Академический Документы

Профессиональный Документы

Культура Документы

2662 tcm1023-4484

Загружено:

sujaydsouza1987Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

2662 tcm1023-4484

Загружено:

sujaydsouza1987Авторское право:

Доступные форматы

NX Nastran Optimization

Automate the optimization process to achieve the best product

performance

Benefits

Reduce design risk by better

understanding the complex

relationships among design

parameters and how design

changes affect these

relationships

Improve confidence that your

product will perform to

specifications under a variety

of operating conditions and

manufacturing tolerances

Accelerate innovation by

determining feasible new

designs that satisfy all design

requirements

Shorten time-to-market by

automating thousands of

simulations that would

otherwise have to be

performed manually

Summary

Designing and producing an innovative product that meets its performance

criteria is a goal of every manufacturer. Using optimization techniques, an

engineer can improve a proposed design, resulting in the best possible

product for minimum cost. Because your designs may have hundreds of

variable parameters, with complex inter-relationships, finding an optimal

design through manual iterations is hit-or-miss at best. NX Nastran

Optimization software relieves the burden involved in improving product

designs by automating the iterative process of comparing your designs

performance against its performance specifications.

Automating the product performance process

Traditional build-test-review-improve product cycles are typically performed

using manual iterations. However, manual design sensitivity assessments are

typically only based on changing one parameter at a time, to enable you to

tell what causes the effects you see. NX Nastran Optimization streamlines

and automates that

process by using

sophisticated

algorithms to search

the entire design

space and find the

right combination

of parameters that

will yield optimal

design or

performance.

To help the program

know what you mean by optimal, you specify design or performance

objectives for characteristics such as minimum weight, shape constraints or

minimum stress or strain. Design parameters that you can vary include

geometric, material and connectivity properties.

Examples where optimization can play a key role include weight or stress

reductions for aircraft; shape optimization for products with packaging

constraints; and multidisciplinary tradeoff studies such as vehicle durability

versus vibration characteristics.

NX

www.siemens.com/nx

NX

NX Nastran Optimization

Major capabilities

Design optimization and sensitivity

analysis can be applied to many analysis

types:

Linear statics, normal modes and

buckling

Transient response, frequency response

and acoustics

Static aeroelasticity and flutter

Upstream superelements

All optimization and sensitivity can be

done simultaneously in one NX Nastran

run. See Table 1 for a complete list:

Table 1 Analysis types in optimization

Basic analysis

Linear statics analysis

Normal modes analysis

Buckling analysis

Dynamic response

Modal frequency response

Direct frequency response

Modal transient response

Direct complex eigenvalue analysis

Modal complex eigenvalue analysis

Aeroelasticity

Static aeroelasticity

Static aeroelastic divergence

Design variables are the designers

parameters:

Shape variables are tied finite element

grid points

Sizing variables are tied to finite element

properties

Shape and sizing variables can both be

used in the same run

Initial design - Max stress = 14 MPa.

Optimized design - Max stress = 4 MPa.

Efficient optimization algorithms permit

the use of hundreds of design variables

and responses for large models.

Efficiencies include:

Design variable linking: multiple design

variables can be linked

Approximation methods: three methods

are provided

Robust optimization algorithms: three

methods are provided

Constraint deletion and regionalization:

only the critical constraints are retained

Restarts: optimization can be restarted

from a completed design cycle and

continued

Adjustable convergence criteria and

move limits: for faster convergence

Sparse matrix solver: faster speed and

minimal disk space

Adjoint sensitivity analysis

Mode tracking

Response can be either the design

objective or the performance constraints.

Responses are:

Present (see Table 2)

User-defined combinations of the

present responses

NX

Table 2 Response types in optimization

Analysis type

Response

All

Weight

Volume

Linear statics

Displacement

Stress

Strain

Force

Lamina strain

Lamina stress

Lamina failure criterion

User-defined equations let you synthesize

the objective, constraints and properties,

permitting:

RMS (root-mean-square) type responses

Cost and other nonstructural objectives

Model updating to match test data

Beam properties as a function of

sectional dimensions

Minimization of the maximum response

Design variable changes

6.00E-01

Buckling

Buckling mode number

Frequency response

Displacement

Velocity

Acceleration

Constraint force

Stress

Force

Transient response

Displacement

Velocity

Acceleration

Constraint force

Stress

Force

Static aeroelasticity

Trim

Stability derivative

Flutter

Damping level

Contact

Siemens Industry Software

Americas

+1 800 498 5351

Europe

+44 (0) 1276 702000

Asia-Pacific +852 2230 3333

www.siemens.com/nx

P_6012

P_6025

P_6030

P_6060

P_6090

P_6026

4.00E-01

3.00E-01

2.00E-01

1.00E-01

0.00E+01

0

Iteration

Weight

6.00E-02

5.00E-02

4.00E-02

3.00E-02

Weight

Normal mode number

Shell thickness

5.00E-01

Normal modes

2.00E-02

1.00E-02

0.00E+00

0

Iteration

2011 Siemens Product Lifecycle Management Software

Inc. All rights reserved. Siemens and the Siemens logo are

registered trademarks of Siemens AG. D-Cubed, Femap,

Geolus, GO PLM, I-deas, Insight, JT, NX, Parasolid, Solid

Edge, Teamcenter, Tecnomatix and Velocity Series are

trademarks or registered trademarks of Siemens Product

Lifecycle Management Software Inc. or its subsidiaries in

the United States and in other countries. All other logos,

trademarks, registered trademarks or service marks used

herein are the property of their respective holders.

X7 2662 10/11 B

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Lead Funnels On Funnel Swipe File - TrelloДокумент5 страницLead Funnels On Funnel Swipe File - TrelloKatherie BriersОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Techniques-Of-Attitude-Scale-Construction FullДокумент344 страницыTechniques-Of-Attitude-Scale-Construction FullLuthfi fharuq Al Fairuz67% (3)

- Creative IndustriesДокумент433 страницыCreative IndustriesDanielTavaresОценок пока нет

- Chalk & TalkДокумент6 страницChalk & TalkmathspvОценок пока нет

- 04F Static Members in C++Документ4 страницы04F Static Members in C++sujaydsouza1987Оценок пока нет

- Handout 3 TMR4305 Lecture 13 09 2007Документ5 страницHandout 3 TMR4305 Lecture 13 09 2007sujaydsouza1987Оценок пока нет

- Me 565 Advanced Fea Spring 03 Final Project, Do Not Discuss With Anyone!Документ1 страницаMe 565 Advanced Fea Spring 03 Final Project, Do Not Discuss With Anyone!sujaydsouza1987Оценок пока нет

- Instructor GuideДокумент14 страницInstructor Guidesujaydsouza1987Оценок пока нет

- Base Motion StepsДокумент2 страницыBase Motion Stepscric30Оценок пока нет

- C++ Programming for C Structs and UnionsДокумент1 страницаC++ Programming for C Structs and Unionssujaydsouza1987Оценок пока нет

- ReadmeДокумент1 страницаReadmesujaydsouza1987Оценок пока нет

- Initial Stress And Strain Loading In LUSASДокумент6 страницInitial Stress And Strain Loading In LUSASsujaydsouza1987Оценок пока нет

- Y 2014 P 3 Q 3Документ1 страницаY 2014 P 3 Q 3sujaydsouza1987Оценок пока нет

- Fea TestsДокумент10 страницFea Testssujaydsouza1987Оценок пока нет

- 2007 Paper 11 Question 3Документ1 страница2007 Paper 11 Question 3sujaydsouza1987Оценок пока нет

- Y 2013 P 3 Q 3Документ1 страницаY 2013 P 3 Q 3sujaydsouza1987Оценок пока нет

- Homework Set 10: Heat Transfer and Vibration HomeworkДокумент1 страницаHomework Set 10: Heat Transfer and Vibration HomeworktaniapalomaОценок пока нет

- Check Girder Calculations with Analytical FormulasДокумент1 страницаCheck Girder Calculations with Analytical Formulassujaydsouza1987Оценок пока нет

- Project 1Документ1 страницаProject 1sujaydsouza1987Оценок пока нет

- Hw2 Benchmark Z BeamДокумент7 страницHw2 Benchmark Z Beamsujaydsouza1987Оценок пока нет

- Project 1Документ1 страницаProject 1sujaydsouza1987Оценок пока нет

- Antler JointДокумент1 страницаAntler Jointsujaydsouza1987Оценок пока нет

- Non-Linear Load Balancing: Workshop 9Документ18 страницNon-Linear Load Balancing: Workshop 9sujaydsouza1987Оценок пока нет

- Plates and Shells Assignment, Due Date: April 12: ME 565 Advanced Finite Element Analysis, Spring Term 2003Документ1 страницаPlates and Shells Assignment, Due Date: April 12: ME 565 Advanced Finite Element Analysis, Spring Term 2003sujaydsouza1987Оценок пока нет

- ME 565 Advanced Finite Element Analysis, Spring Term 2003: Geometric Nonlinearity Assignment, Due Date: May 2Документ1 страницаME 565 Advanced Finite Element Analysis, Spring Term 2003: Geometric Nonlinearity Assignment, Due Date: May 2sujaydsouza1987Оценок пока нет

- Intern Project List in MKS UnitsДокумент2 страницыIntern Project List in MKS Unitssujaydsouza1987Оценок пока нет

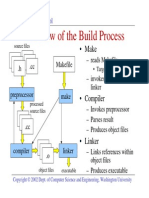

- Overview of The Build Process: - MakeДокумент3 страницыOverview of The Build Process: - Makesujaydsouza1987Оценок пока нет

- Tattoo Designs & Symbols: Tribal TattoosДокумент7 страницTattoo Designs & Symbols: Tribal Tattoossujaydsouza1987100% (1)

- Optimization of Car Rim Using OptiStructДокумент6 страницOptimization of Car Rim Using OptiStructsujaydsouza1987Оценок пока нет

- Manhattan Project SummaryДокумент5 страницManhattan Project Summaryapi-302406762Оценок пока нет

- Keynote Proficient End-Of-Course Test BДокумент7 страницKeynote Proficient End-Of-Course Test Bana maria csalinasОценок пока нет

- Sri Dwi Mutiara-Jurnal CRSS OSNE 1Документ11 страницSri Dwi Mutiara-Jurnal CRSS OSNE 1sri dwi mutiaraОценок пока нет

- 1.1 Thermodynamics 1Документ28 страниц1.1 Thermodynamics 1Lyan SantosОценок пока нет

- Druckabschaltventil enДокумент4 страницыDruckabschaltventil enSakthi Sekar CbiОценок пока нет

- PC 4 Product List 2019 - Pc4Документ28 страницPC 4 Product List 2019 - Pc4ShОценок пока нет

- Hardware Devices Used in Virtual Reality TechnologiesДокумент6 страницHardware Devices Used in Virtual Reality TechnologiesTheMoon LightОценок пока нет

- Marginal Field Development Concepts (Compatibility Mode)Документ17 страницMarginal Field Development Concepts (Compatibility Mode)nallay1705100% (1)

- GbiДокумент14 страницGbimaurice86Оценок пока нет

- GulliverДокумент8 страницGulliverCris LuОценок пока нет

- Final Paper - PARTIALДокумент64 страницыFinal Paper - PARTIALDeanna GicaleОценок пока нет

- Evolution of Computers: A Brief HistoryДокумент15 страницEvolution of Computers: A Brief HistoryshinОценок пока нет

- 2023 Grades 10-12 Mathematics ATP MediationДокумент14 страниц2023 Grades 10-12 Mathematics ATP Mediationkaybeach007Оценок пока нет

- Dayal Bagh: Spircon 2013: Book of AbstractsДокумент202 страницыDayal Bagh: Spircon 2013: Book of AbstractsSant Mat100% (2)

- WaidhanДокумент86 страницWaidhanPatel Nitesh OadОценок пока нет

- Motorship Oct 2023Документ56 страницMotorship Oct 2023Sahil PakhaliОценок пока нет

- Acer Veriton S480G Service ManualДокумент90 страницAcer Veriton S480G Service ManualAndreea Georgiana ChirilaОценок пока нет

- Bashir Ahmad NewДокумент3 страницыBashir Ahmad NewBashir AhmadОценок пока нет

- Presentation SkillsДокумент22 страницыPresentation SkillsUmang WarudkarОценок пока нет

- Texas Final LeadsДокумент36 страницTexas Final Leadsabdullahmohammed4460Оценок пока нет

- DVOR Principle 코이카 양식Документ71 страницаDVOR Principle 코이카 양식Undral Batbayar100% (1)

- Advance Distributed ComputingДокумент2 страницыAdvance Distributed ComputingValia Centre of ExcellenceОценок пока нет

- Effective-Plant-Course Brochure NovДокумент8 страницEffective-Plant-Course Brochure NovAzri HafiziОценок пока нет

- 102DNДокумент2 страницы102DNManuel ZavalaОценок пока нет

- SECURE ROAD BLOCKERS PREVENT VEHICLE ATTACKSДокумент2 страницыSECURE ROAD BLOCKERS PREVENT VEHICLE ATTACKSMuhammad Tahir QamarОценок пока нет

- Kevin Chiu - Solving Procrastination v1.1Документ2 страницыKevin Chiu - Solving Procrastination v1.1TêteHauteОценок пока нет