Академический Документы

Профессиональный Документы

Культура Документы

Ap1275a Vol1 Sec13 Ch30 Mk1b Ah

Загружено:

dsgaviation0 оценок0% нашли этот документ полезным (0 голосов)

528 просмотров10 страницRAF Air Publication Artificial Horizon

Авторское право

© © All Rights Reserved

Доступные форматы

PDF или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документRAF Air Publication Artificial Horizon

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

528 просмотров10 страницAp1275a Vol1 Sec13 Ch30 Mk1b Ah

Загружено:

dsgaviationRAF Air Publication Artificial Horizon

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

Вы находитесь на странице: 1из 10

ALPAZISA, Vol. 1, Sect. 13, Chap. 30

ai. 8, Nov.

Chapter 30

ARTIFICIAL HORIZON, Mk. 1B AND SPERRY TYPE H.L.2

LIST OF CONTENTS:

Fs/l

Para.

Introduction we 1

Principle 5

Description

Rotor assembly oe 6

LIST OF ILLUSTRATIONS

Fig.

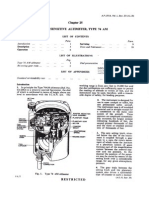

Artificial horizon, Mk. 1B - 1

General arrangement of mechanism, Type H.L.2 2

LIST OF APPENDICES

Standard serviceability test

Introduction

1. The artificial horizons described in this chapter

are air-driven, blind flying instruments which

provide the pilot with a continuous indication of

the attitude of the aircraft in pitch and roll. Three

of instruments are described, Mk. 1B

(Ghoresent) (Ref. No. 64/1519), Blk 1B Gi

nous) (Ref. No. 64/1498) and the Type HLL.

(fluorescent) (Ref. No. 64/2876). The. latter

the civilian version of the Mk. 1B and is similar

in all respects with the exception that a Sperry

type pendulous unit is employed, instead of the

Smith type pendulous unit fitted’ to the Mk. 1B

instruments. “The construction of the two types

of pendulous uit i similar, and the following

description is applicable to both the Mk. 1B an.

the Type H.L.2 instruments,

Fig. 1. Artificial horizon, Mk. 1B

Para.

Horizon bar and gimbal ring 9

Case and bezel assemblies i

Servicing 4

Standard serviceability test 16

Fig.

Sectional plan of artificial horizon, Mk. 1B. 3

DSGaviation

ven dsgaation cok

mal@drgwtation code

App.

1

2. The natural horizon is represented by a single

bar moving over'a dial or skyplate. ‘Ths fomats

horizontal at all times to provide a reference in

roll, and moves up and down the instrument dial

to give indications of dive and climb, respectively.

3. The presentation is completed by a miniature

‘aeroplane fixed centrally in the dial of the instru-

‘ment, and a pointer which moves over a scale on

the lower part of the dial to indicate angle of roll.

4. The instrument has a pitch freedom of 60 de;

in climb and 60 deg in dive, and freedom in roll

of 90 deg left and 90 deg right.

Principle

5. The principle of the gyroscope and its applica-

tion to artificial horizons is fully described

Chapter 1 which explains how the horizon bar is

made to represent changes in aircraft attitude with

respect to a fixed aircraft image.

DESCRIPTION

Rotor assembly

6. The rotor assembly consists of an air-riven

rotor wheel, a rotor case pivoted on its transverse

axis and a pendulous unit which functions as a

gyro erection device.

7. The rotor is a dynamically balanced whee!

carried on a vertical shaft with toroidal pivots

mounted in two five-ball cageless bearing races.

‘The periphery of the rotor is machined to form

buckets which register with two diametrically

RESTRICTED

opposite air jets. Lubrication is by oil, and oil

reservoir pads ensure adequate lubrication through-

‘out the instrument life. The rotor bearings are

shrouded by cylindrical skirts which prevent the

ingress of dust, and prevent the circulating ait

in the instrument from passing over the bearing

surfaces. ‘The fixed lower bearing is carried in a

recess in the bottom of the rotor case, whereas the

upper bearing is carried in a housing which is

loaded within the top cap, to compensate

for differential expansion between the rotor shaft

and rotor is ensures that the instrument

vill operate saisfatonily between 55 and “70

deg C. The rotor spins in a clockwise direction

when viewed through the base of the rotor case.

‘Two resilient stops are mounted on the top of the

rotor case and limit the instrument freedom in

Pitch,

8. A pendulous unit, attached to the base of the

rotor case, inclines the rotor axis with the top 2}

deg forward in the line of flight and } deg to the

left. “This completely compensates for turn and

acceleration errors during a Rate 1 turn at 260

Knots and to a lessening extent at other rates of

turn and speeds. The pendulous unit consists of

1 body each of whose four sides hasa slot controlled

bby a vertical vane, so that the vanes bisect the slots

‘when the gyro axis is at the correct inclination.

In this condition, exhaust air from the rotor casing

is discharged equally in four directions, so that the

reactions, being equal and opposite, equilibrium

is maintained. “Diametrically opposite vanes are

clamped to opposite ends of a common spindle

carried in plain bearings within the walls of the

Bendulous body with the end thrast taken on bal

rings.

SkY PLATE

Rowe

BEARING

HORIZON

‘Ban

BANK ANGLE

POINTER BUMPER

Horizon bar and gimbal ring

9. The rotor assembly is mounted transversely

within the gimbal ring in oil-lubricated toroidal

pivots and bearings which are fitted with oil

reservoir pads. pivots and bearings are

arranged so that on one side the bearing race is

accommodated in the rotor case and engages a pivot

screwed into the gimbal ring, whereas on the other

side the pivot is attached to the rotor case and

engages & race carried in an adjustable

housing within the gimbal ring. This arrangement

provides for the air passages to the rotor through

an air pivot on one side and clearance for the

‘actuating pin projecting from the rotor case through

fan arcuate slot in the other side of the gimbal

ring. The gimbal ring is of rectangular section

allows the rotor assembly freedom in pitch

from 60 deg climb to 60 deg dive, At these [

integral flanges on the gimbal ring contact resilient

stops mounted on top of the rotor case. ‘The gimbal

ring is pivoted fore and aft in the instrument case

and has freedom in roll of 90 deg left and 90 deg

Might. On the Mk. 1B instrument, movement in

is limited by stops, and on the

HLL he sop are yt form of rabber bumps

The air pivot adjacent to the rear cover forms the

connection between the air inlet on the rear cover

end the air passage in the gimbal ring. The front

pivot is mounted on an integral bracket of the

as and engages a bearing race carried inthe front

of the gimbal ring. Adjustable balance weights

are fitted for balancing and calibration purposes.

I

10. The dial or skyplate, attached to the gimbal

fing is nied in mat lack and carries the beak

angle pointer which is treated with either luminous

UPPER BEARING mal@tigmiatonco.

Reusing “

RoToR

RESTRICTED

Fs/2

sen

aL ane

owas.

cuss.

woRmon eas

HORTON BAR ACTURTIC. PM

\\ LAR ren

1B eae

scince weiser

UATE ot

Fig. 3. Sectional plan of artificial horizon, Type Mk. 1B

or fluorescent compound. The horizon bar is an

accurately balanced assembly, pivoted in plain

bearings on the side of the gimbal ring, and is

slotted to engage the actuating pin projecting from

the rotor case. The pointer portion of the bar

is set at right angles tothe bar and pases across

the dial,

Case and bezel assemblies

11, The bezel assembly is secured to the case by

six c/s head screws and includes the front glass,

retained by a spring circlip, and a dial ring which

is riveted to the bezel casting. ‘The dial ring is

graduated to indicate 30 and 60 deg of roll on

cither side of the datum, and incorporates a central

arm which terminates in the silhouette of a

‘miniature aircraft. Finish is in matt-black, with

the miniature aircraft and bank scale graduations

{weated with luminous or fluorescent compound.

Four integral comer lugs on the bezel form the

instrument mounting to the flight instrument panel

and are fitted with self-locking anchor nuts.

12, The case is in the form of a cast light-alloy

eylinder, enclosed at the end by the rear cover.

The instrument cannot be caged after installation

but a shipping lock is provided for use during

transit. This consists of a leaf spring riveted at

‘one end to approximately midway along the inside

‘of the instrument case. When not in use, the

spring rests against the side of the case clear of

instrument mechanism. To apply the shipping

lock, the mechanism is cent ind the

blanking screw on the underside of the case

substituted by a longer lock screw. When the lock

screw is fitted, the spring is brought into contact

with a rubber pad attached to the base of the

pendulous assembly.

13. The rear cover incorporates three alternative

‘connection ports for the vacuum supply and

‘carries the rear bearing of the gimbal ring mounting.

Peripheral holes around the bearing housing

connect with the two gauze inlet screens and the

air filer assembly mounted on the rear cover.

The filter assembly consists of a V.P.1. impregnated

gauze and felt disc retained in the flter housing by

4 spring circlip, the housing being attached to the

rear cover by four ch/hd. screws.

SERVICING

14. On starting the aircraft engines, the horizon

bar should settle to the datum position in not more

than 2 min. from the time that the vacuum gauge

registers 3} in. Hg.

1S. At periods detailed in the relevant Servicing

Schedule, the instrument should be removed from

the aircraft and the filter element renewed.

‘Standard serviceability test

16. Prior to installation and at any time when the

serviceability of the instrument. is suspect, the

instrument should be subjected to the tests detailed

in Appendix 1 to this chapter.

RESTRICTED

Fs/I

ALARA, Vol Sect. 13, on.

GE ae

Appendix 1

STANDARD SERVICEABILITY TEST FOR

ARTIFICIAL HORIZON, Mk. 1B AND TYPE H.L.2

Introduction

1, The tests in this Appendix must be applied to

the above instruments immediately prior to

installation in aircraft and whenever their service

ability is suspect. The tests are also to be applied

at inspections made at Equipment Depots. ‘The

Tolerances apecied must not be exceeded.

‘TEST EQUIPMENT

2. The equipment to be used in this test is the

gyro instrument test table, Mk. 4 (Ref. No.

8/1566).

Note...

ovvarad forall, wih the tata deer

ee ‘frequently with the vacuum indicator

Mie 2A (Ref. No. 6C/S26), which i 10 Be connected

to one of the spare connections at the rear of the

insirument when carrying out this comparison.

METHOD OF TEST

3. Unless otherwise stated the tests must be

carried out with the instrument mounted in its

normal position on the gyro test table. The normal

position is that in which the plane of the mounting.

face of the fixing flange is vertical, and the centre

line. passing through the top two fixing holes is

horizontal to within } deg.

4. Except where otherwise stated, the suction in

the instrument case must be ‘maintained at

3h din. Hg.

5S. Before commencing the tests, the outer filter

‘must be examined for cleanliness’ and a new filter

clement fitted if necessary. The pressure drop across

the filter must not exceed } in. Hg.

6. Ifa shipping lock is fitted, this must be removed

Sd replaced by the short Blanking screw provided

EXERCISING

7. Before any tests are applied the instrument must,

be exercised as follows :—

(1), Set the test table to produce roll, pitch,

and yaw over a total arc of 15 deg at 6-10

oscillations per minute, with the direction of

rotation reversing at one minute intervals.

(2), With the gyro running, start the table motor

and exercise the instrument under these con-

ditions for 15 minutes.

(3)_At the conclusion of this period, re-level

the table and lock in the horizontal plane by

locking knob A and releasing knob

TESTS

Rotor starting test

8. (1). Reduce the suction to 1} in. Hg. by means

of the suction regulator.

2) Without altering the setting of the suction

regulator, cut off the suction to the instrument

and allow the rotor to come to rest.

(3) Re-apply suction at 14 in, Hg. for 30 sec.

Rotate the instrument about the roll axis until

the stop is reached. Check that with further

movement about the roll axis the gyro precesses

about the pitch axis, indicating that the rotor

is running.

(4) Re-apply suction temporarily, and adjust

the suction to 3} in. Hg.

Settling test

9. (1) With the gyro stationary, quickly appl

full suction ‘of 3 in. He. Check that the

horizon bar and roll pointer settle to. within

4 in. of their datum within 2 minutes.

(2) _If the instrument fails this test, two further

attempts must be made. Provided that it is

within tolerance on both these further tests,

the instrument is fit to be subjected to the

remaining tests.

Erection tests

10.) With the srument runing at normal

Speed, precess rolling the case

counter clockwise about its horizontal axis unt

the horizon bar is raised approximately | in,

above the datum and then return the instrument

to the normal position.

(2) Check that the time taken for the horizon

bar to return from j in.to #y in. above the datum

is 1} to 4 minutes. ‘The horizon bar must not

deviate more than $ deg in roll during this test.

(3). Repeat the test but roll the instrument

clockwise to lower the horizon bar. The erection

times must be within the tolerance stated in

para. 10 (2) but must not differ from those

obtained in 10 (1) by more than 80 seconds.

RESTRICTED

11. (1) Turn the gyro test table through 90 deg

counter-clockwise (viewed from above), and

fee roll the, ineuimace locking wail the

horizon, bar is displaced approximately | in.

below datum.” Return the instrument and the

test table to their normal positions, thus dis-

placing the bank pointer in roll.

(2). Check that the time taken for the bank

pointer to return from 30 deg to 10 deg roll is

12 to 4 minutes. During this test the horizon

‘bar must not deviate vertically more than in.

2 Rega shite, tuning the ta tbe 50 dog

gemerchockve ntl the horaon br i dir

approximately 1 in, tum. Returr

the inatent and et ble her norma

Positions, thus ing the bank pointer in

rollin the opposite direction to the previous test.

‘The erection times must be within the tolerance

stated in para. 11 (2) and must not differ from

those obtained in para. 11 (1) by more than 80

seconds.

(@) Allow the horizon bar and bank pointer

to settle to their datum positions, cut off the

suction supply and allow the rotor to come to

rest before removing the instrument from the

counterclockwise and rolling the instrument test table.

DSGAviation

wow depron cou

mal@ergavation cou

RESTRICTED

‘A10700 W1.51951/4387 3000 12/60 MeC.S1-4291

steqaeno pomzquog)

s308q 32 eTqoITedrE, sv pestroHe;eo uoTZo9g quemimby ey; 03

peurnged +9 0} ST IF STNVEYOS ETA UE PTT S805 ot ETTEI guoMAZSUT ou; JT

rountos eTUy

4 Sey (ges098 wTe souspAcooN UE ZoyomoNUMEIOM v ssuTBe g0odens TeASUST

0 fpyeem paxoeus oq 9 SF oTaM, 4893 AUOMN CUT CLE eyy uo oBNeB VOTING BYE | -T

SSLON ONIOLAuSS

speanbsa sv ssoanc ‘saShT pe nesepe

STVIGaien

r cTrM (48e3 susunaqeuy caf? fsotgey 062/95

t Se wits" (ETA Fogetary tlze

Weomvayosa — TS CF (aaqane ausemagsuy fo) fe

“mt STOOL Gy INaaLAsE ON EEE

22°ON “TN

¢ BRIavEO 2 NOTZOSS ‘NOZTHOH

Вам также может понравиться

- AP1275A Vol1 Sec15 Ch9 Brake Pressure GaugesДокумент3 страницыAP1275A Vol1 Sec15 Ch9 Brake Pressure GaugesdsgaviationОценок пока нет

- KCA1501 P12 Compass Overhaul ManualДокумент63 страницыKCA1501 P12 Compass Overhaul Manualdsgaviation100% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- BSX29 Paint InfoДокумент6 страницBSX29 Paint InfodsgaviationОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- AP1086 Vocab of SectionsДокумент49 страницAP1086 Vocab of Sectionsdsgaviation100% (2)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Dunlop Aircraft Wheels ApplicationsДокумент11 страницDunlop Aircraft Wheels Applicationsdsgaviation0% (1)

- MoS SDM IntroductionДокумент3 страницыMoS SDM IntroductiondsgaviationОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- SDM A15 Sec 4 Cable ReplacementsДокумент2 страницыSDM A15 Sec 4 Cable ReplacementsdsgaviationОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Ads Ts20 Ags SpecsДокумент120 страницAds Ts20 Ags Specsdsgaviation100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Cancelled AGS StandardsДокумент1 страницаCancelled AGS StandardsdsgaviationОценок пока нет

- MoS SDM 12 SwitchesДокумент27 страницMoS SDM 12 SwitchesdsgaviationОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hunting Percival DB14-01 ChainsДокумент6 страницHunting Percival DB14-01 ChainsdsgaviationОценок пока нет

- AP2850A Sec5 General InstructionsДокумент13 страницAP2850A Sec5 General InstructionsdsgaviationОценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Hunting Percival DB14-03 SprocketsДокумент2 страницыHunting Percival DB14-03 SprocketsdsgaviationОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Hunting Percival Design Standard DS Chains PDFДокумент4 страницыHunting Percival Design Standard DS Chains PDFdsgaviationОценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- MoS SDM 136 Bolts and NutsДокумент5 страницMoS SDM 136 Bolts and NutsdsgaviationОценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- MoS SDM 36 StiffnutsДокумент3 страницыMoS SDM 36 StiffnutsdsgaviationОценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- AP2850A Sec 3 General InformationДокумент22 страницыAP2850A Sec 3 General InformationdsgaviationОценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- AP2850A Serck TypeДокумент27 страницAP2850A Serck Typedsgaviation100% (1)

- AP2850A Marston TypeДокумент9 страницAP2850A Marston TypedsgaviationОценок пока нет

- AP2580A Gallay TypeДокумент18 страницAP2580A Gallay TypedsgaviationОценок пока нет

- AP1275A Vol1 Sec21 Ch13 Smiths As Type ASIДокумент4 страницыAP1275A Vol1 Sec21 Ch13 Smiths As Type ASIdsgaviationОценок пока нет

- AP2850A Morris TypeДокумент20 страницAP2850A Morris TypedsgaviationОценок пока нет

- AP2850A Section 2Документ22 страницыAP2850A Section 2dsgaviationОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- AP2850A Gen InfoДокумент9 страницAP2850A Gen InfodsgaviationОценок пока нет

- AP1275A Vol1 Sec26 CH 3 Flexible DrivesДокумент2 страницыAP1275A Vol1 Sec26 CH 3 Flexible DrivesdsgaviationОценок пока нет

- AP1275A Vol1 Sec26 Ch4 Tacho IndicatorsДокумент3 страницыAP1275A Vol1 Sec26 Ch4 Tacho Indicatorsdsgaviation100% (2)

- AP1275A Vol1 Sec22 Ch4 RoC IndicatorsДокумент6 страницAP1275A Vol1 Sec22 Ch4 RoC IndicatorsdsgaviationОценок пока нет

- AP1275 Vol1 Sec26 Ch5 Tacho GeneratorДокумент2 страницыAP1275 Vol1 Sec26 Ch5 Tacho GeneratordsgaviationОценок пока нет

- AP1275A Vol1 Sec22 74AM AltimeterДокумент3 страницыAP1275A Vol1 Sec22 74AM Altimeterdsgaviation100% (1)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)