Академический Документы

Профессиональный Документы

Культура Документы

Specification Guide For Dry Type Distribution Transformers, Including Opti-Miser 30 KVA & Larger

Загружено:

Dony Saputra0 оценок0% нашли этот документ полезным (0 голосов)

21 просмотров4 страницыSpecification for Dry Type Transformer

Оригинальное название

Spec.Trafo

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документSpecification for Dry Type Transformer

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

21 просмотров4 страницыSpecification Guide For Dry Type Distribution Transformers, Including Opti-Miser 30 KVA & Larger

Загружено:

Dony SaputraSpecification for Dry Type Transformer

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 4

GENERAL

ACME TRANSFORMER SPECIFICATIONS

Specification Guide for Dry Type Distribution

Transformers, Including Opti-Miser 30 KVA & Larger

1.0 Dry Type Transformers:

1.0.0 The following information should be utilized only by

trained technical personnel. If you need assistance,

please contact Acmes Technical Services Department

at 800-334-5214.

1.0.1 Provide dry type, enclosed and ventilated transformers

as indicated herein. Transformers shall be Acme or

approved equal.

1.0.2 Transformers shall be designed, constructed and rated

in accordance with UL, CSA, NEMA, ANSI, IEEE, and

OSHA standards.

1.0.3 Transformers rated 27 KVA and larger, single and three

phase shall be the ventilated type, incorporating a 220

degree C insulation system and designed not to

exceed 150 degree C temperature rise above a 40

degree C ambient under full load conditions. Taps are

to be provided on the primary side of the transformer

as follows:

(a) 2 - 2.5% above normal full capacity.

4 - 2.5% below normal full capacity.

-or(b) 2 - 2.5% above normal full capacity.

2 - 2.5% below normal full capacity.

Alternate 1: 115 degree C rise transformers shall

incorporate a 220 degree C insulation system and be

designed not to exceed 115 degree C temperature rise

above a 40 degree C ambient under full load conditions.

In addition, the transformer shall have the ability to

carry a continuous 15% overload without exceeding a

150 degree C rise above ambient.

Alternate 2: 80 degree C rise Transformers shall

incorporate a 220 degree C insulation system and be

designed not to exceed 80 degree C temperature rise

above a 40 degree C ambient under full load conditions.

In addition, the transformer shall have the ability to

carry a continuous 30% overload without exceeding a

150 degree C rise above ambient.

1.0.4 Transformer enclosure finish must be ASA 61 gray

powder polyurethane paint. Transformer enclosure

temperature shall not exceed 50 degrees C plus the

ambient under any condition of loading at any specified

temperature rise at or below 150 degrees C.

1.0.5 Transformer enclosure shall be UL/NEMA Type 2 and

UL 3R Listed with the addition of a weather shield

and shall be so marked on the transformer.

1.0.6 Transformer shall incorporate an electrostatic shield

for the attenuation of voltage spikes, line noise, and

transients.

1.0.7 Single phase transformers and three phase transformers

terminate in copper or aluminum bus bar.

1.0.8 Transformer coils designed and manufactured for

increased insulation life, cooler operation, and lower losses.

1.0.9 Transformers must operate at audible sound levels

below NEMA Standard ST-20. Sound levels will not

exceed the following:

30 - 50 KVA

45 db

51 - 150 KVA

50 db

151 - 300 KVA

55 db

301 - 500 KVA

60 db

501 - 750 KVA

65 db

Transformers must incorporate vibration isolation pads

in their construction located between the transformer

core and coil assembly and the transformer case.

External vibration isolation pads will not be used as

they tend to increase audible noise. Transformers shall

be floor mounted on a concrete pad. All connections

to the transformer will be made by means of flexible

metallic conduit.

1.0.10 Transformer enclosure shall be grounded per the

National Electric Code.

1.0.11 Transformers shall be dry-type 600 volt class, KVA rating

as indicated. Contractor to provide all necessary lugs

for all transformers.

1.0.12 Complete shop drawings must be submitted for

approval on all dry type transformers.

1.0.13 Typical performance data must be submitted for approval

on all transformers. Factory tests must be made in

accordance with the latest revisions of ANSI Test Code

C57.12.91 for Dry Type Transformers. Performance

data provided must contain but not be limited to:

(a) No load losses.

(b) Full load losses.

(c) Polarity and phase rotation.

(d) Impedance at reference temperature.

(e) Efficiencies at 25, 50, 75, and 100% load.

(f) Regulation at 100% and 80% power factor.

(g) Audible sound level.

(h) Dimensions and weight.

(i) Applied potential test.

(j) Induced potential test.

(k) Excitation current.

(l) IR, IX, and IZ percentages.

(m) Reference and ambient temperature.

1.0.14 Warranty: Transformers must be warranted against

defects in materials, workmanship, and performance

for ten years from date of manufacture.

ACME ELECTRIC, POWER DISTRIBUTION PRODUCTS DIVISION LUMBERTON, NC 800-334-5214 www.acmepowerdist.com

159

GENERAL

ACME TRANSFORMER SPECIFICATIONS

Specification Guide for Single & Three Phase

Encapsulated Transformers

1.0 Dry Type Transformers:

1.0.0 The following information should be utilized only by

trained technical personnel. If you need assistance,

please contact Acmes Technical Services Department

at 800-334-5214.

1.0.1 Provide dry type, enclosed, epoxy encapsulated

transformers as indicated and specified herein.

Transformers must be Acme or approved equal.

1.0.2 Transformers must be designed, constructed and rated

in accordance with UL, CSA, NEMA, ANSI, IEEE, and

OSHA standards.

1.0.3 Transformers 3.0 - 75 KVA shall be compound filled,

incorporating a 180 degree C insulation system and

designed not to exceed a 115 degree C temperature

rise above a 40 degree C ambient under full load

conditions. Taps are to be provided on the primary side

of the transformer. The catalog number suffix will

provide the tap information outlined below:

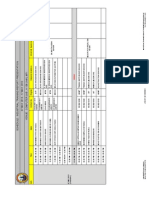

SUFFIX

TAP ARRANGEMENT

- 1S

2-5% BNFC

- 2S

1-5% ANFC & 1-5% BNFC

- 3S

2-2 .5% ANFC & 4-2.5% BNFC

- 4S

2-2 .5% ANFC & 2-2.5% BNFC

- 5S

2-5% ANFC & 2-5% BNFC

1.0.4 Transformer enclosure finish must be ASA 61 gray

powder polyurethane paint.

1.0.5 Transformer enclosure temperature shall not exceed 65

degrees C plus the ambient.

1.0.6 Transformer enclosure shall be UL/NEMA Type 3R and

so marked on the transformer.

1.0.7 Transformer shall incorporate an electrostatic shield

for the attenuation of voltage spikes, line noise and

transients.

1.0.8 Transformer coils are typically wound with aluminum or

copper for increased insulation life, cooler operation

and lower losses.

160

1.0.9 All primary tap connections and both primary and

secondary phase conductors must be either copper

wire or copper bus bar.

1.0.10 Transformers must operate at audible sound levels

below ANSI/NEMA Standard ST-20. Sound levels will

not exceed the following:

Up to 9 KVA

40 db

10 - 50 KVA

45 db

51 - 150 KVA

50 db

1.0.11 Transformer enclosures shall be grounded per the

National Electric Code.

1.0.12 Complete shop drawings must be submitted for

approval on all Dry Type Transformers.

1.0.13 Typical performance data must be submitted for

approval on all transformers. Factory tests must be

made in accordance with the latest revisions of ANSI

Test Code C57.12.91 for Dry Type Transformers.

Performance data must contain but not be limited to:

(a) No load losses.

(b) Full load losses.

(c) Polarity and phase rotation.

(d) Impedance at reference temperature.

(e) Efficiencies at 25, 75, and 100% load.

(f) Regulation at 100% and 80% power factor.

(g) Audible sound level.

(h) Insulation class and rated temperature rise.

(i) Dimensions and weight.

(j) Applied potential test.

(k) Induced potential test.

(l) Excitation current.

(m) IR, IX, and IZ percentages.

(n) Reference and ambient temperature.

1.0.14 Warranty: Transformer must be warranted against

defects in materials, workmanship and performance

for ten years from date of manufacture.

ACME ELECTRIC, POWER DISTRIBUTION PRODUCTS DIVISION LUMBERTON, NC 800-334-5214 www.acmepowerdist.com

GENERAL

ACME TRANSFORMER SPECIFICATIONS

Specification Guide for Non-Linear Load

Isolation Transformers

1.0 Dry Type Transformers:

1.0.0 The following information should be utilized only by

trained technical personnel. If you need assistance,

please contact Acmes Technical Services Department

at 800-334-5214.

1.0.1 Provide dry type, enclosed, and ventilated transformers

as indicated and specified herein. Transformers must be

Acme or approved equal. Transformers must be UL listed

for non-sinusoidal current loads of a specified K Factor

(UL Standard 1561), CSA certified and labeled as such.

1.0.2 For sizes 15 KVA and larger, low voltage dry transformers

will be ventilated type, incorporating a 220 degree C

insulation system and designed not to exceed 150

degree C temperature rise above a 40 degree C

ambient under full load conditions. Taps will be provided

on the primary side of the transformer. There will be 2,

2.5% taps above normal full capacity and 4, 2.5% taps

below normal full capacity.

Alternate 1: 115 degree C rise Transformers shall

incorporate a 220 degree C insulation system and be

designed not to exceed 80 degree C temperature rise

above a 40 degree C ambient under full load conditions.

In addition, the transformer shall have the ability to carry

a continuous 15% overload without exceeding a 150

degree C rise above ambient.

Alternate 2: 80 degree C rise Transformers shall

incorporate a 220 degree C insulation system and be

designed not to exceed 80 degree C temperature rise

above a 40 degree C ambient under full load conditions.

In addition, the transformer shall have the ability to carry

a continuous 30% overload without exceeding a 150

degree C rise above ambient.

1.0.3 Transformers shall incorporate an electrostatic shield

for the attenuation of voltage spikes, line noise, and

transients.

1.0.4 Transformers must be designed to handle non-linear

loads and the adverse effects of harmonics. Transformer

coils will be wound with foil to minimize the heating

effects caused by harmonic currents.

1.0.5 Transformers must be able to power non-linear loads

with a K-Factor as high as 20.

1.0.6 Transformers must operate at audible sound levels

below NEMA ST-20. Sound levels will not exceed the

following:

30 - 50 KVA

45 db*

51 - 150 KVA

50 db*

151 - 300 KVA

55 db*

301 - 500 KVA

60 db*

Enclosed, ventilated transformers must incorporate

vibration dampening pads in their construction, located

between the transformer core and coil assembly and

the transformer case. External vibration dampening

pads will not be used on enclosed, ventilated designs

as they tend to increase audible noise. Transformers

15 KVA and larger shall be floor mounted on a concrete

pad. All connections to the transformer will be made

by means of flexible metallic conduit.

1.0.7 Transformers shall incorporate a neutral conductor

sized at 2 times rated phase current. Transformer

cases shall be grounded per the National Electric Code.

1.0.8 Transformers shall be 60 Hz, 480 or 600 volts delta

primary, 208Y/120 volt secondary. KVA rating as

indicated. Contractor to provide all necessary lugs for

all transformers. Transformer enclosures shall be Type

2 and UL-3R listed with the addition of a weather shield.

1.0.9 Complete shop drawings must be submitted for

approval on all dry type transformers.

1.0.10 Typical performance data must be submitted for

approval on all transformers. Factory tests must be

made in accordance with the latest revisions of ANSI

Test Code C57.12.91 for Dry Type Transformers.

Performance data must contain but not be limited to:

(a) No load losses.

(b) Full load losses.

(c) Polarity and phase rotation.

(d) Impedance at reference temperature.

(e) Efficiencies at 25, 75, 50 and 100% load.

(f) Regulation at 100% and 80% power factor.

(g) Audible sound level.

(h) Insulation class and rated temperature rise.

(i) Dimensions and weight.

(j) Applied potential test.

(k) Induced potential test.

(l) Excitation current.

(m) IR, IX, and IZ percentages.

(n) Reference and ambient temperature.

1.0.11 Warranty: Transformers must be warranted against

defects in materials, workmanship and performance

for ten years from date of manufacture.

* Sound levels are based on transformers with a K-Factor of

4 and a temperature rise of 150 degrees centigrade.

ACME ELECTRIC, POWER DISTRIBUTION PRODUCTS DIVISION LUMBERTON, NC 800-334-5214 www.acmepowerdist.com

161

GENERAL

ACME TRANSFORMER SPECIFICATIONS

Specification Guide for Drive Isolation Transformers

1.0 Dry Type Transformers:

1.0.0 The following information should be utilized only by

trained technical personnel. If you need assistance,

please contact Acmes Technical Services Department

at 800-334-5214.

1.0.1 Provide dry type, enclosed, epoxy encapsulated

transformers as indicated and specified herein.

Transformers shall be designed for use with AC/DC

Drive applications and labeled as such.

1.0.2 Transformers shall be designed, constructed and rated

in accordance with UL, CSA, NEMA, ANSI, IEEE, and

OSHA standards.

1.0.3 Transformers 7.5 - 20 KVA shall be three phase,

compound filled, incorporating a 180 degree C insulation

system and designed not to exceed a 115 degree C

temperature rise above a 40 degree C ambient under

full load conditions. Taps are provided on the primary

side of the transformer as follows:

(a) 1-5% above normal full capacity.

(b) 1-5% below normal full capacity.

Transformers 27 - 750 KVA shall be the ventilated type,

incorporating a 220 degree C insulation system and

designed not to exceed a 150 degree C temperature

rise above a 40 degree C maximum ambient under full

load conditions. Taps are to be provided on the primary

side of the transformer as follows:

(a) 2 - 2.5% above normal full capacity.

(b) 2 - 2.5% below normal full capacity.

Alternate 1: 115 degree C rise transformers shall

incorporate a 220 degree C insulation system and be

designed not to exceed a 115 degree C temperature

rise above a 40 degree C maximum ambient under full

load conditions.

Alternate 2: 80 degree C rise transformers shall

incorporate a 220 degree C insulation system and be

designed not to exceed 80 degree C temperature rise

above a 40 degree C maximum ambient under full

load conditions.

1.0.4 Transformer enclosure finish must be ASA 61 gray

powder polyurethane paint. Ventilated transformer

enclosure temperature shall not exceed 50 degrees

C plus the ambient. Compound filled transformer

enclosure temperature shall not exceed 65 degrees

C, plus the ambient.

1.0.5 Compound filled transformer enclosure shall be

UL/NEMA Type 3R and so marked on the transformer

(7.5 - 20 KVA). No weather shield is required. Ventilated

transformer enclosure shall be UL/NEMA Type 2 and

UL-3R listed with the addition of a weather shield and

shall be so marked on the transformer (27 - 750 KVA).

1.0.6 Transformers shall incorporate an electrostatic shield for

the attenuation of voltage spikes, line noise, and transients.

1.0.7 Transformers up to 220 KVA shall terminate in copper

bus bar or copper wire.

1.0.8 Transformer coils must be wound with aluminum strip

conductors for increased insulation life, cooler operation

and lower losses.

162

1.0.9 Transformers must operate at audible sound levels

below NEMA standard ST-20. Sound levels will not

exceed the following:

up to 9KVA

40 db

10 - 50 KVA

45 db

51 - 150 KVA

50 db

151 - 300 KVA

55 db

301 - 500 KVA

60 db

501 - 750 KVA

65 db

Transformers must incorporate vibration isolation pads

in their construction located between the transformer

core and coil assembly and the transformer case, (27 750 KVA).

External vibration pads should not be used as they tend

to increase audible noise. Transformers shall be floor

mounted on a concrete pad. All connections to the

transformer will be made by means of flexible metallic

conduit.

1.0.10 Transformer enclosure shall be grounded per the

National Electrical Code.

1.0.11 Transformer voltages shall be as follows:

(a) 460 Delta - 460Y/266

(b) 460 Delta - 230Y/133

(c) 575 Delta - 230Y/133

(d) 575 Delta - 460Y/266

(e) 230 Delta-230Y/133

(f) Other

Transformer shall be 60 Hz. KVA rating as indicated.

Contractor to provide all necessary lugs for all transformers.

1.0.12 Complete shop drawings must be submitted for

approval on all dry type transformers.

1.0.13 Typical performance data must be submitted for

approval on all transformers. Factory tests must be

made in accordance with the latest revisions of ANSI

Test Code C57.12.91 for Dry Type Transformers.

Performance data provided must contain, but not be

limited to:

(a) No load losses.

(b) Full load losses.

(c) Polarity and phase rotation.

(d) Impedance at reference temperature.

(e) Efficiencies at 25, 75, 50 and 100% load.

(f) Regulation at 100% and 80% power factor.

(g) Audible sound level.

(h) Insulation class and rated temperature rise.

(i) Dimensions and weight.

(j) Applied potential test.

(k) Induced potential test.

(l) Excitation current.

(m) IR, IX, and IZ percentages.

(n) Reference and ambient temperature.

1.0.14 Warranty: Transformers must be warranted against

defects in materials, workmanship and performance

for ten years from date of manufacture.

ACME ELECTRIC, POWER DISTRIBUTION PRODUCTS DIVISION LUMBERTON, NC 800-334-5214 www.acmepowerdist.com

Вам также может понравиться

- Solar IrradiationДокумент9 страницSolar IrradiationDony SaputraОценок пока нет

- Troubleshooting Induction MotorsДокумент14 страницTroubleshooting Induction MotorsImelda LadrilloОценок пока нет

- CIGRE Guide For Transformer Fire Safety PracticesДокумент139 страницCIGRE Guide For Transformer Fire Safety Practicesdugdane7775% (4)

- GU - Cabine MT BT (EN) - 1VCP000591 1511Документ88 страницGU - Cabine MT BT (EN) - 1VCP000591 1511Fatmir JashariОценок пока нет

- CT Analyzer 61869 2 Flyer ENU PDFДокумент8 страницCT Analyzer 61869 2 Flyer ENU PDFDony SaputraОценок пока нет

- MV Motors HyundaiДокумент136 страницMV Motors HyundaiDony SaputraОценок пока нет

- MPD 600 White Paper PD Testing Makes Good Sense ENUДокумент8 страницMPD 600 White Paper PD Testing Makes Good Sense ENUcuntОценок пока нет

- Power Xpert UX - BR - AU - Oct2013 - 150dpiДокумент20 страницPower Xpert UX - BR - AU - Oct2013 - 150dpiDony SaputraОценок пока нет

- GE Multilin Relay Selection GuideДокумент40 страницGE Multilin Relay Selection GuideSaravanan Natarajan100% (1)

- 545-2012 Electrical FormsДокумент8 страниц545-2012 Electrical FormsAnghelo AlcaldeОценок пока нет

- Tech Specification VSDДокумент9 страницTech Specification VSDDony SaputraОценок пока нет

- NS189Документ48 страницNS189Dony SaputraОценок пока нет

- IEC Flame and Fire StandardsДокумент1 страницаIEC Flame and Fire StandardsArianta S. S.Оценок пока нет

- IEC Motor Insulation Classes B, F, H Temperature LimitsДокумент1 страницаIEC Motor Insulation Classes B, F, H Temperature Limitsmr_badihiОценок пока нет

- A Guide For Flammable and Combustible Liquids: Under The Work Health and Safety Act 2011Документ18 страницA Guide For Flammable and Combustible Liquids: Under The Work Health and Safety Act 2011overlord5555Оценок пока нет

- Tech Specification VSDДокумент9 страницTech Specification VSDDony SaputraОценок пока нет

- Vibration Testing Procedure PDFДокумент15 страницVibration Testing Procedure PDFpapathsheila100% (1)

- NS189Документ48 страницNS189Dony SaputraОценок пока нет

- 545-2012 Electrical FormsДокумент8 страниц545-2012 Electrical FormsAnghelo AlcaldeОценок пока нет

- Measuring 3 Phase Current With 2 Current TransformersДокумент3 страницыMeasuring 3 Phase Current With 2 Current TransformersDony SaputraОценок пока нет

- Motor Type TestДокумент1 страницаMotor Type TestDony SaputraОценок пока нет

- Comparison of VSI Versus LCI Systems FINALДокумент14 страницComparison of VSI Versus LCI Systems FINALivandario67Оценок пока нет

- Motor Type TestДокумент1 страницаMotor Type TestDony SaputraОценок пока нет

- Testing A Metalenclosed Bus PDFДокумент10 страницTesting A Metalenclosed Bus PDFTunoNegro1Оценок пока нет

- Residual Current-Operated Circuit Breakers (RCCBS) F 360 and F 370 RangeДокумент16 страницResidual Current-Operated Circuit Breakers (RCCBS) F 360 and F 370 RangepaldopalОценок пока нет

- GE Multilin Relay Selection GuideДокумент40 страницGE Multilin Relay Selection GuideSaravanan Natarajan100% (1)

- SenseBig Transformer Shipping Impact Recorder HandbookДокумент33 страницыSenseBig Transformer Shipping Impact Recorder Handbookrajeshgat2008100% (1)

- IEC Motor Insulation Classes B, F, H Temperature LimitsДокумент1 страницаIEC Motor Insulation Classes B, F, H Temperature Limitsmr_badihiОценок пока нет

- Tech Specification VSDДокумент9 страницTech Specification VSDDony SaputraОценок пока нет

- GU - Cabine MT BT (EN) - 1VCP000591 1511Документ88 страницGU - Cabine MT BT (EN) - 1VCP000591 1511Fatmir JashariОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- UniKL MFI Industrial Training Report Presentation Schedule May 2013Документ45 страницUniKL MFI Industrial Training Report Presentation Schedule May 2013Syahmi Azhar100% (1)

- 2013 PLSED309005EN (Web)Документ156 страниц2013 PLSED309005EN (Web)Alberto AriasОценок пока нет

- Pakistan Is Not A Poor Country But in FactДокумент5 страницPakistan Is Not A Poor Country But in Factfsci35Оценок пока нет

- New Microsoft Word DocumentДокумент6 страницNew Microsoft Word DocumentSanket KareОценок пока нет

- Hydraulic Power Unit Cum Control Panel: Sheet No. 1 of 1Документ1 страницаHydraulic Power Unit Cum Control Panel: Sheet No. 1 of 1rakeshsundaramurthyОценок пока нет

- Aquion Battery Technology - 1216Документ18 страницAquion Battery Technology - 1216sinnlosОценок пока нет

- PSFK presents the Future of LightДокумент157 страницPSFK presents the Future of Lightashok-rajashekar-7137Оценок пока нет

- ERA Energy SubsystemДокумент47 страницERA Energy SubsystemrhusmenОценок пока нет

- POME Plant CostДокумент8 страницPOME Plant Costtamil vaanan100% (1)

- Parts and Working of Fluid Power SystemsДокумент14 страницParts and Working of Fluid Power SystemsnidhidarklordОценок пока нет

- Harga Grundfos Type CR (Vertical Multistage)Документ40 страницHarga Grundfos Type CR (Vertical Multistage)Bagus Deddy AndriОценок пока нет

- Discover how EDDY Pumps increase uptime and productivity for industrial processesДокумент3 страницыDiscover how EDDY Pumps increase uptime and productivity for industrial processesSekson JunsukplukОценок пока нет

- HP SuppliesДокумент52 страницыHP SuppliesNadia QureshiОценок пока нет

- Recp. CompressorДокумент12 страницRecp. CompressorrajeevkumarrajeevОценок пока нет

- EPA Workshop On Radioactivity Contaminated SitesДокумент189 страницEPA Workshop On Radioactivity Contaminated SitesrmansОценок пока нет

- Caustic Soda Market in South Africa 2016-2021 Review - Sample PagesДокумент23 страницыCaustic Soda Market in South Africa 2016-2021 Review - Sample PagesShumani Pharamela100% (2)

- VP Director Government Public Affairs in Washington DC Resume Mark BurtschiДокумент2 страницыVP Director Government Public Affairs in Washington DC Resume Mark BurtschiMarkBurtschiОценок пока нет

- Adv Mark 2018 Company Profile 12Документ31 страницаAdv Mark 2018 Company Profile 12Vaijayanti JoshiОценок пока нет

- Determining The Cost of WeldingДокумент7 страницDetermining The Cost of WeldingSriram VjОценок пока нет

- Owner's Engineering PDFДокумент4 страницыOwner's Engineering PDFVj ReddyОценок пока нет

- Abb CaseДокумент10 страницAbb CaseNikhil RaoОценок пока нет

- Kadapa PDFДокумент20 страницKadapa PDFMadhavi KurraОценок пока нет

- 9ha Power PlantsДокумент2 страницы9ha Power PlantsIzzadAfif1990Оценок пока нет

- Diesel GenerationДокумент11 страницDiesel GenerationJoel GuiaoОценок пока нет

- UntitledДокумент34 страницыUntitledCarlos InfanteОценок пока нет

- Margaret Thatcher and The MinersДокумент372 страницыMargaret Thatcher and The MinersPierre François Gouiffès100% (2)

- Brief Industrial Profile of DelhiДокумент36 страницBrief Industrial Profile of DelhiJohnОценок пока нет

- FESCO ONLINE BILL MayДокумент2 страницыFESCO ONLINE BILL MaySajid AliОценок пока нет

- Acid Rain - The Southern Company FinalДокумент26 страницAcid Rain - The Southern Company Finalapi-250891173100% (5)

- NS2-DVN-2586 R2 Final PL of BLR Piping Hanger Support Beam-Unit 1 - 20200821Документ8 страницNS2-DVN-2586 R2 Final PL of BLR Piping Hanger Support Beam-Unit 1 - 20200821PHAM PHI HUNGОценок пока нет