Академический Документы

Профессиональный Документы

Культура Документы

B.tech Welding LAb Questions

Загружено:

Arg Sreekar0 оценок0% нашли этот документ полезным (0 голосов)

75 просмотров2 страницыlab welding

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документlab welding

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

75 просмотров2 страницыB.tech Welding LAb Questions

Загружено:

Arg Sreekarlab welding

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 2

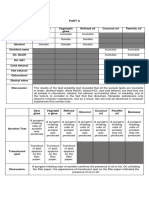

Joining Lab Class 1

Solid State Welding Processes (FSW, FS, FW)

Note: 1. Use both the sides of A4 sheet

2. Use schematics where ever necessary

Date: 20-08-14

1) List different types of solid state welding processes

2) What are the advantages of solid state welding processes over fusion welding processes

3) List out the important process parameters in friction welding(FW), friction stir welding (FSW)and

friction surfacing(FS)

4) Draw a neat sketch of Tool of FSW also with neat drawings explain different stages in FSW.

5) Draw a neat sketch of FSW joint and Identify different zones in it.

6) With neat schematics explain different stages in FW.

7) Explain with a graph how process parameters vary in each stage during rotary friction welding. Compare

the same with inertia friction welding.

8) Can you think of welding a long pipe, a plate, using FW techniques (Yes/No)?Justify your answer

9) Can you think of 3 possible dissimilar material combinations which are not weldable by fusion based

processes? Do you think solid state welding techniques help you in welding these combinations

(Yes/No)? Justify your answer.

10) List 5 possible industrial applications for these processes FW, FSW, FS

11) Instead of having so many advantages, why do you think above processes are not widely used in day to

day application like fusion based processes

Gas Tungsten Arc Welding

1. Define welding and classify the different types of fusion welding process.

2. With a neat schematic explain the construction of GTAW process.

3. Briefly explain the effect of electrode polarity and different electrode tip configuration in GTAW

process (line drawing).

4. Briefly explain the types of GTA welding technique and explain why pulse technique is advantageous

over normal mode?

5. Briefly explain the technique of arc initiation in GTAW and justify why touch retract method is not

preferred.

6. Brief about the pre , post , back purging in welding process and why is it needed. Give one example that

requires all these purging.

7. For GTAW of Aluminum alloy what kind of polarity do you chose? Justify

8. Why GTAW process is widely used for depositing root pass when compared to subsequent passes in a

multi-pass weld?

Joining Lab class 2

Gas Metal Arc Welding

1.

2.

3.

4.

5.

6.

7.

With a neat schematic explain the construction of GMAW process

MIG and MAG - Differentiate

List 5 differences between GTAW and GMAW process

What type polarity is preferred in GMAW process and why Alternating Current is not used in GMAW ?

What are different types of shielding gases used in GMAW process

What are different modes of metal transfer in GMAW and how is it achieved?

What are the advantages/ disadvantages of GTAW process over GMAW process and vice versa?

CMT MIG welding

1. What is Cold Metal Transfer MIG? Justify the name Cold Metal Transfer

2. What is the mode of metal transfer in CMT? How does it vary with conventional MIG process?

3. Heat input by CMT MIG is comparatively lower than any other process- Justify the statement

4. What is the effect of Pulsing in CMT compared to normal CMT mode?

5. How does the molten metal detach from the wire consumable to base in CMT process how is it different

from the conventional MIG welding process?

6. Give some industrial application of CMT MIG process

7. Draw backs/ disadvantages that you have noticed while welding with CMT

Вам также может понравиться

- Which Process?: A Guide to the Selection of Welding and Related ProcessesОт EverandWhich Process?: A Guide to the Selection of Welding and Related ProcessesОценок пока нет

- Advance Welding TechniqueДокумент4 страницыAdvance Welding TechniqueGunabalan SellanОценок пока нет

- 9A14401 Production TechnologyДокумент4 страницы9A14401 Production TechnologysivabharathamurthyОценок пока нет

- Me6302 Manufacturing Technology - I QBДокумент5 страницMe6302 Manufacturing Technology - I QBHODMECHANICAL AKTMCETОценок пока нет

- Permanent JointsДокумент1 страницаPermanent Jointsdoua hmidaОценок пока нет

- B-Tech. Mechanical UNIT-1: Bme 206 Manufacturing Technology - 1Документ6 страницB-Tech. Mechanical UNIT-1: Bme 206 Manufacturing Technology - 1Michael ButlerОценок пока нет

- Production TechnologyДокумент4 страницыProduction TechnologysandchinniОценок пока нет

- QB Mem 103Документ4 страницыQB Mem 103Geetu KumariОценок пока нет

- Important Questions For Nov Dec 2016 ME6008 Welding TechnologyДокумент1 страницаImportant Questions For Nov Dec 2016 ME6008 Welding TechnologyRajueswarОценок пока нет

- DOM S2022oДокумент3 страницыDOM S2022oKhalit JamundeОценок пока нет

- Describe The Ultrasonic Welding Process With Neat DiagramДокумент1 страницаDescribe The Ultrasonic Welding Process With Neat DiagramBharani KumarОценок пока нет

- Manufacturing Technology-I - Department of Mechanical EngineeringДокумент4 страницыManufacturing Technology-I - Department of Mechanical EngineeringSoma SundaramОценок пока нет

- Metal FormingДокумент6 страницMetal FormingHarish Kumar SОценок пока нет

- Questions For Self AssessmentДокумент3 страницыQuestions For Self AssessmentChethan SkОценок пока нет

- 4-Iii Me-Mee214-FmpДокумент5 страниц4-Iii Me-Mee214-FmpAgnivesh SharmaОценок пока нет

- Manufacturing Technology Question Papers of JntuaДокумент15 страницManufacturing Technology Question Papers of JntuaHimadhar SaduОценок пока нет

- Manufacturing Processes-1 Assignemnts-Converted-CompressedДокумент7 страницManufacturing Processes-1 Assignemnts-Converted-Compressedmd junaidОценок пока нет

- I-V Unit Imp QuationsДокумент6 страницI-V Unit Imp QuationsSK NAGOOR VALIОценок пока нет

- MII Manufacturing TechnologyДокумент5 страницMII Manufacturing TechnologyRameez FaroukОценок пока нет

- Interview Type Question Manufacturing PDFДокумент4 страницыInterview Type Question Manufacturing PDFSourav KayalОценок пока нет

- Irjet V3i2175Документ1 страницаIrjet V3i2175AbhayОценок пока нет

- Year Wise Quation BankДокумент7 страницYear Wise Quation BankSK NAGOOR VALIОценок пока нет

- Manufacturing Tech-1Документ6 страницManufacturing Tech-1Vikram Rao0% (1)

- MFP QB PDFДокумент6 страницMFP QB PDFCharan KumarОценок пока нет

- Course Outline Djj1043 (2016)Документ6 страницCourse Outline Djj1043 (2016)Sergio SyamilОценок пока нет

- Code: R7210301 B.Tech II Year I Semester (R07) Supplementary Examinations, May 2013Документ1 страницаCode: R7210301 B.Tech II Year I Semester (R07) Supplementary Examinations, May 2013sivabharathamurthyОценок пока нет

- Production Technology R10 JntukДокумент4 страницыProduction Technology R10 JntukSrimanthula SrikanthОценок пока нет

- Total Workshop QuestionsДокумент8 страницTotal Workshop QuestionsSanjeet KumarОценок пока нет

- Manufacturing Process 1 Question BankДокумент6 страницManufacturing Process 1 Question BankAshok PradhanОценок пока нет

- Unit-4: Casting and Welding Process Group 1 (Part A: Easy)Документ2 страницыUnit-4: Casting and Welding Process Group 1 (Part A: Easy)Milan MottaОценок пока нет

- Unit 1 Question Bank Welding EngineeringДокумент5 страницUnit 1 Question Bank Welding EngineeringSayiram GОценок пока нет

- Assignment - 2 Section - AДокумент1 страницаAssignment - 2 Section - AAaronОценок пока нет

- R7210301 Production TechnologyДокумент1 страницаR7210301 Production TechnologysivabharathamurthyОценок пока нет

- Questions On Welding For Welding, QC EngineerДокумент8 страницQuestions On Welding For Welding, QC EngineerSaad AfzalОценок пока нет

- Manufacturing Process 1 Question BankДокумент11 страницManufacturing Process 1 Question BankAshok PradhanОценок пока нет

- Me 63021Документ6 страницMe 63021Kumar SubramanianОценок пока нет

- Introduction To Welding API 577 Capter 7Документ12 страницIntroduction To Welding API 577 Capter 7Edo Destrada100% (1)

- Mechanical Engineering - Mp-Ii Final Exam Question BankДокумент4 страницыMechanical Engineering - Mp-Ii Final Exam Question BankupenderОценок пока нет

- MT I Question BankДокумент10 страницMT I Question BankAnonymous ZB6qyhD6Оценок пока нет

- API 653 - 577 Flash Cards - 62 QuestionsДокумент8 страницAPI 653 - 577 Flash Cards - 62 QuestionsSERFORTEC CIA. LTDA.Оценок пока нет

- MT 2 Terminal Test 1Документ1 страницаMT 2 Terminal Test 1Rajchandar KannanОценок пока нет

- X20818 (Me6008 Ptme6008)Документ3 страницыX20818 (Me6008 Ptme6008)saranОценок пока нет

- Manufacturing Process 1 Question BankДокумент6 страницManufacturing Process 1 Question BankAshok PradhanОценок пока нет

- Gujarat Technological University: InstructionsДокумент3 страницыGujarat Technological University: InstructionsDhruvin KagdiОценок пока нет

- 1616403439362-Subjective Questions On Manufacturing Process MET-03Документ4 страницы1616403439362-Subjective Questions On Manufacturing Process MET-03Dashmeet SinghОценок пока нет

- Manufacturing Technology - I Syllabus: Topic AnalysisДокумент6 страницManufacturing Technology - I Syllabus: Topic AnalysisjayctaОценок пока нет

- G.C.R.G.Memorial Trust'S Group of Institutions: Advanced Welding Technology EME-022Документ1 страницаG.C.R.G.Memorial Trust'S Group of Institutions: Advanced Welding Technology EME-022Andrea DouglasОценок пока нет

- MT 20 MSДокумент2 страницыMT 20 MSHAPPY CHAUHANОценок пока нет

- Dhanalakshmi College of Engineering Department of Mechanical Engineering Me 6302 Manufacturing Technology - 1 (Question Bank)Документ10 страницDhanalakshmi College of Engineering Department of Mechanical Engineering Me 6302 Manufacturing Technology - 1 (Question Bank)arulОценок пока нет

- Tutorial 2 BETP 1323 Sem 1 2014 2015Документ2 страницыTutorial 2 BETP 1323 Sem 1 2014 2015Tarmizi BahariОценок пока нет

- Technoi 2006 2007 Exemples Questions ExamДокумент1 страницаTechnoi 2006 2007 Exemples Questions ExamElie KahambaОценок пока нет

- MT QB Unit 1& 2Документ4 страницыMT QB Unit 1& 2sivasaОценок пока нет

- 29-05 Manufacturing Technology (MT)Документ1 страница29-05 Manufacturing Technology (MT)a11972003Оценок пока нет

- Manufacturing Process 1 Question BankДокумент8 страницManufacturing Process 1 Question Bankashok PradhanОценок пока нет

- Kings: PR1204-Manufacturing Technology-IДокумент4 страницыKings: PR1204-Manufacturing Technology-IJayavignesh ReddyОценок пока нет

- Workshop Technology - Assignment - 18 Oct-14 NovДокумент2 страницыWorkshop Technology - Assignment - 18 Oct-14 Novvikrantsinghoo848Оценок пока нет

- Manufacturing Engineering Guide BookДокумент2 страницыManufacturing Engineering Guide BookGiridharan SharmaОценок пока нет

- Various Parameter Effects On Friction SДокумент7 страницVarious Parameter Effects On Friction SmanishcguptaОценок пока нет

- How to prepare Welding Procedures for Oil & Gas PipelinesОт EverandHow to prepare Welding Procedures for Oil & Gas PipelinesРейтинг: 5 из 5 звезд5/5 (1)

- CH 02 - The Evolution of ManagementДокумент37 страницCH 02 - The Evolution of ManagementArg SreekarОценок пока нет

- Lec 11Документ35 страницLec 11Arg SreekarОценок пока нет

- Ril SR2007 08Документ99 страницRil SR2007 08Arg SreekarОценок пока нет

- Ch. 3 - The Environmental Context of ManagementДокумент24 страницыCh. 3 - The Environmental Context of ManagementArg SreekarОценок пока нет

- Chapter 4 - PlanningДокумент47 страницChapter 4 - PlanningArg SreekarОценок пока нет

- MM2030 July2012 Quiz2Документ1 страницаMM2030 July2012 Quiz2Arg SreekarОценок пока нет

- Immerse 2015 CДокумент77 страницImmerse 2015 CArg SreekarОценок пока нет

- MM5017 Assignment1Документ2 страницыMM5017 Assignment1Arg SreekarОценок пока нет

- Assignment 5Документ11 страницAssignment 5Arg SreekarОценок пока нет

- CalenderДокумент2 страницыCalenderM036Оценок пока нет

- Solidification Processes PartIIДокумент5 страницSolidification Processes PartIIArg SreekarОценок пока нет

- Bravais LatticesДокумент1 страницаBravais LatticesArg SreekarОценок пока нет

- Matlab TutorialДокумент173 страницыMatlab TutorialSaurabh Tiwari100% (8)

- MML2014 GA.R.G Sreekar REPCompressionДокумент5 страницMML2014 GA.R.G Sreekar REPCompressionArg SreekarОценок пока нет

- Macro and Micro Hardness Testing: A.R.G Sreekar, M M 1 2 B 0 0 2Документ6 страницMacro and Micro Hardness Testing: A.R.G Sreekar, M M 1 2 B 0 0 2Arg SreekarОценок пока нет

- Up2201 Data SheetДокумент3 страницыUp2201 Data SheetArg SreekarОценок пока нет

- Aluminium AlloysДокумент43 страницыAluminium AlloysArg SreekarОценок пока нет

- Vector and Tensor AnalysisДокумент10 страницVector and Tensor Analysisrammar147Оценок пока нет

- Cast IronДокумент9 страницCast IronArg Sreekar100% (1)

- Lec 8 9 SlideДокумент10 страницLec 8 9 SlideArg SreekarОценок пока нет

- Dual PhaseДокумент4 страницыDual PhaseArg SreekarОценок пока нет

- Academic Calendar Jul-Dec 2014 26.12.2013Документ2 страницыAcademic Calendar Jul-Dec 2014 26.12.2013Arg SreekarОценок пока нет

- How's Steel Manufactured?: Raw Materials For IronmakingДокумент6 страницHow's Steel Manufactured?: Raw Materials For Ironmakingamitkhanna71Оценок пока нет

- Gibbs TriangleДокумент4 страницыGibbs TriangleArg SreekarОценок пока нет

- Book-16 FMДокумент10 страницBook-16 FMYsharath ChandramouliОценок пока нет

- Energy Sources Supply Demand Lec1 4sep13Документ43 страницыEnergy Sources Supply Demand Lec1 4sep13Arg SreekarОценок пока нет

- Chemistry Lab Manual 2Документ21 страницаChemistry Lab Manual 2Nischay SanjayОценок пока нет

- Diagnose and Repair Exhaust SystemsДокумент38 страницDiagnose and Repair Exhaust SystemslittleprayerbyjacksОценок пока нет

- Copper e FinalДокумент12 страницCopper e FinalgoranОценок пока нет

- Practice 2 - Questions - CSWIPДокумент10 страницPractice 2 - Questions - CSWIPravichandran0506Оценок пока нет

- Rastogi and Pospisil 2010Документ7 страницRastogi and Pospisil 2010anshuslsОценок пока нет

- CID A-A-344B - Lacquer (Clear Gloss), With Notice 1Документ4 страницыCID A-A-344B - Lacquer (Clear Gloss), With Notice 1エドワードОценок пока нет

- Hydrogenated Nitrile Butadiene Rubber (HNBR) : Properties and ApplicationsДокумент4 страницыHydrogenated Nitrile Butadiene Rubber (HNBR) : Properties and ApplicationsAjit SamalОценок пока нет

- Vanadium: Vanadium Is A Chemical Element With The Symbol VДокумент20 страницVanadium: Vanadium Is A Chemical Element With The Symbol VVysakh Vasudevan0% (1)

- Chem Balancing EquationsДокумент23 страницыChem Balancing EquationsForkensteinОценок пока нет

- Biofibers From Agricultural Byproducts For Industrial ApplicationsДокумент6 страницBiofibers From Agricultural Byproducts For Industrial Applicationslami75Оценок пока нет

- Mor-Free™ Elm 415A Adhesive/Cr 88-101Документ3 страницыMor-Free™ Elm 415A Adhesive/Cr 88-101Manuel HurtadoОценок пока нет

- Infrared Spectra and Bonding in Transition Metal Nitrosyl ComplexesДокумент5 страницInfrared Spectra and Bonding in Transition Metal Nitrosyl ComplexesSaurav PaulОценок пока нет

- Class 7 Symbols+and+Formulae Study+MaterialДокумент14 страницClass 7 Symbols+and+Formulae Study+MaterialJ SoujanyaОценок пока нет

- Astm B210Документ18 страницAstm B210Len LujanОценок пока нет

- Analysis of The Flocculation Process of Fine Tailings Particles in Saltwater Through A Population Balance ModelДокумент43 страницыAnalysis of The Flocculation Process of Fine Tailings Particles in Saltwater Through A Population Balance Model1105195794Оценок пока нет

- Activity 1 Calc 1 and 2 PDFДокумент7 страницActivity 1 Calc 1 and 2 PDFonyxОценок пока нет

- Basic Manufacturing ProcessesДокумент71 страницаBasic Manufacturing Processessuneel kumar rathoreОценок пока нет

- 2 FuelsДокумент18 страниц2 FuelsCllyan ReyesОценок пока нет

- Classi of PoisonДокумент12 страницClassi of PoisonShaik Abdul MuneerОценок пока нет

- Uji Sakarin - AOAC Official Method 941.10 Saccharin in Food Qualitative TestsДокумент1 страницаUji Sakarin - AOAC Official Method 941.10 Saccharin in Food Qualitative TestsfajardianhОценок пока нет

- Flowserve PumpsДокумент16 страницFlowserve Pumpsdavidgaro12100% (1)

- Dye RemovalДокумент10 страницDye Removalfairus100% (5)

- Module 8 - BIOCHEM LABДокумент5 страницModule 8 - BIOCHEM LABStarrrОценок пока нет

- 10cordination CompДокумент22 страницы10cordination Compaleena'Оценок пока нет

- Modelling & Experimental Study of Biomass Gasifier ForДокумент22 страницыModelling & Experimental Study of Biomass Gasifier ForAvinashKSinghОценок пока нет

- 0131 0136 PDFДокумент6 страниц0131 0136 PDFWahid KarolОценок пока нет

- Vat DyesДокумент3 страницыVat Dyesusmanazeem100% (1)

- Mock 1523Документ58 страницMock 1523Javaria AjmalОценок пока нет

- TI - GLYSACORR G93 Green - EN - GVcwHUQjajctHwNdDgwUДокумент4 страницыTI - GLYSACORR G93 Green - EN - GVcwHUQjajctHwNdDgwUSiaОценок пока нет

- AppendixesДокумент22 страницыAppendixesFauzan HardiОценок пока нет