Академический Документы

Профессиональный Документы

Культура Документы

JSA Splicing

Загружено:

luisАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

JSA Splicing

Загружено:

luisАвторское право:

Доступные форматы

Job Safety Analysis

Effective Date: 03/09/2000

JOB SAFETY ANALYSIS

Job Analyzed: Cable Splicing

Page 1 of 3

Completed By:

JSA Reference #: SC-31

Reviewed by LPT:

Date:

Location/Site: Reda Production Systems

Service Centers

Specific loss exposures (Quality, Health,

Safety, Environment)

(LPT Leader /date)

1. Required Personal Protective

Equipment (PPE)

2. Inspect work area and equipment:

a. Cable stands

b. Soldering Iron

c. Grounding equipment

d. Visible Hazards

1. Personal Injury

3. Prepare cable for splicing.

1. a. Safety Shoes

b. Safety Glasses w/Side Shields

2. a. Check cable stands to ensure they

are safe.

b. Check electrical cords on soldering

iron for damage; repair/replace if

necessary.

c. Check grounding equipment to

ensure it is working properly.

d. Check area for visible hazards and

scrap cable/armor that is laying on

floor and place in proper disposal

container.

3. a. Always make sure cable is secured

properly in cable stands.

b. Make others in the work area aware

of dangers.

c. Always ground the cable before

splicing; cable can hold an electrical

charge for a long period of time.

d. Make sure the ground is sufficient;

grounding the cable against a work

table with rubber wheels does not

provide an electrical conductor to

ground.

Task Steps

2. a. Injury from cable falling from stands.

b. Electrical shock hazard

c. Injury from slipping/ falling.

a. Injury from cable falling.

b. Electrical shock hazard.

Recommended Controls (Engineered,

Administrative, PPE)

QHSE Advisor Signature:

Site/Project Manager Signature:

Date:

Date:

RPS-JSA-SC-xx

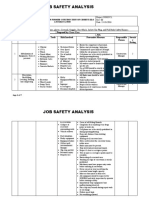

Job Safety Analysis

Effective Date: 03/09/2000

JOB SAFETY ANALYSIS

Job Analyzed: Cable Splicing

Page 2 of 3

Completed By:

JSA Reference #: SC-31

Reviewed by LPT:

Date:

Location/Site: Reda Production Systems

Service Centers

Specific loss exposures (Quality, Health,

Safety, Environment)

(LPT Leader /date)

4. Remove armor from cable in splice area.

4. a. Hand and finger cuts from hacksaw

and armor.

4.

5. Remove jacket/sheath from insulating

conductor.

5. a. Damage to insulation causing cable

splice failure.

b. Injury from being cut by knife.

5.

6. Clean insulating conductors.

6. a. Improper electrical conductivity from

conductors not cleaned properly.

6.

7. Install splicing sleeves.

7. a. Injury to fingers and hands from

being pinched.

b. Improper electrical conductivity due

to incorrect sleeve installation.

7.

8. Apply tape to splice.

8. a. Injury from knife cuts.

b. Defective cable splice causing

premature failure.

9.

Task Steps

Recommended Controls (Engineered,

Administrative, PPE)

QHSE Advisor Signature:

Site/Project Manager Signature:

Date:

Date:

RPS-JSA-SC-xx

a. Keep fingers and hands clear of

hacksaw blade when cutting armor

and away from the sharp edges of

the cable armor when peeling it off.

a. Do not cut into the conductor

insulation when removing the cable

jacket/sheath. If the insulation is

damaged a new splice must be

started.

b. When removing insulation from the

conductor, always cut away from

your body.

a. Always clean exposed conductors

with proper cleaner.

a. Keep fingers and hands away from

the jaws of the crimping tool when

installing splicing sleeves.

b. Install splicing sleeves and crimp

as per splicing instructions in the

Service Manual..

a. When cutting tape with a knife, cut

with knife away from your body.

b. Install tape as per splicing

instructions in Service Manual.

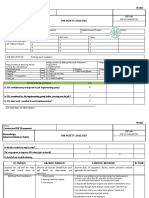

Job Safety Analysis

Effective Date: 03/09/2000

JOB SAFETY ANALYSIS

Job Analyzed: Cable Splicing

Page 3 of 3

Completed By:

JSA Reference #: SC-31

Reviewed by LPT:

Date:

Location/Site: Reda Production Systems

Service Centers

Specific loss exposures (Quality, Health,

Safety, Environment)

(LPT Leader /date)

10. Apply armor.

10. a. Finger and hand cuts.

b. Burns from soldering iron.

c. Insulation failure due to improper

armor insulation.

10.

11. Test cable.

11. a. Cable splice integrity.

11.

12. Clean Area.

12. a. Safety Hazard.

12.

13. Check for hazardous material waste.

13. a. Breathing harmful hazardous waste

vapors.

13.

Task Steps

Recommended Controls (Engineered,

Administrative, PPE)

QHSE Advisor Signature:

Site/Project Manager Signature:

Date:

Date:

RPS-JSA-SC-xx

a. Watch for sharp edges on armor

that can cut.

b. Be careful when using soldering

iron not to get close enough to

be burned; watch for hot dripping

solder than can burn.

c. Install armor as per application

instructions in the Service Manual.

a. Refer to Job Safety Analysis

Procedure SC-32, Hipot Testing

Submergible Pump Cable after

completing the splice.

a. Clean floor to remove any foreign

material including cable, armor,

and tape scraps; dispose of

properly.

b. Place all tools and solder iron in

proper storage area and make

sure the work area is left clean.

a. Reference Material Safety Data

Sheets (MSDS) for material specs.

Вам также может понравиться

- Jsa - Cable TerminationДокумент4 страницыJsa - Cable TerminationSantos Rex73% (15)

- Job Safety Analysis (14) For Cable Laying and PullingДокумент4 страницыJob Safety Analysis (14) For Cable Laying and Pullingnasar_mahsood79% (34)

- JSA Template 2017-05-31 Cable Tray InstallationДокумент19 страницJSA Template 2017-05-31 Cable Tray InstallationJayvee Baradas ValdezОценок пока нет

- JSA - Fire Proofing WorksДокумент5 страницJSA - Fire Proofing WorksAnis Uddin100% (3)

- JSA-Manual Lifting of MaterialsДокумент3 страницыJSA-Manual Lifting of Materialsfrancis_e_tan75% (4)

- JSA Cable LayingДокумент2 страницыJSA Cable Layingnishanth100% (2)

- JSA For SealantДокумент11 страницJSA For SealantdipmipОценок пока нет

- JSA of Pipe Unloading.Документ2 страницыJSA of Pipe Unloading.vijay kumar singh100% (1)

- Mie Hse Jha 004 - Installation of TransformerДокумент5 страницMie Hse Jha 004 - Installation of TransformerLuqman Osman67% (6)

- Jsa - Earthing SystemДокумент4 страницыJsa - Earthing SystemAkash Shukla75% (4)

- JSA HandToolsДокумент2 страницыJSA HandToolsCristina Rican100% (3)

- 013 JSA For Earthwork at Receiving BasinДокумент4 страницы013 JSA For Earthwork at Receiving BasinHilbrecht De Pedro100% (1)

- JSA For Cable Tray Installation-Reviewed by CBREДокумент10 страницJSA For Cable Tray Installation-Reviewed by CBREPrakash Tiwari88% (8)

- Job Safety Analysis: Cable Jointing & Termination in Wind TurbinesДокумент1 страницаJob Safety Analysis: Cable Jointing & Termination in Wind TurbinesPerwez2186% (7)

- Hydro Test JSAДокумент2 страницыHydro Test JSAEruse Okejero88% (17)

- 004 Annexure D Job Safety SAnalysis JSAДокумент3 страницы004 Annexure D Job Safety SAnalysis JSAAvoor Khan75% (4)

- JSA For Installation of Fire PumpsДокумент2 страницыJSA For Installation of Fire Pumpsperquino oasan100% (3)

- JSA-Use of Temporary Energization (Power Generator)Документ4 страницыJSA-Use of Temporary Energization (Power Generator)MajdiSahnoun100% (1)

- JSA For False CeilingДокумент4 страницыJSA For False CeilingJaved100% (3)

- JSA FORMAT For Materials LoadingДокумент2 страницыJSA FORMAT For Materials LoadingVikky KumarОценок пока нет

- JSA - Hydro-Testing of Pipe & EquipmentДокумент1 страницаJSA - Hydro-Testing of Pipe & EquipmentRajuОценок пока нет

- Jsa For Drilling.Документ3 страницыJsa For Drilling.Belsyah Nofriyan75% (4)

- JSA Cable Pulling and Laying WorksДокумент6 страницJSA Cable Pulling and Laying WorksLuqman Osman100% (6)

- Jsa Cable TerminationДокумент4 страницыJsa Cable TerminationSyed Yousuf Ali100% (1)

- Draft JSA Levelling & GradingДокумент9 страницDraft JSA Levelling & GradingAzeem Khan33% (3)

- Up Dated Job Safety Analysis-Gypsum Plastering WorksДокумент12 страницUp Dated Job Safety Analysis-Gypsum Plastering WorksAkhtar Ali100% (1)

- JSA FOR Shakthi ElectricalДокумент8 страницJSA FOR Shakthi Electricalwahyu nugroho100% (1)

- Mie Hse Jha 002 - Welding, Cutting, Fabrication WorkДокумент4 страницыMie Hse Jha 002 - Welding, Cutting, Fabrication WorkLuqman Osman100% (1)

- JHA For Loop CheckДокумент8 страницJHA For Loop CheckFrancis Enriquez Tan83% (6)

- JSA Cable Laying PDFДокумент2 страницыJSA Cable Laying PDFManoj WaskelОценок пока нет

- Jha - Transformer Installation PDFДокумент6 страницJha - Transformer Installation PDFperquino oasan0% (1)

- Job Safety Analysis: 1 Confined Space Entry JSA ExampleДокумент7 страницJob Safety Analysis: 1 Confined Space Entry JSA Examplerashid zamanОценок пока нет

- JSA Erection of Steel StructureДокумент9 страницJSA Erection of Steel StructureLuqman Osman77% (13)

- Job Safety Analysis (Rolling For MS Plates)Документ1 страницаJob Safety Analysis (Rolling For MS Plates)Muhammad Ali100% (2)

- Jsa For Operating A BobcatДокумент2 страницыJsa For Operating A Bobcatsoubhagya100% (2)

- JSA-020-Safety Watch-Hot WorkДокумент2 страницыJSA-020-Safety Watch-Hot WorkNishad MuhammedОценок пока нет

- JSA. Electrical PullingДокумент2 страницыJSA. Electrical PullingSajid Hussain100% (1)

- Job Safety Analysis Sheet: Cold CuttingДокумент1 страницаJob Safety Analysis Sheet: Cold CuttingGanga Daran100% (2)

- Health, Safety & Environmental Program Jsa (Job Safety Analysis)Документ7 страницHealth, Safety & Environmental Program Jsa (Job Safety Analysis)Osiobe Ewomazino50% (2)

- Petrofac: Job Safety AnalysisДокумент3 страницыPetrofac: Job Safety AnalysisMon Trang Nguyễn100% (5)

- Job Safety Analysis Sheet: Electrical IsolationДокумент1 страницаJob Safety Analysis Sheet: Electrical IsolationLal Dhwoj100% (2)

- Jsa Working at Height (Maintenance & Cleaning)Документ2 страницыJsa Working at Height (Maintenance & Cleaning)Nur Syafiqah Mat Rapie100% (1)

- Fire Fighting JSAДокумент14 страницFire Fighting JSANikhil Manjrekar83% (6)

- Civil JSA Form Block WorkДокумент3 страницыCivil JSA Form Block Workdrmuhsin86% (7)

- ISC-JSA Installation of Portable CabinДокумент4 страницыISC-JSA Installation of Portable CabinSameer Almahboub25% (4)

- Jsa For Piping and Erection RevisedДокумент1 страницаJsa For Piping and Erection RevisedAlvin Smith77% (26)

- Demolition PDFДокумент2 страницыDemolition PDFvinothОценок пока нет

- Job Safety Analysis Template - BatteryДокумент2 страницыJob Safety Analysis Template - Batteryvenkateshbitra63% (8)

- Jsa For ScaffoldingДокумент3 страницыJsa For Scaffoldingsoubhagya100% (4)

- JSA Maintenance Fire Alarm PDFДокумент2 страницыJSA Maintenance Fire Alarm PDFBernath100% (3)

- Confined Space JSAДокумент1 страницаConfined Space JSADILAL B P100% (16)

- JHA Scaffolding ErectionДокумент12 страницJHA Scaffolding ErectionChayank TiwariОценок пока нет

- TEIPL-JSA-014 Manual Material HandlingДокумент2 страницыTEIPL-JSA-014 Manual Material Handlingba ratnaparkhe75% (4)

- JSA MasnoryДокумент4 страницыJSA Masnorysubhanmusadiq100% (1)

- 71 Arc Welding - Job Procedure - 2Документ3 страницы71 Arc Welding - Job Procedure - 2Angga EHSKOINОценок пока нет

- 71 Arc Welding - JOB PROCEDUREДокумент3 страницы71 Arc Welding - JOB PROCEDUREAdilMunirОценок пока нет

- Arc WeldingДокумент2 страницыArc WeldingYoga PradiptaОценок пока нет

- Unit 35 Portfolio Answer 2018Документ22 страницыUnit 35 Portfolio Answer 2018Hatem HusseinОценок пока нет

- M3LB-001 - Wire StrippingДокумент4 страницыM3LB-001 - Wire Strippingashleyanne.bantayОценок пока нет

- Test Report 259 - Brass 1" Flat Tape Saddle - ES25BДокумент14 страницTest Report 259 - Brass 1" Flat Tape Saddle - ES25BannamalaiОценок пока нет

- Quality Problems OringДокумент2 страницыQuality Problems OringluisОценок пока нет

- Foreign Material Indentation Specs InchesДокумент1 страницаForeign Material Indentation Specs InchesluisОценок пока нет

- ENG P122 Pump Shimeki UntenДокумент4 страницыENG P122 Pump Shimeki UntenluisОценок пока нет

- BALTEC Directional LimitsДокумент3 страницыBALTEC Directional LimitsluisОценок пока нет

- Dogleg, Deviation ESP Recommendation (Generic)Документ2 страницыDogleg, Deviation ESP Recommendation (Generic)luis100% (1)

- Dogleg, Deviation ESP Recommendation (Generic)Документ2 страницыDogleg, Deviation ESP Recommendation (Generic)luis100% (1)

- Capilar InstallationДокумент4 страницыCapilar InstallationluisОценок пока нет

- Axial Thrust in Centrifugal PumpsДокумент14 страницAxial Thrust in Centrifugal PumpsAndré Da Cunha SilveiraОценок пока нет

- Chapter-18-Hazard-and-Risk-Management 36 PDFДокумент36 страницChapter-18-Hazard-and-Risk-Management 36 PDFCarl WilliamsОценок пока нет

- SPE HFTS Are You Applying HF HP As Per The Industry GuidanceДокумент23 страницыSPE HFTS Are You Applying HF HP As Per The Industry GuidanceRast losОценок пока нет

- JSA MasnoryДокумент4 страницыJSA Masnorysubhanmusadiq100% (1)

- Tayyab Imtiaz, 00713532, PSTC 1178.Документ7 страницTayyab Imtiaz, 00713532, PSTC 1178.shu,yab kashirОценок пока нет

- Nut Bolt Tighten by Hammering Spanner and Torque Machine JsaДокумент4 страницыNut Bolt Tighten by Hammering Spanner and Torque Machine JsaAKBAR ALIОценок пока нет

- JOB SAFETY ANALYSIS Grout Placement, Curing and CoatingДокумент5 страницJOB SAFETY ANALYSIS Grout Placement, Curing and Coatingmuhammad zaman50% (2)

- Operation SOP 47Документ4 страницыOperation SOP 47pothanОценок пока нет

- Job Safety Analysis: Department: (Bagian/fungsi)Документ9 страницJob Safety Analysis: Department: (Bagian/fungsi)Yosua SitumorangОценок пока нет

- JSA Erection StructureДокумент11 страницJSA Erection StructureJAYESH JOSHIОценок пока нет

- Jsa Ndt-BuildingДокумент5 страницJsa Ndt-BuildingFirdaus RidzuanОценок пока нет

- Confined SpaceДокумент31 страницаConfined SpacegshdavidОценок пока нет

- Conduct Workplace Communication: CPCCCM1014AДокумент14 страницConduct Workplace Communication: CPCCCM1014ABobby BettencourtОценок пока нет

- Job Safety Analysis - Cement SiloДокумент7 страницJob Safety Analysis - Cement SiloArgi Bramantara100% (1)

- Job Safety Analysis For Hydro Test: Indmax Prime-G, Ighds Unit, Iocl, BGRДокумент5 страницJob Safety Analysis For Hydro Test: Indmax Prime-G, Ighds Unit, Iocl, BGRAkash ShuklaОценок пока нет

- Mr. Asif Hussain: Std. CVДокумент9 страницMr. Asif Hussain: Std. CVAsif HussainОценок пока нет

- JSA - Anchor Bolt and Template Lifting From Ground To Elevated Work PlatformДокумент6 страницJSA - Anchor Bolt and Template Lifting From Ground To Elevated Work PlatformRaju KhalifaОценок пока нет

- SHE Regulation 2020 With Attachment (Approved)Документ212 страницSHE Regulation 2020 With Attachment (Approved)Ainur RohmanОценок пока нет

- Job Safety Analysis: Removing Porta Cabin & Loading at Trailor's ActivityДокумент7 страницJob Safety Analysis: Removing Porta Cabin & Loading at Trailor's ActivityMuhammad TariqОценок пока нет

- JSA ExcavationДокумент6 страницJSA ExcavationidreisОценок пока нет

- Method of Statement For Road Crossing WorkДокумент7 страницMethod of Statement For Road Crossing WorkAnonymous voA5Tb0Оценок пока нет

- 20.JSA - Hendra Manual Pouring CongcreteДокумент3 страницы20.JSA - Hendra Manual Pouring CongcreteMuhamad Rizki AzisОценок пока нет

- 6.JSA of Batching Plant InstallationДокумент4 страницы6.JSA of Batching Plant InstallationNitesh Kumar100% (1)

- Excavation Safety Dos and DontsДокумент4 страницыExcavation Safety Dos and DontsVidya SagarОценок пока нет

- JSA Painting Aut Tranformer Unit 3 OutageДокумент7 страницJSA Painting Aut Tranformer Unit 3 OutageMarhendraОценок пока нет

- 007-MS For Structural Steel Assembly Warehouse, Workshops PDFДокумент25 страниц007-MS For Structural Steel Assembly Warehouse, Workshops PDFKöksal PatanОценок пока нет

- Hazard Identification and Risk AssessmentДокумент41 страницаHazard Identification and Risk AssessmentShameer KhanОценок пока нет

- WMC - Contractor Management StandardДокумент19 страницWMC - Contractor Management StandardGuntur E. AdiwinataОценок пока нет

- Job Safety Analysis: Description of Job: Torque Wrench OperationДокумент2 страницыJob Safety Analysis: Description of Job: Torque Wrench OperationPrakash PalaiОценок пока нет

- 11 - HSE Management SystemДокумент37 страниц11 - HSE Management SystemMohammed AffrozeОценок пока нет

- Batteries Handling Disposal ProcedureДокумент17 страницBatteries Handling Disposal ProcedureBALAJIОценок пока нет