPaae221519spc en PDFDenis NuñezОценок пока нет

- MAN B&W Alpha DieselДокумент12 страницMAN B&W Alpha Dieselamin_corporation100% (3)

- Project Guide B32 - 40A 2018Документ145 страницProject Guide B32 - 40A 2018Guilherme Henrique FilhoОценок пока нет

- Alarm List of Wartsila 20v32 Engine PDFДокумент54 страницыAlarm List of Wartsila 20v32 Engine PDFtomi100% (4)

- Wartsila 50 DF Dual Fuel Engine Reference For LNGC 04 01 07 PPTДокумент47 страницWartsila 50 DF Dual Fuel Engine Reference For LNGC 04 01 07 PPTEDDIN1960100% (3)

- (1-1) Main Engine (Wartsila)Документ532 страницы(1-1) Main Engine (Wartsila)Pratham A Diwadkar100% (2)

- Operational Limits With Turbocharger Cut-Out: Technical BulletinДокумент8 страницOperational Limits With Turbocharger Cut-Out: Technical Bulletinneofytos78100% (2)

- Marine Combustion Practice: The Commonwealth and International Library: Marine Engineering DivisionОт EverandMarine Combustion Practice: The Commonwealth and International Library: Marine Engineering DivisionРейтинг: 5 из 5 звезд5/5 (1)

- New Technologies for Emission Control in Marine Diesel EnginesОт EverandNew Technologies for Emission Control in Marine Diesel EnginesОценок пока нет

- RA 002 - LPSG Steam Pipe Hot Work in ERДокумент6 страницRA 002 - LPSG Steam Pipe Hot Work in ERdassi99Оценок пока нет

- Qual 002 Evaluation of Supplier - SubcontractorДокумент1 страницаQual 002 Evaluation of Supplier - Subcontractordassi99Оценок пока нет

- Conversion Table For PressureДокумент4 страницыConversion Table For Pressuredassi99Оценок пока нет

- RA 002 - HFO Line Pressure TestДокумент4 страницыRA 002 - HFO Line Pressure Testdassi99100% (1)

- Qual 001 Supplier-Subcontractor Quality HistoryДокумент1 страницаQual 001 Supplier-Subcontractor Quality Historydassi99Оценок пока нет

- RA 002 - D.O. Tank Inspection and CleaningДокумент6 страницRA 002 - D.O. Tank Inspection and Cleaningdassi99100% (1)

- RA 002 - Engine Casing Exhaust Funnel - Hot WorkДокумент6 страницRA 002 - Engine Casing Exhaust Funnel - Hot Workdassi99Оценок пока нет

- RA 002 - BunkeringДокумент5 страницRA 002 - Bunkeringdassi99Оценок пока нет

- Installation Guide EnglishДокумент11 страницInstallation Guide Englishdassi99Оценок пока нет

- Quick Reference - EnglishДокумент44 страницыQuick Reference - Englishdassi99Оценок пока нет

- 06 - Major Alarm& Safety of 50DF With UNIC (DNV)Документ16 страниц06 - Major Alarm& Safety of 50DF With UNIC (DNV)dassi99100% (1)

- E1 - Purging & Gas Leakage Test SequencesДокумент6 страницE1 - Purging & Gas Leakage Test Sequencesdassi99Оценок пока нет

- All About ECDISДокумент12 страницAll About ECDISdassi99Оценок пока нет

- Final Impa Pilot Ladder PosterДокумент1 страницаFinal Impa Pilot Ladder Posterdassi99Оценок пока нет

- DNV CertificateДокумент1 страницаDNV Certificatedassi99Оценок пока нет

- Shipping Law Handbook - Part E CollisionДокумент21 страницаShipping Law Handbook - Part E Collisiondassi99Оценок пока нет

- Cause and Effect Diagram - HHISHI (01-LIST - 1040438Документ2 страницыCause and Effect Diagram - HHISHI (01-LIST - 1040438dassi99Оценок пока нет

- JAN 701B HandoutsДокумент22 страницыJAN 701B Handoutsdassi990% (1)

- Piezoelectricity:: Principle Knock SensorsДокумент1 страницаPiezoelectricity:: Principle Knock Sensorsdassi99Оценок пока нет

- Point Fortin - Umm Bab Port OptimoorДокумент7 страницPoint Fortin - Umm Bab Port Optimoordassi99Оценок пока нет

- Practical TestДокумент4 страницыPractical Testdassi99100% (1)

- 4.10.1 Ramp Up-Ramp Down Plan-AsclepiusДокумент1 страница4.10.1 Ramp Up-Ramp Down Plan-Asclepiusdassi99100% (1)

- Gas System Double WallДокумент1 страницаGas System Double Walldassi99Оценок пока нет

- Owners' Damages For Repudiation by CharterersДокумент16 страницOwners' Damages For Repudiation by Charterersdassi99Оценок пока нет

- Calculating Damages by Clive AstonДокумент10 страницCalculating Damages by Clive Astondassi99100% (1)

- WISE Cargo User Manual - Ver 6 (A4)Документ36 страницWISE Cargo User Manual - Ver 6 (A4)dassi9950% (2)

- RTCM Auto Acquisition Vs Manual Guard Ring ARPAДокумент10 страницRTCM Auto Acquisition Vs Manual Guard Ring ARPAdassi99Оценок пока нет

- The Law of Shipbuilding Contracts - PART 1 The Nature of The Shipbuilding ContractДокумент3 страницыThe Law of Shipbuilding Contracts - PART 1 The Nature of The Shipbuilding Contractdassi99Оценок пока нет

- Winch Drum SpoolingДокумент2 страницыWinch Drum Spoolingdassi99Оценок пока нет

- Srinivasa Ramanujan Institute of TechnologyДокумент2 страницыSrinivasa Ramanujan Institute of TechnologyPandu RangareddyОценок пока нет

- AIMS Manual - 2021Документ82 страницыAIMS Manual - 2021Randyll TarlyОценок пока нет

- Research TopicsДокумент15 страницResearch TopicsmalinksОценок пока нет

- AbstractДокумент1 страницаAbstractJignesh PrajapatiОценок пока нет

- Lesson PlanДокумент11 страницLesson PlanKim Gabrielle Del PuertoОценок пока нет

- Amiel Houser - LévinasДокумент8 страницAmiel Houser - Lévinaschristyh3Оценок пока нет

- AquaMapPublic v202Документ26 страницAquaMapPublic v202engfeupОценок пока нет

- PT2 Exam CLASS XI CS 2023Документ2 страницыPT2 Exam CLASS XI CS 2023Aditya AurangeОценок пока нет

- Cultural Competence Refers To An Ability To Interact Effectively With People of Different CulturesДокумент5 страницCultural Competence Refers To An Ability To Interact Effectively With People of Different CulturesKim EliotОценок пока нет

- Rack Interface Module 3500 20SДокумент71 страницаRack Interface Module 3500 20SmaheshОценок пока нет

- AYLS Annual Report 2019 LampДокумент136 страницAYLS Annual Report 2019 LampHigh FourОценок пока нет

- Advanced Numerical Modelling of Geogrids and Steel Wire Meshes - Daniele TubertiniДокумент94 страницыAdvanced Numerical Modelling of Geogrids and Steel Wire Meshes - Daniele TubertiniSze Mian KuehОценок пока нет

- IEC Certification Kit: Model-Based Design For EN 50128Документ31 страницаIEC Certification Kit: Model-Based Design For EN 50128Ícaro VianaОценок пока нет

- TSS Training Package Implementation Guidefinal 0Документ18 страницTSS Training Package Implementation Guidefinal 0hanabbecharaОценок пока нет

- Summary Good To GreatДокумент5 страницSummary Good To GreatAziz ur RehmanОценок пока нет

- Antennas L01Документ15 страницAntennas L01Domenico RizzoОценок пока нет

- Sony HCD Dx8Документ66 страницSony HCD Dx8videoson100% (1)

- Communication Skills For Effective LeadershipДокумент12 страницCommunication Skills For Effective LeadershipKovaОценок пока нет

- Comparing Registers: MIPS vs. ARM AssemblyДокумент12 страницComparing Registers: MIPS vs. ARM Assemblyshruti chouhanОценок пока нет

- Laboratorios RoeДокумент11 страницLaboratorios RoeVioleta CubaОценок пока нет

- Complete-Crp SPC Shamli r01-1562323540Документ291 страницаComplete-Crp SPC Shamli r01-1562323540p nandyОценок пока нет

- Pro-Watch Ecosystem: The Power of TheДокумент1 страницаPro-Watch Ecosystem: The Power of TheNik SiagОценок пока нет

- Dramix: Dramix Economic Concrete Reinforcement For Safe Floors On PilesДокумент9 страницDramix: Dramix Economic Concrete Reinforcement For Safe Floors On PilesMohammad IqbalОценок пока нет

- Virtual Screening of Natural Products DatabaseДокумент71 страницаVirtual Screening of Natural Products DatabaseBarbara Arevalo Ramos100% (1)

- Innoversant Solutions - Business Consulting Services IndiaДокумент15 страницInnoversant Solutions - Business Consulting Services Indiaispl123Оценок пока нет

- Is 800-2007 - Indian Code of Practice For Construction in SteelДокумент41 страницаIs 800-2007 - Indian Code of Practice For Construction in SteelshiivendraОценок пока нет

- Tutorial Chapter 2Документ5 страницTutorial Chapter 2Naasir SheekeyeОценок пока нет

- Pdpa CraДокумент3 страницыPdpa CraAdyrah RahmanОценок пока нет

- Important Questions - BlockchainДокумент1 страницаImportant Questions - BlockchainHarsh Varshney100% (1)

- Key Term Arabic Meaning Link: Life ScienceДокумент5 страницKey Term Arabic Meaning Link: Life ScienceReemОценок пока нет