Академический Документы

Профессиональный Документы

Культура Документы

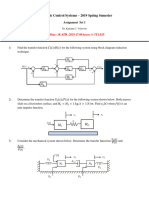

Design of Magnetic Levitation System Undergraduate: A Control An Project

Загружено:

Ishrat JamalОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Design of Magnetic Levitation System Undergraduate: A Control An Project

Загружено:

Ishrat JamalАвторское право:

Доступные форматы

196

IEEE TRANSACTIONS ON EDUCATION, VOL. E-29, NO. 4, NOVEMBER 1986

Design of a Magnetic Levitation Control System

Undergraduate Project

T. H. WONG

Abstract-A magnetic levitation control system is built as a classroom demonstration device for systems and control courses. System

linearization and phase-lead compensation techniques are used to control the unstable nonlinear system.

INTRODUCTION

A CLASSROOM demonstration device is always very

helpful in teaching engineering courses particularly

for automatic control. The magnetic levitation control

system is considered an interesting and impressive device

for this purpose. In addition, the system is so simple and

small that is very convenient to be carried from class to

class.

There are, generally, two approaches for the design of

magnetic levitation. One way is by using the eddy current

magnetic repulsive force [1]. Another way is by using

electromagnetic attractive force [2]-[4]. This design project is based on the second method because it is more efficient than the first method in energy consumption [4].

The magnetic levitation system is an unstable nonlinear

system. The following is a detailed description of how to

design the controller to stabilize the system.

SYSTEm ANALYSIS

In Fig. 1, a ball bearing of mass m is placed underneath

the electromagnet at distance x. The current flowing into

the electromagnetic coil will generate electromagnetic

force to attract the ball bearing. The net force between the

electromagnetic force and gravitational force will induce

an up or down motion of the ball bearing. The photoresistor senses the variation of the position of the ball bearing

by the amount of shadow casted on its surface and feeds

back this signal to the control circuit and amplifier to

regulate the input current i. The ball bearing is kept in a

dynamic balance around its equilibrium point.

The system's dynamic equations can be obtained as (see

Appendix)

i 2

()

e= Ri+L

di

IEEE Log Number 8610515.

point

Col

pho to resils tor

ligght source

lih

sorc

Fig. 1. Magnetic levitation control system.

m

d2x

2 = mg - f

(3)

where

f

i

x

C

e

R

L

electromagnetic force

coil current

distance between electromagnet and ball bearing

constant

voltage across the coil

coil resistance

coil inductance

mass

of ball

bearing

gravitational acceleration.

The system dynamic equations are nonlinear. Before we

can apply the linear control theoty, the system dynamic

equations are linearized at an operating point. The linear-

ized equations describing the variations from the operating point are obtained by using only the linear terms from

the Taylor series expansion. If the variables of the operating point are expressed with subscript "0" and the variables at the neighborhood of the operating point are represented with subscript "1," then linearized equations are

fi=

200

2 i1

x0

M(1)

el=

Ri1

(2)

d 2x,

mdF2L = f

Manuscript received July 11, 1985; revised December 19, 1985.

The author is with the Department of Mechanical Engineering, Tulane

University, New Orleans, LA 70118.

electromagnet

controller amplifler

operating

where

li 2

x0

(4)

~~~~~~~~~~~~~~~~~~di,

(5)

+ L

fo = mg = C

0018-9359/86/ 1100-0196$01.00 1986 IEEE

2Ci2

-2-I

3

d-

(6)

\Xo/

197

WONG: MAGNETIC LEVITATION CONTROL SYSTEM

disturbance

controller

+

70

electromagnet

E,

IE(S)l

bal

__________

l-bearingl_r

T(S)

X1(S)1I

IF (S)

m 7

/00

90

Fig. 2. Block diagram.

Fig. 3. System's dimensions (mm).

Laplace transformation of (4)-(6) yields

F1(S) = kLI,(S)

Im

Xl(S)]

--

(7)

E1(S) = (R + LS)11(S)

mS2X1(S)

(8)

(9)

-F1(S)

where

--

-58 -49.5

49.5

Re

k = 2C .

x2o

The block diagram of the magnetic levitation system is

shown in Fig. 2. The characteristic equation of the control

system can be obtained.

Q(S) = xoLmS3 + xoRmS2 -kioLS kioR + Gc(S)kXoB = 0.

Fig. 4. System root loci (constant amplifier gain).

TABLE I

(10)

From (10), we know that the system is unstable without

a proper controller.

xO

m

R

0.008 m

0.068 kg

28 Q

0.483 H

0.76 A

iOC

COMPENSATION TECHNIQUE

7.39 x i0-5 N .m2 /A2

k

1.756 N/A

In Fig. 3, the electromagnet is made of a 3600-turn coil

B

1.14 x 103 V/m

of gage 22 insulation wire closely wound around a low

carbon steel cylinder of diameter d = 25 mm and length

1 = 100 mm. The other measured parameters are listed in

Table I.

First, considering Gc(S) is a proportional controller (i.e.,

Equation (10) can be rearranged as

constant amplifier gain), the root loci of the system is

V(S)

I +

LGS3c+

R S2 kxB

xOLMS3 xORmS2 Q(S)

GC(S)kXOB

1 +

LS

kioLS

kioR

(11)

and

Q(S) = 1 +

GC(S)

ki0

mx0

kB

ML

Fki0

Substituting the parameters into (12), we get

Q(S)

1 +(S + 49.5)(S - 49.5)(S + 58) =

shown in Fig. 4.

Fig. 4 indicates that system can never be stabilized by

simply adjusting the amplifier gain only. It is required to

shift the loci to the left of the S plane so that the system

can be stabilized by selecting the proper amplifier gain.

Since a lead network can serve this purpose, a phase-lead

controller is considered for Gc(s). The technique of the

phase-lead compensation design in this case is to place

=0. the zero of the compensator in between 0 and -49.5, and

close to -49.5, on the, real axis of the S plane, while the

>

S,<JV

pole

of the compensator is placed about 10 times the zero

L

position [7]. Hence, the phase-lead compensator is cho(12) sen as

G'(S. - K S + 4014

1)The characteristic equation of (13) becomes

198

IEEE TRANSACTIONS ON EDUCATION, VOL. E-29, NO. 4, NOVEMBER 1986

Im

s2 /

K'= 3.05 x

K'

4.702

106

10

(K = 50)

-400

-58

72g)j;tZ

40

~~~~~K'=1. 421

S1

106

49.5

Re

-4.5\

n 100

Fig. 5. System root loci (with phase-lead compensation).

+42 V

1000II h

110

-42 v_

(15)~ ~~~~0

outpu)lt

detection

disturbance

input

Fig. 6. Electronic circuit of the magnetic levitation system.

K' (S + 40)

Q(S) = 1 + (S + 49.5)(S - 49.5)(S + 58)(S + 400)

K' = 60990 K,

K: amplifier gain.

The root locus of (15) for K' changes from O

OD is

shown in Fig. 5. In Fig. 5, for a stable system the minimum system gain is K' = 1.421 x 106 or K = 23 at point

Si and the maximum system gain is K' = 4.702 x 106 or

K = 77 at point S2 We select the medium amplifier gain

of K = 50. The control circuit for the magnetic levitation

system is shown in Fig. 6.

/-'9015

33t

<

3 3

233

-40 20AF

_l ______

]0

Fig. 7. Design layout (mm).

a feedback signal to control the position of the ball bearing. Since the photoresistor is very sensitive to the intenSYSTEM DESIGN AND EXPERIMENTS

The layout of the control demonstration device is shown sity of light on its surface, a black tube is used to cover

in Fig. 7. The deviation from the equilibrium position of the photoresistor and to block the disturbance effect from

the ball bearing casts a shadow on the photoresistor which outside light sources. In designing the system, the lead

will generate the varying voltage corresponding to the compensator is achieved by using a simple RC circuit as

changing position. Then, the changing voltage is used as in Fig. 8.

199

WONG: MAGNETIC LEVITATION CONTROL SYSTEM

From

photorRt2

Vl

2

phtresistor

R2

2RV

O

Fig. 8. Lead compensator.

To

amplifier

inpVt

frequency response. The demonstration device was

brought to the class twice for the course. First, a demonstration was conducted at the beginning of the semester

to explain the concept of feedback control systems. Students reacted with a great deal of curiosity and interest.

The second demonstration was given after the students

had learned the root locus compensation technique. In this

demonstration, the complete magnetic levitation control

system from system modeling, analysis, and synthesis was

used as a live control system design example. The students' responses were enthusiastic. Many questions were

asked about the technical details in the design of the control system.

In demonstrations, in order to enhance the effect, a

function generator was used to supply a sinusoidal waveforn of different frequencies at the disturbance input of

the circuit. Then, the ball bearing would oscillate at the

frequencies accordingly.

Actual levitated system.

Fig.

9.

Fig. 9.Actual levitated system.metr

Students' reaction to this course is very encouraging;

that can be observed from 58 percent of senior students

choosing this course as their one of the two career electives out of six courses offered by the department this semester.

(mm)

CONCLUSION

The magnetic levitation control system has proven successful for classroom demonstration of feedback control.

._It is very effective in teaching a control course using this

7.0 l/_,_,_,_,_,_

0.16

demonstration device as a live control system design ex0.08

Tlme (Second)

ample. It is also possible to include this device as part of

a control lab for compensator design with a different operating point or a different size of the ball bearing.

This paper presents the design details on how to use the

Fig. 10. System step response.

linear control theory to control a nonlinear unstable magThe most difficult part for this design work is to select netic levitation system.

RI and R2 such that the steady state value of V2 has the

APPENDIX

proper bias voltage to the power transistor which, in turn,

DERIVATION OF SYSTEM EQUATIONS

will supply the current for the coil to generate the electromagnetic force approximately equivalent to the weight of

The magnetic forcef exerted on the ball bearing is given

the ball bearing at the operating point. Several experiby the well known equation [21

mental trials are necessary.

'2 dL

Fig. 9 is the picture of display of the controlled system.

(Al)

f= -- In Fig. 10, the system's dynamic time response is ob2 dx

tained from HP 7015B X-Y recorder by applying a step

disturbance to the system. If the disturbance exceeds the The inductance L has its largest value when the ball bearlinearized range, the system will become unstable and loss ing is next to the coil and decreases to a constant value LI

of control. In the lab experiments, we found that the limit as the ball bearing is removed to x = oo. For the present

of allowable disturbance to the system is about + 1.0 mm purpose we assume that this dependence is

away from xo.

Loxo

8.5

L L + x

(A2)

DEMONSTRATIONS

The magnetic levitation system is intended to be used where Lo is a constant and xo is the operating levitation

as a classroom demonstration device for my control and gap. Substituting (A2) into (Al) we get

automation course which also includes six control labs

2

2

.

(A3)

consisting of instrumentations, dc-motor system paramef = 2 LoXo (' = C

2

ter identification, velocity control, position control, and

(D

IEEE TRANSACTIONS ON EDUCATION, VOL. E-29, NO. 4. NOVEMBER 1986

200

The differential equation of the circuit is

d(Li)

e = Ri +

dt

(A4)

cloe neighborhood

neighbrhood of

ept around

aroud the close

x i alwayskept

Since x isSince

always

xo, L can be considered as a constant that will greatly simplify the system model without losing much accuracy.

Therefore, (A4) can be written as

di

(AS)

e =Ri +L-.

dt

The equation of motion of the mechanical system is

d 2x

m 2=mg-J

(A6)

a magnetic

[61 L. 0. Kehinde, "Analysis of limit cycle oscillations in Int.

J. Eng.

suspension system using the describing function method,"

Sci., vol. 22, no. 4, pp. 419-437, 1984.

17] J. J. D'azzo and C. H. Houpis. Linear Control System Analysis and

[8]

New York: McGraw-Hill, 1975.

H. H. Woodson and J. R. Melcher, Electromechanical Dvnamni cs:

Design, Conventional and Modern.

Part I Discrete Systems.

New York: Wiley. 1968.

19] G. H. Hostetter, C. J. Savant. Jr., and R. T. Stefani, Design of Feedback Control Systems. Ncw York: Holt, Rinehart and Winston,

1982.

110] R. H. Cannon, Dynamics of Physical Systems. New York: McGrawHill 1967.

The simplified system dynamic equations are (A3), (A5),

and (A6).

REFERENCES

11] E. R. Laithwaite, 'Electromagnetic levitation," Proc. IEE, vol. 112,

no. 12, pp. 2361-2375, 1965.

[2] B. V. Jayawant and D. P. Rea, "New electromagnetic suspension and

its stabilisation," Proc. IEE, vol. 115, no. 4, pp. 549-554, 1968.

13] B. V. Jayawant, P. K. Sinha, A. R. Wheeler, R. J. Whorlow, and J.

Willsher, "Developement of I-ton magnetically suspended vehicle

using controlled dc electromagnets," Proc. IEE, vol. 123, no. 9, pp.

941-948,e1976.

[4] F. Matsumura and S. Yamada, 'A control method of suspension control system by magnetic attractive force," Trans. I.E.E.J., (Japanese), vol. 94-B, no. 11, pp. 33-40, 1974.

15] R. Frazier, P. Gillinson, and G. Oberback, Magnetic and Electrical

Suspension. Cambridge, MA: MIT Press, 1974.

_

_

REFERENCES

T. H. Wong received the B.S.M.E. degree from

Tatung Institute of Technology, Taiwan, in 1967,

the S.M. degree from the Massachusetts Institute

of Technology, Cambridge, in 1974, and the

Ph.D. degree from the State University of New

York at Buffalo, in 1983.

From 1967 to 1968 hc served in the Chinese

army as an R.O.T.C. Officer. From 1968 to 1972

he was with Toung-Yuan Electrical Company and

Tatung Company, Taiwan. He joined the Mechanical Engineering Faculty of Tatung Institute

of Technology Taiwan from 1974 to 1980, and taught courses primarily in

the systems and controls areas. In 1983 he became an Assistant Professor

at Tulane University, New Orleans, LA. His research interests include system dynamics and control theory.

Вам также может понравиться

- Electromagnetic Levitation System: An Experimental ApproachДокумент7 страницElectromagnetic Levitation System: An Experimental Approachsh1n00b1Оценок пока нет

- 244 1 AhmedSalmanДокумент8 страниц244 1 AhmedSalmanSalman AhmedОценок пока нет

- Magnetic Levitation PDFДокумент8 страницMagnetic Levitation PDFAman MathurОценок пока нет

- Loop Shapind Design ProcedureДокумент4 страницыLoop Shapind Design ProcedureRitesh SinghОценок пока нет

- Online Control of SVC Using ANN Based Pole Placement ApproachДокумент5 страницOnline Control of SVC Using ANN Based Pole Placement ApproachAbdo AliОценок пока нет

- Feedback Linearization and Notch Filter For A Magnetic Levitation System (MagLev)Документ7 страницFeedback Linearization and Notch Filter For A Magnetic Levitation System (MagLev)Luca MaggioriОценок пока нет

- Nonlinear Model & Controller Design For Magnetic Levitation System-IsPRAДокумент5 страницNonlinear Model & Controller Design For Magnetic Levitation System-IsPRAIshtiaq AhmadОценок пока нет

- Exp 1Документ33 страницыExp 1k4nishkkОценок пока нет

- Acs 2017s1 Assn1Документ5 страницAcs 2017s1 Assn1MiraelОценок пока нет

- PROJEKAT ACC04 - Maglev PDFДокумент6 страницPROJEKAT ACC04 - Maglev PDFRandall MillerОценок пока нет

- Design and Analysis of A Practical Three-Phase Grid-Connected Photovoltaic InverterДокумент5 страницDesign and Analysis of A Practical Three-Phase Grid-Connected Photovoltaic InverterAhmed RefaatОценок пока нет

- An Improved Efficiency of Fuzzy Sliding Mode Cont PDFДокумент5 страницAn Improved Efficiency of Fuzzy Sliding Mode Cont PDFNoureddine BounaslaОценок пока нет

- Control of DC Electric MotorДокумент16 страницControl of DC Electric MotorNa ChОценок пока нет

- Vibration Control Simulation of Beams With Piezoelectric Actuators Using Impedance and FemДокумент5 страницVibration Control Simulation of Beams With Piezoelectric Actuators Using Impedance and FemHoang-Long CaoОценок пока нет

- 1, March 47: of ForДокумент8 страниц1, March 47: of Forcarlos gomez reyesОценок пока нет

- Prediction of Stability and Performance of An Active Mechanical Structure Under Uncertainty Conditions Using Finite Element and Neural ComputationДокумент8 страницPrediction of Stability and Performance of An Active Mechanical Structure Under Uncertainty Conditions Using Finite Element and Neural ComputationHadhoud MécaniqueОценок пока нет

- A Local Multimachine Control System With Simplified Output Feedback Undisturbed by Both Primary and Local Power Systems' FluctuationsДокумент5 страницA Local Multimachine Control System With Simplified Output Feedback Undisturbed by Both Primary and Local Power Systems' FluctuationsArjun GulatiОценок пока нет

- Effect of Compensation Factor On The Subsynchronous Resonance in Single Machine Infinite Bus SystemДокумент6 страницEffect of Compensation Factor On The Subsynchronous Resonance in Single Machine Infinite Bus SystemLong LeoОценок пока нет

- 2010 - State Space Controller For Bidirectional DC-DC Converter Buck Mode - OcilkaДокумент3 страницы2010 - State Space Controller For Bidirectional DC-DC Converter Buck Mode - OcilkaWGSОценок пока нет

- Basic Elements of Control SystemДокумент36 страницBasic Elements of Control Systemeugeni madaОценок пока нет

- Determination of Suitable Locations For Power System Stabilizers and Static Var Compensators For Damping of Electromechanical Oscillations in Large Scale Power SystemsДокумент9 страницDetermination of Suitable Locations For Power System Stabilizers and Static Var Compensators For Damping of Electromechanical Oscillations in Large Scale Power SystemsSherif HelmyОценок пока нет

- Fuzzy Logic Based Photovoltaic Peak Power Tracking ControllerДокумент46 страницFuzzy Logic Based Photovoltaic Peak Power Tracking ControllerAlexandra Moinhos100% (1)

- Power System Stabilizers As Undergraduate Control Design ProjectsДокумент8 страницPower System Stabilizers As Undergraduate Control Design Projectsabhikirk99Оценок пока нет

- AkhilsinghДокумент13 страницAkhilsinghalpha kumarОценок пока нет

- Pole Slip ProtectionДокумент10 страницPole Slip ProtectionAdrian ConstantinОценок пока нет

- Response Improvement of Proportional Control Solenoid Valve For Automatic TransmissionДокумент6 страницResponse Improvement of Proportional Control Solenoid Valve For Automatic TransmissionsayproОценок пока нет

- 2 Muhammad RehanДокумент7 страниц2 Muhammad Rehanengrzee5516Оценок пока нет

- Robust H Controller For Construction Elevator Drivesystem Vibrations AttenuatorДокумент9 страницRobust H Controller For Construction Elevator Drivesystem Vibrations AttenuatorDr Saba TareqОценок пока нет

- Dieu Khien He Thong Bi Trong Tu TruongДокумент5 страницDieu Khien He Thong Bi Trong Tu TruongNinhĐứcThànhОценок пока нет

- Backstepping Algorithm With Sliding Mode Control For Magnetic Levitation SystemДокумент5 страницBackstepping Algorithm With Sliding Mode Control For Magnetic Levitation SystemAlfian MaarifОценок пока нет

- Application of The Dq0 Transformation in The 3 Phase Grid Connected PV Systems With Active and Reactive Power Control 04746965Документ6 страницApplication of The Dq0 Transformation in The 3 Phase Grid Connected PV Systems With Active and Reactive Power Control 04746965new7677100% (1)

- Design of Optimal Controllers For A Ball & Beam SystemДокумент10 страницDesign of Optimal Controllers For A Ball & Beam SystemGRD JournalsОценок пока нет

- Power System Dynamic Performance With STATCOM Controller: Mfareed@kfupm - Edu.sa Ahrahim@kfupm - Edu.saДокумент5 страницPower System Dynamic Performance With STATCOM Controller: Mfareed@kfupm - Edu.sa Ahrahim@kfupm - Edu.sapragatinareshОценок пока нет

- Design Simulation For A 3 Phase Grid Connected PV Inverter in Simulink PDFДокумент9 страницDesign Simulation For A 3 Phase Grid Connected PV Inverter in Simulink PDFNguyen KhoaОценок пока нет

- Decentralized PI/PD Position Control For Active Magnetic BearingsДокумент7 страницDecentralized PI/PD Position Control For Active Magnetic BearingsMuhammadОценок пока нет

- Design of Robust Power System Stabilizer Using Mixed Sensitivity Based H Output-Feedback Control in LMI FrameworkДокумент6 страницDesign of Robust Power System Stabilizer Using Mixed Sensitivity Based H Output-Feedback Control in LMI FrameworkFernando RamosОценок пока нет

- Eccentric Mass Dynamic Vibration Absorber - Vibrations - 2131Документ4 страницыEccentric Mass Dynamic Vibration Absorber - Vibrations - 2131southertontimothy100% (4)

- Transient Stability Enhancement Using Self Adjusting-Flexible Variable Series Capacitor CompensationДокумент7 страницTransient Stability Enhancement Using Self Adjusting-Flexible Variable Series Capacitor CompensationVenkata Krishna ReddyОценок пока нет

- Review PPT Modified KLJLKДокумент30 страницReview PPT Modified KLJLKPranith KumarОценок пока нет

- Theoretical Study of A Shunt Reactor Sub Synchronous Resonance StabilizerДокумент14 страницTheoretical Study of A Shunt Reactor Sub Synchronous Resonance StabilizerFranck Mofati KasangalaОценок пока нет

- PSSEДокумент6 страницPSSESyed Faizan AliОценок пока нет

- Feasibility Analysis On FESS Damping For Power System OscillationДокумент4 страницыFeasibility Analysis On FESS Damping For Power System OscillationAshik AhmedОценок пока нет

- Magnetic Levitation: A. MesonesДокумент3 страницыMagnetic Levitation: A. MesonesRubí GradosОценок пока нет

- Acs 2019s1 Assn1Документ5 страницAcs 2019s1 Assn1MiraelОценок пока нет

- 23D AdvanceДокумент8 страниц23D AdvancePATEL SWAPNEELОценок пока нет

- Microcontroller-Based Boost ConverterДокумент10 страницMicrocontroller-Based Boost ConverterDevendra DwivdiОценок пока нет

- Real Time Stabilisation Triple Link Inverted: Pendulum Using Single Control InputДокумент7 страницReal Time Stabilisation Triple Link Inverted: Pendulum Using Single Control InputKuldeep KumarОценок пока нет

- PV BoostДокумент6 страницPV BoostlestherroqueОценок пока нет

- Acs 2018s2 Assn1Документ4 страницыAcs 2018s2 Assn1MiraelОценок пока нет

- Pendulum Positioning System Actuated by Dual Motorized PropellersДокумент4 страницыPendulum Positioning System Actuated by Dual Motorized Propellerspatmos666Оценок пока нет

- Ball-And-Beam Laboratory System Controlled by Simulink Model Through Dedicated Microcontrolled-Matlab Data Exchange ProtocolДокумент11 страницBall-And-Beam Laboratory System Controlled by Simulink Model Through Dedicated Microcontrolled-Matlab Data Exchange ProtocolIrawan MalikОценок пока нет

- Synthesis of The Adaptive Excitation Control System of High Power Synchronous GeneratorsДокумент14 страницSynthesis of The Adaptive Excitation Control System of High Power Synchronous Generators3KaiserEОценок пока нет

- Lab Experiment # 04: A. ObjectiveДокумент4 страницыLab Experiment # 04: A. ObjectiveMuhammad Samee baigОценок пока нет

- SVC ModeloДокумент4 страницыSVC ModeloLuc JeanОценок пока нет

- Exp01 EEE318Документ7 страницExp01 EEE318Abid AbdullahОценок пока нет

- Simulation of Some Power System, Control System and Power Electronics Case Studies Using Matlab and PowerWorld SimulatorОт EverandSimulation of Some Power System, Control System and Power Electronics Case Studies Using Matlab and PowerWorld SimulatorОценок пока нет

- Electrical Correcting Elements in Automatic Control and Regulation CircuitsОт EverandElectrical Correcting Elements in Automatic Control and Regulation CircuitsОценок пока нет

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetОт EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetОценок пока нет

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetОт EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetРейтинг: 2 из 5 звезд2/5 (1)

- Term Paper On Strategic ManagementДокумент8 страницTerm Paper On Strategic Managementea7j5ys3100% (1)

- Modul MarketingДокумент5 страницModul MarketingDeni IrvandaОценок пока нет

- Amy CuddyДокумент5 страницAmy CuddygeetaОценок пока нет

- WEEK 11 - LAB 2 LEVEL 0 - BS Lab Electrical Supply - Domestic House Wiring & Accessories Including Lighting - DONEДокумент6 страницWEEK 11 - LAB 2 LEVEL 0 - BS Lab Electrical Supply - Domestic House Wiring & Accessories Including Lighting - DONEMuhd Alif MikhailОценок пока нет

- P16mba7 1Документ4 страницыP16mba7 1Vishalatchi MОценок пока нет

- GRADE 8 3rd Quarter DLP in EnglishДокумент484 страницыGRADE 8 3rd Quarter DLP in EnglishJulius Salas100% (4)

- Sherman Notes PDFДокумент213 страницSherman Notes PDFAbdul Hamid Bhatti100% (1)

- PCI Express Test Spec Platform 3.0 06182013 TSДокумент383 страницыPCI Express Test Spec Platform 3.0 06182013 TSDeng XinОценок пока нет

- Assignment 9 Nomor 1Документ2 страницыAssignment 9 Nomor 1Alexander Steven ThemasОценок пока нет

- ENG-116: Branches of Linguistics: Books) .Farmer, A. K Demers, R. A. A Linguistics WorkbookДокумент6 страницENG-116: Branches of Linguistics: Books) .Farmer, A. K Demers, R. A. A Linguistics WorkbookBILAL ZAFARОценок пока нет

- Pilot Implementation of The Limited Face-to-Face Class Program at Librada Avelino Elementary SchoolДокумент10 страницPilot Implementation of The Limited Face-to-Face Class Program at Librada Avelino Elementary SchoolCher GeriОценок пока нет

- Super 6 Comprehension StrategiesДокумент1 страницаSuper 6 Comprehension StrategiesrosypatelОценок пока нет

- BITS Pilani: Scale Up and Post Approval ChangesДокумент56 страницBITS Pilani: Scale Up and Post Approval ChangesshrikantmsdОценок пока нет

- 5S For Service Organizations and OfficesДокумент28 страниц5S For Service Organizations and OfficesSilviaОценок пока нет

- 3 Tan 8.3 Tan108 Tan 8 - 1 3tan 8.3: Single Choice CorrectДокумент3 страницы3 Tan 8.3 Tan108 Tan 8 - 1 3tan 8.3: Single Choice CorrectShehbaz ThakurОценок пока нет

- Pre Delivery Inspection Checklist For Home Oxygen ConcentratorДокумент2 страницыPre Delivery Inspection Checklist For Home Oxygen ConcentratorPranavKaisthaОценок пока нет

- Astro-Spiri Camp - Chinmaya Vibhooti - Shankar Kumaran PDFДокумент10 страницAstro-Spiri Camp - Chinmaya Vibhooti - Shankar Kumaran PDFShankar KumaranОценок пока нет

- Rociadores - FT - GFS-100B - GL SeriesДокумент2 страницыRociadores - FT - GFS-100B - GL SeriesJimmy FernándezОценок пока нет

- Legislation Statutory Inspection ChecklistДокумент2 страницыLegislation Statutory Inspection ChecklistAry PutraОценок пока нет

- Jurnal Ari Maulana Ullum Sasmi 1801038Документ12 страницJurnal Ari Maulana Ullum Sasmi 180103803. Ari Maulana Ullum Sasmi / TD 2.10Оценок пока нет

- CES Wrong Answer SummaryДокумент2 страницыCES Wrong Answer SummaryВладислав КомаровОценок пока нет

- Module 2: Most Essential Learning Competencies (Melcs) : Lesson 1: Background, Rationale, and Development of MelcsДокумент5 страницModule 2: Most Essential Learning Competencies (Melcs) : Lesson 1: Background, Rationale, and Development of MelcsRobert Kier Tanquerido TomaroОценок пока нет

- List Katalog Fire Hydrant (Box)Документ3 страницыList Katalog Fire Hydrant (Box)Sales1 mpicaОценок пока нет

- Barangay Labangon Shelter Plan: Group 6 Blackjacks Ar 3134 HousingДокумент21 страницаBarangay Labangon Shelter Plan: Group 6 Blackjacks Ar 3134 HousingGicelle SenoОценок пока нет

- ISO IEC 11801-5 - IT - Generic Cabling For Data CentreДокумент63 страницыISO IEC 11801-5 - IT - Generic Cabling For Data Centreshazwanshaiful1Оценок пока нет

- EKONET CPRS Importer 26062014Документ6 страницEKONET CPRS Importer 26062014anthony0216Оценок пока нет

- SuperboltДокумент32 страницыSuperboltRajeev Chandel100% (1)

- Experimental Psychology & The Scientific MethodДокумент73 страницыExperimental Psychology & The Scientific MethodRuru LavariasОценок пока нет

- CCR Control System Interface HandbookДокумент17 страницCCR Control System Interface Handbooklcastrey23Оценок пока нет