Академический Документы

Профессиональный Документы

Культура Документы

Project Name: Repair of Afam Vi Boiler (HRSG) Evaporator Tubes

Загружено:

Leann WeaverИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Project Name: Repair of Afam Vi Boiler (HRSG) Evaporator Tubes

Загружено:

Leann WeaverАвторское право:

Доступные форматы

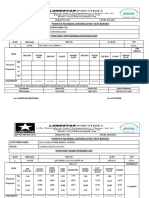

REPAIR OF AFAM VI HRSG EVAPORATOR TUBES

PROCEDURE FOR ISSUE OF PROJECT

DNL

AP6R-PP-05-P-01

PROJECT NAME: REPAIR OF AFAM VI BOILER (HRSG)

EVAPORATOR TUBES

SUBJECT: PROCEDURE FOR ISSUE OF PROJECT

DOCUMENT NO.: AP6R-PP-05-P-01

FOR REVIEW

SPDC Contract No. NG01015577

Document

Review

Status

1.

2.

Approved

Comments As Noted

3.

4.

Not Approved.

Received as

Supplementary

Documents

Permission to proceed does not constitute acceptance or approval of design

details, calculations, analyses, test methods or materials developed or selected by

the supplier and does not relieve supplier from full compliance with contractual

obligations

CLIENT

SHELL PETROLEUM DEVELOPMENT COMPANY

OF NIGERIA LIMITED

CONTRACTOR

SOMENI NIGERIA LIMITED

SUBCONTRACTOR

21 Nov. 14

AP6R-PP-05-P-01 REV.A

First Review

DURUNNA .T

CHOI. H.R

J. H. CHUNG

PAGE 0 OF11

REPAIR OF AFAM VI HRSG EVAPORATOR TUBES

PROCEDURE FOR ISSUE OF PROJECT

Rev

No

Date

Description

DNL

AP6R-PP-05-P-01

Prepared by

Reviewed by

Approved by

This document and information therein may NOT be used, disclosed or reproduced for other purposes without

the specific written prior permission of Daewoo Nigeria Ltd.

TABLE OF CONTENT

1.0

SCOPE

2.0

REFERENCE

3.0

RESPONSIBILITY

4.0

DEFINITION

5.0

PROCEDURE

6.0

5.1

Hierarchy of Project Procedure

5.2

Project Management Plan and Project Execution Plan

5.3

Procedure except for Construction Procedure

5.4

Construction Procedure

5.5

Preparation, review and approval for Procedure

5.6

Distribution

5.7

Forms Control

5.8

Revision Control

ATTACHMENTS

Attachment 1 : Procedure Cover Sheet

Attachment 2 : Table of Contents

Attachment 3 : Blank Procedure Form

AP6R-PP-05-P-01 REV.A

PAGE 1 OF11

REPAIR OF AFAM VI HRSG EVAPORATOR TUBES

PROCEDURE FOR ISSUE OF PROJECT

DNL

AP6R-PP-05-P-01

1.0 SCOPE

This procedure describes the responsibilities and methods for the preparation, review, approval

and revision of project plans, procedures and instructions for the project.

2.0 REFERENCE

2.1

Project Quality Plan (AP6R-PP-05)

3.0 RESPONSIBILITY

3.1

The QA Manager is responsible for the development of this procedure.

3.2

Each discipline Manager or Construction Manager (hereafter called responsible Manager) is

responsible for identifying the need and development of the relevant project plan, procedures and

instructions.

3.3

The Project Execution Plan, procedure and instruction shall be prepared, reviewed and approved in

accordance with this procedure.

4.0 DEFINITION

4.1

Project Execution Plan

The Project execution plan is a structured document which contains the strategic, tactical and

fundamental plans for executing each phase and major division of this project.

The followings consist in the project execution plans:

4.2

Project Quality Plan

Construction Plan

HSE Plan

Quality Control Procedure

Quality control procedure covers the quality control activities such as receiving inspection,

nonconformance control, calibration, inspection & test control, source inspection, welding material

control, welding procedure qualification and welder qualification etc.

Quality control procedure does not include technical requirements and deals only with

administrative controls in the performance of duties.

AP6R-PP-05-P-01 REV.A

PAGE 2 OF11

REPAIR OF AFAM VI HRSG EVAPORATOR TUBES

PROCEDURE FOR ISSUE OF PROJECT

4.3

DNL

AP6R-PP-05-P-01

Construction Procedure

Construction procedure covers the project construction work activities at site such as civil work,

architecture work, and mechanical work and electrical & instrument work.

This procedure shall be included the detailed methods and technical requirements for performing

work that includes requirements for quality control.

4.4

HSE Procedure

HSE procedure covers the project health, safety and environment activities such as safety control

and security control etc.

5.0 PROCEDURE

5.1

Hierarchy of Project Procedure

The procedures are documented with levels in the picture below, and in case their contents conflict

with each other, upper document is superior to the lower documents.

Project Management Plan

Project Execution Plan

Project Procedure

Instruction, Guideline

5.2

5.2.1

Project Management Plan and Project Execution Plan

Contents

The content structure for the Project Plan shall not be restricted, and shall be suitably composed

according to the characteristics of the discipline.

5.3

5.3.1

Procedures except for Construction Procedure

Contents

AP6R-PP-05-P-01 REV.A

PAGE 3 OF11

REPAIR OF AFAM VI HRSG EVAPORATOR TUBES

PROCEDURE FOR ISSUE OF PROJECT

DNL

AP6R-PP-05-P-01

Procedures except for construction procedure shall be prepared in the following format and will

include details to perform basic requirement of the Project Execution Plan.

Section

Heading

1.0

SCOPE

Contents

Contains a brief description of the subject matter and may define

topics specifically excluded.

2.0

REFERENCE

Lists related procedure and/or data.

3.0

RESPONSIBILITY

Defines the general responsibilities for implementing the

activities described in a procedure.

4.0

DEFINITION

Define any words, terms or abbreviations used within the

procedure.

5.0

PROCEDURE

Describes the steps taken to perform the activity, or, if necessary,

more than one Section may be used with title of procedures.

6.0

ATTACHMENTS

List all attachments such as forms, checklists, figures and flow

charts.

5.3.2

If any of the above headings are not applicable to a procedure and other headings are necessary to

a procedure, the above headings may be deleted or changed.

5.4

Construction Procedure

5.4.1

Contents

The following shall describe the contents of the Construction Procedure and shall include the

required subsections.

Section

1.0

Heading

SCOPE

Contents

Contain a brief description of the subjected matter and

applicability of the procedures.

2.0

REFERENCE

List applicable section of procedures and other references which

directly affect the subject activity and which are referenced in the

text of the Procedure.

3.0

RESPONSIBILITY

Defines the general responsibilities for implementing the

Construction Procedure.

4.0

DEFINITION

Define any words, terms or abbreviations used within the

Procedure, which may require clarification.

5.0

PROCEDURE

Describes the steps taken to perform the activity including the

instructions, methods, inspection methods, acceptance criteria

and characteristics to be inspected. Additionally, denotes the

AP6R-PP-05-P-01 REV.A

PAGE 4 OF11

REPAIR OF AFAM VI HRSG EVAPORATOR TUBES

PROCEDURE FOR ISSUE OF PROJECT

DNL

AP6R-PP-05-P-01

actions step by step, which are required to accomplish the

purpose of the procedure such as, What to do, Why to do it,

Who to do it, Where to do it, How to do it and When/how

often to do it.

6.0

ATTACHMENT

List all attachments to the Construction Procedure such as

forms, checklists, figures and flow charts.

5.4.2

If any of the above headings are not applicable to a procedure and other headings are necessary,

the above headings may be deleted or changed.

5.5

5.5.1

Preparation, review and approval for Project Procedure

Preparation, review and approval for Project Procedures are shown below :

Preparation

Review

Discipline

Engineer

Responsible

Manager

Quality Control

Procedure

QC Engineer

QC Manager

Non-destructive

Test Procedure

NDT Level II or

Level III

NDT Level III

Project Execution Plan

Quality

Procedure

General

Procedure (**)

Construction

Procedure

Work Procedure

Method

Statement

Responsible

Manager

Discipline

Engineer

Approval

Project Manager

or his designee(*)

QC Manager

Inspection and

Test Plan

HSE Procedure

HSE engineer

HSE Manager

(Note)

(*) : Project Manager may delegate the authority to the Site Manager for approval of Project

Procedures such as Quality Control Procedure, NDT Procedure, Construction Procedure, HSE

Procedure, Commissioning Procedure , Project Construction Plan, etc.

(**) : General Procedure covers the general activities to be related the Civil, Arch., Mech. and

Electric work such as material control, customs entry, etc.

If the above review/approval is unacceptable, the procedure shall be returned to the responsible

engineer with comments. The responsible engineer shall reflect the comment(s) on the procedure

after discussion with the relevant Manager.

AP6R-PP-05-P-01 REV.A

PAGE 5 OF11

REPAIR OF AFAM VI HRSG EVAPORATOR TUBES

PROCEDURE FOR ISSUE OF PROJECT

5.5.2

DNL

AP6R-PP-05-P-01

Instructions or Guidelines are used whenever it is determined that further details are required from

those are specified in aforementioned Procedure, to assure that correct performance,

documentation, and completion of activity have been accomplished by the responsible Manager.

The content structure for the Instruction or Guidelines shall not be restricted, and shall be suitably

composed according to the characteristics of the discipline.

5.5.3

Procedure shall be identified by the document title, document No., revision No., brief description of

revision and showed the assigned personnels initials for column of the prepared by, reviewed by

and approved by and dates on Procedure Cover Sheet (Attachment 1).

5.5.4

The Contents of the procedure shall be described by using Table of contents (Attachment 2) and

Blank procedure form (Attachment 3).

5.5.5

Project Execution Plans and instructions shall be made by using format of PCS (attachment 1),

Table of contents (Attachment 2) and Blank form (Attachment 3).

5.5.6

Numbering Structure for Procedures Construction Procedure only)

Numbering Structure for Project Procedures is shown as below:

AP6 PP

(6) Discipline Identification

(Apply to Construction Procedure only)

(5) Serial Number of Project Procedure

(4) Type of Project Procedure

(3) Serial Number of Project Plan

(2) Initial of Project Plan

(1) Initial of Project Name

1) Initial of Project Name

AP6R : REPAIR OF AFAM VI HRSG EVAPORATOR TUBES

2) Initial of Project (Management or Execution) Plan

PP : Project (Management or Execution) Plan

MS: Method Statement

IT: Inspection and Test Plan

3) Serial Number of Project Plan

01 : Project Management Plan

02 : Project Control Plan

03 : Project Engineering Management Plan

04 : Project Procurement Plan

05 : Project Quality Plan

AP6R-PP-05-P-01 REV.A

PAGE 6 OF11

REPAIR OF AFAM VI HRSG EVAPORATOR TUBES

PROCEDURE FOR ISSUE OF PROJECT

06 : Construction Plan

07 : Project Commissioning Plan

08 : HSE Plan (08/1,/2,/3,.)

09 : Community Affairs Management Plan

10 : Security Plan

DNL

AP6R-PP-05-P-01

4) Type of Project Procedure

P : Procedure

I : Instruction

G : Guide

5) Serial Number of Project Procedure

Numeral (from 01 to 99)

6) Discipline Identification : ( Apply to Construction Procedure only )

G : General Procedure

A : Architecture Procedure

C : Civil Procedure

E : Electrical ( Incl. I&C ) Procedure

M : Mechanical Procedure

Example:

Project Quality Plan: AP6R-PP-05

Material Control Procedure: AP6R-PP-05-P-11

5.6

5.6.1

Distribution

The distribution of procedures shall be carried by the Document controller through the Document

Drawing Control Center (DDCC) according to the Document Control Procedure.

5.6.2

The personnel who possess controlled copies shall receive the revised procedure automatically.

5.6.3

Each Team, which receives procedures (including Plans) from the Document Controller, shall file

them by the proper method or binder.

5.7

5.7.1

Forms Control

The form No. of all attachments, except for the Procedure cover sheet, Table of contents, Blank

procedure form and tag, etc. shall be printed at the bottom of left side of the attachment when it is

used.

5.7.2

The forms shall state the procedure No. plus attachment No. and the sequential revision No. of

the form as follows :

Form No.: XXXXXX XX (X)

AP6R-PP-05-P-01 REV.A

PAGE 7 OF11

REPAIR OF AFAM VI HRSG EVAPORATOR TUBES

PROCEDURE FOR ISSUE OF PROJECT

1

DNL

AP6R-PP-05-P-01

1 : Project Procedure No.

2 : Attachment No.

3 : Form sequential revision No.

5.7.3

The actual form shall be used without the cloud mark and head/bottom area of attachments which

are indicative of procedure title, attachment No., procedure No., Rev. No., and sheet No, etc.

In addition, the Forms of this procedure such as Procedure Cover Sheet, Table of Contents and

Blank Procedure Form shall be used without the Form No.

5.8

5.8.1

Revision Control

Procedure revision shall be made by the responsible engineer, reviewed, approved and submitted in

the same manner as the original.

5.8.2

When the revised procedures are distributed, all superseded procedures shall be physically

destroyed or clearly marked as obsolete by the recipient.

5.8.3

The identification method against revised items shall be marked with vertical line a margin of the

right of the revised paragraph. And the revised form shall be identified by encompassing the

changed area with a cloud mark on the form.

All denotations of previous revision shall be

eliminated.

6.0 ATTACHMENTS

Attachment 1 Procedure Cover Sheet

Attachment 2 Table of Contents

Attachment 3 Blank Procedure Form

AP6R-PP-05-P-01 REV.A

PAGE 8 OF11

REPAIR OF AFAM VI HRSG EVAPORATOR TUBES

PROCEDURE FOR ISSUE OF PROJECT

DNL

AP6R-PP-05-P-01

REPAIR OF AFAM VI BOILER (HRSG)

PROJECT NAME: EVAPORATOR TUBES

Attachment 1 Cover Sheet

SUBJECT: XXXXXXXXXX

DOCUMENT NO.: AP6R-XX-00-X-00

FOR REVIEW

SPDC Contract No. NG01015577

Document

Review

Status

1.

2.

Approved

Comments As Noted

3.

4.

Not Approved.

Received as

Supplementary

Documents

Permission to proceed does not constitute acceptance or approval of design

details, calculations, analyses, test methods or materials developed or selected by

the supplier and does not relieve supplier from full compliance with contractual

obligations

CLIENT

SHELL PETROLEUM DEVELOPMENT COMPANY

OF NIGERIA LIMITED

CONTRACTOR

SUBCONTRACTOR

ISSUED FOR CONSTRUCTION

First Review

Description

Prepared by

Rev

No

Date

Reviewed by

Approved by

This document and information therein may NOT be used, disclosed or reproduced for other purposes without

the specific written prior permission of Daewoo Nigeria Ltd.

AP6R-PP-05-P-01 REV.A

PAGE 9 OF11

REPAIR OF AFAM VI HRSG EVAPORATOR TUBES

PROCEDURE FOR ISSUE OF PROJECT

DNL

AP6R-PP-05-P-01

Attachment 2 Table of Comment

REPAIR OF AFAM VI HRSG EVAPORATOR TUBES

DOCUMENT TITLE

DNL

AP6R-PP-XX-XXX

TABLE OF CONTENTS

1.0

SCOPE

2.0

REFERENCE

3.0

RESPONSIBILITY

4.0

DEFINITION

5.0

PROCEDURE

5.1 XXXX

5.2 XXXX

5.3 XXXX

5.4 XXXX

5.5 XXXX

5.6 XXXX

6.0

ATTACHMENTS

Attachment 1 :

Attachment 2 :

Attachment 3 :

(Form No. : AP6R-PP-05-QF-P01A

AP6R-PP-05-P-01 REV.A

PAGE 10 OF11

REPAIR OF AFAM VI HRSG EVAPORATOR TUBES

PROCEDURE FOR ISSUE OF PROJECT

DNL

AP6R-PP-05-P-01

Attachment 3 Blank Procedure Form

(Blank Procedure Form)

AP6R-PP-05-P-01 REV.A

PAGE 11 OF11

Вам также может понравиться

- NG-018-XX-PNL-430926 - Rev04 Weld Numbering System and Procedure UnsignedДокумент20 страницNG-018-XX-PNL-430926 - Rev04 Weld Numbering System and Procedure UnsignedFolarin Ayodeji100% (1)

- 50037-ME-DOC-001 - Marine Spread Specifications and Certifications DossierДокумент9 страниц50037-ME-DOC-001 - Marine Spread Specifications and Certifications DossierseehariОценок пока нет

- Addax Daily ReportsДокумент1 страницаAddax Daily ReportsRobert Williams0% (1)

- Design of Offshore Steel Structures, General (LRFD Method) : Offshore Standard DNV-OS-C101Документ49 страницDesign of Offshore Steel Structures, General (LRFD Method) : Offshore Standard DNV-OS-C101sanwang12345Оценок пока нет

- Yard Evaluation Check List: Project NameДокумент8 страницYard Evaluation Check List: Project NameMOHIT SHARMAОценок пока нет

- PEP Onshore PipelineДокумент76 страницPEP Onshore PipelineYudha MaulanaОценок пока нет

- NG-018-XX-PNL-431203 - Rev07 NDT MatricesДокумент20 страницNG-018-XX-PNL-431203 - Rev07 NDT MatricesFolarin Ayodeji100% (1)

- 2019.09.03 - EST & SCHED - r.2 - Combined OverviewДокумент1 страница2019.09.03 - EST & SCHED - r.2 - Combined OverviewSriОценок пока нет

- WPS Sa 517Документ2 страницыWPS Sa 517DHANANNJAI SINGH -Оценок пока нет

- Muhammad Ayub Bin Khalid: Personal DataДокумент5 страницMuhammad Ayub Bin Khalid: Personal DataAnwarul Shafiq AwalludinОценок пока нет

- CVMCДокумент4 страницыCVMCAzhar HussainОценок пока нет

- PT - Mcci Document Register List Rev.B 110811Документ3 страницыPT - Mcci Document Register List Rev.B 110811adityadhОценок пока нет

- Existing Pipeline Cable Under Crossings - ADDENDUM To PROCEDURE - RO3Документ8 страницExisting Pipeline Cable Under Crossings - ADDENDUM To PROCEDURE - RO3MitchellgranyОценок пока нет

- WPS Asme Ix PDFДокумент4 страницыWPS Asme Ix PDFSergiu LungОценок пока нет

- Al-Uqlah Central Processing Facility Water Level & Settlement TableДокумент12 страницAl-Uqlah Central Processing Facility Water Level & Settlement TableSantosh Kumar BogelaОценок пока нет

- Saka Indonesia Pangkah Limited Contract No. 4600012838: Piping Test Package W3-0103-01 Production HeaderДокумент19 страницSaka Indonesia Pangkah Limited Contract No. 4600012838: Piping Test Package W3-0103-01 Production HeaderriandiОценок пока нет

- FLNGДокумент14 страницFLNGPavin PiromОценок пока нет

- Fabrication and InstallationДокумент6 страницFabrication and Installations33d_2010Оценок пока нет

- TPCO ProjectДокумент40 страницTPCO ProjectJebran0% (1)

- MS002-UZ-PRO-0B1-50220 - B01 Welding Qualification Plan For Riser FabДокумент19 страницMS002-UZ-PRO-0B1-50220 - B01 Welding Qualification Plan For Riser FabPuspita LerianaОценок пока нет

- Inspection Engineer - Senior Welding - Arunkumar Andavar - CVДокумент7 страницInspection Engineer - Senior Welding - Arunkumar Andavar - CVArun KumarОценок пока нет

- WPS Flow Proceess ChartДокумент1 страницаWPS Flow Proceess ChartSatish KeskarОценок пока нет

- BGEP-JPKE-P133-PAXX-PL-08-142-0015-D (1) March 11Документ48 страницBGEP-JPKE-P133-PAXX-PL-08-142-0015-D (1) March 11Gururaj P KundapurОценок пока нет

- Oil Penetrant Test ProcedureДокумент4 страницыOil Penetrant Test Procedurehasan_676489616Оценок пока нет

- Subsea Pipelines and Risers: Yong BaiДокумент18 страницSubsea Pipelines and Risers: Yong Bainina_kawai88745Оценок пока нет

- Api-Mip-5lДокумент76 страницApi-Mip-5lVan LinhОценок пока нет

- WelderPOT 2009finalДокумент160 страницWelderPOT 2009finalMayo de la PazОценок пока нет

- Saipem Pipeline 2013Документ86 страницSaipem Pipeline 2013kbarzahОценок пока нет

- F-CD-19 Pipe and Weld Book 26-Abr-19Документ84 страницыF-CD-19 Pipe and Weld Book 26-Abr-19Jorge Isaac Lara RamosОценок пока нет

- 23792turret Buoy BookДокумент32 страницы23792turret Buoy BookTeck Tiong Huan100% (1)

- 6.9. Handling Storage & Preservation ProcedureДокумент10 страниц6.9. Handling Storage & Preservation Procedurerendra syamОценок пока нет

- ENV-SPV-DR-B-011 Dimensional Inspection Procedure-Rev - AДокумент9 страницENV-SPV-DR-B-011 Dimensional Inspection Procedure-Rev - AyoeyОценок пока нет

- API 570 Pipeline Inspection PDFДокумент1 страницаAPI 570 Pipeline Inspection PDFKhalidMoutarajiОценок пока нет

- B1304-Welding Procedure Specifications TechnipДокумент17 страницB1304-Welding Procedure Specifications Technipliviu_dova0% (1)

- Pp4 CM Ir 1004 001 - Rev. A - Itp For PipingДокумент7 страницPp4 CM Ir 1004 001 - Rev. A - Itp For PipingHungManhОценок пока нет

- 028120-SPL-003 Pipeline Material Rev. DДокумент36 страниц028120-SPL-003 Pipeline Material Rev. DRokan PipelineОценок пока нет

- Tank Fabrication & ErectionДокумент72 страницыTank Fabrication & ErectionPramod GrОценок пока нет

- Pmi ReportДокумент5 страницPmi ReportMANIMARAN QCОценок пока нет

- Earth Moving Equipment ChekclistДокумент2 страницыEarth Moving Equipment ChekclistBakri Bin SapilahОценок пока нет

- Earth Moving EquipmentsДокумент2 страницыEarth Moving EquipmentsSHARAFUDHEEN TKОценок пока нет

- Ug-Til-43-Sin1-415702 - 02 - Afc - 20220623 - JBR09 To JBR08Документ2 страницыUg-Til-43-Sin1-415702 - 02 - Afc - 20220623 - JBR09 To JBR08AHMED LASSOUEDОценок пока нет

- Office: Printout Sample - ASME WPSДокумент2 страницыOffice: Printout Sample - ASME WPSDanem HalasОценок пока нет

- DH3 39U C ITP 0019 ITP For CW Pipe (Civil) Ver AДокумент17 страницDH3 39U C ITP 0019 ITP For CW Pipe (Civil) Ver ADoan Ngoc DucОценок пока нет

- Engineering Management in Offshore Projects Uten Film 4Документ40 страницEngineering Management in Offshore Projects Uten Film 4limresОценок пока нет

- Report Tank CY3DRДокумент52 страницыReport Tank CY3DRMahmoud GaberОценок пока нет

- Elding Rocedure Pecification: 7200-HDPE Butt WeldДокумент2 страницыElding Rocedure Pecification: 7200-HDPE Butt Weldsamer8saifОценок пока нет

- A2V2D5 - Condition 17 - Field Joining Program - Appendix B3 - Welding Procedure Specifications - BPP-11-WP5Документ5 страницA2V2D5 - Condition 17 - Field Joining Program - Appendix B3 - Welding Procedure Specifications - BPP-11-WP5ochableОценок пока нет

- DOD-ITP - INS-008-ITP FOR Installation and Testing of Fiber Optic Cable - Rev.0Документ2 страницыDOD-ITP - INS-008-ITP FOR Installation and Testing of Fiber Optic Cable - Rev.0Bharathi100% (1)

- Weld ElectrodesДокумент42 страницыWeld ElectrodesNarendraОценок пока нет

- T-14.427.475 Work Method Statement For Construction of Abutment and Slope Protection Works - 210623Документ77 страницT-14.427.475 Work Method Statement For Construction of Abutment and Slope Protection Works - 210623JosiahОценок пока нет

- Swamp DredgingДокумент19 страницSwamp Dredgingmaniacs14Оценок пока нет

- AL-2208-6'' Pig Launcher Engineering and Fabrication - KNOCДокумент5 страницAL-2208-6'' Pig Launcher Engineering and Fabrication - KNOCCaptainToniesОценок пока нет

- Utoc Preliminary Wps Shell Project 270807 PDFДокумент55 страницUtoc Preliminary Wps Shell Project 270807 PDFErick HoganОценок пока нет

- IDBU-CW-LSPDS-000030 Rev D Upstream Process Piping Welding and InspectionДокумент32 страницыIDBU-CW-LSPDS-000030 Rev D Upstream Process Piping Welding and Inspectionjoey garciaОценок пока нет

- 7704 Quot PDFДокумент4 страницы7704 Quot PDFdineshmithiaОценок пока нет

- Welding Log DW-CWДокумент12 страницWelding Log DW-CWhasan shahriarОценок пока нет

- 2G & 5GДокумент2 страницы2G & 5GRahul MoottolikandyОценок пока нет

- NRC Inspection ManualДокумент15 страницNRC Inspection Manualelsayed abdemagiedОценок пока нет

- PLE QA QSP 12 Technical AuditДокумент6 страницPLE QA QSP 12 Technical Auditkumarkrishna29Оценок пока нет

- Ppqa TutorialДокумент4 страницыPpqa Tutorialyjr_yogeshОценок пока нет

- BIOS 203: Free Energy Methods Tom MarklandДокумент23 страницыBIOS 203: Free Energy Methods Tom MarklandNemanja ĐokovićОценок пока нет

- Chapter 7 Notes Computer OrganizationДокумент20 страницChapter 7 Notes Computer OrganizationsriОценок пока нет

- AquaCal Tropical Brochure PDFДокумент2 страницыAquaCal Tropical Brochure PDFJC ParedesОценок пока нет

- Diet Coke & Mentos Geyser Lab 2011-2012Документ4 страницыDiet Coke & Mentos Geyser Lab 2011-2012Frederick LoganОценок пока нет

- Chapter 19A ConcreteДокумент10 страницChapter 19A ConcreteMofasa EОценок пока нет

- Advanced Fluid Mechanics: Luigi Di Micco Email: Luigi - Dimicco@dicea - Unipd.itДокумент16 страницAdvanced Fluid Mechanics: Luigi Di Micco Email: Luigi - Dimicco@dicea - Unipd.itHubert MoforОценок пока нет

- Curriculum Vitae: Augusto Javier Puican ZarpanДокумент4 страницыCurriculum Vitae: Augusto Javier Puican Zarpanfrank_d_1Оценок пока нет

- Chapter 2 - 2 Plane Curvilinear MotionДокумент37 страницChapter 2 - 2 Plane Curvilinear MotionAlfredo Ruiz ValenciaОценок пока нет

- Dogging Guide 2003 - WorkCover NSWДокумент76 страницDogging Guide 2003 - WorkCover NSWtadeumatas100% (1)

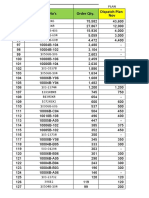

- Order Qty Vs Dispatch Plan - 04 11 20Документ13 страницOrder Qty Vs Dispatch Plan - 04 11 20NPD1 JAKAPОценок пока нет

- RT 8090 TДокумент40 страницRT 8090 TManuel100% (1)

- Korantin PPДокумент4 страницыKorantin PPteddy garfieldОценок пока нет

- Ofdma: LTE Air Interface CourseДокумент63 страницыOfdma: LTE Air Interface CourseAkhtar KhanОценок пока нет

- Justine J. Beroy: Career ObjectivesДокумент5 страницJustine J. Beroy: Career ObjectivesJustine BeroyОценок пока нет

- Ammonia Production From Natural Gas-Haldor Topsoe ProcessДокумент22 страницыAmmonia Production From Natural Gas-Haldor Topsoe ProcessYash BhimaniОценок пока нет

- Bernard D. Marquez Eduardo M. Axalan Engr. William A.L.T. NGДокумент1 страницаBernard D. Marquez Eduardo M. Axalan Engr. William A.L.T. NGRhon Nem KhoОценок пока нет

- UMTS AircomДокумент20 страницUMTS AircomDũng PhạmОценок пока нет

- Coal Combustion Monitoring Report Unwashed Semi Rev02 08.24.2021Документ17 страницCoal Combustion Monitoring Report Unwashed Semi Rev02 08.24.2021Keith Danae SuquibОценок пока нет

- AB-522 Standard Pneumatic Test Procedure RequirementsДокумент16 страницAB-522 Standard Pneumatic Test Procedure RequirementsShank HackerОценок пока нет

- Opc PDFДокумент20 страницOpc PDFnirajОценок пока нет

- Diesel Generator Set QSL9 Series Engine: Power GenerationДокумент4 страницыDiesel Generator Set QSL9 Series Engine: Power Generationsdasd100% (1)

- Antikythera MechanismДокумент25 страницAntikythera MechanismchetansergiurazvanОценок пока нет

- Computer Networking: A Top-Down Approach Featuring The InternetДокумент27 страницComputer Networking: A Top-Down Approach Featuring The InternetmssacОценок пока нет

- Kinematics-03-Subjective SolvedДокумент11 страницKinematics-03-Subjective SolvedRaju SinghОценок пока нет

- Distributed PowerДокумент3 страницыDistributed PowertibvalОценок пока нет

- PBLauncherДокумент50 страницPBLauncherborreveroОценок пока нет

- C12200Документ3 страницыC12200xgiorg100% (1)

- Tube Well Design Project SolutionДокумент5 страницTube Well Design Project SolutionEng Ahmed abdilahi IsmailОценок пока нет

- Manual PC Soundcard Scope 1.4.5Документ17 страницManual PC Soundcard Scope 1.4.5NatashaKillerОценок пока нет