Академический Документы

Профессиональный Документы

Культура Документы

Saic W 2011rev 0

Загружено:

fariboy123Исходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Saic W 2011rev 0

Загружено:

fariboy123Авторское право:

Доступные форматы

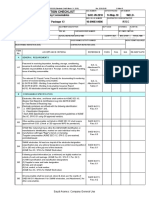

SAUDI ARAMCO ID/PID - 2/19/05 - REV 0 (Standards Cutoff - August 2004)

SAUDI ARAMCO INSPECTION CHECKLIST

Validation of Welding Equipment (Power Supply)

SAIC NUMBER

DATE APPROVED

SAIC-W-2011

PROJECT TITLE

WBS / BI / JO NUMBER

EQUIPMENT ID NUMBER(S)

EQUIPMENT DESCRIPTION

LAYOUT DRAWING NUMBER

REV. NO.

SCHEDULED INSPECTION DATE & TIME

ACTUAL INSPECTION DATE & TIME

25-May-05

QR NUMBER

WELD-

CONTRACTOR / SUBCONTRACTOR

EQPT CODE

SYSTEM ID.

PURCHASE ORDER NUMBER

PLANT NO.

EC / PMCC / MCC NO.

QUANTITY INSP.

MH's SPENT

TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER

SAUDI ARAMCO ACTIVITY NUMBER

SAUDI ARAMCO INSPECTION LEVEL

CONTRACTOR INSPECTION LEVEL

ITEM

No.

ACCEPTANCE CRITERIA

REFERENCE

Welding power supplies shall be VALIDATED in accordance with

BS 7570 or an approved equivalent if impact toughness test is

NOTE:

required by the applicable company or industry specifications or

codes.(SAES-W-011, Para. 19.2)

SAES-W-011,

Para. 19.2

Preparation

A1

Personnel conducting calibration/validation was verified to be

qualified/expert. (Verification was made by observing his performance

and his certifications and resume, or by approval of the Company.)

(

BS 7570, Para. 7)

SAES-W-011,

Para. 19.2

A2

Equipment used for validation/calibration have calibration traceable to

national standards. (BS 7570, Para. 7)

SAES-W-011,

Para. 19.2

A3

Measuring instruments are in good condition. (BS 7570, Para. 9.3)

SAES-W-011,

Para. 19.2

A4

Measuring instruments are calibrated by a recognized calibrator, with

standards traceable to a national standard.

(BS 7570, Para. 9.3)

SAES-W-011,

Para. 19.2

A5

Measuring instruments are at least twice more accurate than the

accuracy required for the validation grade, (preferably more).

(BS 7570, Para. 9.3)

SAES-W-011,

Para. 19.2

A6

Ambient temperature is measured to ensure it is within the limilts

specified for the power source, and the instrument rating been

been tested. Ambient temperature is recorded.

(BS 7570, Para. 9.5.1.1)

SAES-W-011,

Para. 19.2

A7

Input voltage is measured to ensure compliance with specified value for

the power source. This measurement is recorded on the validation

certificate. Correct tappings been connected within the power source if

relevant. (BS 7570, Para. 9.5.1.2)

SAES-W-011,

Para. 19.2

A8

For engine driven power sources, the rated load speed and no-load

speed is checked to ensure that the power source meets the rated

values. (BS 7570, Para. 9.5.1.3)

SAES-W-011,

Para. 19.2

A9

Power Source for each welding process are subjected to the following

loads:

a. TIG - is loaded with a conventional load of drooping

characteristics{(U2 = (10 + 0,04 I2) V up to I2 = 600 A},

after which it remains constant at 34V.

b. SMAW- is loaded with a conventional load of Drooping

characteristic {U2 = (20 + 0,04 I2) V up to I2 = 600 A}, after

which U2 remains constant at 44 V.

c. MIG/MAG/FCAW/SAW - loaded with Flat characteristic

{U2 = (14 + 0,05 I2) V up to I2 = 600 A}, after which U2

remains constant at 44 V.

d. SAW - loaded with a conventional load U2 = (20 + 0,04 I2) V

up to I2 = 600 A, after which U2 remains constant at 44 V.

(BS 7570, Para. 9.4)

SAES-W-011,

Para. 19.2

Page 1 of 4

WORK PERMIT REQUIRED?

PASS

FAIL

N/A

RE-INSP DATE

SAUDI ARAMCO ID/PID - 2/19/05 - REV 0 (Standards Cutoff - August 2004)

SAUDI ARAMCO INSPECTION CHECKLIST

Validation of Welding Equipment (Power Supply)

PROJECT TITLE

ITEM

No.

SAIC NUMBER

SAIC-W-2011

WBS / BI / JO NUMBER

ACCEPTANCE CRITERIA

REFERENCE

The resistive load across the output terminals of the power source, is

connected as far as practical. The instrumentation used for validation of

A10

the voltage across the resistive load and the transducer in the circuit, is

connected. (BS 7570, Para. 9.5.1.4)

SAES-W-011,

Para. 19.2

The wire feed unit being validated, is connected to the source of power

A11 supply normally used during welding.

(BS 7570, Para. 9.5.1.5)

SAES-W-011,

Para. 19.2

A12

The wire feeder is assembled and adjusted according to the

manufacturer's instructions. (BS 7570, Para. 9.5.1.6)

SAES-W-011,

Para. 19.2

The wire feeder shall not be driven driven at speeds, or loaded with filler

A13 wire diameters in excess of that shown on the rating plate.

(BS 7570, Para. 9.5.1.7)

SAES-W-011,

Para. 19.2

The current rating of validation welding cables used exceeded the

maximum current flowing in the welding circuits by a factor of two.

A14 (NOTE: Excepton is where the welding system is being validated with

specific welding cable, or circuit assemble characteristics .)

(BS 7570, Para. 9.5.1.9)

SAES-W-011,

Para. 19.2

The validation/calibration range of the control or meter fitted to the power

source is selected from one of the following:

a) the full range of the control or meter;

A15 b) a partial range of the control or meter;

c) selected points over the range of the control or meter.

NOTE: Either b) or c) is agreed upon before carrying out

validation/calibration.

(BS 7570, Para. 9.5.1.10)

SAES-W-011,

Para. 19.2

A16

Measurements are taken at the minimum setting, the maximum

setting and three other points nominally equally spaced between

minimum and maximum, over the full or partial range.

(BS 7570, Para. 9.5.1.10)

SAES-W-011,

Para. 19.2

Validation process

B1

The equipment is switched on 5 minutes before any calibration

requirements. (BS 7570, Para. 9.5.2.1)

SAES-W-011,

Para. 19.2

B2

Validation starts at the minimum output setting. The power source output

is energized and stabilized for 10 seconds, and a reading is taken. The

procedure is repeated for each of the measurement points up to the

maximum. (BS 7570, Para. 9.5.2.2)

SAES-W-011,

Para. 19.2

B3

After a further 10 seconds a second reading is taken at the max. setting.

This procedure is repeated for each of the measurement points down to

the minimum. ( BS 7570, Para. 9.5.2.3)

SAES-W-011,

Para. 19.2

B4

The power source is loaded in excess of that shown on the rating plate.

( BS 7570, Para. 9.5.2.4)

SAES-W-011,

Para. 19.2

B5

If validation at a particular current and or voltage is required, but the

nature of the load does not permit that current or voltage at the

corresponding load voltage or current to be achieved, points are taken

above and below the desired values, and the required value calculated.

(BS 7570, Para. 9.5.2.5)

SAES-W-011,

Para. 19.2

Page 2 of 4

DATE APPROVED

25-May-05

QR NUMBER

WELD-

CONTRACTOR / SUBCONTRACTOR

PASS

FAIL

N/A

RE-INSP DATE

SAUDI ARAMCO ID/PID - 2/19/05 - REV 0 (Standards Cutoff - August 2004)

SAUDI ARAMCO INSPECTION CHECKLIST

Validation of Welding Equipment (Power Supply)

PROJECT TITLE

SAIC NUMBER

SAIC-W-2011

WBS / BI / JO NUMBER

ITEM

No.

ACCEPTANCE CRITERIA

REFERENCE

B6

At each validation point selected point,the following is recorded on SATRW-2011:

a) the current and/or voltage control setting.

b) the power source meter readings.

c) the two values of the true measurement of current and/or voltage from

the test instrumentation.

d) the mean value of the two measurements.

The results of measurements are systematically recorded and supplied

on, or with the validation certificate.

(BS 7570, Para. 9.5.2.6)

SAES-W-011,

Para. 19.2

B7

If the power source has a slope control, the setting is noted. If it is

necessary to validate the power source at different settings of the slope

control, this is agreed prior to the validation.

(BS 7570, Para. 9.5.2.7)

SAES-W-011,

Para. 19.2

B8

A consistency test is carried out on controls which cannot be calibrated

or validated because they are not graduated in absolute units or the

original validation is not applicable due to the way the

equipment is being used, e.g. under abnormal load conditions.

( BS 7570, Sec. 5)

SAES-W-011,

Para. 19.2

B9

On completion of a validation the results are compared with the Accuracy

set in Table 1 of BS 7570, as shown in Attachment 1.

(BS 7570, Para. 9.5.2.8)

SAES-W-011,

Para. 19.2

B10

Equipment that meets the accuracy in Attachment 1(Table 1) are

labeled with the following information:

a) the statement "PASSED"

b) the date the label is valid;

c) the date of expiry of the validation;

d) the name of the authority issuing the label;

e) the make, model and serial number of the

equipment.

(BS 7570, Para. 10.1.2)

SAES-W-011,

Para. 19.2

B11

Equipment that does not meet the accuracy recommended in

Attachment 1(Table 1), a label bearing the following information is

attached, Or, the equipment is subsequently be taken out of the project

site.

a) the statement "FAILED"

b) the date the label was issued;

c) the name of the authority issuing the label;

d) the make, model and serial number of the

equipment.

(BS 7570, Para. 10.1.3)

SAES-W-011,

Para. 19.2

REMARKS:

REFERENCE DOCUMENTS:

1.

2.

SAES-W-011, Welding Requirements for On-Plot Piping, (30 October, 2002)

BS 7570 2000, Code of Practice for Validation of Arc Welding Equipment, 2000

ATTACHMENT:

1.

Attachment 1 - Validation Accuracies for Standard Grade Power Sources

Page 3 of 4

DATE APPROVED

25-May-05

QR NUMBER

WELD-

CONTRACTOR / SUBCONTRACTOR

PASS

FAIL

N/A

RE-INSP DATE

SAUDI ARAMCO ID/PID - 2/19/05 - REV 0 (Standards Cutoff - August 2004)

SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Validation of Welding Equipment (Power Supply)

DATE APPROVED

SAIC-W-2011

PROJECT TITLE

WBS / BI / JO NUMBER

ITEM

No.

ACCEPTANCE CRITERIA

REFERENCE

Contractor / Third-Party

25-May-05

QR NUMBER

WELD-

CONTRACTOR / SUBCONTRACTOR

PASS

FAIL

N/A

RE-INSP DATE

Saudi Aramco

Construction Representative*

PMT Representative

Work is Complete and Ready for Inspection:

Name, Initials and Date:

T&I Witnessed

QC Record Reviewed

Work Verified

T&I Witnessed

QC Record Reviewed

Work Verified

T&I Witnessed

QC Record Reviewed

Work Verified

Name, Initials and Date:

QC Inspector

PID Representative

Performed Inspection

Work / Rework May Proceed

Name, Initials and Date:

Name, Initials and Date:

QC Supervisor

Proponent and Others

Quality Record Approved:

Name, Sign and Date:

Name, Organization,

Initials and Date:

*Person Responsible for Completion of Quality Work / Test

Y = YES

ATTACHMENT 1

Page 4 of 4

N = NO F = FAILED

Вам также может понравиться

- Saudi Aramco Inspection ChecklistДокумент2 страницыSaudi Aramco Inspection ChecklistJoni Carino SuniОценок пока нет

- Saudi Aramco Inspection ChecklistДокумент19 страницSaudi Aramco Inspection ChecklistIrshad IqbalОценок пока нет

- SAIC-M-2012 Rev 7supportsДокумент33 страницыSAIC-M-2012 Rev 7supportsvijayachiduОценок пока нет

- Saudi Aramco Inspection Checklist: Review of WPS & Process Control Procedure (Pipelines) SAIC-W-2038 WeldДокумент4 страницыSaudi Aramco Inspection Checklist: Review of WPS & Process Control Procedure (Pipelines) SAIC-W-2038 Weldhamidjoyia100% (1)

- Saic MPT 2004 Rev 0Документ6 страницSaic MPT 2004 Rev 0philipyapОценок пока нет

- SAIC-W-2015 Rev 7 (NDE Selection)Документ17 страницSAIC-W-2015 Rev 7 (NDE Selection)vijayachiduОценок пока нет

- Saudi Aramco Inspection ChecklistДокумент13 страницSaudi Aramco Inspection ChecklistAli AhmedОценок пока нет

- SAIC-X-3104 Rev 3Документ4 страницыSAIC-X-3104 Rev 3Imran khanОценок пока нет

- SAIC-W-2085 Pre-Welding Inspection PDFДокумент4 страницыSAIC-W-2085 Pre-Welding Inspection PDFkarioke mohaОценок пока нет

- Saic RT 2007Документ9 страницSaic RT 2007munnaОценок пока нет

- SAIC-D-2005 Rev 2Документ4 страницыSAIC-D-2005 Rev 2ரமேஷ் பாலக்காடுОценок пока нет

- Saudi Aramco Inspection Checklist: Review of Welding Procedure Specification SAIC-W-2001 25-May-05 WeldДокумент13 страницSaudi Aramco Inspection Checklist: Review of Welding Procedure Specification SAIC-W-2001 25-May-05 WeldAnonymous S9qBDVky100% (1)

- Saudi Aramco Inspection Checklist: In-Process Welding Inspection SAIC-W-2006 30-Apr-13 WeldДокумент3 страницыSaudi Aramco Inspection Checklist: In-Process Welding Inspection SAIC-W-2006 30-Apr-13 WeldManoj KumarОценок пока нет

- Saep 324Документ13 страницSaep 324Up WeldОценок пока нет

- SAIC-W-2043 Rev 0Документ3 страницыSAIC-W-2043 Rev 0philipyapОценок пока нет

- Saudi Aramco Typical Inspection Plan: Welding of On-Plot Piping SATIP-W-011-01 31-Dec-14 MechanicalДокумент5 страницSaudi Aramco Typical Inspection Plan: Welding of On-Plot Piping SATIP-W-011-01 31-Dec-14 MechanicalpravinОценок пока нет

- Welding Procedures and Welders QualificationДокумент41 страницаWelding Procedures and Welders QualificationHamid MansouriОценок пока нет

- Saudi Aramco Inspection Checklist: Inprocess Welding Inspection - Offshore Structures SAIC-W-1313 WeldДокумент1 страницаSaudi Aramco Inspection Checklist: Inprocess Welding Inspection - Offshore Structures SAIC-W-1313 Weldkartik_harwani4387Оценок пока нет

- Saic RT 2001Документ24 страницыSaic RT 2001munnaОценок пока нет

- 625 CRO - SAW Study - Final Report PDFДокумент21 страница625 CRO - SAW Study - Final Report PDFAnouar AbdelmoulaОценок пока нет

- Saudi Aramco Inspection ChecklistДокумент5 страницSaudi Aramco Inspection ChecklistManoj KumarОценок пока нет

- Saudi Aramco Inspection Checklist: SAIC-W-2032 24-Jul-18 Weld-Upgrade Aramco JNGLFP Propane System BI-21-00087 MacoДокумент7 страницSaudi Aramco Inspection Checklist: SAIC-W-2032 24-Jul-18 Weld-Upgrade Aramco JNGLFP Propane System BI-21-00087 MacojahaanОценок пока нет

- Saudi Aramco Inspection ChecklistДокумент23 страницыSaudi Aramco Inspection ChecklistjahaanОценок пока нет

- Saudi Aramco Inspection Checklist: Field Hydrostatic Testing of Isolation Valves SAIC-L-2042 25-May-05 MechДокумент3 страницыSaudi Aramco Inspection Checklist: Field Hydrostatic Testing of Isolation Valves SAIC-L-2042 25-May-05 MechHamidОценок пока нет

- Oxygen Level in Purging Gas During Welding of Duplex Stainless Steel - Google GroupsДокумент6 страницOxygen Level in Purging Gas During Welding of Duplex Stainless Steel - Google GroupssanketОценок пока нет

- 175 325100Документ2 страницы175 325100sridhar100% (1)

- Dimensions (Based On ASME/ANSI B16.9) and Example Weights For Long Radius ElbowsДокумент3 страницыDimensions (Based On ASME/ANSI B16.9) and Example Weights For Long Radius ElbowsRAFAEL BRAVOОценок пока нет

- Satr-W-2010Документ1 страницаSatr-W-2010Joni Carino SuniОценок пока нет

- Satr-W-2008 Atyb TRДокумент6 страницSatr-W-2008 Atyb TRDeo MОценок пока нет

- Weld Summary: SATIP-W-011-01 SATR-W-2008 30/apr/13 19/04/2020Документ3 страницыWeld Summary: SATIP-W-011-01 SATR-W-2008 30/apr/13 19/04/2020bishalОценок пока нет

- Brazing BPS 107-1 PДокумент5 страницBrazing BPS 107-1 Pmbe josephОценок пока нет

- Welder Repair Assessment and Tracer Weld Report-Weekly SATR-W-2018 22-Jan-18 WeldДокумент2 страницыWelder Repair Assessment and Tracer Weld Report-Weekly SATR-W-2018 22-Jan-18 Weldkarthi51289Оценок пока нет

- Bluewater MIR Roc Master CPP IR 003 (Jun.20 PDFДокумент8 страницBluewater MIR Roc Master CPP IR 003 (Jun.20 PDFANIL PLAMOOTTIL100% (1)

- Ir 175-010000Документ2 страницыIr 175-010000Abu Anas M.SalaheldinОценок пока нет

- 04 Samss 035Документ16 страниц04 Samss 035liuyx866Оценок пока нет

- 175 011100Документ2 страницы175 011100Abu Anas M.SalaheldinОценок пока нет

- T 91 WeldingДокумент12 страницT 91 WeldingMohammad KhaliquzzamaОценок пока нет

- CWB - Welding Requirements Csa-S6 Canadian Highway Bridge Design Code Welding RequirementsДокумент2 страницыCWB - Welding Requirements Csa-S6 Canadian Highway Bridge Design Code Welding RequirementsStephen TilleyОценок пока нет

- Duplex Welding GuidelinesДокумент13 страницDuplex Welding GuidelinesadelОценок пока нет

- Saes W 011Документ2 страницыSaes W 011hendraox3996Оценок пока нет

- 1044 Plant Inspection Career Poster March 2015 PDFДокумент1 страница1044 Plant Inspection Career Poster March 2015 PDFHoque Anamul100% (1)

- Aramco Wellhead Christmas Tree RehabilitationДокумент9 страницAramco Wellhead Christmas Tree RehabilitationHaleem Ur Rashid BangashОценок пока нет

- Saudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Jul-18 WeldДокумент2 страницыSaudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Jul-18 Weldm4metzОценок пока нет

- SAES-W-012 - Google Search3Документ1 страницаSAES-W-012 - Google Search3fayceal0% (1)

- Saudi Aramco Inspection ChecklistДокумент3 страницыSaudi Aramco Inspection ChecklistAbdul HannanОценок пока нет

- 175 030100Документ2 страницы175 030100Abu Anas M.Salaheldin100% (1)

- D1.5M D1.5 2015 AMD1 Form O 2 FillableДокумент1 страницаD1.5M D1.5 2015 AMD1 Form O 2 Fillablevikasphopale1Оценок пока нет

- Module 9.qualification 1.welding PerformanceДокумент6 страницModule 9.qualification 1.welding PerformanceMohd NizamОценок пока нет

- SAIC-L-2014 Flange Joint Insp PDFДокумент7 страницSAIC-L-2014 Flange Joint Insp PDFAnonymous S9qBDVkyОценок пока нет

- Saudi Aramco Test Report: 25-May-05 Weld-Weekly Weld Status Report SATR-W-2019Документ2 страницыSaudi Aramco Test Report: 25-May-05 Weld-Weekly Weld Status Report SATR-W-2019David RodriguesОценок пока нет

- Part2 Notice 1Документ21 страницаPart2 Notice 1Danem Halas100% (1)

- Weekly Weld Repair AnalysisДокумент1 страницаWeekly Weld Repair AnalysisknocknocknockОценок пока нет

- B-Qac-Pro-210-391xx QCP Welding ControlДокумент22 страницыB-Qac-Pro-210-391xx QCP Welding ControlZaidiОценок пока нет

- Active Doc ListДокумент405 страницActive Doc Listnadeem UddinОценок пока нет

- CWBДокумент2 страницыCWBShyam ParsanaОценок пока нет

- Rererence - PIM-SC-2505-N - CS PIPING FABRICATIONДокумент14 страницRererence - PIM-SC-2505-N - CS PIPING FABRICATIONaslam.ambОценок пока нет

- Section Subject: Shaybah CPF Expansion ProjectДокумент21 страницаSection Subject: Shaybah CPF Expansion ProjectAdhie Waelacxh100% (1)

- SAIC-W-2082 Validation of Welding Equipment (EE)Документ4 страницыSAIC-W-2082 Validation of Welding Equipment (EE)karioke mohaОценок пока нет

- Saudi Aramco Inspection ChecklistДокумент4 страницыSaudi Aramco Inspection ChecklistjahaanОценок пока нет

- Saic W 2011Документ3 страницыSaic W 2011munnaОценок пока нет

- Astm B 841Документ5 страницAstm B 841fariboy123Оценок пока нет

- KDK Exhaust FanДокумент28 страницKDK Exhaust Fanfariboy123Оценок пока нет

- Commercial 95 HDPE FabricДокумент6 страницCommercial 95 HDPE Fabricfariboy123100% (1)

- Hallowell Full Line Catalog 2019Документ140 страницHallowell Full Line Catalog 2019fariboy123Оценок пока нет

- Advisory Circular: 1. PurposeДокумент50 страницAdvisory Circular: 1. Purposefariboy123Оценок пока нет

- KDK - 40gseДокумент1 страницаKDK - 40gsefariboy123Оценок пока нет

- Manual IG5Документ36 страницManual IG5fariboy123Оценок пока нет

- 59 Sabit MC-1 PDFДокумент1 страница59 Sabit MC-1 PDFfariboy123Оценок пока нет

- Damper Pressure LossДокумент2 страницыDamper Pressure Lossfariboy123Оценок пока нет

- 310 15B16Документ1 страница310 15B16HoodmyОценок пока нет

- Saes o 119Документ2 страницыSaes o 119fariboy123Оценок пока нет

- CVS02100 - Site Preparation, Excavation, and Backfill SpecificationДокумент17 страницCVS02100 - Site Preparation, Excavation, and Backfill SpecificationIrene Jar Yee Tan100% (2)

- Manual IG5Документ117 страницManual IG5fariboy123100% (1)

- Gas Change Over PanelДокумент2 страницыGas Change Over Panelfariboy123Оценок пока нет

- Saes A 004Документ17 страницSaes A 004Arvind ShakyaОценок пока нет

- Welding Consumables Issuance Record Saudi Aramco Inspection ReportДокумент1 страницаWelding Consumables Issuance Record Saudi Aramco Inspection Reportfariboy123Оценок пока нет

- Washing Machine Manual T1113TEFTДокумент78 страницWashing Machine Manual T1113TEFTfariboy123Оценок пока нет

- Iso 10211 Heat2 Heat3Документ16 страницIso 10211 Heat2 Heat3nsk377416100% (1)

- Ao-90265ba Pci CardДокумент46 страницAo-90265ba Pci CardFrancisco Javier PérezОценок пока нет

- Manas Lahon: Areas of Interests EducationДокумент2 страницыManas Lahon: Areas of Interests EducationmanaslahonОценок пока нет

- Fibretherm FT12Документ47 страницFibretherm FT12Dana Iulia Moraru50% (2)

- Estimation and Costing by M Chakraborty PDFДокумент4 страницыEstimation and Costing by M Chakraborty PDFAakash Kamthane0% (3)

- Binthen Motorized Curtain Price List Rev1.0 Jan 2022Документ4 страницыBinthen Motorized Curtain Price List Rev1.0 Jan 2022Emil EremiaОценок пока нет

- Kristian Tlangau - November, 2016 PDFДокумент52 страницыKristian Tlangau - November, 2016 PDFMizoram Presbyterian Church SynodОценок пока нет

- λ-based Design Rules PDFДокумент3 страницыλ-based Design Rules PDFvinosujaОценок пока нет

- Mathematical Description of OFDMДокумент8 страницMathematical Description of OFDMthegioiphang_1604Оценок пока нет

- GPS Vehicle Tracker: User ManualДокумент9 страницGPS Vehicle Tracker: User ManualFeJuniorОценок пока нет

- DH Xvr4b16Документ3 страницыDH Xvr4b16Jumar JumadiaoОценок пока нет

- NHD Works Cited 2015Документ9 страницNHD Works Cited 2015miakellerОценок пока нет

- Bank Statement - Feb.2020Документ5 страницBank Statement - Feb.2020TRIVEDI ANILОценок пока нет

- Performance Impact Analysis With KPP Using Application Response Measurement in E-Government SystemsДокумент4 страницыPerformance Impact Analysis With KPP Using Application Response Measurement in E-Government SystemsFredrick IshengomaОценок пока нет

- The Impact of Internet Use For StudentsДокумент8 страницThe Impact of Internet Use For StudentsCharlesОценок пока нет

- Why Rife Was Right and Hoyland Was Wrong and What To Do About ItДокумент4 страницыWhy Rife Was Right and Hoyland Was Wrong and What To Do About ItHayley As Allegedly-Called Yendell100% (1)

- INDUSTRIAL LUBRICANTS-misr Petroleum PDFДокумент17 страницINDUSTRIAL LUBRICANTS-misr Petroleum PDFIslam FawzyОценок пока нет

- Gudenaaparken (Randers) - All You Need To Know BEFORE You GoДокумент8 страницGudenaaparken (Randers) - All You Need To Know BEFORE You GoElaine Zarb GiorgioОценок пока нет

- View/Update Profile Apply For STC: Upload Sponsorship STC Applied Download Certificate Change PasswordДокумент2 страницыView/Update Profile Apply For STC: Upload Sponsorship STC Applied Download Certificate Change PasswordlakshmilavanyaОценок пока нет

- Animal and Human Brain Work With Treatment Its Malfunction: Pijush Kanti BhattacharjeeДокумент6 страницAnimal and Human Brain Work With Treatment Its Malfunction: Pijush Kanti BhattacharjeeNilakshi Paul SharmaОценок пока нет

- Trial On CompresorДокумент3 страницыTrial On CompresorA JОценок пока нет

- A Feasibility Study On Drilling of Metals Through Microwave HeatingДокумент6 страницA Feasibility Study On Drilling of Metals Through Microwave HeatingT J GОценок пока нет

- Data CenterДокумент108 страницData CenterKhanh Nato100% (5)

- Bhopal Gas TragedyДокумент25 страницBhopal Gas TragedyHarry AroraОценок пока нет

- Infineon IKFW50N65DH5Документ15 страницInfineon IKFW50N65DH5nithinmundackal3623Оценок пока нет

- Ric RG90 y RG60Документ1 страницаRic RG90 y RG60GabrielConsentidoОценок пока нет

- Reynolds EqnДокумент27 страницReynolds EqnSuman KhanalОценок пока нет

- Radios of America in EnglishДокумент3 страницыRadios of America in Englishvitor_pedroОценок пока нет

- EP T8 Diesel ForkliftsДокумент7 страницEP T8 Diesel ForkliftsHein Sithu KyawОценок пока нет

- ¿Cómo Se Utilizan Las Partituras en La Enseñanza y El Aprendizaje de La Música?Документ15 страниц¿Cómo Se Utilizan Las Partituras en La Enseñanza y El Aprendizaje de La Música?manaimanaОценок пока нет