Академический Документы

Профессиональный Документы

Культура Документы

High Temperature Super Conductor Moter

Загружено:

VipulChandrakerОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

High Temperature Super Conductor Moter

Загружено:

VipulChandrakerАвторское право:

Доступные форматы

HIGH TEMPERATURE SUPERCONDUCTOR MOTOR

Chapter-1

INTRODUCTION

1.1. History

The phenomenon in which the electrical resistance falls down to zero when some

materials are cooled to very low temperatures is known as Superconductivity. It was

discovered by Heike Kamerlingh Onnes on 1911 in Leiden, Netherlands. When he cooled

Mercury to 4 K it showed zero resistance for the flow of electrons.

For seventy-five years after that, researchers attempted to observe superconductivity

at higher and higher temperatures. In the late 1970s, superconductivity was observed in

certain metal oxides at temperatures as high as 13 K (260.2 C), which were much higher

than those for elemental metals. In 1987, K Alex Mueller and J. Georg Bednorz, working at

the IBM research lab near Zurich, Switzerland were exploring a new class of ceramics for

superconductivity. Bednorz encountered a compound of Lithium, Barium and Copper oxide

whose resistance dropped down to zero at a temperature around 35 K (238.2 C). This is

how High Temperature Superconductivity was discovered.

1.2. Introduction to High Temperature Superconductors (HTS)

High-temperature superconductors (abbreviated high- Tc or HTS) are materials that

behave as superconductors at unusually high temperatures. Whereas "ordinary" or metallic

superconductors usually have transition temperatures (temperatures below which they super

conduct) of about 30 K (243.2 C), HTS superconductors have been observed with

transition temperatures as high as 110 K (163 C).

The search for high temperature superconductors (HTS) has been ongoing since the

discovery of the first superconductor. A graph of the high temperature superconductors and

the year of their discovery can be found in figure 1. In 1986, the high temperature

superconductor LaBaCuO which has a Tc of 35K was discovered by Karl Muller and

Johannes Bednorz. This discovery led to the a new interest in a class of superconductors

known as cuprates that consist of copper-oxygen planes. The critical temperature was

EEE Dept, BITM

Page 1

HIGH TEMPERATURE SUPERCONDUCTOR MOTOR

increased to 90K, above the liquid temperature of nitrogen, with the discovery of YBaCuO in

1987. Cuprates remained (and still do) a high priority due to its high Tc until the discovery of

superdconductivity in iron-pnictides bled by Yoichi Kamihara who discovered that the CuO

plane is not a requirement for superconductivity. [3] While the mechanism for

superconductivity in both cuprates and pnictides is still to a greunknown, there have been

many attempts made to explain the phenomenon. HTS are type-II superconductors. The

meaning and repercussions of this will be explored as well as the mechanism for

superconductivity in the relatively new discovered pnictides.

As of 2009, the highest-temperature superconductor (at ambient pressure) is mercury

barium calcium copper oxide (HgBa2Ca2Cu3Ox), at 135 K and is held by a cuprate-perovskite

material, which possibly reaches 164 K under high pressure.

Fig.1.1:Graph of the highest temperature superconductors and the year of discovery.

EEE Dept, BITM

Page 2

HIGH TEMPERATURE SUPERCONDUCTOR MOTOR

Chapter-2

HTS Motors

Motors are machines that convert electrical energy into mechanical energy using

magnetic forces. When current is passed through a wire loop that lies in a magnetic field, a

turning force, or torque, is created that causes the loop to rotate. In motors, this rotating

motion is transmitted to a shaft. This rotational energy is then utilized for useful work in the

form of mechanical power. Industrial motors are used for running pumps, fans, and

compressors as well as in equipment involved in the handling and processing of

manufactured materials. Marine propulsion motors are used to propel commercial vessels and

warships.

Electric motors were first designed in the 1890s, despite the lengthy period of time in

which motors have been in development, motors are still far from being perfectly efficient

converters of electrical to mechanical energy. The principal causes of lost power in motors

come from the electrical resistance of the wire and from mechanical friction.

2.1. Superconducting Motors

Superconducting motors are new types of AC synchronous motors that employ HTS

(High Temperature Superconductor) windings in place of conventional copper coils [Masson,

2005]. Because HTS wire can carry significantly larger currents than can copper wire, these

windings are capable of generating much powerful magnetic fields in a given volume of

space.

2.2. HTS Wire Development

Superconductors are used in electric motors to create a magnetic field in the air gap that is

about twice the value as that found in a conventional, nonsuperconducting motor. The

increased magnetic field results in a smaller motor size and reduced motor loss for the same

motor output power compared to a conventional motor. Commercially viable HTS motors

will require high performance HTS wire. The HTS field winding in the superconducting

motor must carry a current density in the superconducting material on the order of 100,000

EEE Dept, BITM

Page 3

HIGH TEMPERATURE SUPERCONDUCTOR MOTOR

amps/cm2 (645,000 amps/in2) in a magnetic field of 5 Tesla . American Superconductor

company (AMSC) Boston, Massachusetts, USA is the leader in HTS wire development.

Generally the HTS wire material used in machine are BSCCO (Bismuth strontium

calcium copper oxide) or Bi-2223(the n=3 compound (Bi2Sr2Ca2Cu3O10+x)) materials. Bi2223 wires are able to carry current densities of abt. 100 times higher than copper. The Bi2223 is a high strength reinforced wire which is able to with stand close to 30MPa tensile

strength and 0.4% tensile strain at 77k. These reinforced wires provide a mechanically robust

and reliable product, which are suitable for making high performance propulsion motors and

generators.

Fig .2.1: BSCCO Tapes and Wire

EEE Dept, BITM

Page 4

HIGH TEMPERATURE SUPERCONDUCTOR MOTOR

2.3. Design and Principle of operation

Motors consist of two main parts, a rotor and a stator. The interaction between the

magnetic field provided by the rotor and the alternating currents (AC) flowing in the

windings result in electromagnetic torque. Conventional motors use copper windings and an

iron core to increase the magnitude of the air gap flux density created by copper windings.

Iron has a nonlinear magnetic behavior and saturates at a flux density of 2 tesla, thus limiting

the electromagnetic torque. In HTS motors, the copper rotor windings can be replaced with

superconducting windings with a resulting current density 10 times greater without any

resistive losses. The superconducting motor is virtually an air core where the stator is

constructed without the iron teeth of a conventional motor. This type of construction

eliminates core saturation and iron losses.

Figure 2.2: Comparison between a conventional synchronous motor and an HTS

Synchronous motor [Masson, 2005].

EEE Dept, BITM

Page 5

HIGH TEMPERATURE SUPERCONDUCTOR MOTOR

Figure 2.1 shows a comparison between the construction of a conventional motor and

an HTS motor. In the HTS motor, the rotor consists of field coils made with HTS wires fed

with direct current (DC). The dc inductor windings typically operate at a temperature of 25

40 K (415 to 388oF), with a dc flux density of up to 4 tesla. Although high temperature

superconducting wires can carry direct current with almost no losses, transient loads on the

motor can lead to variations of magnetic field on the coils. HTS wires are sensitive to such

field variations, and the resulting losses can lead to a decrease in current density and a loss of

the superconducting state. In order to prevent this, an electromagnetic shield is placed in the

air gap, usually as part of the rotor assembly. This shield can be a bulk metallic hollowed

cylinder or a squirrel cage.

EEE Dept, BITM

Page 6

HIGH TEMPERATURE SUPERCONDUCTOR MOTOR

Figure 2.3: Cutaway view of 5-MW HTS motor [Masson, 2005]

EEE Dept, BITM

Page 7

HIGH TEMPERATURE SUPERCONDUCTOR MOTOR

Figure 2.4: AMSC/ONR 5-MW HTS motor [Masson, 2005]

Figures 2.3 and 2.4 show an actual 5-MW HTS motor designed and built by

American Superconductor (AMSC) and ALSTOM for the U.S. Navys Office of Naval

Research. This 230-rpm HTS ship propulsion motor is a model for larger motors to be used

in ship propulsion. The motor has completed factory acceptance tests and has undergone

extensive testing at the Center for Advanced Power Systems at Florida State University,

Tallahassee. The tests include full power test at 5MW and dynamic long-term testing

emulating ship propeller action to determine how an HTS motor performs under realistic

service conditions onboard a ship. AMSC is presently designing a 36.5-MW (50,000- hp)

HTS motor, also for the U.S. Navy, as a full-scale propulsion motor for use on surface ships .

Superconducting wires currently available are too sensitive to flux variation to be

used in the armature. Flux variation results in ac losses raising the temperature in the

superconductor and thereby limiting the operating current. Therefore, conventional copper

wires are used in the armature. The synchronous motor configuration represents the most

feasible topology for superconducting motors; however, many unconventional HTS motor

configurations based on the unique properties of superconductors have been developed in

laboratories worldwide.

EEE Dept, BITM

Page 8

HIGH TEMPERATURE SUPERCONDUCTOR MOTOR

2.4. Commercial HTS Motor Topology

Figure 3.4 presents the salient features of the HTS synchronous

motor topology. Its geometry is similar to that of superconducting

synchronous generators developed in the past. The motor has an air core

(i.e. nonmagnetic) construction so that the air gap field can be increased

without the core loss and saturation problems imposed by a laminated

stator and rotor iron core. Only the outer layer, the laminated frame and

flux shield, is made of magnetic material which acts as a flux shunt to

confine the high magnetic fields within the motor. A nonmagnetic and

nonconducting support structure for the copper armature winding is

located inside the frame.

The normal conducting (copper) armature winding lies just outside of the air gap. It

must be constructed from transposed filaments to reduce eddy current losses. The armature

conductors will experience field levels that are about an order of magnitude above those

experienced in a conventional motor. Conventional motor conductors lie in high permeability

teeth which redirect the flux away from the conductors so that only the slot leakage flux

actually penetrates the copper. In the superconducting motor, since the armature conductors

see the entire air gap flux density, the armature winding must be carefully designed to

minimize eddy current losses.

Under steady state operation the motor rotor rotates in synchronism with the rotating

field created by the three phase armature currents and the superconducting field winding

experiences only DC magnetic fields. Under load or source transients, however, the rotor will

move with respect to the armature created rotating field and it will experience AC fields. In a

conventional synchronous motor these AC fields induce currents in damper windings or bars

that create restoring torques to bring the rotor back into synchronism after a disturbance.

These damper windings also serve as the rotor cage winding for across-the-line starting.

The superconducting motor will be started by ramping the output frequency of the

armature inverter, therefore a starting cage will not be necessary. Damping will be provided

by concentric conducting shells located outside of and rotating with the field winding. These

are designated as the AC flux shield and high strength damper in Figure 3.4 The shells must

EEE Dept, BITM

Page 9

HIGH TEMPERATURE SUPERCONDUCTOR MOTOR

also act to shield the field winding from all AC fields created during transients to prevent AC

losses from occurring in the superconductors. It is expected that a two layer shielding

structure will be utilized to accomplish the damping and shielding effectively. The outer layer

(the high strength damper in Figure 3.4) will be a high strength material at room temperature

(a warm shield) which will act as the damper winding and provide some AC flux shielding.

Fig2.5 Cross-section of a large horsepower synchronous motor with HTS field windings

EEE Dept, BITM

Page 10

HIGH TEMPERATURE SUPERCONDUCTOR MOTOR

Inside of the outer warm shield will be a thermal insulation space (vacuum) that

surrounds the rotor cryostat. The inner layer of the rotor damper/shield structure will be a

high conductivity shell that is near the operating temperature of the superconducting coils.

This inner shield (the high conductivity AC flux shield in Figure 1.6) will provide some

damping and, most importantly, acts to shield the superconducting field winding from any

AC fields that pass through the outer warm shield. Inside the inner shield is the

superconducting field winding on a nonmagnetic support structure. The superconducting

field coils will be immersed in some cryogenic coolant. The coolant will leave the cold space

of the rotor through heat exchangers which will minimize the conduction of heat into the cold

space through the torque tubes. The coolant will be transferred into and out of the rotor

through a rotating transfer coupling and be refrigerated by some means outside the motor.

EEE Dept, BITM

Page 11

HIGH TEMPERATURE SUPERCONDUCTOR MOTOR

Chapter-3

ADVANTAGES AND DISADVANTAGES OF HTS MOTORS

3.1. Advantages of using HTS Motors

Compared to equivalent rating of conventional Synchronous motors these HTS motors are

expected to be:1. Lighter and compact i.e., about half the length and two-thirds of the diameter of a

conventional Synchronous Motor.

2. Less expensive due to compact in size and lighter in weight.

3. Provide superior stable operation in a power system.

4. More efficient and reliable.

5. It emits very less heat so can be cooled with low cost.

6. The field windings of the HTS Motor are made with HTS conductor material which

operates at 35-40 kelvin and can be cooled with least expense.

7. The HTS field winding produces magnetic fields higher than those of conventional

Synchronous Motors.

8. HTS Motors have higher efficiency at part load (down to 5% of full speed), that

results in savings in fuel use and operating cost. The advantage in efficiency can be

over 10% at low speed.

9. HTS motors have lower sound emissions than conventional machines.

10. HTS air-core motors are characterized by a low synchronous reactance which results

in operation at very small load angles. Operating at a small load angle provides

greater stiffness during the transient and hunting oscillations

EEE Dept, BITM

Page 12

HIGH TEMPERATURE SUPERCONDUCTOR MOTOR

3.2. Disadvantages of HTS Motors

1. The cost, size, weight, and complications of the cooling system.

2. A sudden decrease or elimination of motor or generator action if the superconductors

leave their superconductive state.

3. A greater tendency for rotor speed instability. A superconducting rotor does not have

the inherent damping of a conventional rotor. Its speed may hunt or oscillate around

its synchronous speed.

4. Motor bearings need to be able to withstand cold or need to be insulated from the cold

rotor.

5.

As a synchronous motor, electronic control is essential for practical operation.

Electronic control introduces expensive harmonic loss in the super cooled rotor

electromagnet.

EEE Dept, BITM

Page 13

HIGH TEMPERATURE SUPERCONDUCTOR MOTOR

Chapter-4

APPLICATIONS AND BENIFITS

4.1 Applications of HTS Motors in ships

The HTS ship propulsion motors offer a range of benefits and advantages for both naval and

commercial shipping applications including the following:

Up to three-time higher torque density than alternative technologies, HTS machines

are more compact and lighter in weight. The size and weight benefits make HTS

machine less expensive and easier to transport and install as well as allowing for

arrangement flexibility in the ship.

High efficiency from full-to-low speed, boosting fuel economy, sustained speed, and

mission range, all key mission parameters for warships.

A typical navy ship, needs two propulsion motors, each rated 36.5 MW, 120 rpm.

Such large motors have been built using conventional technology but they are four to

five times heavier than the 36.5 MW HTS Motor.

Fig. 4.1Difference between HTS and conventional propulsion Motors

4.2. What are the Benefits?

EEE Dept, BITM

Page 14

HIGH TEMPERATURE SUPERCONDUCTOR MOTOR

Less vibration and noise - Elimination of iron teeth in the stator results in a lightweight

motor that boasts quiet and smooth operation.

Smaller size and weight - The compact design of HTS motors will facilitate placement in

transportation applications where space and/or weight is at a premium, as well as in upgrades

of industrial facilities where increased power requirements conflict with limited space

availability. Figure 6.1 and 6.2 shows a comparison between a conventional motors used for

marine purpose and the HTS motors.

Figure 4.1: Comparison of HTS Motors with Conventional motors in terms of Volume

[MSCL, 2001]

Figure 4.2: Comparison of HTS Motors with Conventional motors in terms of Weight

[MSCL, 2001]

EEE Dept, BITM

Page 15

HIGH TEMPERATURE SUPERCONDUCTOR MOTOR

Superconducting technology will be employed in a variety of motor designs.

Industrial HTS motors are designed for constant speed application. They will be operated at

1800 or 3600 rpm. For marine propulsion, a high-torque, low-speed design is favored. These

motors will be designed to operate at variable speeds below 200 rpm.

HTS generators offer improved efficiency thereby reducing machine losses by as

much as 50 percent compared to conventional generators of comparable size. In addition,

HTS generators are substantially smaller and lighter than copper based machines. These

advantages are very attractive in a ship environment where space and weight are at a

premium. Heat and thermal cycling of conventional rotating machines are one of the biggest

detractors to reliability and life expectancy. HTS rotating machines virtually eliminate these

failure modes by operating a near constant cryogenic temperature

EEE Dept, BITM

Page 16

HIGH TEMPERATURE SUPERCONDUCTOR MOTOR

Chapter-5

FUTURE SCOPE AND CONCLUSION

5.1. Future Scope

1. HTS motors will offer an attractive economic alternative to conventional motors by

virtue of their lower first (acquisition) cost and their reduced ongoing (operating) cost

2. Electric marine propulsion market is expected to quadruple over the next decade by

the use of HTS motors.

3. Superconducting specialty motors will be particularly attractive for niche applications

in which size and weight considerations come into play.

4. The military is also looking at using superconductive tape as a means of reducing the

length of very low frequency antennas employed on submarines.

5.2. Conclusion

In conclusion, superconducting motors can have a potentially large impact

on electrical energy utilization through reduced losses and size when

compared to conventional energy efficient iron core motors. This reduced

loss and smaller size will be the driving force for their commercial

introduction in industrial applications. Preliminary first cost analyses

predict that large HTS motors (larger than 1000 hp or 746 kW) will be an

economically viable commercial product. The quantity of superconducting

motors will be large and the energy savings potential as a result of their

application will be substantial both in the INDIA and worldwide.

EEE Dept, BITM

Page 17

HIGH TEMPERATURE SUPERCONDUCTOR MOTOR

References

[1]. https://www.wikipedia.org

[2]. IEEE Transactions on Industry Applications, Vol.44, NO.5, September/October 2008

[3]. http://www.azom.com/article.aspx?ArticleID=949#_Where_and_How

[4]. http://www.superconductors.org/uses.htm

EEE Dept, BITM

Page 18

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Manual BrontoДокумент115 страницManual BrontoDaniel Reinoso Rojo83% (6)

- The Relative Nature of Low Probability of Detection Radar: A Countermeasures PerspectiveДокумент36 страницThe Relative Nature of Low Probability of Detection Radar: A Countermeasures PerspectiveamenendezamОценок пока нет

- Es - 101Документ8 страницEs - 101Subrata PaulОценок пока нет

- PSCAD IntroductionДокумент72 страницыPSCAD IntroductionksbwingsОценок пока нет

- Hollow and Solid PlugДокумент2 страницыHollow and Solid PlugSandra DevannyОценок пока нет

- PISMДокумент3 страницыPISMKishore KumarОценок пока нет

- GSR9 FP1 Compatibility Matrix Bts / BSCДокумент2 страницыGSR9 FP1 Compatibility Matrix Bts / BSCuukrul98Оценок пока нет

- 10 Tips For Getting More Instagram Followers PDFДокумент3 страницы10 Tips For Getting More Instagram Followers PDFSunarto DaspanОценок пока нет

- 9 IndexДокумент25 страниц9 IndexbuturcasОценок пока нет

- 1 Safety Precautions 4 Grounding 6 External and Cut-Out DimensionsДокумент2 страницы1 Safety Precautions 4 Grounding 6 External and Cut-Out DimensionsshankarОценок пока нет

- And 8030Документ8 страницAnd 8030varngoldОценок пока нет

- Basic Lamp DimmerДокумент3 страницыBasic Lamp DimmereeindustrialОценок пока нет

- Binary To BCDДокумент10 страницBinary To BCDbobbyn7Оценок пока нет

- ManualДокумент63 страницыManualGus Shuga100% (1)

- Gazi University Department of Electrical and Electronics EngineeringДокумент4 страницыGazi University Department of Electrical and Electronics EngineeringemreОценок пока нет

- 2009MY CM Manual AC SystemДокумент4 страницы2009MY CM Manual AC SystemHumberto LojanОценок пока нет

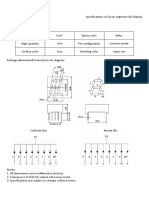

- 0.56" Milky Anode RedДокумент2 страницы0.56" Milky Anode RedPutinun TachavatapornОценок пока нет

- D10T Track-Type Tractor Power Train System: Rjg1-UpДокумент2 страницыD10T Track-Type Tractor Power Train System: Rjg1-UpJHOSMAR_22Оценок пока нет

- CompositeДокумент242 страницыCompositescribdangeloОценок пока нет

- Acoustic Noise Cancellation: From Matlab and Simulink To Real Time With Ti DspsДокумент26 страницAcoustic Noise Cancellation: From Matlab and Simulink To Real Time With Ti DspsSapantan MariaОценок пока нет

- 2mag Magnetic Stirrer Catalogue 2012Документ40 страниц2mag Magnetic Stirrer Catalogue 2012Wareyho HarkatekОценок пока нет

- Wa0011.Документ22 страницыWa0011.prabhat2000.kОценок пока нет

- Group8 SectionA Case3Документ6 страницGroup8 SectionA Case3Nikhil S 23Оценок пока нет

- Dynamic Performance of Surge Arrester Under VFTOДокумент9 страницDynamic Performance of Surge Arrester Under VFTOjegadeesh kumarОценок пока нет

- Manual Sensor A B Sense GuardДокумент5 страницManual Sensor A B Sense GuardMateus Rodolfo DiasОценок пока нет

- Deutsch CatalogДокумент160 страницDeutsch CatalogYoga Uta NugrahaОценок пока нет

- Workbook SmartStruxure Lite - Ver 1.2.0Документ70 страницWorkbook SmartStruxure Lite - Ver 1.2.0Oscar Javier Martinez Martinez0% (1)

- 2sc5294 PDFДокумент2 страницы2sc5294 PDFRachid RachidОценок пока нет

- RADAR BRIDGE MASTER ''E'' Series Radar Ship's ManualДокумент161 страницаRADAR BRIDGE MASTER ''E'' Series Radar Ship's Manualtoumassis_p100% (11)

- Application Note 135 April 2012 Implementing Robust Pmbus System Software For The Ltc3880Документ12 страницApplication Note 135 April 2012 Implementing Robust Pmbus System Software For The Ltc3880HahdОценок пока нет