Академический Документы

Профессиональный Документы

Культура Документы

Bush Type Coupling

Загружено:

Sandeep PrajapatiАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Bush Type Coupling

Загружено:

Sandeep PrajapatiАвторское право:

Доступные форматы

Pin Bush Couplings

for drives of 1 hp upto

200 hp at 100 rpm

The purpose of fixing the flexible coupling is to transmit torque from one shaft to another, where

misalignments may occur and also to absorb shock loads, etc

Those machines which are going to be fitted with flexible couplings should first be well aligned. It is, only then

that the coupling will deal with misalignments occurring due to heavy shaft loading by belt, temperature

variations etc. Bearing wear or settling of machine foundations can also be a reason for causing extra

loading on the coupling. Any or all of these conditions can occur after the machines have been coupled The

Easyflex flexible coupling has been designed to transmit the torque through high tensile steel bolts and

flexible bearings, to the machine input shaft- Since it is of the cushioned drive type, it can absorb shock loads,

torsional vibrations and any misalignments*

Very simple in construction, the Easyflex Pin Bush coupling is so designed that it transmits high powers and

maximum speed. Though normally the flanges are of cast iron, but for higher speeds .flanges can be

provided in good quality steel. This type of coupling will permit drive on either direction, does not require any

lubrication nor adjustment after fitting. These flexible bearings remain unaffected either by dust, water or

atmospheric conditions. Two identical halves form the couplings. The Rayon reinforced rubber bearings

being driven into each half, while the holes for the connecting bolts, or pins, are alternately arranged

between them, If desired only one half of the coupling may be used to connect to suitable holes in a fly-wheel

or any existing flange adaptor, however, this will reduce by 50% the listed power of the complete coupling.

The following listed couplings are of standard size. The flanges are available in Pilot Bore Standard

Specifications unless otherwise specified - However, Finished Bore and sizes can be considered if the quantity

is reasonable.

Powers for the standard couplings range from 075 HP to 208 HP at 100 rpm and sizes from 3.75" to 20.5"

outside diameter.

Pin Bush Couplings

Table of Dimensions

B

C

3 3/4"

3 1/8"

1 1/2"

1/8"

1 3/4"

4 1/2"

3 7/8"

1 7/8"

1/8"

2"

6 5/16"

4 3/16"

2"

3/16"

2 15/16"

7 1/2"

4 15/16"

2 3/8"

3/16"

8 7/8"

6 3/16"

3"

3/16"

4 5/16"

10"

7 3/16"

3 1/2"

3/16"

5 3/4"

12 5/8"

9 11/16"

4 3/4"

3/16"

6 7/16"

14"

11 5/16"

5 9/16"

3/16"

7 7/16"

17 3/4"

15 3/16"

7 1/2"

3/16"

8 1/4"

19"

15 15/16"

7 7/8"

3/16"

9 1/4"

20 1/2"

18 7/16"

9 1/8"

3/16"

10 5/6"

E BORE

BORE

LOCKING SCREW

LOCKING SCREW

Table of Dimensions

K1

K2

K3

K4

K5

K6

K7

K8

K9

K10

K11

12

0.75

1.5

2.75

15

21

26

46

77

120

208

39

78

144

315

787

1100

1365

2415

4040

6610

10920

Min.

1/2"

5/8

3/4

1 1/4

2 1/2

2 3/4"

3 1/2"

4"

4 3/4"

Max.

1"

1 1/8"

1 1/4"

2 1/4"

2 3/4"

3 1/2"

4 1/2"

4 3/4"

5 3/4"

6"

7"

5000

4200

3000

2800

2500

2300

1700

1500

1250

1150

1050

Size

No. of

Pins

H. P. per

100 RPM

Torque

Lbs. Ft.

Bore

Max.

Speed

in rpm

A Est of service factors for the more common

type of machines is given below

Driven Machine

Prime Mover

Electric Steam I. C. Engine I. C. Engine

Engine

Multi

Single

Motor

Water

Cylinder

Cylinder

Steam

Diesel

Turbine Turbine

MultiCylinder

Shafting

Diesel

Engine

Single

Cylinder

Even torque Machines : Smooth Loads : Generators : Centrifugal Pumps : Blowers : Small

Fans : Line Shafting.

1.25

1.5

2.5

Machine Tolls (light) : Beaters : Exhausters : Wood-Working Machines (light) : Alternators :

Welding Generators : Textile Machines

1.25

1.5

1.75

2.25

2.75

Multi-crank Compressors and Pumps : Generators (fluctuating loads) : Rotary Dryers and

Screens : Rotary Compressors : Planers : Wood-working machines (heavy), pulp Girders

Shakers : Mine Fans

1.5

1.75

2.75

1.75

2.25

3.25

2.25

2.5

3.25

3.5

2.25

2.5

2.75

3.5

3.75

Wire Mils : Cement Mills : Small Printing Presses

Single Crank Compressors and Pumps ; Hammer Ball and Tube Mills (light). Shearing

Machines : Punches : Flock and Stone Crushers : Brick Making and similar machines :

Printing Presses (large) : Grinders : Pulverisors : Cranes and Winches : Mechanical

Shovels and dredges : winding Gears Drums

Heavy Rolling Mill Drives : Continuous, prolonged and reversing drives : Severe

Traction and Haulage Loads

Вам также может понравиться

- Acoplamientos TSK PDFДокумент4 страницыAcoplamientos TSK PDFBenicio Joaquín Ferrero BrebesОценок пока нет

- Autoflex Catalogue PDFДокумент24 страницыAutoflex Catalogue PDFDenis AugustoОценок пока нет

- Tyre CouplingДокумент4 страницыTyre CouplingRavi KrishnanОценок пока нет

- PYI RD Catalog 2011Документ20 страницPYI RD Catalog 2011pacificbikerguyОценок пока нет

- John Crane Met A StreamДокумент4 страницыJohn Crane Met A StreamGОценок пока нет

- Rubber Design Vibration and Noise ControlДокумент14 страницRubber Design Vibration and Noise Controlcvishwas1159Оценок пока нет

- TSKДокумент4 страницыTSKar174_569868987Оценок пока нет

- CopperalloybrakeДокумент4 страницыCopperalloybrakeReinaldo Side JuniorОценок пока нет

- Tyre Coupling CatalogДокумент9 страницTyre Coupling CatalogKariem R NoweerОценок пока нет

- RandD ShaftДокумент4 страницыRandD ShaftloloОценок пока нет

- Control Choke Valve 9000Документ8 страницControl Choke Valve 9000sabi_shi100% (2)

- Gearbox SuperДокумент15 страницGearbox Super10delpiОценок пока нет

- Alignment Coupling Operation Manual Tyre-FlexДокумент37 страницAlignment Coupling Operation Manual Tyre-Flexer_sanjaypatelОценок пока нет

- Technical Bulletin: Valtek Mark One Control ValvesДокумент20 страницTechnical Bulletin: Valtek Mark One Control ValvesOscar CruzОценок пока нет

- Bus Bar Bolting A4Документ4 страницыBus Bar Bolting A4Kordofan100% (1)

- Catalogo Giunti Samiflex - GB PDFДокумент8 страницCatalogo Giunti Samiflex - GB PDFDANE80Оценок пока нет

- TX-450SB - Pump - 2009Документ2 страницыTX-450SB - Pump - 2009mawannnОценок пока нет

- BAGFLOДокумент68 страницBAGFLOAlicia ViridianaОценок пока нет

- Eliminator Torsion Axles: Shock Cord Cross SectionДокумент23 страницыEliminator Torsion Axles: Shock Cord Cross SectionRaju ManjuОценок пока нет

- m1433 6in Sand FighterДокумент2 страницыm1433 6in Sand Fighterwpt_meОценок пока нет

- SAF 2507™ Super Duplex Weld FittingsДокумент8 страницSAF 2507™ Super Duplex Weld FittingsRoo FaОценок пока нет

- Bowex Fle-Pa Bowex-Elastic: Flange Coupling For I. C.-EnginesДокумент14 страницBowex Fle-Pa Bowex-Elastic: Flange Coupling For I. C.-EnginesÓscar PereiraОценок пока нет

- DBS Rotary Distributors RDДокумент8 страницDBS Rotary Distributors RDKashif MasudОценок пока нет

- Phased Out Products: Gear Pumps and Motors General ProductsДокумент18 страницPhased Out Products: Gear Pumps and Motors General ProductsAndrei VladОценок пока нет

- ShaftingДокумент3 страницыShafting41vaibhavОценок пока нет

- Concentrating Table Wifley-1Документ4 страницыConcentrating Table Wifley-1felixsamuelalvarado100% (2)

- Bolts FastenerДокумент20 страницBolts FastenerUpadrasta HarishОценок пока нет

- Gear CouplingsДокумент15 страницGear CouplingsVishweshwar MadhavОценок пока нет

- P08-1021-I-MN-1044 Rev 1 Simark - Flanged Turbine ManualДокумент12 страницP08-1021-I-MN-1044 Rev 1 Simark - Flanged Turbine ManualrehanОценок пока нет

- Expension Joints Engineering AppliancesДокумент30 страницExpension Joints Engineering AppliancesAcid BurnsОценок пока нет

- HSCДокумент12 страницHSCSuhas Natu100% (1)

- Tightening TorqueДокумент6 страницTightening TorqueShirish100% (1)

- Rexroth CDT4 NFPA Heavy Duty (3000 PSI) Largr Bore CylindersДокумент24 страницыRexroth CDT4 NFPA Heavy Duty (3000 PSI) Largr Bore CylindersDarioОценок пока нет

- Falk Coupling SGДокумент16 страницFalk Coupling SGJorge Ernesto PinzonОценок пока нет

- ActuatorДокумент12 страницActuatorDeepu RockzzОценок пока нет

- Bomba Hidraulica Sp25Документ5 страницBomba Hidraulica Sp25Javier SumozaОценок пока нет

- CDA - Elecon Flexible CouplingДокумент5 страницCDA - Elecon Flexible CouplingMohit GuptaОценок пока нет

- Power Stream Couplings-Specn SheetsДокумент6 страницPower Stream Couplings-Specn SheetsAmol PatkiОценок пока нет

- Auto Arc WelderДокумент4 страницыAuto Arc Weldergraham4877Оценок пока нет

- Technical Specifications For Centrifugal Pumps PDFДокумент12 страницTechnical Specifications For Centrifugal Pumps PDFVicky GautamОценок пока нет

- Catalog Mud Pump 25864Документ24 страницыCatalog Mud Pump 25864agus100% (1)

- Ariel JGK and JGT CompressorsДокумент5 страницAriel JGK and JGT CompressorsPablo GutierrezОценок пока нет

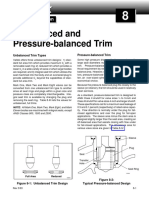

- Unbalanced and Pressure-Balanced Trim: Sizing & SelectionДокумент6 страницUnbalanced and Pressure-Balanced Trim: Sizing & SelectionPratik134Оценок пока нет

- Thomson Super Metric Ball Bushing Bearings SpecsheetДокумент11 страницThomson Super Metric Ball Bushing Bearings SpecsheetElectromateОценок пока нет

- Acople Falk-WrapflexДокумент16 страницAcople Falk-Wrapflexhenkis73Оценок пока нет

- Compresores Serie-A ChampionДокумент4 страницыCompresores Serie-A ChampionFrancisco100% (1)

- Centrifugal Slurry Pump RangeДокумент16 страницCentrifugal Slurry Pump Rangecitramuara100% (4)

- CA Motors Product DetailsДокумент25 страницCA Motors Product DetailsP Venkata Suresh100% (2)

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesОт EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesРейтинг: 5 из 5 звезд5/5 (1)

- High-Performance GM LS-Series Cylinder Head GuideОт EverandHigh-Performance GM LS-Series Cylinder Head GuideРейтинг: 4.5 из 5 звезд4.5/5 (2)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceОт EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceОценок пока нет

- Bearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsОт EverandBearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsРейтинг: 4 из 5 звезд4/5 (1)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsОт EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsРейтинг: 4.5 из 5 звезд4.5/5 (10)

- Southern Marine Engineering Desk Reference: Second Edition Volume IiОт EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IiОценок пока нет

- Linotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeОт EverandLinotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeОценок пока нет

- Wood Turning - The Lathe and Its Accessories, Tools, Turning Between Centres Face-Plate Work, Boring, PolishingОт EverandWood Turning - The Lathe and Its Accessories, Tools, Turning Between Centres Face-Plate Work, Boring, PolishingОценок пока нет

- Akshay Vaishnav's Answer To What Are Some of The Best Interview Questions Asked For A Mechanical Engineering Student - QuoraДокумент10 страницAkshay Vaishnav's Answer To What Are Some of The Best Interview Questions Asked For A Mechanical Engineering Student - QuoraSandeep PrajapatiОценок пока нет

- CEE 3710 - Strength Versus StiffnessДокумент3 страницыCEE 3710 - Strength Versus StiffnessSandeep PrajapatiОценок пока нет

- Dual-Phase Steel - WikipediaДокумент3 страницыDual-Phase Steel - WikipediaSandeep PrajapatiОценок пока нет

- Materials Corrosion - Basic Types of Corrosion That Designers and Engineers Must BeДокумент4 страницыMaterials Corrosion - Basic Types of Corrosion That Designers and Engineers Must BeSandeep PrajapatiОценок пока нет

- Metallurgical Engineering - MATERIAL STEEL: CLASSIFICATIONS, GRADES AND PДокумент8 страницMetallurgical Engineering - MATERIAL STEEL: CLASSIFICATIONS, GRADES AND PSandeep PrajapatiОценок пока нет

- Dinesh Bajaj's Answer To What Is The Best Course Books To Go For Preparation of ISRO Examination, When You Are Mechanical Engineer - QuoraДокумент2 страницыDinesh Bajaj's Answer To What Is The Best Course Books To Go For Preparation of ISRO Examination, When You Are Mechanical Engineer - QuoraSandeep PrajapatiОценок пока нет

- Metallurgical Engineering - Widmannstatten Ferrite and Cementite Widmanstätten StructuДокумент2 страницыMetallurgical Engineering - Widmannstatten Ferrite and Cementite Widmanstätten StructuSandeep PrajapatiОценок пока нет

- Answers Should Be Written in QCAB Format Only.: InstructionsДокумент81 страницаAnswers Should Be Written in QCAB Format Only.: InstructionsSandeep PrajapatiОценок пока нет

- Can You Disclose Your ESE 2018 Marks Sheet Along With Some Tips To Maximize Score in Conventional Papers?Документ7 страницCan You Disclose Your ESE 2018 Marks Sheet Along With Some Tips To Maximize Score in Conventional Papers?Sandeep PrajapatiОценок пока нет

- 09 Test ESE 2020 ME Mains - Final - (Questions)Документ13 страниц09 Test ESE 2020 ME Mains - Final - (Questions)Sandeep PrajapatiОценок пока нет

- Answers Should Be Written in QCAB Format Only.: InstructionsДокумент76 страницAnswers Should Be Written in QCAB Format Only.: InstructionsSandeep PrajapatiОценок пока нет

- Physical Testing of Rubbers - R.P.BrownДокумент350 страницPhysical Testing of Rubbers - R.P.BrownSandeep Prajapati100% (1)

- EXAM - (M) 2018: Mechanical Engineering Paper - IIДокумент12 страницEXAM - (M) 2018: Mechanical Engineering Paper - IISandeep PrajapatiОценок пока нет

- Answers Should Be Written in QCAB Format Only.: InstructionsДокумент73 страницыAnswers Should Be Written in QCAB Format Only.: InstructionsSandeep PrajapatiОценок пока нет

- BPSC MechДокумент13 страницBPSC MechSandeep PrajapatiОценок пока нет

- Answers Should Be Written in QCAB Format Only.: InstructionsДокумент70 страницAnswers Should Be Written in QCAB Format Only.: InstructionsSandeep PrajapatiОценок пока нет

- Answers Should Be Written in QCAB Format Only.: InstructionsДокумент87 страницAnswers Should Be Written in QCAB Format Only.: InstructionsSandeep PrajapatiОценок пока нет

- Answers Should Be Written in QCAB Format Only.: InstructionsДокумент78 страницAnswers Should Be Written in QCAB Format Only.: InstructionsSandeep PrajapatiОценок пока нет

- Daily Practice ProblemДокумент1 страницаDaily Practice ProblemSandeep PrajapatiОценок пока нет

- Computer Science & IT: GATE 2019Документ7 страницComputer Science & IT: GATE 2019Sandeep PrajapatiОценок пока нет

- 2100 Asanas The Complete Yoga Poses Daniel LacerdaДокумент288 страниц2100 Asanas The Complete Yoga Poses Daniel LacerdaSandeep Prajapati0% (1)

- Basic Concepts in Engineering Metallurgy - Gate Mechanical Concepts - Mechanical Engineering World - Project Ideas - Seminar Topics - E-Books (PDF) - New TrendsДокумент4 страницыBasic Concepts in Engineering Metallurgy - Gate Mechanical Concepts - Mechanical Engineering World - Project Ideas - Seminar Topics - E-Books (PDF) - New TrendsSandeep PrajapatiОценок пока нет

- New Microsoft Office Word DocumentДокумент2 страницыNew Microsoft Office Word DocumentButnaru BogdanОценок пока нет

- Ekm - March - 2023Документ3 страницыEkm - March - 2023only indianОценок пока нет

- Pyroban C15 HazpakДокумент4 страницыPyroban C15 Hazpakcacalot93Оценок пока нет

- 0599 PDFДокумент2 страницы0599 PDFEdinson Ariel Chavarro QuinteroОценок пока нет

- Brochure 1400 1600 MPI MAJ 2014Документ4 страницыBrochure 1400 1600 MPI MAJ 2014sebasfarsaОценок пока нет

- Volumetric EfficiencyДокумент7 страницVolumetric EfficiencyDumithJayathilaka100% (1)

- Suzuki ST30 Engine2Документ4 страницыSuzuki ST30 Engine2MALIK MUHAMMAD HAMZA FAROOQ MALIK MUHAMMAD FAROOQОценок пока нет

- Atomic 4 Illustrated Parts CatalogДокумент72 страницыAtomic 4 Illustrated Parts CatalogBroncoBobОценок пока нет

- 2 StrokeДокумент8 страниц2 StrokeUsama AnsariОценок пока нет

- An Engine Compression Test Is The Most Practical Way To Learn About The Mechanical Condition of Your EngineДокумент10 страницAn Engine Compression Test Is The Most Practical Way To Learn About The Mechanical Condition of Your EngineJAYSON CANDELARIAОценок пока нет

- ECU EternaДокумент2 страницыECU EternaLelaki Pemberani100% (2)

- Testing & Adjusting Injector AdjustmentДокумент10 страницTesting & Adjusting Injector AdjustmentROnggosutedJOОценок пока нет

- Sherlock Holmes Diagnosis: Jim Morton Jim HaldermanДокумент63 страницыSherlock Holmes Diagnosis: Jim Morton Jim Haldermanabul hussain50% (2)

- Series - 230 / 250: Marine Common Rail EnginesДокумент2 страницыSeries - 230 / 250: Marine Common Rail EnginesZdravko PodolskiОценок пока нет

- Swaraj Tractor EngineДокумент7 страницSwaraj Tractor EngineHarmanjit SinghОценок пока нет

- On-Vehicle Inspection (4A-Fe) : Spark TestДокумент4 страницыOn-Vehicle Inspection (4A-Fe) : Spark TestNathaly MarcanoОценок пока нет

- Reno Laguna x56 f3r k729 PinoviДокумент5 страницReno Laguna x56 f3r k729 PinovilittleborgОценок пока нет

- Sabroe CMO Maintenance ScheduleДокумент3 страницыSabroe CMO Maintenance ScheduleOprea Marius100% (1)

- Internal Combustion Engine: Teknik Mesin Universitas Maarif Hasyim Latf SidoarjoДокумент158 страницInternal Combustion Engine: Teknik Mesin Universitas Maarif Hasyim Latf SidoarjoAdhi PrayogaОценок пока нет

- Installation Instruction V8 and V12 PDFДокумент228 страницInstallation Instruction V8 and V12 PDFBayanaka Tehnik75% (4)

- A21 Engine - 1.6Документ53 страницыA21 Engine - 1.6ahmedОценок пока нет

- 601 CD Ignition Control SystemДокумент2 страницы601 CD Ignition Control SystemAlejandro MuñozОценок пока нет

- Ignition SystemДокумент49 страницIgnition SystemmdkhayumОценок пока нет

- DT2 (77 79)Документ18 страницDT2 (77 79)Anonymous jbeHFUОценок пока нет

- Massey Ferguson MF 174 CДокумент133 страницыMassey Ferguson MF 174 Cjose cocoОценок пока нет

- 2 Phase Hybrid Stepper Motor: 23HS Series-Size 57mm (1.8 Degree)Документ2 страницы2 Phase Hybrid Stepper Motor: 23HS Series-Size 57mm (1.8 Degree)joker63000Оценок пока нет

- SIAUT Fuel Injection Systems-DieselДокумент39 страницSIAUT Fuel Injection Systems-DieselFlorea AndreiОценок пока нет

- Db33 G-Drive: Power RatingДокумент2 страницыDb33 G-Drive: Power RatingDafa' DzakyОценок пока нет

- BMW - Approved AntifreezeДокумент1 страницаBMW - Approved Antifreezehellfire22000100% (1)

- Serafin Spark 2010 Taxi PDFДокумент2 страницыSerafin Spark 2010 Taxi PDFOliver lealОценок пока нет