Академический Документы

Профессиональный Документы

Культура Документы

14 - 12 Konsentrasi HCN Subagio 2006

Загружено:

Herwin Apri AmbodoОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

14 - 12 Konsentrasi HCN Subagio 2006

Загружено:

Herwin Apri AmbodoАвторское право:

Доступные форматы

Food Sci. Technol. Res.

, 14 (1), 12 17, 2008

Effects of Protein Isolate from Hyacinth Beans (Lablab purpureus (L.) Sweet)

Seeds on Cake Characteristics

Achmad SUBAGIO1* and Naofumi MORITA2

1

Laboratory of Chemistry and Biochemistry of Agricultural Products, Faculty of Agricultural Technology, University of Jember, Jl. Kalimantan I Jember 68121 Indonesia

Laboratory of Food Chemistry, Graduate School of Life and Environmrntal Sciences, Osaka Prefecture University, 1-1Gakuen-cho, Nakaku, Sakai, Osaka 593-8531, Japan

Received June 28, 2006; Accepted August 16, 2007

Effects of protein isolate prepared from hyacinth bean (Lablab purpureus (L.) Sweet) seeds on cake

characteristics were studied. The addition of up to 1% of the protein isolate from hyacinth bean seeds

could improve the baking properties of the cake. The volume development and specic volume of the cake

with 1% protein isolate were 206.0%, and 2.63 ml/g, whereas those of the control were 160.3% and 2.17

ml/g. Isolate additions of up to 1% softened the cake, as indicated by decreases in texture values, i.e., 184,

112, 100 and 89 g of force for the control, 0.5, 0.75 and 1.0% protein isolate, respectively. However, when

more than 1% protein isolate was added, the cake quality tended to decrease compared with that at 1%.

Moreover, the more protein isolate was added, the more vivid the colour and the lower the staling rate.

Therefore, the protein isolate from hyacinth beans merits further assessment as a practical food additive.

Keywords: cake improver, hyacinth bean, protein isolate

Introduction

Indonesia is rich in non-oilseed legumes, such as hyacinth

bean (Lablab. purpureus (L.) Sweet), which is commonly

planted in marginal land with less of attention. According to

Stephens (1994), hyacinth bean has many local names, such

as lablab, bonavist, Chinese flowering, Egyptian, Pharao,

shink, wild field, and Indian bean. In Indonesia, the local

name of this bean is koro komak. It is generally considered to

have originated in Southeast Asia. However, some authorities

place its origin in Africa, where it has been known since the

eighth century. Presently, it is widely cultivated throughout

the tropics and subtropics. According to Indonesian farmers,

productivity of hyacinth beans plant on dry land can reach

to 1000 1200 kg of dry seeds/ha. Unfortunately, no data is

available for the total production of the seeds in Indonesia.

In some hyacinth bean-producing areas, the young pods are

boiled separately as a vegetable, or together with corn as an

soup. The dry seeds are cooked together with rice after soaking water for one night to supply protein. The seeds are also

*To whom correspondence should be addressed.

E-mail: subagio@ftp.unej.ac.id

used as raw materials of tempeh, an traditional Indonesian

fermented food usually made from soybeans.

Previous study (Subagio, 2006) has reported that hyacinth bean seeds have a moderate protein content (17.1

1.5%), and low concentration of HCN (1.1 0.1 mg/100 g).

However, before the seeds can be used as food, treatment is

needed to reduce their anti-nutritional components, such as

trypsin inhibitor (0.15 0.02 TIU/mg) and phytate (18.9

0.2 mg/g). Using an isoelectric method followed by washing

with ethanol, protein isolate produced from the seeds had

light colour, neutral odour, high protein content (89.78 0.82

%), and low ash (2.97 0.36 %). The protein isolate had also

good functional properties such as solubility, foaming capacity, and emulsifying activity. However, the yield was low

(7.38 0.2 g per 100 g of the seeds) (Subagio, 2006).

Cake is a food system that requires good emulsion performance and foam development. A sponge-cake batter with

emulsier can be whipped in a rst stage process, in which

the incorporation and stability of air bubbles are improved,

resulting in a ner dispersion and higher cake quality (Richardson et al., 2002). Accordingly, the addition of protein isolate from hyacinth bean seeds, which has good capacities as

13

Protein Isolate from Hyacinth Beans as Cake Improver

an emulsier and foaming agent, may improve the quality of

cake. The aim of this study was to investigate the inuence

of protein isolate from hyacinth bean seeds on baking properties, second Maillard reaction products, colour and sensory

properties of cake. The staling rate of the cake was also studied by the measurement of texture during storage.

Materials and Methods

Materials Hyacinth beans used in this study were collected from a farm in Bondowoso City, East Java, Indonesia.

After arrival in the laboratory, seeds were sorted to remove

immature and defective beans. The sorted beans were then

stored in a cold room (4 6C) until use. Wheat our, sugar,

shortening, egg, and emulsier (Ryoto Ester SP, Mitsubishi

Chemical Ltd., Japan) were obtained from local market. The

chemicals and solvents used were of guaranteed grade.

Preparation of the protein isolate Protein isolate was

prepared using isoelectric method as reported previously

(Subagio, 2006). The protein isolate had 89.78 0.82% of

protein on dry basis.

Cake preparation A standard cake formulation was used

for the study (Table 1). The protein isolate was added in concentrations of 0, 0.5, 0.75, 1.0, 1.25 and 1.5% against wheat

flour. The dry ingredients were combined and sifted well.

Egg, crystal sugar and emulsier were whipped for 6 min at

high speed using a Philips HR 1500 (Indonesia) mixer. The

fat and our mixture was transferred to the whipped egg, and

mixed manually until homogenized. Cake batter was then

transferred to a cake pan and baked at 180C for 60 min using an oven (Selecta Oven, Spain).

Measurement of cake characteristics Loaf volume of the

cake was determined using the seed displacement method.

Specic volume of cake was calculated by dividing volume

to weight of the cake. Baking loss of cake was expressed

using the percentage of decrement of cake weight after baking and the weight of cake batter. Firmness or texture of

cake was determined using a Rheometer (RHEOTEX Type

SD-700, Japan) with a standard plunger at 7 mm of penetra-

tion.

To evaluate the colour of the seeds and the protein isolate, Chromameter CR-100 (Minolta, Japan) was used with C

illumination for daylight, and an averaging mode to produce

8 replications per sample. The instrument was calibrated

externally with a standard white tile, and the tristimulus coordinates L*, a*, and b* (CIE Lab colour scale) system was

applied to express the colour (McGuire, 1992; Voss, 1992;

Gonnet, 1999).

Secondary products of the Maillard reaction in the cake

were measured. A sample of cake (0.5 g) was stirred in

ethanol (10 ml) for 10 min and centrifuged (2500g for 10

min). The supernatant was collected, and the residue was reextracted twice using the spectrophotometer method of Lerici et al. (1990, with some modications) with ethanol. The

collected supernatant was combined, and the volume was adjusted to 30 ml using ethanol. Absorbance of the supernatant

was measured at a wavelength of 420 nm by spectrophotometer (PRIM, Secomam, France) to express the concentration

of the Maillard reaction secondary product.

Staling rate Staling rate of the cake was determined

by storing the cake in a box placed at room temperature for

5 days. Each day, cake texture was measured by Rheometer

(RHEOTEX). Changes in the texture value were calculated

by subtracting the texture value of the cake after storage with

before storage. To prevent microbial spoilage, the box was

exposed to UV light for 15 min after opening.

Sensory evaluation A trained panel of 25 judges carried out the sensory evaluation of cake samples by assigning

scores for crumb cell uniformity (1 = uneven, 5 = even), colour (1 = in vivid, 5 = vivid), taste (1 = foreign, 5 = typical),

aroma (1 = foreign, 5 = typical), texture (1 = very rm, 5 =

very soft), mouth feel (1 = tough, 5 = very tender), and overall preference (1 = very bad, 5 = very good).

Statistical analysis Statistical analysis of data was performed using analysis of variance (ANOVA) on 6 experimental groups in triplicate. The experimental groups were

then separated by using Duncans new multiple range test, as

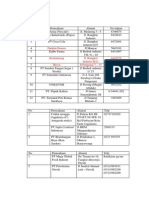

Table 1. Cake formulation.

Ingredients

Wheat flour

Sugar

Egg

Shortening

Emulsifier (Ryoto Ester SP)

Protein isolate*

75

75

75

30

1

0, 0.375, 0.5625, 0.75, 0.9375 and 1.125

*Calculated as percentage of wheat flour: 0, 0.5, 0.75, 1.0, 1.25 and 1.5%.

A. SUBAGIO et al.

14

Table 2. Effect of the addition of protein isolate from hyacinth bean seeds on certain

cake characteristics*.

Protein isolate

Volume

Specific volume

development (%)

(ml/g)

Baking loss

(%)

Texture

(g force)

0%

160.3 c

2.17 c

17.25 a

184 a

0.5%

0.75%

185.0 ab

189.0 ab

2.33 b

2.44 ab

14.70 a

14.55 a

112 c

100 cd

1.00%

1.25%

1.50%

206.0 a

188.7 ab

180.7 bc

2.63 a

2.50 ab

2.44 ab

15.50 a

16.20 a

16.50 a

89 d

148 b

165 ab

*Values in the same column followed by different letter showed significant differences

(P < 0.05). Number of experiments: 3.

described by OMahony (1986).

Results and Discussion

Cake characteristics The effects of addition of protein

isolate from hyacinth beans on the baking properties of

cake are presented in Table 2. The addition of the protein

isolate in low concentrations could increase the volume development of the cake. However, the volume development

would decrease when the protein isolate was added at high

concentrations. The addition of 0.5, 0.75, and 1.0 % could

increase the volume development to 185.0, 189.0, and 206.0

%, respectively. These values are much higher than that of

the control (160.3%). However, the volume development

decreased to 188.7 and 180.7% by the addition of 1.25 and

1.5 % protein isolate, respectively. The increase in volume

development may be related to the foaming capability of

the protein isolate of hyacinth bean seeds, which can reach

232 ml/g (Subagio, 2006). The volume of cake is affected

by the gas expansion that occurs during mixing (Kilara,

1994). Since the protein isolate could decrease the surface

tension of gas/liquid, the addition of the isolate can increase

the foam formation. However, the addition at high level will

disrupt the gluten matrix, resulting in the decrease of volume

after baking, since the structure of the cake was not sufcient

to retain the original volume.

Accordingly, the addition of protein isolate from hyacinth

bean seeds had a similar effect on the specic volume of the

cake. As shown in Table 2, addition at a low level could signicantly increase the specic volume of the cake. The addition of 0.5, 0.75, and 1.0 % increased the specic volume to

2.33, 2.44, and 2.63 ml/g, respectively. These values were 7.4,

12.4 and 21.2 % higher than that of the control (2.17 ml/g).

However, the specific volume would significantly decrease

to 2.50 and 2.44 ml/g when 1.25 and 1.5%, respectively, of

protein isolate was added. Similar to volume development,

the increase in the specic volume may be due to the foaming capability of the protein isolate of hyacinth bean seeds,

which can reach 232 ml/g (Subagio, 2006).

Moreover, the addition of protein isolates from hyacinth

bean seeds did not affect the baking loss of the cake signicantly (Table 2). Although protein isolate from hyacinth bean

seeds have a high water holding capacity (WHC) of 321%

(Subagio, 2006), the addition did not signicantly affect the

baking loss. This may be due to the high temperature (180 C)

for baking, which could annul the effect on WHC increment.

Since the baking losses of the samples were not signicantly

different, the specic gravity of the cake was markedly affected by changes in the cake volume inuenced by the addition of the protein isolate.

Table 2 also shows the effect of the addition of protein

isolate from hyacinth bean seeds on cake texture. The addition of up to 1% isolate softened the cake as shown by the

following texture values: 184, 112, 100 and 89 g force for 0

(control), 0.5, 0.75 and 1.0 % isolate, respectively. However,

the value of the cake texture increased to 148 and 165 g force

when the concentration of the isolate was 1.25 and 1.5%, respectively. Therefore, the addition of up to 1% isolate could

soften the cake, but more than 1% could harden the cake.

Cake texture is inuenced by the three-dimensional structure,

and the size and distribution of gas cells in the cake. The protein isolate from hyacinth bean seeds might decrease the surface tension of the colloidal system, resulting in a decrease in

the globule size of the foam during cake mixing. This would

improve the distribution of gas cells in the cake, resulting in

shortening of the cake texture, as shown in cross section of

the cake (Figure 1). However, since the protein isolate could

disturb the gluten matrix, the addition of the isolate at high

levels might harden the cake texture signicantly.

The data on the effects of protein isolate from hyacinth

bean seeds on the cake colour are presented in Table 3. As is

Protein Isolate from Hyacinth Beans as Cake Improver

15

shown in this table, addition of the protein isolate resulted in

cake colour becoming more brownish red, as expressed by

H values. Cake without addition of the protein isolate had H

value of 67.23 2.33, whereas with addition of 0.5, 0.75, 1.0,

1.25 and 1.5% of the protein isolate, the H values of cake colour were 63.43 3.51, 60.50 2.25, 56.54 1.37, 56.56

2.89 and 54.59 3.04, respectively. Since H values are the

angles of dots having coordinate of a* and b*, the addition

of protein isolate would increase the value of a*, the degree

of redness, and would decrease the value of b*, the degree of

yellowness (Table 3).

These phenomena coincided with the results of analysis

of secondary products of the Maillard reaction, which are

pigments bearing a brownish red colour, as shown in Figure

2. Addition of 1% protein isolate increased the secondary

products to nearly two times of that of the control. However,

the addition of more than 1.25% did not further increase

the values of the secondary products. The Maillard reaction

involves the reaction of aldehydes with amines, and through

numerous reactions, dark pigments (melanoidins) are formed

(Bailey, 1998). Therefore, the addition of protein isolate

would increase the concentration of the reactant, especially

the amine compounds, resulting in more melanoidins, and

more intense brownish red colour. However, when the addi-

tion of the protein isolates would provide amine compound

in the imbalance amount with the aldehyde compounds, the

Maillard reaction would not increase further, as shown in the

1.25 and 1.5% isolate results.

Staling rate Further observation of the cake textures

during storage showed that the more protein isolate was

added, the lower the rate of staling. The addition of the isolate decreased changes in the texture value of the cake during storage (Figure 3A). As a result, although the addition of

the protein isolate up to 1% could soften cake texture, while

more than 1% could harden the texture (Table 2 and Figure

3B-solid bar), the texture remained unchanged four days

after baking (Figure 3B-open bar). Therefore, the more protein isolate was added to the cake, the lower the staling rate.

These results agreed with the ndings of Eliasson and Larsson (1993), which clarified that protein affects the staling

rate in several ways: (a) protein-starch interactions decrease

the retrogradation of the starch; (b) protein affects the rheological properties in the continuous phase; and (c) protein

affects the distribution of water.

Sensory properties Sensory properties of the cake af0.5

Abs 420 nm (AU)

0.4

0.3

0.2

0.1

0.0

0

0.5

1.5

Protein isolate (%)

Fig. 1. Cross sections of cakes with various concentrations of protein isolate from hyacinth bean seeds.

Fig. 2. Effect of the addition of protein isolate from hyacinth bean

seeds on the Maillard reaction in cake. Number of experiments: 3.

Table 3. Effects of protein isolate from hyacinth bean seeds on cake colour.

Protein isolate

0%

0.5%

0.75%

1.00%

1.25%

1.50%

Colour parameters

L

78.67 0.18

78.47 1.13

77.57 0.99

77.28 0.21

78.18 0.44

77.10 0.04

Number of experiments: 3.

a*

6.61 0.32

7.05 0.16

7.34 0.82

7.75 0.82

7.71 0.86

8.35 0.47

b*

15.82 1.14

13.32 2.52

13.09 2.40

11.77 1.60

11.74 1.76

11.78 1.08

c*

17.16 0.94

15.99 2.31

15.02 2.47

14.09 1.77

14.06 1.82

14.45 0.90

H

67.23 2.33

63.43 3.51

60.50 2.25

56.54 1.37

56.56 2.89

54.59 3.04

A. SUBAGIO et al.

16

Change in texture (g force)

140

120

Colour

5

4

3

2

1

0

100

Uniformity

80

60

40

Taste

20

Aroma

Mouth feel

0

0

Time of storage (days)

Texture

300

Texture (g force)

Overall preference

350

250

200

150

3

2

1

0

0

100

0.5

0.75

1.0 1.25

1.5

Protein isolate (%)

50

0

0

0.5

0.75

1.0 1.25

1.5

Protein isolate (%)

Fig. 3. Effects of the addition of protein isolate from hyacinth bean

seed on staling rate of cake. (A) Changes of cake texture during

storage. : Control; : 0.5%; : 0.75%; : 1.0%; : 1.25%;

and +: 1.5% of the isolate. (B) Cake texture values after 0 (solid) to

4 days (open) of storage. Number of experiments: 3.

ter baking affected by the addition of the protein isolate are

shown in Figure 4. The panellists clearly judged that addition of the protein isolate had signicant effects on colour,

texture, mouth feel, uniformity (Figure 4A), and overall

preference (Figure 4B). However, the addition did not have a

signicant effect on the taste and aroma of the cake (Figure

4A). These results coincided with the physical and chemical

analysis as described in previous sections.

Fig. 4. Effects of the addition of protein isolate from hyacinth bean

seed on sensory properties of cake. (A) Descriptive properties of

three cakes ( : Control; : 1.0%; and : 1.5%); (B): Overall

preference. Number of experiments: 3.

the rate of staling.

At present, we could not elucidate the mechanism of the

improving effects of protein isolate from hyacinth bean seeds

for cake making. However, the results of the present study

indicate that this isolate has merit for further assessment as a

practical and functional food additive.

Acknowledgements Achmad Subagio was supported by the International Foundation for Science (Sweden), the Committee on Scientic and Technological Cooperation of the Organization of Islamic

Conference (Pakistan), and the Prohibition of Chemical Weapons

(The Netherlands).

References

Bailey, M. E., (1998). Maillard reactions and meat avour develop-

Conclusion

In conclusion, the addition of the protein isolate from

hyacinth bean seeds in concentrations up to 1% could improve the properties of the cake by increasing loaf volume,

increasing specic volume, softening the texture and improving overall preference. When protein isolate of more than

1% was added, these properties tended to decrease compared

with the cake with 1% isolate. However, the more protein

isolate was added, the more vivid the colour and the lower

ment. In: Flavour of Meat, Meat Products and Seafoods (edited

by S. Shahidi). pp. 267-289. London, UK: Blackie Academic &

Professional.

Eliasson, A. C., & Larsson, K., (1993). Cereals in Breadmaking.

New York, USA: Marcel Dekker, Inc.

Gonnet, J. (1999). Colour effects of co-pigmentation of anthocyanins revisited 2. A colourimetric look at the solutions of cyanin

copigmented by rutin using the CIELAB scale. Food Chem, 66,

387-394.

Protein Isolate from Hyacinth Beans as Cake Improver

Kilara, A. (1994). Whey protein functionality. In: Protein Functionality in Food Systems (edited by N. S. Hettiarachchy, and G. R.

Ziegler). pp. 325-355. New York, USA: Marcel Dekker, Inc.

Lerici, C. R., Barbanti, D., Monzano, M., & Cherubini, S. (1990).

Early indicators of chemical changes in food due to non-enzymatic and enzymatic browning reactions 1. Lebensmittel Wissenschaftund Technology, 23, 289-294.

McGuire, R.G. (1992). Reporting of objective colour measurements. Horticulture Science, 27, 1254-1255.

OMahony, M. (1986). Sensory Evaluation of Food. New York,

USA: Marcel Dekker, Inc.

Richardson, G., Langton, M., Faldt, P., & Hermanson, A. M. (2002).

17

Microstructure of a-crystalline emulsier and their inuence on

air incorporation on cake batter. Cereal Chem, 79, 546-552.

Stephens, J. M. (1994). Bean, Hyacinth -- Dolichos lablab L., or

Lablab purpureus (L.) Sweet. Florida, USA: University of Florida, Institute of Food and Agricultural Sciences (UF/IFAS).

Subagio A. (2006). Characterization of hyacinth bean (Lablab purpureus (L.) Sweet) seeds from Indonesia and their protein isolate.

Food Chem, 95, 65-70.

Voss, D. H. (1992). Relating colorimeter measurement of plant colour to the Royal Horticultural Society colour chart. Horticulture

Science, 27, 1256-1260.

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (120)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Generalized Guidelines For Structural Steel Welding InspectionДокумент19 страницGeneralized Guidelines For Structural Steel Welding InspectionHariPrasath100% (1)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Matter Sphere For Mage The AscensionДокумент2 страницыMatter Sphere For Mage The AscensionBeth100% (3)

- Chemical DosingДокумент3 страницыChemical DosingMasoodyОценок пока нет

- 3 Thermochemistry of Fuel-Air MixturesДокумент86 страниц3 Thermochemistry of Fuel-Air MixturesArsalan Ahmad100% (1)

- 1-Internal Heat GainДокумент15 страниц1-Internal Heat GainWunNa100% (1)

- Metal Sprays and Spray DepositionДокумент569 страницMetal Sprays and Spray DepositionPassanai100% (1)

- TabelllДокумент26 страницTabelllHerwin Apri AmbodoОценок пока нет

- Prak FermenДокумент8 страницPrak FermenAnonymous xj2JQ1s0PОценок пока нет

- List Sponshor BismillahДокумент2 страницыList Sponshor BismillahHerwin Apri AmbodoОценок пока нет

- 4452 11811 1 PBДокумент10 страниц4452 11811 1 PBHerwin Apri AmbodoОценок пока нет

- Evaluasi Sifat Putih Telur Ayam Pasteurisasi Ditinjau Dari PH Kadar Air Sifat Emulsi Dan Daya Kembang Angel Cake PDFДокумент8 страницEvaluasi Sifat Putih Telur Ayam Pasteurisasi Ditinjau Dari PH Kadar Air Sifat Emulsi Dan Daya Kembang Angel Cake PDFHerwin Apri AmbodoОценок пока нет

- Evaluasi Sifat Putih Telur Ayam Pasteurisasi Ditinjau Dari PH Kadar Air Sifat Emulsi Dan Daya Kembang Angel Cake PDFДокумент8 страницEvaluasi Sifat Putih Telur Ayam Pasteurisasi Ditinjau Dari PH Kadar Air Sifat Emulsi Dan Daya Kembang Angel Cake PDFHerwin Apri AmbodoОценок пока нет

- Presentation 1Документ7 страницPresentation 1Herwin Apri AmbodoОценок пока нет

- Interrelationship Phases of The Hydrologic CycleДокумент37 страницInterrelationship Phases of The Hydrologic CycleHeart DaclitanОценок пока нет

- MT BitsДокумент12 страницMT BitsKundan KumarОценок пока нет

- Lab Report: Organic Chemistry I CHM3201Документ5 страницLab Report: Organic Chemistry I CHM3201Sehnegha KasirajanОценок пока нет

- Bpo C Chapter 18Документ74 страницыBpo C Chapter 18Cristiano Hamdiansyah SempadianОценок пока нет

- Waste Management Study of FoundriesДокумент64 страницыWaste Management Study of FoundriesSumit GusainОценок пока нет

- MOA of BarbituratesДокумент3 страницыMOA of BarbituratesReymart FernandezОценок пока нет

- Properties of Gelatins From Skins of Fish - Black Tilapia (Oreochromis Mossambicus) and Red Tilapia (Oreochromis Nilotica)Документ4 страницыProperties of Gelatins From Skins of Fish - Black Tilapia (Oreochromis Mossambicus) and Red Tilapia (Oreochromis Nilotica)Rizky Febrian SatrianiОценок пока нет

- Concrete Aggregates: Standard Specification ForДокумент2 страницыConcrete Aggregates: Standard Specification ForanjadelyОценок пока нет

- MME 3518-Powder Metallurgy-1-2Документ80 страницMME 3518-Powder Metallurgy-1-2Mohammed GhisheerОценок пока нет

- Chemicals Zetag MSDS Inverse Emulsion Zetag 8849 FS - 0710Документ6 страницChemicals Zetag MSDS Inverse Emulsion Zetag 8849 FS - 0710PromagEnviro.comОценок пока нет

- Photosynthesis in PlantsДокумент5 страницPhotosynthesis in Plantskay69max47Оценок пока нет

- Shjohntec 2008218115733800771Документ36 страницShjohntec 2008218115733800771Kristin NgoОценок пока нет

- 01-0105 Pyrocatechol Developer FormulaДокумент2 страницы01-0105 Pyrocatechol Developer FormulaEugene KulikovОценок пока нет

- ASTM A193: GradesДокумент1 страницаASTM A193: GradesRamon MendozaОценок пока нет

- CRE Previous Year QuestionsДокумент14 страницCRE Previous Year QuestionsAbhishek GadhwalОценок пока нет

- Schultz 1987Документ18 страницSchultz 1987Ruiz ManuelОценок пока нет

- Dye Penetrant TestingДокумент2 страницыDye Penetrant TestingshreeambhasankaranОценок пока нет

- 1st Preliminary Exam (Science 6) 2021-2022 - Google FormsДокумент4 страницы1st Preliminary Exam (Science 6) 2021-2022 - Google FormsEl CruzОценок пока нет

- Metrology AND MeasurementsДокумент56 страницMetrology AND Measurementsvasanthmech092664Оценок пока нет

- SynopsisДокумент4 страницыSynopsisyashaahmadОценок пока нет

- 2561 Rubber Based Adhesives For Automobile IndustryДокумент14 страниц2561 Rubber Based Adhesives For Automobile IndustryKaushik SenguptaОценок пока нет

- Want To Be A DoctorДокумент17 страницWant To Be A DoctormadhavОценок пока нет

- Monel K500 PDFДокумент6 страницMonel K500 PDFOZAIRTRADELINKОценок пока нет

- CL ALOX enДокумент2 страницыCL ALOX enmikael8118Оценок пока нет