Академический Документы

Профессиональный Документы

Культура Документы

Us 2802332

Загружено:

wewewewАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Us 2802332

Загружено:

wewewewАвторское право:

Доступные форматы

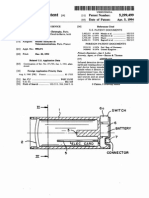

Aug.

13, 1957

2,802,332

A. J. ORSINO

HIGH ENERGY GAS PRODUCER

Filed Dec. 28, 1955

Il NIl I.'

li l I

24

/5

f2

23 5,2

Zi

SfLr;.X

.32

States VI_)altti'lf,F

1C@

~2,802,332

e Patented Aug. 13, 1957V

Figure `1 is a cross-sectional View of the rocket showing

the cellular type construction partly in broken section,

Figure 2 is a cross-sectional view of the rocket cham

l

ber and the cellular construction taken on lines 2-2 of

2,802,332

Figure l,

rnGH ENERGY GAS PRODUCER

Anthony Joseph Orsino, Schenectady, N. Y., assignor to

General Electric Company, a corporation of New `York

(c1. sii-35.6)

'

q Figure 4 is a cross-sectional view of the ller.

_Briey stated and according to one aspect of this in

\ Application December 28, 1955, Serial No..555,9201

s Claims.

Figure 3 is a modified form of the invention showing a

cellular construction `for retaining several propellants,

V10 vention, a high energy gas producer is provided in which

fluid propellants are used without the necessity of includ

ing additional pressurizing devices. The device is` capable

of providing a self pressurizing system of reactants in

the combustion chamber of a rocket in which the reaction

This invention relates to liquid propellant rockets and

or combustion takes place.

in particular to a liquid propellant rocket of the type

Referring to Figures 1 and 2 the numeral 10 generally

provided with its own self supplying `fuel medium within

designates a rocket motor or highenergy gas producer.

The rocket motor consists of a combustion chamber 12

the rocket` chamber itself.

"

q t

Inthe previously used methods of `supplying liquid pro

having an outside metal container 13. The rocket motor

pellants in rockets, >a turbopump or the'flik'e `is necessary 2.o also is provided with a nozzle 14 havinga throat 16. The

to provide the pressure for forcing the liquid through an .

top of the rocketnrotor contains a ceramic shield 18 in

injector into the combustion chamber ofthe rocket motor.

Theuse of a turbopump system requires in addition, ap

paratus for driving the turbopurnp. This is very disad

vantageous since it adds considerable weight in addition 25

order to protect and insulate the top of the rocket motor

from the high temperatures. The rocket motor is lined

with a cellular like structure 20. The expendible cellular

`like structure comprises an inner cylinder wall 22 radially

to that of the rocket.

spaced from an outer cylindrical wall 24. The inner and

Another `method used for supplying liquid propellant i gouter walls are integrally connected by a top portion 26

tothe combustion chamber-of the rocket has been by

and lower portion 28 curvedto fit the contour of the

providing agas pressurizing system. Here again these

rocket motor. Additional cylindrical walls 30 are spaced

gasesmust bey stored in high pressure tanks which require 30 intermediate the inner and outer cylindrical walls 22 and

thick walls to..retain such pressures thereby increasing ,e

24 and formed integral with the top and lower portions

the `weight of the rocket. The increase in weight is very

26 and 28. Openings 25 interconnect the spaces between

`the adjacent walls. Longitudinally extending partitions

detrimental since e it cuts Vdown the amount of fuel the

are shown at 32 and are formed integral with the walls 22,

rocket can `carry.` Therefore, it is an object of this inven

tion to decrease the weight ofthe rocket and keep it down 35 `24 and 30. Thespaces formed between the walls and

partitions define chambers 34 containing liquid propel

`to a minimum sothat additional fuel may "be carried on ,

board the rocket. , i

e

lants for use in the combustion process to produce the

`Another `system `for supplying a propellant to a com

required thrust for the rocket. Oriflces 35 in the parti

bustion chamber without using turbopumps or gas tanks

tions 32 interconnect the chambers 34. The outside metal

underhighpressure is by using solid propellants within 40 container of the rocket motor is provided with a boss

the combustion chamber of the rocket motor.

>or protuberance 36in orderto provide a filler port 3S

the use of solid propellants has certain disadvantages

best shown in Figure 4. The wall 24 of the cell like struc

e

However,.

mostlyfrom a logistics standpoint. The solid propellant

ture lining the inside ofthe combustion chamber also

must be cast within the rocket chamber at. the time it

lines the inside of the filler port 38 as shown at 40. The

`islbeing constructed atthe chemical plant."` Therefore, 45 mouth of the filler port terminates into a tapered portion

considerablecare must be used yin transporting the rocket

42 in order to provide a seat or the like. The filler cap

containing the solid propellant. .Solid propellants are

is shown at 44 which is of any well known type of con

dangerous during `handling and the transporting of the

struction >andis mounted on the boss 36 by threads Vor

rocket in that the constituents of the " solid propellant

the like 46. A tapered male portion 48 is provided on

must be initially mixed so as to be in contact with each 50 `the `cap to t into the mouth ofthe ller port so as to

other to begirluwith1 and arecasily combustible due to

friction and impact during handling. This danger is

seat on the tapered porti-on 42. The tapered `metal por

tion has` a sealing material bonded thereto, such as poly

something that lcannot be avoided when using solid pro

ethylene or the like' 49, in order to form a seal therebe

pellants as the reactants. It is therefore, a general object

tween. A pyrotechnic or catalytic device.` 50 for igniting

of this invention 'to provide a liquidypropellant rocket 55 the propellants extends into the cylindrical walls defining

capable of obviatin'g the above difficulties.

`

an expandible combustion chamber 12. In order to start

It is" a further' object of this invention to provide a

the initial combustion by igniting the pyrotechnic or cata

liquid propellant-t rockethaving the features of a solid

lytic device 50 a pluralitylof lead wires 52 is provided.

propellant without the detriments accompanying the solid

propellantsf

"

>

Another further object of this invention is to provide a

liquid propellant rocket without the necessity of provid

`To `establish reaction thrust` for acceleration of the

60 rocket, the pyrotecbnic device is set off to rupture the

cellular structure which admits `the reactant `into the com

bustion chamber 12 where it will proceed to react under

ing a pressurization and fuel system for supplying liquid

the influence of temperature and pressure provided initially

propellants to the combustion chamber of the rocket.

by the pyrotechnic device or under the influence of the

It is -a still further object of this invention to provide 65 catalyst previously mentioned. The reaction will con

a liquid system for a rocket motor without moving parts.

These and other objects will become more apparent

tinue to support itself as the cellular structure decays,

burns or ruptures and admits iluid into the reaction taking

when read in the light of the accompanying specification

place. I prefer that the walls 22 and 30 of the cellular

and drawing wherein similar parts are referred to by the

structure be made of polyethylene although other mate

same numbers and wherein the parts are designated spe 70 rials which are equally satisfactory for this use are fluo

cically but are intended to be applied as generically as

carbons (commercial examples of which are Teflon or

>the prior art will permit, and wherein;

Kel-F), silicone rubbers or any plastic providing it is

3V

not spontaneously ignitable lon contact with the liquid

propellant employed. In general, the walls 22 and 30

What I claim as new and desire to secure by Letters

Patent of the United States is:

l. A high energy gas producer comprising a casing

are not metallic except that aluminum or magnesium can

having an exhaust nozzle, a cellular-like structure con

be used providing the metal can be oxidized properly to

become an attractive source of thrust. The cell structure Ul taining a plurality of cells therein disposed within the

is not subjected to great pressures since it hydraulically

casing, at least one reactant carried within the cells, the

cell-like structure having a plurality of interconnected

transmits all pressure directly to the 'outer' walls of `the l

radially outwardly extending chambers, means for initiat

combustion chamber. As soon as combustion is estab

ing a chemical reaction of said reactant to rupture said

lished and the combustion chamber is up to full'pressure,

the entire cellular structure becomes pressurized. How 10 cellular-like structure, said reactant producing high energy

ever any one cell, although it is raised to chamber pres

gas upon rupture of said cellular-like structure, each of

said chambers rupturing successively.

sure, is actually under very little stress. Therefore, there

is >no need for a strong, diicult-to-breach cell wall. As

the reaction continues the cellular-structure dissipates and

the chamber 12 expands. This will continue until the

reactant has been exhausted and the combustion chamber

12 expands and nally takes the shape of the outer metal

Wall 13. By this arrangement the self pressurizing char

acteristic of the fluid contained in the expendible cell-like

structure eliminates the need for the use of expensive

turbopumps which requires additional fuel for its opera

tion, an additional tank for the storing ofthe propellant,

f 2.. A high energy gas producer comprising a container

having a casing forming a combustion chamber and ter

minating in an exhaust nozzle capable of producing thrust

upon gas being forced therethrough, an expendible cellu

lar-like structure positioned in said casing, said cellular

like structure forming a plurality of chambers adapted

to contain at least one reactant, at least one, filler port in

20 the casing of said container, a filler port in said expend

and various types of valves for controlling the ow of the

reactant into the combustion chamber of the rocket motor.

ible cellular-like structure lining the filler port in said

casing, each of said ller portsadapted to receive one

reactant, said cellular like structure having chambers

therein which are interconnected byl ports so as to pro

A system, in which two or more reactants are used in 25 vide a series of successive radially positioned chambers,

the rocket motor, is shown in Figure 3. In this embodi

means for rupturing and igniting the innermost chamber,

>said reactant forming combustion 'products under suf

ciently >high pressure to produce thrust as they pass

through the nozzle of the gas pnoducer.

nected chambers 52. This is accomplished by providing 30

3. A high energy gas producer having a casing of

each chamber 34 in Figure l, with a plurality of trans

cylindrical form, said container terminating in an exhaust

verse partitions 54 extending between adjacent walls, for

nozzle .at one end thereof, an expendible cellular-like

example,.22 and 30. The partitions 54 and the walls 22

structure lining the inside of said cylindrical casing, said

and 30 form the chambers 52. Also, for example, the

expendible cellular-like structure having a plurality of

ment, the cell like structure is of diiferent construction

in that three Vdiiferent reactants are shown in A, B, C. The

cellular structure 20 is formed with a series of intercon

chambers containing reactant A, are interconnected 35 longitudinally extending walls extending the entire length

through the orifices 56. Each chamber 52 is in communi

cation with the radially inwardly adjacent chamber con

of the casing, a plurality of partitions extending longi

nected to the outermost radially outwardly chamber by

positioned chamber without communication therewith,

each of said chambers being separated from other

adjacent chambers positioned radially outwardly but

tudinally and radially outwardly so as to form longi

tudinal segments, each of said longitudinal segments

taining a like reactant, each of the chambers 52 are sep

arated from an adjacent longitudinally positioned 4cham

having aplurality of transverse walls so as to divide

ber by partition 54 having a different reactant.l In this 40 each segment into small chambers, each of said charn

manner, the innermost radially inwardly chamber is con

bers being separated from its adjacent longitudinally

orifices 56 so that uponthe cylindrical wall 22 collapsing

under the initial combustion process, the remaining rows

of reactants will ignite in a sequential manner. vThe cham

ber conguration for each reactant isV proportioned in

such -a manner in relation to the chambers of the other

reactants so as to provide the correct amounts of reactants

for ideal mixing of the reactants to obtain optimum >per

formance. It is noted that in this modification where

more than one liquid is used, the size of the cellular

chambers 52 should be designed in accordance with a

chemical reaction that is intended to take place. Also, a

different filler plug is used for each reactant. For ex

ample, filler plug 60 provides a means for lling par

ticular chambers with reactant A, filler plug 62`for other

chambers with reactant B, and filler plug 64 for still other

chambers with reactant C.

While the particular embodiment `of the invention has

been illustrated and described, it will be obvious to those

skilled in the art that various changes and modifications

may be made without departing from the invention, and

it is intended to cover in the appended claims all such

changes and modifications that come Within the true spirit

65

and scope of this invention'.

being in communication therewith through an orice,

each adjacent radially inwardly chamber containing the

same reactant,Y and means for rupturing the innermost

longitudinal chambers to enable the different reactants to

chemically unite to produce the gaseousrproducts capable

of producing thrust upon passing through the nozzle,

each ofthe longitudinal rows of chambers successfully

rupturing to produce a sustained length of combustion

rather than a single explosion.

References Cited in the file of this patent

UNITED STATES PATENTS

1,376,316

2,462,099

2,700,337

`chiiowsky ___________ __ Apr. 26, 1921

Hickman ____________ __ Feb. 22, 1949

cumming ____________ _- Jan. 25, 195s

543,739

Great Britain _________ __ Mar. 11, 1942

FOREIGN PATENTS

reif-:w

Вам также может понравиться

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Us 5149907Документ7 страницUs 5149907wewewewОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Us 5775636Документ6 страницUs 5775636wewewewОценок пока нет

- Us 8809689Документ7 страницUs 8809689wewewewОценок пока нет

- United States Patent (191: Hau (11) Patent Number: (45) Date of PatentДокумент7 страницUnited States Patent (191: Hau (11) Patent Number: (45) Date of PatentwewewewОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- United States Patent (191: WinerДокумент5 страницUnited States Patent (191: WinerwewewewОценок пока нет

- Us 3690255Документ5 страницUs 3690255wewewewОценок пока нет

- United States Patent: Ronn Et Al. (10) Patent N0.: (45) Date of PatentДокумент7 страницUnited States Patent: Ronn Et Al. (10) Patent N0.: (45) Date of PatentwewewewОценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- United States Patent (191: Ahlstriim Et A1. (11) Patent Number: (45) Date of PatentДокумент5 страницUnited States Patent (191: Ahlstriim Et A1. (11) Patent Number: (45) Date of PatentwewewewОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Sept. 13, 1966: J. Marsh EtalДокумент4 страницыSept. 13, 1966: J. Marsh EtalwewewewОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- United States Patent: Berej Noi Et AlДокумент6 страницUnited States Patent: Berej Noi Et AlwewewewОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- (A Oe Émgoueogmo: +2 (ll/l4fl2Документ6 страниц(A Oe Émgoueogmo: +2 (ll/l4fl2wewewewОценок пока нет

- United States Patent (191Документ7 страницUnited States Patent (191wewewewОценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- United States Patent (10) Patent N0.: US 7,540,240 B2Документ4 страницыUnited States Patent (10) Patent N0.: US 7,540,240 B2wewewewОценок пока нет

- Ester: United States PatentДокумент5 страницEster: United States PatentwewewewОценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- LL L'L///"/"Z//: (12) United States PatentДокумент4 страницыLL L'L///"/"Z//: (12) United States PatentwewewewОценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Us 20010047736Документ6 страницUs 20010047736wewewewОценок пока нет

- Us 3823668Документ4 страницыUs 3823668wewewewОценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Us 5299499Документ5 страницUs 5299499wewewewОценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Us 5237927Документ4 страницыUs 5237927wewewewОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- United States Patent: CarverДокумент4 страницыUnited States Patent: CarverwewewewОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- SFA TRAINING MODULE Week 1Документ14 страницSFA TRAINING MODULE Week 1Ivan Perez100% (1)

- Electrochemistry DPP-1Документ2 страницыElectrochemistry DPP-1tarunОценок пока нет

- People Vs CorreaДокумент2 страницыPeople Vs CorreaRmLyn Mclnao100% (1)

- GSM Rtu Controller Rtu5011 v2 PDFДокумент27 страницGSM Rtu Controller Rtu5011 v2 PDFAbdul GhaniОценок пока нет

- Ev Conversion PDFДокумент2 страницыEv Conversion PDFShannonОценок пока нет

- Demand Management in Global Supply Chain - Disertasi S3Документ166 страницDemand Management in Global Supply Chain - Disertasi S3Ahmad BuchoriОценок пока нет

- State Magazine, May 2001Документ38 страницState Magazine, May 2001State MagazineОценок пока нет

- Generic NdaДокумент2 страницыGeneric NdalataminvestmentsОценок пока нет

- FeCl3 Msds - VISCOSITYДокумент9 страницFeCl3 Msds - VISCOSITYramkesh rathaurОценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- 16.3 - Precipitation and The Solubility Product - Chemistry LibreTextsДокумент14 страниц16.3 - Precipitation and The Solubility Product - Chemistry LibreTextsThereОценок пока нет

- Sears Canada: Electric DryerДокумент10 страницSears Canada: Electric Dryerquarz11100% (1)

- CPM Pert Multiple Choice Questions and AnswersДокумент2 страницыCPM Pert Multiple Choice Questions and Answersptarwatkar123Оценок пока нет

- Dual Nature and RadiationДокумент39 страницDual Nature and RadiationWedger RealmeОценок пока нет

- Ekoplastik PPR Catalogue of ProductsДокумент36 страницEkoplastik PPR Catalogue of ProductsFlorin Maria ChirilaОценок пока нет

- 17 Samss 518Документ20 страниц17 Samss 518Mohamed H. ShedidОценок пока нет

- Marketing Plan Potato Food TruckДокумент25 страницMarketing Plan Potato Food TruckAhasan h. ShuvoОценок пока нет

- Effect of Different Laser Texture Configurations On Improving Surface Wettability and Wear Characteristics of Ti6Al4V Implant MaterialДокумент14 страницEffect of Different Laser Texture Configurations On Improving Surface Wettability and Wear Characteristics of Ti6Al4V Implant Materialnitish kumar100% (1)

- Stonecoal v3 Guidelines 2023-03-22Документ71 страницаStonecoal v3 Guidelines 2023-03-22Esha RamaswamiОценок пока нет

- Install Sensor Lsi Fl061Документ14 страницInstall Sensor Lsi Fl061AlterSon Grafi KalayОценок пока нет

- Police Log September 24, 2016Документ14 страницPolice Log September 24, 2016MansfieldMAPoliceОценок пока нет

- Packet Tracer - VLSM Design and Implementation Practice TopologyДокумент3 страницыPacket Tracer - VLSM Design and Implementation Practice TopologyBenj MendozaОценок пока нет

- Deviation Control MethodsДокумент4 страницыDeviation Control MethodsLazuardhy Vozicha FuturОценок пока нет

- WP Seagull Open Source Tool For IMS TestingДокумент7 страницWP Seagull Open Source Tool For IMS Testingsourchhabs25Оценок пока нет

- How To Deliver A Good PresentationДокумент9 страницHow To Deliver A Good PresentationGhozi Fawwaz Imtiyaazi LabiibaОценок пока нет

- Body Wash Base Guide Recipe PDFДокумент2 страницыBody Wash Base Guide Recipe PDFTanmay PatelОценок пока нет

- Intern JanataДокумент59 страницIntern JanataKhairul IslamОценок пока нет

- CHAPTER 5 Ground ImprovementДокумент47 страницCHAPTER 5 Ground ImprovementBeman EasyОценок пока нет

- Netflix Annual Report 2010Документ76 страницNetflix Annual Report 2010Arman AliОценок пока нет

- Contemporary ArtsДокумент16 страницContemporary Artsantoinette100% (2)

- The Messenger 190Документ76 страницThe Messenger 190European Southern ObservatoryОценок пока нет

- Well Control for Completions and InterventionsОт EverandWell Control for Completions and InterventionsРейтинг: 4 из 5 звезд4/5 (10)