Академический Документы

Профессиональный Документы

Культура Документы

C210 WML 502

Загружено:

Efrén SantínОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

C210 WML 502

Загружено:

Efrén SantínАвторское право:

Доступные форматы

8410-00

02-3

1. CAUTIONS WHEN WORKING ON ELECTRICAL UNITS

- Disconnect the negative cable from the battery

in advance when working on electrical units.

Make sure to turn "OFF" the ignition switch

and other lamp switches before disconnecting

or connecting the negative battery cable.

(Otherwise, semiconductor parts can be

damaged.)

- Do not drop or appy excessive impact to

sensors and relays.

80

- If a fuse is blown, replace it with a fuse which

has the correct amperage rating. If you use a

fuse with higher capacity than the

specification, the component can be

damaged or catch fire.

10 A

15 A

02-4

- Make sure a connector is connected

securely. Loose connection results in

malfunction.

- When disconnecting a connector equipped with

a lock, press it down to the direction in the below

figure.

- When checking voltage or continuity of the

connector terminal with a circuit tester, connect

the tester probe to the terminal at the harness

side. For a sealed type connector, connect the

probe to the terminal through the hole in the

rubber cap of the wiring. Take care not to

damage the insulation of the wires. Insert the

probe until it contacts the terminal completely.

When inspecting the airbag system, make sure to use a diagnostic device, not a circuit tester.

8410-00

02-5

2. CHECKING CABLES AND WIRES

-

Check for loose connection or rust.

Check terminals and wires for corrosion due to electrolyte leakage.

Check terminals and wires for open circuit.

Check the wire insulation and coat for damage, cracks or deterioration.

Check if the conductive parts of the terminals do not contact with vehicle body or other metal parts.

Check that the grounding part has continuity with mounting bolts and vehicle body.

Check that wires are properly routed.

Make sure that wires are securely fixed to avoid contact with sharp body parts and high-temperature

parts, such as the exhaust manifold and exhaust pipes.

The rotating parts, such as fan pulley and fan belt, perturbative parts and wiring should be secured

tightly at regular intervals.

Secure the wiring between the fixed parts, such as the vehicle body, and vibrating parts, such as the

engine, after slackening it slightly to prevent it from being damaged.

02-6

3. MAJOR CHANGES

Changes for engine compartment fuse box

8410-02

Engine compartment fuse box

- Changed layout

Name

Changes made

ALT terminal and fuse (150A)

Newly adopted

A/C compressor relay

Changed to PCB type

Headlamp high beam

Changed to PCB type

Rear glass/heated mirror relay

Changed to PCB type

Cooling fan high-speed relay

Changed to Micro type

Blower motor relay

Changed to Micro type

Cooling fan low-speed relay

Changed to Micro type

Cooling fan relay

Changed to Micro type

Fuel heater relay

Changed to Micro type

PTC1 heater relay

Changed to Micro type

Power window relay

Changed to Micro type

Starting relay

Changed to Micro type

8410-00

8410-02

Changed connector position

- Change position of connectors A, B and D

8410-02

Changed connector D

- Connector D changed (32 pin 40 pin)

8410-02

- Interior fuse box label changed

Interior fuse box

02-7

02-8

1. OVERVIEW

The fuse and relay boxes in this vehicle are mounted on the engine compartment, left side of the

instrument panel and rear of the instrument cluster (3 off in total). The capacities and its names for each

fuse and relay are marked on the each fuse and relay box cover.

The label attached on each fuse box indicates only major fuses and relays. For detailed information, see

the power distribution circuit diagram.

2. SYSTEM LAYOUT

ICM box

Engine compartment

fuse box

Interior fuse box

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Thomas Calculus 11th (Textbook + Solutions)Документ140 страницThomas Calculus 11th (Textbook + Solutions)Sendhilkumar Alalasundaram76% (33)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Vendor documentation for distribution transformersДокумент148 страницVendor documentation for distribution transformersCu TíОценок пока нет

- Pressure SensorДокумент19 страницPressure SensorMohamed MohebОценок пока нет

- Installation QualificationДокумент17 страницInstallation Qualificationtrinath16198067% (6)

- SCE-Hardware Configuration S7-1200 (2016)Документ94 страницыSCE-Hardware Configuration S7-1200 (2016)Jorge_Andril_5370100% (1)

- C210 WML 201Документ13 страницC210 WML 201Efrén SantínОценок пока нет

- C210 WML 102Документ1 страницаC210 WML 102Efrén SantínОценок пока нет

- C210 WML 209Документ13 страницC210 WML 209Efrén SantínОценок пока нет

- Oferta Red LIneДокумент10 страницOferta Red LIneEfrén SantínОценок пока нет

- Major Dimension: Top ViewДокумент16 страницMajor Dimension: Top ViewEfrén SantínОценок пока нет

- C210 WML 211Документ11 страницC210 WML 211Efrén SantínОценок пока нет

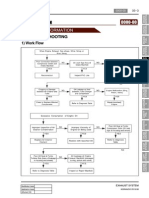

- Troubleshooting: 1) Work FlowДокумент4 страницыTroubleshooting: 1) Work FlowEfrén SantínОценок пока нет

- C210 WML 103Документ1 страницаC210 WML 103Efrén SantínОценок пока нет

- C210 WML 104Документ1 страницаC210 WML 104Efrén SantínОценок пока нет

- C210 WML 206Документ20 страницC210 WML 206Efrén SantínОценок пока нет

- C210 WML 203Документ30 страницC210 WML 203Efrén SantínОценок пока нет

- C210 WML 212Документ11 страницC210 WML 212Efrén Santín0% (1)

- C210 WML 202Документ30 страницC210 WML 202Efrén SantínОценок пока нет

- C210 WML 204Документ10 страницC210 WML 204Efrén SantínОценок пока нет

- C210 WML 207Документ7 страницC210 WML 207Efrén SantínОценок пока нет

- C210 WML 208Документ9 страницC210 WML 208Efrén SantínОценок пока нет

- C210 WML 501Документ14 страницC210 WML 501Efrén SantínОценок пока нет

- C210 WML 213Документ5 страницC210 WML 213Efrén SantínОценок пока нет

- C210 WML 215Документ48 страницC210 WML 215Efrén SantínОценок пока нет

- C210 WML 503Документ120 страницC210 WML 503Efrén SantínОценок пока нет

- C210 WML 210Документ12 страницC210 WML 210Efrén SantínОценок пока нет

- C210 WML 214Документ15 страницC210 WML 214Efrén SantínОценок пока нет

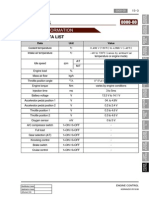

- Specifications: Smart Key Module Component Item SpecificationsДокумент32 страницыSpecifications: Smart Key Module Component Item SpecificationsEfrén SantínОценок пока нет

- C210 WML 505Документ49 страницC210 WML 505Efrén SantínОценок пока нет

- C210 WML 506Документ50 страницC210 WML 506Efrén SantínОценок пока нет

- Lamp Specifications: 1) Exterior LampsДокумент41 страницаLamp Specifications: 1) Exterior LampsEfrén SantínОценок пока нет

- C210 WML 508Документ24 страницыC210 WML 508Efrén SantínОценок пока нет

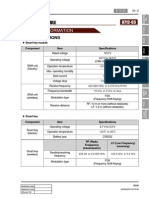

- Unit Item SpecificationДокумент22 страницыUnit Item SpecificationEfrén SantínОценок пока нет

- Specification: Pin No. Specification Pin No. SpecificationДокумент8 страницSpecification: Pin No. Specification Pin No. SpecificationEfrén SantínОценок пока нет

- DC Datasheet B1enДокумент19 страницDC Datasheet B1enykcorОценок пока нет

- Test Electronic ComponentsДокумент3 страницыTest Electronic Components'aleXandy OchavilloОценок пока нет

- Eti Fuses PDFДокумент2 страницыEti Fuses PDFCaseyОценок пока нет

- Circuit Note: Adrv-PackrfДокумент15 страницCircuit Note: Adrv-PackrfwesОценок пока нет

- Triac PDFДокумент3 страницыTriac PDFyuj oОценок пока нет

- HPL - Solar All in One OfferingДокумент2 страницыHPL - Solar All in One OfferingShivamОценок пока нет

- Dialight LED Catalog UL StreetSense-StreetLight Americas EnglishДокумент2 страницыDialight LED Catalog UL StreetSense-StreetLight Americas EnglishDonalyn AdolfoОценок пока нет

- VMAX Local ReplicationДокумент30 страницVMAX Local ReplicationJaap AapОценок пока нет

- Understanding and Testing The Negative-Sequence Directional ElementДокумент12 страницUnderstanding and Testing The Negative-Sequence Directional ElementJosé Miguel Ochoa AcerosОценок пока нет

- VT-05 Operation ManualДокумент12 страницVT-05 Operation ManualKashif Ali Hasnain0% (2)

- 36.331 RRCДокумент217 страниц36.331 RRCBilal AwanОценок пока нет

- PMC-670 English Datasheet (20151026)Документ8 страницPMC-670 English Datasheet (20151026)Ronald H SantosОценок пока нет

- Forte SE-Musicians Guide RevCДокумент374 страницыForte SE-Musicians Guide RevCLJAОценок пока нет

- Surface Roughness Parameters and MeasurementДокумент11 страницSurface Roughness Parameters and MeasurementHafiz Ghulam NabiОценок пока нет

- Maxximo: Diagnostic Manual MAN-00129Документ1 страницаMaxximo: Diagnostic Manual MAN-00129LeelaОценок пока нет

- Pioneer - Avic n1 - Avic x1r crt3423Документ312 страницPioneer - Avic n1 - Avic x1r crt3423psapwell100% (1)

- E+H Menu Docs IOMs Analysis Turbidity BA200CEN Liquisys M Cum 223 253 OMДокумент96 страницE+H Menu Docs IOMs Analysis Turbidity BA200CEN Liquisys M Cum 223 253 OMSuraj PillaiОценок пока нет

- WS-100 To WS-235: Arun SeriesДокумент3 страницыWS-100 To WS-235: Arun Seriesajitp123Оценок пока нет

- Hus VM Block Module Hitachi Thin Image User Guide V 73-03-3xДокумент164 страницыHus VM Block Module Hitachi Thin Image User Guide V 73-03-3xarungarg_itОценок пока нет

- Analogue Electronics 1, DEE 1 Notes - 075733Документ137 страницAnalogue Electronics 1, DEE 1 Notes - 075733Kirimi DanОценок пока нет

- Sure Step Manuals PДокумент70 страницSure Step Manuals PjondeividОценок пока нет

- Mobile Fading-Rayleigh and Lognormal SuperimposedДокумент4 страницыMobile Fading-Rayleigh and Lognormal Superimposedأحمد عليОценок пока нет

- Metaserv 250Документ8 страницMetaserv 250sigitdyОценок пока нет

- Making The Perfect Connection: Protectron Electromech Pvt. LTDДокумент33 страницыMaking The Perfect Connection: Protectron Electromech Pvt. LTDlingubhОценок пока нет

- SIVACON - The Versatile Low-Voltage Switchboard: Type-Tested Power Distribution Board 8PTДокумент28 страницSIVACON - The Versatile Low-Voltage Switchboard: Type-Tested Power Distribution Board 8PTharianaОценок пока нет