Академический Документы

Профессиональный Документы

Культура Документы

Outside Screw and Yoke (OS&Y) Gate Valve: OGB50F

Загружено:

Oscar CRОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Outside Screw and Yoke (OS&Y) Gate Valve: OGB50F

Загружено:

Oscar CRАвторское право:

Доступные форматы

Outside Screw and Yoke (OS&Y) Gate Valve

OGB50F

Control Valves

Technical Features

Sizes available (Nominal) : DN50/2, DN65/21/2,

DN80/3, DN100/4, DN125/5, DN150/6, DN200/8,

DN250/10 and DN300/12.

Working pressure : 16 bar (235 psi)

Working temperature : -10C to 120C

Seat : Metal

Finish : Red liquid expoxy coating internal and external

Connections : Grooved metric or AWWA C606 standard.

Specifications : Face to face length in accordance with

EN558-1 basic series 3 and ASME B16.10-2000.

Outside Screw and Yoke (OS&Y) Gate Valve - OGB50F

Nominal Pipe Size

Metric

inch

DN50

2

DN65

DN80

DN100

3

4

DN125

DN150

DN200

DN250

DN300

8

10

12

Pipe O.D.

(mm / inch)

60.3 / 2.37

73.0 / 2.86

76.1 / 3.00

88.9 / 3.50

114.3 / 4.50

139.7 / 5.50

141.3 / 5.56

165.1 / 6.50

168.3 / 6.63

219.1 / 8.63

273.0 / 10.75

323.9 / 12.75

190 / 7.5

366 / 14.4

190 / 7.5

203 / 8.0

229 / 9.0

430 / 16.9

587 / 23.1

190 / 7.5

250 / 9.8

254 / 10.0

652 / 25.7

305 / 12.0

267 / 10.5

745 / 29.3

356 / 14.0

292 / 11.5

330 / 13.0

356 / 14.0

1100 / 43.3

1228 / 48.3

1373 / 54.1

356 / 14.0

405 / 15.9

457 / 18.0

OGB50F

Reference

OGB50F-0200

OGB50F-0250

OGB50F-0250-076

OGB50F-0300

OGB50F-0400

OGB50F-0500-139

OGB50F-0500-141

OGB50F-0600-165

OGB50F-0600-168

OGB50F-0800

OGB50F-1000

OGB50F-1200

Weight

(kg / lbs)

18 / 39.7

22 / 48.5

26 / 57.3

42 / 92.6

55 / 121.3

80 / 176.4

140 / 308.6

230 / 507.1

320 / 705.5

Materials List

Worldwide Fire Protection

EN Specifications

EN-JS1050

EN1982 CC491K

EN1982 CC491K

EN-JS1050

EN1982 CC491K

BS970 420S37

EN-JS1050

Non-Asbestos

EN-JS1050

Non-Asbestos

EN-JS1050

ASTM Specifications

ASTM A536 65-45-12

ASTM B62 C83600

ASTM B62 C83600

ASTM A536 65-45-12

ASTM B62 C83600

AISI 420

ASTM A536 65-45-12

Non-Asbestos

ASTM A536 65-45-12

Non-Asbestos

ASTM A536 65-45-12

New datasheet created

Material

Ductile Iron

Bronze

Bronze

Ductile Iron

Bronze

Stainless Steel

Ductile Iron

Graphite

Ductile Iron

Graphite

Ductile Iron

2011-04-20

Description

Body

Body Trim

Wedge Trim

Wedge

Yoke Nut

Stem

Bonnet

Gasket

Yoke

Packing

Handwheel

Physical Data

Dimensions (mm / inch)

L

H (open)

D

178 / 7.0

342 / 13.5

190 / 7.5

www.vikinggroupinc.com

FireKing is a trademark of The Viking Corporation. Pressure ratings require the use of couplings with equivalent pressure ratings. Rigid couplings are recommended for all valve end connections. Refer to Manufacturers datasheet.

Specifications subject to change without notice.

Outside Screw and Yoke (OS&Y) Gate Valve

OGB50F

Inspection and Maintenance

1.

1.

2.

3.

4.

5.

6.

7.

8.

9.

Piping systems and valves should be

thoroughly cleaned and free from ingress of

foreign materials.

Visually inspect the valve seating and

ports for cleanliness immediately prior to

installation.

All valves should be independently

supported against movement and stress

from the connected piping system.

Ensure that the valve pressure rating is

compatible with service conditions

Operate the valve at least once from the

open to closed position.

Verify that packing nuts are tight before

pressurizing the system

Check valves must be oriented properly

for flow and gravity and must be installed

sufficiently distant from pumps or other

devices producing turbulence.

8 Gate valves are not suitable for throttling

plications.

Gate valves should be installed in the

vertical position on horizontal pipework

and in the horizontal position on vertical

pipework.

2.

3.

Valves should be inspected periodically

and should be cycled to prevent buildup of

foreign materials in the piping system and

valve body.

In the event of a packing leak adjust the

packing nuts to increase pressure on the stem

packing. Packing nuts should be tightening

evenly approximately a quarter turn in a

clockwise direction.

Always shut down the system before

repacking the valve. Valves are designed with

backseats for repacking under pressure but

this is not recommended.

Control Valves

Installation

Operation

2011-04-20

New datasheet created

Gate valves are manually operated multi-turn

valves and are opened by a handwheel or

other operating device, generally in a clockwise

direction and then closed counterclockwise. Gate

valves with counterclockwise opening should be

clearly identified to ensure safe operation.

Worldwide Fire Protection

www.vikinggroupinc.com

FireKing is a trademark of The Viking Corporation. Pressure ratings require the use of couplings with equivalent pressure ratings. Rigid couplings are recommended for all valve end connections. Refer to Manufacturers datasheet.

Specifications subject to change without notice.

Вам также может понравиться

- Series V100 Ball ValveДокумент20 страницSeries V100 Ball ValvejenniferОценок пока нет

- Tomoe General CatalogДокумент508 страницTomoe General CatalogArianto SutarnioОценок пока нет

- PVR-108-2 Fueling Model SheetДокумент2 страницыPVR-108-2 Fueling Model SheetLetycia RosalesОценок пока нет

- Valves & Controls: Crosby Safety Valves Style HSLДокумент12 страницValves & Controls: Crosby Safety Valves Style HSLeborresonОценок пока нет

- Series 825Y Specification SheetДокумент2 страницыSeries 825Y Specification SheetFEBCOОценок пока нет

- Dual Plate Check Valve WeightДокумент1 страницаDual Plate Check Valve WeightbisworupmОценок пока нет

- Manifold Swagelok Ms 01 178Документ16 страницManifold Swagelok Ms 01 178papashoОценок пока нет

- Control Valve Norriseal - Series2200 O&MДокумент16 страницControl Valve Norriseal - Series2200 O&MJairo AlonsoОценок пока нет

- IOM Ball Valve Top EntryДокумент8 страницIOM Ball Valve Top Entrytoader56Оценок пока нет

- Manual Zetkama Fig.215 - 216Документ8 страницManual Zetkama Fig.215 - 216George_Wabag_2014Оценок пока нет

- Essential features and installation instructions for Velan valvesДокумент9 страницEssential features and installation instructions for Velan valvesrawatbs2020Оценок пока нет

- Es F 856STДокумент4 страницыEs F 856STFEBCOОценок пока нет

- Type 2600 Relief Valve Capacities GuideДокумент2 страницыType 2600 Relief Valve Capacities GuidetakenoveraccountОценок пока нет

- Flow Divertor Ball Valve DN20 - DN32 - DN50: DescriptionДокумент3 страницыFlow Divertor Ball Valve DN20 - DN32 - DN50: Description윤병택Оценок пока нет

- Es Acv M115F M1115FДокумент4 страницыEs Acv M115F M1115FWattsОценок пока нет

- installation_operating_manual_forged_valveДокумент39 страницinstallation_operating_manual_forged_valveBenny 37Оценок пока нет

- Orbinox VG08 Knife Gate ValveДокумент8 страницOrbinox VG08 Knife Gate ValveYorkistОценок пока нет

- AOP Series B3, B6 Floating Ball Valve Installation and Maintenance GuideДокумент2 страницыAOP Series B3, B6 Floating Ball Valve Installation and Maintenance GuiderjОценок пока нет

- EPE AccumulatorsДокумент6 страницEPE AccumulatorsGuru VagaОценок пока нет

- Iom MVT ValvesДокумент5 страницIom MVT ValvesNaser JahangiriОценок пока нет

- 14 400E 6DC Final Valvula BermadДокумент4 страницы14 400E 6DC Final Valvula Bermadmax_powerОценок пока нет

- Lead Free Series SS009 Specification SheetДокумент2 страницыLead Free Series SS009 Specification SheetWattsОценок пока нет

- Series 825YD Specification SheetДокумент2 страницыSeries 825YD Specification SheetFEBCOОценок пока нет

- Eko4000-4100 WebДокумент4 страницыEko4000-4100 WebSubramanian SaravananОценок пока нет

- 3 Valve ManifoldДокумент16 страниц3 Valve Manifoldwengjf83Оценок пока нет

- Es Acv 1116FMДокумент4 страницыEs Acv 1116FMWattsОценок пока нет

- Rei Vol IiДокумент142 страницыRei Vol IiDineshОценок пока нет

- Pressure Seal Valves-GateДокумент24 страницыPressure Seal Valves-GateHieu NguyenОценок пока нет

- 6 Way InstructionsДокумент2 страницы6 Way InstructionsFercho NoriegaОценок пока нет

- Flowcon ABM InstructionДокумент4 страницыFlowcon ABM InstructionJeff Anderson CollinsОценок пока нет

- SIT630 Installation InstructionsДокумент2 страницыSIT630 Installation Instructionsmelisa63Оценок пока нет

- Alarm ValveДокумент6 страницAlarm ValveAnonymous ZPTCAz9Оценок пока нет

- Fire HydrantДокумент6 страницFire HydrantdileepsiddiОценок пока нет

- Cat AXCATДокумент80 страницCat AXCATgazwang478Оценок пока нет

- Model"Dc": Dual Chamber Orifice FittingДокумент13 страницModel"Dc": Dual Chamber Orifice FittingFrankОценок пока нет

- AloycoДокумент32 страницыAloycoSidney RiveraОценок пока нет

- Series 805YD Specification SheetДокумент2 страницыSeries 805YD Specification SheetFEBCOОценок пока нет

- 187 - Robineti Retinere Cu Bila PVC FiletДокумент6 страниц187 - Robineti Retinere Cu Bila PVC FiletCiprianSarbuОценок пока нет

- WW 770-UДокумент4 страницыWW 770-UAhmad NasserОценок пока нет

- VAAS Fig 740 and 730 Series IOMДокумент9 страницVAAS Fig 740 and 730 Series IOMCarlos GutierrezОценок пока нет

- SV 3 Safety ValveДокумент7 страницSV 3 Safety ValveWanderley FonsecaОценок пока нет

- VALVULA DE SOLENOIDE HS7 BulletinДокумент4 страницыVALVULA DE SOLENOIDE HS7 BulletinJoséMarcanoОценок пока нет

- Installation and Operations Maintenance Manual Ball Valve: Valvtechnologies, IncДокумент20 страницInstallation and Operations Maintenance Manual Ball Valve: Valvtechnologies, IncJUANITOPYTОценок пока нет

- Angle Seat Valve: High Cycle-Life On/Off Control ValveДокумент6 страницAngle Seat Valve: High Cycle-Life On/Off Control ValveIbhar Santos MumentheyОценок пока нет

- Valvula de Solenoide HS6 BulletinДокумент4 страницыValvula de Solenoide HS6 BulletinJoséMarcanoОценок пока нет

- Apv Delta Sv1Документ20 страницApv Delta Sv1VLASTARОценок пока нет

- Yukenmodularvalves Yuken CatДокумент140 страницYukenmodularvalves Yuken Catchidambaram kasi100% (1)

- Standard Gate Valves ManualДокумент8 страницStandard Gate Valves ManualmechanikyОценок пока нет

- Vortex Float ValveДокумент3 страницыVortex Float ValveFrancisco Javier Villegas AndersonОценок пока нет

- Crane - Series.rs Center LineДокумент23 страницыCrane - Series.rs Center LinenedwestОценок пока нет

- Double Block Bleed TOSVДокумент8 страницDouble Block Bleed TOSVplanet123Оценок пока нет

- Brochure - Ex TENDДокумент4 страницыBrochure - Ex TENDBilly ZununОценок пока нет

- 3-Way Dual Shut Off ValvesДокумент1 страница3-Way Dual Shut Off ValvesPete DechaОценок пока нет

- M-VF Series: Safety Excess Flow ValveДокумент5 страницM-VF Series: Safety Excess Flow ValvebiomenggОценок пока нет

- SDE Gate Valve IntroductionДокумент1 страницаSDE Gate Valve IntroductionRiju MathewОценок пока нет

- 52 32 Convertible Namur Solenoid Valve Model 51424 51424Lw 51424is PDFДокумент7 страниц52 32 Convertible Namur Solenoid Valve Model 51424 51424Lw 51424is PDFysr3eeОценок пока нет

- SEVO 1230 Technical Data Sheets - All PDFДокумент18 страницSEVO 1230 Technical Data Sheets - All PDFYeni Paola SierraОценок пока нет

- Valve Selection Handbook: Engineering Fundamentals for Selecting the Right Valve Design for Every Industrial Flow ApplicationОт EverandValve Selection Handbook: Engineering Fundamentals for Selecting the Right Valve Design for Every Industrial Flow ApplicationРейтинг: 4.5 из 5 звезд4.5/5 (21)

- Pipes and FittingsДокумент17 страницPipes and FittingsRichard Jason LitangОценок пока нет

- Troubleshooting positive displacement rotary pump issuesДокумент4 страницыTroubleshooting positive displacement rotary pump issuesابو المعالي الهمامОценок пока нет

- WK 496 480 Subplates Type G Nominal Size 6: Ns6 32 MpaДокумент4 страницыWK 496 480 Subplates Type G Nominal Size 6: Ns6 32 MpaРома БлошенкоОценок пока нет

- SB/SBH/SBI Manual Installation and Maintenance GuideДокумент24 страницыSB/SBH/SBI Manual Installation and Maintenance GuideErkan TakОценок пока нет

- WCB Uc Spare Parts GB 04-2015 - KomplettДокумент28 страницWCB Uc Spare Parts GB 04-2015 - KomplettdebiОценок пока нет

- Design wellhead control panel specification under 40 charsДокумент3 страницыDesign wellhead control panel specification under 40 charsaminmuminiОценок пока нет

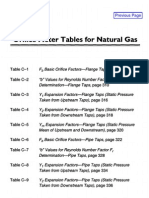

- Orifice Meter TablesДокумент35 страницOrifice Meter TablesilublessingОценок пока нет

- Lines Piping - Gross Air Leak TestДокумент1 страницаLines Piping - Gross Air Leak TestHashemAliHashemОценок пока нет

- 119E2423G001Документ1 страница119E2423G001Eduard MachadoОценок пока нет

- LMI Milton Roy P SeriesДокумент2 страницыLMI Milton Roy P SeriesPT Tirtapure EnvirotekОценок пока нет

- Instrument Hookup 8Документ1 страницаInstrument Hookup 8Wael ZakariaОценок пока нет

- Heavy Duty Grade High Force Hydraulic Products, Systems and ToolsДокумент11 страницHeavy Duty Grade High Force Hydraulic Products, Systems and ToolsAlaa saidОценок пока нет

- Manual de Partes PK 62002 EH PDFДокумент190 страницManual de Partes PK 62002 EH PDFLuiz Angel MvОценок пока нет

- 2-5b Contoh Standard Watermain DrawingsДокумент59 страниц2-5b Contoh Standard Watermain Drawingsizzati istiharaОценок пока нет

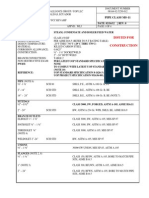

- Issued For Construction: Pipe Class Ms-11Документ4 страницыIssued For Construction: Pipe Class Ms-11Yapo Freddy50% (2)

- Accumulator Charging Valve Drive Axle Block: Brake LightsДокумент20 страницAccumulator Charging Valve Drive Axle Block: Brake LightsCarlo ArevaloОценок пока нет

- EDL Panduan Desain Rev 1Документ3 страницыEDL Panduan Desain Rev 1zat572000Оценок пока нет

- PC W130B 08 EUДокумент178 страницPC W130B 08 EUОблачноОценок пока нет

- Trex 05106Документ10 страницTrex 05106OSDocs2012Оценок пока нет

- Inspection Checklist For: Control ValvesДокумент2 страницыInspection Checklist For: Control Valvesabdelkader benabdallahОценок пока нет

- Brosur Handal Heatpump NewДокумент23 страницыBrosur Handal Heatpump Newewina90Оценок пока нет

- 1.EPV NORTH SEA Exploded PartviewДокумент45 страниц1.EPV NORTH SEA Exploded PartviewPSC RFQОценок пока нет

- Hyva Gear PumpsДокумент2 страницыHyva Gear Pumpsاصلي والفصل شبوة alkingОценок пока нет

- Final ReportДокумент118 страницFinal Reportdivmech1988Оценок пока нет

- Problemas de Hidráulica AvanzadaДокумент172 страницыProblemas de Hidráulica AvanzadaLuis RossoОценок пока нет

- Hydraulic data and pump specificationsДокумент4 страницыHydraulic data and pump specificationsJafarОценок пока нет

- L3206en PDFДокумент2 страницыL3206en PDFRaphael LinoОценок пока нет

- Provisional Time Table - IPPL 2023 - MS As On 10-08-2023Документ2 страницыProvisional Time Table - IPPL 2023 - MS As On 10-08-2023Kahah gdaubОценок пока нет

- DSR - Standard FormatДокумент8 страницDSR - Standard FormatkeviletuoОценок пока нет

- Lab V - Energy Losses in Bends-LO6Документ6 страницLab V - Energy Losses in Bends-LO6Rymshah MoezОценок пока нет