Академический Документы

Профессиональный Документы

Культура Документы

Gyro Position Control - Student Manual

Загружено:

Bruno Martins LeiteАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Gyro Position Control - Student Manual

Загружено:

Bruno Martins LeiteАвторское право:

Доступные форматы

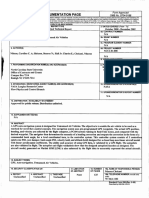

Quanser Specialty Plant: 3 DOF Gyroscope

Gyroscope Position Control

Student Manual

All of Quanser's systems have an inherent open architecture design. It

should be noted that the following experimental setup, accompanying

files, and configuration are merely one of the many possible uses of

this product.

Gyroscope Position Control Laboratory Student Manual

Table of Contents

1. INTRODUCTION..........................................................................................................................................2

2. PREREQUISITES.........................................................................................................................................3

3. OVERVIEW OF FILES..................................................................................................................................3

4. PRE-LAB ASSIGNMENTS.............................................................................................................................5

4.1. Open Loop Transfer Function ..........................................................................................................5

4.2. Proportional Controller.....................................................................................................................7

4.2.1. Routh-Hurwitz Criterion........................................................................................................................8

4.3. Proportional-Integral Controller ....................................................................................................11

4.4. LEAD Controller............................................................................................................................14

4.5. State-Feedback LQR Controller ....................................................................................................16

4.5.1. LQR......................................................................................................................................................17

5. IN-LAB PROCEDURES...............................................................................................................................20

5.1. Proportional Controller in SISO-tool..............................................................................................20

5.2. Proportional-Integral Controller in SISO-tool................................................................................23

5.3. LEAD Controller in SISO-tool.......................................................................................................25

5.4. Simulating LEAD Controller on Linearized Model.......................................................................28

5.5. Simulating LEAD Controller on Non-Linear Model......................................................................33

5.5.1. Non-Minimum Phase Zeros..................................................................................................................37

5.6. LQR Simulation on Non-Linear Plant ...........................................................................................42

5.7. LEAD and LQR Controllers Actual Implementation.....................................................................48

6. OBTAINING SUPPORT...............................................................................................................................52

7. REFERENCES...........................................................................................................................................53

Document Number 807 Revision 1.0 Page i

Gyroscope Position Control Laboratory Student Manual

1. Introduction

The objective of this experiment is to design a position controller for the gyroscope system depicted in

Figure 1. Gyroscopes have become of great practical interest as they are used in control and guidance

systems for air, sea, and space vehicles. The Quanser 3 DOF Gyroscope system can be actuated about

all of its frames using the mounted motors while encoders measure the angle about each axis. In

addition the rotor itself is actuated and measured in the same manner.

Figure 1: Quanser 3 DOF Gyroscope

The outer rectangular frame, outer red gimbal and the inner blue gimbal are designed such that they can

be individually fixed in place upon desire. This allows the users to perform a variety of different

experiments using the device. Throughout this experiment, the outer rectangular frame will be fixed

while all other frames are free to rotate. For instructions on how to fix each frame please refer to [1].

In this laboratory, the gyroscopic effect will be employed to control the angle of the red gimbal , by

Document Number 807 Revision 1.0 Page 2

Gyroscope Position Control Laboratory Student Manual

applying the control command about the blue gimbal only. In order to do this, the rotor has to have

acquired enough angular momentum (RPM) for the gyroscopic effect to take place. Therefore a

controller is required to control the angular speed of the disk while another is required to control the red

gimbal angle . You will design both these controllers during this experiment while the following

topics are covered:

Obtaining the system transfer function from a set of provided equations of motion.

System stability analysis using the Routh-Hurwitz method.

System stability analysis using the Root Locus method and the MATLAB 'sisotool'.

Effects of non-minimum phase zeros on the system response.

State-feedback control design using LQR.

Friction estimation.

As mentioned earlier all rotating frames of the Quanser 3 DOF Gyroscope plant can be fixed upon

desire giving the user the flexibility to perform various experiments with different setups. For example

the entire material covered in this experiment can be used to perform the same set of tasks with the red

gimbal fixed and the rectangular frame being controlled. As another setup the blue gimbal can be fixed,

while the red gimbal is actuated to control the angle of the rectangular frame.

Please keep in mind that as the purpose of this experiment is to emphasize on design, simulation and

implementation of a control system for the gyro, minimal focus is put on the modeling procedure

involved to obtain equations of motion for this system. However the equations are used throughout the

laboratory to design and implement a complete control system. If you are interested in detailed

information on obtaining equations of motion for the gyro, please refer to [2].

2. Prerequisites

In order to successfully carry out this laboratory, the user should be familiar with the following:

Data acquisition card (e.g. Q8), the power amplifier (e.g. AMPAQ), and the main components

of the Gyroscope (e.g. actuator, sensors), as described in References [3], [4], and [1]

respectively.

Wiring and operating procedure of the Gyroscope plant with the AMPAQ and DAC device, as

discussed in Reference [1].

Transfer function fundamentals, e.g. obtaining a transfer function from a differential equation.

3. Overview of Files

Table 1 below lists and describes the various files supplied with the Gyroscope Position Control

laboratory.

Document Number 807 Revision 1.0 Page 3

Gyroscope Position Control Laboratory Student Manual

File Name

Description

Gyro Position Control Student

Manual.pdf

This laboratory guide contains pre-lab and in-lab exercises

demonstrating how to design an implement a control system

on the Quanser gyroscope plant using QUARC.

Gyro User Manual.pdf

This user guide contains general information on the

gyroscope hardware, its accompanying devices, and wiring

procedure.

Gyro_model_params.m

The main MATLAB script that sets the necessary

parameters required to perform this laboratory. Run this file

only to setup the experiment!

s_gyro_position_control_linear.mdl

Simulink model that simulates a LEAD controller on the

linearized gyroscope plant.

s_gyro_position_control_nonlinear.mdl Simulink model that simulates a LEAD controller on the

non-linear gyroscope plant.

s_gyro_position_control_lqr.mdl

Simulink model that simulates an LQR controller on the

non-linear gyroscope plant.

q_gyro_calibrate.mdl

Simulink model used to reset the encoder counts on the

actual gyroscope hardware.

q_gyro_position_control.mdl

Simulink model used to implement both LEAD and LQR

controllers on the actual gyroscope hardware.

d_gui_lqr_tuning.m

MATLAB file that creates a user input dialog box for

interactive LQR controller tuning. The dialog box allows

input of the Q and R weighting matrices as well as saving

the parameters, for future reference to the following file:

lqr_tuning_logfile.txt.

d_gui_lqr_tuning.fig

MATLAB GUI file that contains the graphical user interface

used in interactive LQR controller tuning.

Table 1: Files supplied with the Gyroscope Position Control experiment.

Document Number 807 Revision 1.0 Page 4

Gyroscope Position Control Laboratory Student Manual

4. Pre-Lab Assignments

4.1. Open Loop Transfer Function

The following pair of equations describe the motion of the Gyroscope plant and were obtained by

consulting [2].

J y h

=M y

[1]

h J

z =0

[2]

Figure 2 shows the reference co-ordinate frame that results when the configuration mentioned in

section 1 is adopted with the Quanser 3 DOF Gyroscope system.

Figure 2: 3 DOF Gyroscope Co-ordinate Frame

In equations [1] and [2] Jy is the moment of inertia around the y-axis, is the angle about the y-axis, h

is a constant calculated based on the moment of inertia of the gyroscope rotor about its own axis as well

as its RPM. The variable is the angle about the z-axis and is the variable we are interested in

controlling. As mentioned earlier the only actuated axis in this SISO system is the y-axis and the

control input is the torque applied in this direction denoted by My. Finally Jz is the moment of inertia

about the z-axis.

The block diagram shown in Figure 3 is a simplified general feedback system with a compensator

block, C(s), denoting the controller and a G(s) block denoting the Gyroscope plant. The measured

output, Y(s) which in our case is , is supposed to track the reference signal R(s).

Document Number 807 Revision 1.0 Page 5

Gyroscope Position Control Laboratory Student Manual

Figure 3: Typical Feedback Diagram

In order to design the controller block C(s) that can stabilize the gyroscope plant, we will apply various

control schemes starting with a basic proportional controller and inspect the stability of the system. But

before applying the proportional control, we need to come up with the open loop plant transfer function

G(s).

1. Using equations [1] and [2] derive the open loop transfer function G(s) for the gyroscope plant

from input My to output .

0 1 2

2. The following table contains numerical values for the parameters appearing in the system

Document Number 807 Revision 1.0 Page 6

Gyroscope Position Control Laboratory Student Manual

equations of motion. Use these values to obtain the numerical open-loop transfer function G(s).

Parameter

Numerical

Value

1.0891

Unit

kg m

s

Jy

0.0026

Jz

0.0342

kg m

kg m

2

2

Table 2: Parameter Numerical Values

0 1 2

4.2. Proportional Controller

In this section a simple proportional controller will be studied as the C(s) block in Figure 3. The general

form for a proportional controller is:

C( s ) = k p

[3]

This controller is simply a gain that is multiplied by the error signal and fed into the plant. In this

section we will obtain the closed loop transfer function from the reference input to the system output.

This transfer function now includes the effect of the controller and can be used to determine whether a

proportional controller can stabilize the gyroscope plant or not.

Document Number 807 Revision 1.0 Page 7

Gyroscope Position Control Laboratory Student Manual

1. With C(s) = kp, obtain the complete closed-loop transfer function from the reference input R(s)

to output Y(s). Provide both parametric and numerical transfer functions.

0 1 2

A system is deemed to be stable if the poles of its closed loop transfer function lie strictly in the left

half of the complex plane. In other words in order for a system to be stable the real part of all the poles

of its closed loop transfer function must be negative. There are various methods available to check for

stability of a linear system. The Routh-Hurwitz stability criterion is a necessary (and frequently

sufficient) method to establish the stability of a SISO system. This method works directly with the

characteristic polynomial associated with the closed loop transfer function to determine if there are any

poles with positive real part that will give rise to system instability. The next section gives a brief

discussion on the Routh-Hurwitz procedure and then applies it to the above controller. For more details

on this method and its special cases you are encouraged to refer to your course text book where this

material is covered.

4.2.1. Routh-Hurwitz Criterion

Consider a characteristic polynomial of the following form:

Document Number 807 Revision 1.0 Page 8

Gyroscope Position Control Laboratory Student Manual

n1

P s=a n s a n1 s

[4]

...a 1 sa 0

The Routh-Hurwitz method consists of forming a table that has n rows and the following general

structure:

an

an-2

an-4

...

an-1

an-3

an-5

...

b1

b2

b3

...

c1

c2

c3

...

...

...

...

...

Table 3: General Form of a Routh-Hurwitz Array

where the elements bi and ci can be computed as follows:

bi =

ci =

an 1 an 2 i an an 2 i 1

an 1

b1 an 2 i 1 bi + 1 an 1

b1

[5]

[6]

The number of sign changes in the first column of the Routh-Hurwitz table indicates the number of

unstable poles for the closed loop system. Therefore if the entries in the first column of the RouthHurwitz array are all positive or all negative the closed loop system can be deemed as being stable. As

mentioned above you are encouraged to refer to your course textbook or the web for more details on the

Routh-Hurwitz method and its special cases.

1. Using the Routh-Hurwitz method check for the stability of the closed loop system obtained by

applying a proportional controller to the Gyro plant.

Document Number 807 Revision 1.0 Page 9

Gyroscope Position Control Laboratory Student Manual

0 1 2

In the later in-lab sections you will be asked to use the MATLAB siso-tool to check whether a

proportional controller is sufficient for stabilizing the gyroscope plant.

Document Number 807 Revision 1.0 Page 10

Gyroscope Position Control Laboratory Student Manual

4.3. Proportional-Integral Controller

In this section a proportional-integral (PI) controller will be studied as the C(s) block in Figure 3. The

general form for a PI controller is:

C( s ) =

k p ( TI s + 1 )

TI s

[7]

This is a feedback controller that drives the gyroscope plant with a weighted sum of the error

(difference between the output and the desired set-point) and the integral of that value. In equation [7]

kp is the proportional gain and TI is chosen to place a zero on a desired location on the real axis. In this

section we will obtain the closed loop transfer function from the reference input to the system output.

This transfer function now includes the effect of the controller and can be used to determine whether a

PI controller can stabilize the gyroscope plant or not.

1. With C(s) as defined in [7], obtain the complete closed-loop transfer function from the reference

input R(s) to output Y(s). Provide both parametric and numerical transfer functions.

0 1 2

Document Number 807 Revision 1.0 Page 11

Gyroscope Position Control Laboratory Student Manual

2. Using the transfer function you obtained in the previous question, form the Routh-Hurwitz table

for the gyroscope plant driven by a PI controller.

0 1 2

3. Analyze the Routh-Hurwitz table you obtained in the previous question to conclude whether the

gyroscope plant can be stabilized when driven by a PI controller.

Document Number 807 Revision 1.0 Page 12

Gyroscope Position Control Laboratory Student Manual

0 1 2

Document Number 807 Revision 1.0 Page 13

Gyroscope Position Control Laboratory Student Manual

4.4. LEAD Controller

In this section a LEAD controller will be studied as the C(s) block in Figure 3. The parametric transfer

function of the LEAD controller under study in this section is:

C( s ) =

k (s + )

s+

[8]

This controller introduces a pole-zero pair into the open loop transfer function. In this section we will

use the Routh-Hurwitz method to determine if there are any possible combinations of and that will

cause the above controller to stabilize the closed loop gyroscope system. You will also check for the

stability of the above system during the lab session and using the MATLAB 'sisotool' utility.

1. With C(s) as defined in [8], obtain the complete closed-loop transfer function from the reference

input R(s) to output Y(s). Provide both parametric and numerical transfer functions.

0 1 2

Document Number 807 Revision 1.0 Page 14

Gyroscope Position Control Laboratory Student Manual

2. Using the transfer function you obtained in the previous question, form the Routh-Hurwitz table

for the gyroscope plant driven by a LEAD controller.

0 1 2

3. Analyze the Routh-Hurwitz table you obtained in the previous question to conclude whether the

gyroscope plant can be stabilized when driven by a LEAD controller.

0 1 2

Document Number 807 Revision 1.0 Page 15

Gyroscope Position Control Laboratory Student Manual

4.5. State-Feedback LQR Controller

In this section a state-feedback controller will be applied to the gyroscope plant. We will first examine

whether state-feedback can be used to stabilize this system or not. In order to do so we should refer

back to equations [1] and [2] and use them to obtain a state-space representation in the following form:

x = AxBu

y=CxDu

[9]

1. Using equations [1] and [2] and the state vector given below, obtain the complete state-space

representation for the gyroscope plant. Provide both parametric and numerical values for A and

B matrices.

x=

[10]

Document Number 807 Revision 1.0 Page 16

Gyroscope Position Control Laboratory Student Manual

0 1 2

4.5.1. LQR

A system is deemed as being controllable if its poles can be placed at any desired location via statefeedback. One method of determining if a system is controllable is called the rank test. In performing

the rank test a matrix called the controllability matrix is first obtained which has the following form:

2

n1

C A , B =[ B , AB , A B , ... , A

B]

[11]

where A is an n x n matrix. If the controllability matrix has full rank (ie. rank (CA,B) = n) the system is

controllable meaning that its closed loop poles can be placed at any desired location using statefeedback.

Once a system has proven to be controllable the LQR method can be used to design a controller of the

following form:

u= Kx

[12]

where K is the control gain obtained by using the LQR method and x is the state-vector which in the

case of our gyroscope plant was defined in equation [10]. In general the LQR method finds the signal

u(t) as defined above that minimizes the cost function:

Document Number 807 Revision 1.0 Page 17

Gyroscope Position Control Laboratory Student Manual

J =

T

T

x( t ) Q x( t ) + u( t ) R u( t ) dt

[13]

.

where Q and R are user-defined weighting matrices that can be tuned in the design process to obtain

desired performance. For any chosen Q and R the LQR method finds the state-feedback gain that will

result in minimizing the cost function defined in [13].

1. Use the rank test to show that the gyroscope plant is controllable.

0 1 2

One of the problems with the LQR method is that there are little guidelines for choosing the Q and R

weighting matrices. Typically they are initially set to their corresponding identity matrices, the

optimization algorithm is ran and the system is simulated using the generated gain to observe the

closed-loop response. The weighting matrices are then adjusted until the desired performance is

obtained. For the gyroscope plant the weighting matrices will be of the following form:

q1 0 0

Q= 0 q 2 0

0 0 q3

and

R=1

[14]

It is useful to gain some insight on how the weighting parameters affect the gain being generated when

using LQR:

1. Expand the expression under the integral of the cost function given in [13] such that it is written

in terms of the weighting parameters qi , the system states and the generated state-feedback gain

vector.

Document Number 807 Revision 1.0 Page 18

Gyroscope Position Control Laboratory Student Manual

0 1 2

2. Based on the result you obtained in the previous question determine which gains are primarily

affected by which weighting parameter. Give the correlations between the qi and the elements of

K.

0 1 2

Document Number 807 Revision 1.0 Page 19

Gyroscope Position Control Laboratory Student Manual

5. In-Lab Procedures

During the In-Lab procedure you will first use the MATLAB siso-tool utility to verify your findings in

the pre-laboratory section on different control actions on the gyroscope plant. Next a controller that

shows to be able to stabilize the plant will be simulated on the linearized gyroscope model that you

obtained earlier. This controller will also be applied to a non-linear model of the gyroscope (which is

the actual case) and its performance will be compared to that of the controller acting on the linearized

model. Finally this controller will be implemented on the actual gyroscope plant. A state-feedback

controller designed using LQR is also provided to be implemented on the gyro plant. You will tune this

controller to improve its performance using the intuition you have developed during the pre-laboratory

exercises in section 4.5.1.

5.1. Proportional Controller in SISOtool

The MATLAB siso-tool utility provides a SISO design GUI for interactive compensator design. This

graphical environment allows the user to design single-input/single-output controllers using root locus,

Bode diagrams, Nicholse and Nyquist techniques. The siso-tool can also provide response plots for

various input types such as step and ramp with real-time update as you tune your controller parameters.

You will use the root locus diagrams to design controllers in this laboratory. As mentioned above the

controllers studied in the pre-laboratory section will be examined using the siso-tool and the root locus

diagrams. The first controller studied in section 4.2 was a proportional controller with the following

transfer function:

C( s ) = k p

[15]

Follow the steps below to design an apply a proportional controller to the gyro plant using the

MATLAB siso-tool environment:

1. Load the MATLAB software.

2. Browse through the Current Directory tab in MATLAB and find the folder that contains the

experiment files supplied.

3. Open the script named Gyro_model_params.m. Make sure that the parameter CONTROL_TYPE

has been set to 'MANUAL' and run the file by clicking on the Run button found in the toolbar or

pressing F5 while the above script is the active window. This sets the necessary values for gyro

parameters such as the ones found in Table 2 and also the open-loop gyro transfer function, G,

into the MATLAB workspace.

4. Close the setup script and type sisotool(G) in the MALTAB command prompt and hit the

enter key. This will open the Control and Estimation Tools Manager and the SISO Design Task

windows. The SISO Design Task window shows a plot of the open-loop system poles in the

polar co-ordinate system as well as an open-loop Bode diagram as depicted in Figure 4. The

Control and Estimation Tools Manager window provides various tools to design and tune

compensator blocks, plot responses to various inputs and also lets you to export and import data

Document Number 807 Revision 1.0 Page 20

Gyroscope Position Control Laboratory Student Manual

between the siso-tool and the MATLAB workspace.

Figure 4: SISO Design Task Window

The purple squares shown in Figure 4 denote the closed loop system poles. You can add poles and

zeros to the closed loop system by right clicking on the root locus plot and selecting Add Pole/Zero

from the drop down menu. This will provide you with another menu from which you can choose what

type of pole or zero (real or complex) you want to add. Once you have selected this clicking any

location on the plot will place your choice of pole/zero on that location and the updated root locus

diagram will be shown. You can also enter the exact location of where you would like your zero/pole to

be placed. To do this bring up the Control and Estimation Tools Manager window and click on the

Compensator Editor tab. The Compensator pane shows the current transfer function of the controller

C(s). To add poles/zeros you can right-click on the Dynamics pane found under the Pole/Zero tab. This

provides you with a drop down menu from which you can choose the type of zero/pole being added.

Once this is selected the corresponding pole or zero is shown in the Dynamics pane. You can edit the

location of an added pole or zero by selecting it from the Dynamics pane and editing its corresponding

value in the Location text box found under the Edit Selected Dynamics tab. Now continuing with our

proportional controller:

5. Looking at [15] we see that the proportional controller is simply a gain and hence does not add

any poles or zeros to the controller transfer function. The value of kp only changes the location

of the poles already present in the system. Try different values for kp by entering them into the

text-box found in front of the drop down menu under the Compensator pane. Examine the

Document Number 807 Revision 1.0 Page 21

Gyroscope Position Control Laboratory Student Manual

resulting changes in the root locus diagram. You can also move backwards meaning you can

manually change the location of the closed-loop system poles by selecting them with your

mouse cursor and moving them around the plot. You can then go to the Control and Estimation

Tools Manager and look at the value of kp that would be required to have the closed-loop poles

in the locations you have chosen. Try placing all three closed-loop poles in the left half plane to

stabilize the system and answer the following question.

1. Can the closed-loop system be stabilized using a proportional controller? If yes, provide the

value of kp that results in a stable system. If no, comment on why this is not possible. Does this

result validate your answer to question 1 in section 4.2.1?

0 1 2

Exit the siso-tool by closing the Control and Estimation Tools Manager window.

Document Number 807 Revision 1.0 Page 22

Gyroscope Position Control Laboratory Student Manual

5.2. Proportional-Integral Controller in

SISO-tool

In this section we examine the proportional-integral controller that was studied in section 4.3. This

controller had the following transfer function:

C( s ) =

k p ( TI s + 1 )

TI s

[16]

Similar to section 5.1 we will use the MATLAB siso-tool to study the effects of applying a PI controller

to the gyro plant. By looking at [15] we see that the PI controller has a pole at the origin and a zero at

-1/TI . Follow the steps below to design an apply a PI controller to the gyro plant using the siso-tool:

1. Type sisotool(G) in the MATLAB command prompt and hit the enter key. This will open the

same two windows (Control and Estimation Tools Manager and SISO Design Task) as

mentioned earlier.

2. In the Control and Estimation Tools Manager window click on the Compensator Editor tab.

3. Right-click in the Dynamics pane found under the Pole/Zero tab and select Add Pole/Zero and

then Real Pole from the menu.

4. The added pole will be shown under the Dynamics pane with a default location of -1. Since our

controller has a pole at zero, select the newly added pole under the Dynamics pane and change

its value to zero in the text-box found in front of Location under the Edit Selected Dynamics

pane.

5. Right-click in the Dynamics pane again and select Add Pole/Zero and then Real Zero from the

menu.

6. The added zero will be shown under the Dynamics pane with a default location of -1. You can

choose a starting value for TI that will result in a corresponding zero location and enter this as

the location of the newly added zero using the same procedure as explained in step 4 above.

7. You can now look at the resulting root locus diagram by opening up the SISO Design Task

window. Notice that there are now 4 purple squares corresponding to the four closed-loop

system poles. The red circle denotes the zero you have added while the red cross at the origin

corresponds the pole you placed at zero. The three original open-loop system poles are also

denoted by blue crosses seen on the imaginary axis and the origin although the open-loop pole

at the origin now lies under the new pole we have added there. You can select any of the closed

loop poles (purple squares) and move them around. This will change the value of kp appearing in

[16].

8. Vary the location of your added zero as well as the proportional gain kp to try to stabilize the

system by placing all four closed loop poles in the left half plane and answer the following

question.

Document Number 807 Revision 1.0 Page 23

Gyroscope Position Control Laboratory Student Manual

1. Can the closed loop system be stabilized using a PI controller? If yes provide the controller

transfer function. If no comment on why this is not possible. Does this result validate your

answer to question 3 in section 4.3?

0 1 2

Exit the siso-tool by closing the Control and Estimation Tools Manager window.

Document Number 807 Revision 1.0 Page 24

Gyroscope Position Control Laboratory Student Manual

5.3. LEAD Controller in SISO-tool

In this section the LEAD controller of section 4.4 will be studied using the MATLAB siso-tool. The

controller had the following transfer function:

C( s ) =

k (s + )

s+

[17]

Similar to the last two sections the siso-tool will be used to introduce a pole-zero pair into the closedloop transfer function and tune the pole locations by varying k trying to place all poles in the left half

plane and hence stabilizing the system. Follow the steps below to design the LEAD controller defined

in [17]:

1. Type sisotool(G) in the MATLAB command prompt and hit the enter key. This will open the

same Control and Estimation Tools Manager and SISO Design Task windows as in the last two

sections.

2. In the Control and Estimation Tools Manager window click on the Compensator Editor tab.

3. Right-click in the Dynamics pane found under the Pole/Zero tab and select Add Pole/Zero and

then Real Pole from the menu.

4. The added pole will be shown under the Dynamics pane with a default location of -1. Select a

location for this pole keeping in mind that poles in the right hand plane give rise to system

instability and enter it as the pole location.

5. Right-click in the Dynamics pane again and select Add Pole/Zero and then Real Zero from the

menu.

6. The added zero will be shown under the Dynamics pane with a default location of -1. Choose a

value for the zero location () and enter it.

7. You can now look at the resulting root locus diagram. Notice that regardless of the shape of the

root locus plot there are now 4 closed-loop poles as indicated by the 4 purple squares. The three

original open-loop poles are also denoted by blue crosses two of which lie on the imaginary

axis and the third located at the origin.

8. Vary the location of the compensator pole/zero pair that you have added and tune the k

parameter in [17] by moving the closed-loop poles (the purple squares) around and try to place

all 4 closed-loop poles in the left half plane. You can use the zoom button found in the toolbar

above the plot to change the zoom level as sometimes selecting between adjacent poles/zeros

becomes difficult depending on your design values. Answer the following question once you are

done tuning your controller:

Document Number 807 Revision 1.0 Page 25

Gyroscope Position Control Laboratory Student Manual

1. Can the closed loop system be stabilized using a LEAD controller? If yes provide the controller

transfer function. If no comment on why this is not possible.

Document Number 807 Revision 1.0 Page 26

Gyroscope Position Control Laboratory Student Manual

2. How does your answer to the above question compare to what you obtained in question 3 of

section 4.4?

Document Number 807 Revision 1.0 Page 27

Gyroscope Position Control Laboratory Student Manual

0 1 2

Exit the siso-tool by closing the Control and Estimation Tools Manager window.

5.4. Simulating LEAD Controller on

Linearized Model

In this section you will be given a LEAD controller. You will first simulate this controller on the

linearized model of the gyro that was obtained during the pre-laboratory section. Then you will be

prompted to tune this controller using the siso-tool until it satisfies the two conditions below:

Rise Time < 2 s

% OS < 20

Controller step response peak Amplitude < 5

Use the following LEAD Controller to start:

C s =17.35

23.81s

s29.41

[18]

Follow the steps below to import this controller into the siso-tool environment so that you can begin

tuning it for specifications:

1. Save the above controller transfer function in the MATLAB workspace under the variable

named C by typing the following in the MATLAB command prompt and hitting the enter key.

(If you have closed MATLAB or cleared the workspace from the beginning of this lab re-run the

Gyro_model_params.m script so that the gyro open-loop transfer function, G, is loaded into

the workspace)

C = 17.35*(23.81-s)/(s+29.41);

2. Type sisotool(G) in the MATLAB command prompt and hit the enter key.

3. In the SISO Design for SISO Design Task window click on file and select Import.

Document Number 807 Revision 1.0 Page 28

Gyroscope Position Control Laboratory Student Manual

4. In the System Data window that pops up, double-click in the cell corresponding to C (third row,

second column) and change its value from 1 to C. Click on OK when you're done.

5. Looking at the resulting root locus diagram it is clear that the system is stable.

6. Click on the Analysis tab in the SISO Design for SISO Design Task window and select

Response to Step Command. This will open the LTI Viewer for SISO Design Task window in

which the closed loop step response of the system is plotted in blue. The green plot shows the

output of the controller in response to the step command. As mentioned earlier one of the design

specifications is to keep this value below a threshold of three which is clearly not met under the

current controller.

7. Right-click on the step response plot and select Characteristics and then Rise Time from the

menu. This causes the rise times of both responses to be shown so that you can see the value of

this design requirement while tuning.

8. Without closing the Control and Estimation Tools Manager and SISO Design Task windows,

use the MATLAB current directory window to open the Simulink model named

s_gyro_position_control_linear.mdl. This model is shown below. The Input block sets the

reference signal to a square wave with an amplitude of 1 and frequency of 0.1 Hertz. The system

output is the gyro angle about the z-axis, . The Compensator block holds the C(s) controller

that you entered above, and the Plant block holds the linearized gyro model, G, that was

obtained in the pre-laboratory section.

Figure 5: Gyro Position Control Simulation Model

9. Run the simulation by clicking on the Start simulation button found in the toolbar. Examine the

Torque and Psi () scopes. Figures 6 and 7 below depict plots of these parameters under the

controller defined in [18]. Keep in mind that as mentioned in section 1 we are controlling the

gyro angle about the z-axis by actuating the plant only and only about the y-axis. This is a direct

result of the Gyroscopic Effect. Stop the simulation by clicking on the Stop simulation button

found in the Simulink toolbar.

Document Number 807 Revision 1.0 Page 29

Gyroscope Position Control Laboratory Student Manual

Figure 6: Gyro Angle (rad) Under Controller [18]

Figure 7: Control Signal Under Controller [18]

As you have already noticed, there is a fairly large amount of overshoot on the gyro angle . One way

to measure this overshoot is to type max(Psi) in the MATLAB command prompt and hitting enter.

The scope showing this variable in the Simulink model is also saving it to the workspace. Therefore

running the above command returns a two element vector. The first element is the simulation time at

which the maximum amplitude has been recorded and the second element is this value. Of course there

are many other ways to measure this overshoot such as plotting against time in a MATLAB figure

and using a data cursor to measure the overshoot.

1. Using the above procedure to measure the overshoot or any other preferred method, calculate

the percentage overshoot of the closed-loop system output when running under controller [18].

0 1 2

Document Number 807 Revision 1.0 Page 30

Gyroscope Position Control Laboratory Student Manual

Go back to the SISO Design for SISO Design Task window. Also have the LTI Viewer for SISO Design

Task window which is showing the system step response open. Begin tuning the controller by moving

the compensator pole and zero around. You can also modify the proportional gain k, by moving the

closed-loop poles (purple squares) around. Notice that the step responses change in real-time while you

tune the controller. Tune the controller until the controller step response amplitude is below 5.

Remember the other two specifications as well. As mentioned earlier you can right-click on the plot on

LTI Viewer for SISO Design Task window and select Characteristics / Rise Time from the menu to see

a real-time updated value of both response rise times on the graph. Tune the controller until all three

specifications are met.

2. Once all three specifications are satisfied, print the LTI Viewer for SISO Design Task window

that is showing your closed-loop and controller step responses as well as the rise time and attach

it to this report. Also provide the transfer function of your controller. In the SISO Design for

SISO Design Task window click on the Designs tab and select Edit Compensator. The controller

transfer function is shown in the Control and Estimation Tools Manager window under the

Compensator pane.

Document Number 807 Revision 1.0 Page 31

Gyroscope Position Control Laboratory Student Manual

0 1 2

You can now simulate your designed controller on the linearized model and make sure that the design

specifications are satisfied. Follow the steps below:

1. If the s_gyro_position_control_linear.mdl model is still open close it.

2. In the MATLAB command prompt type clear C and hit the enter key.

3. Enter the transfer function of the controller you have designed in the MATLAB command

prompt under the variable C, as was done before for the initial controller.

4. Using the MATLAB current directory, open the Simulink model named

s_gyro_position_control_linear.mdl.

5. Run the simulation and examine the scopes plotting the torque commanded by the controller

and the gyro angle .

6. Once you are done stop the model. Using any preferred method calculate the new percentage

overshoot.

0 1 2

Document Number 807 Revision 1.0 Page 32

Gyroscope Position Control Laboratory Student Manual

5.5. Simulating LEAD Controller on

Non-Linear Model

The open loop model, G, that has been used up to this point to apply and analyze different controller

types is the linearized model obtained in questions 1 and 2 of section 4.1. The actual gyroscope plant

however is non-linear and hence we need to verify whether our earlier findings on the linearized plant

are also valid on the actual one. In this section you will simulate the LEAD controller you have

designed in the previous section on the non-linear gyroscope plant. You will be able to monitor the

system output and make sure that the specifications mentioned in the previous section are still met.

Satisfying a set of specifications on a linearized model does not guarantee that all those specifications

will be met on the non-linear model under the same controller.

In this section you will also use the Virtual Reality toolbox which is a solution for interfacing with

virtual models of dynamic systems over time. You can create virtual worlds or three-dimensional

scenes that allow you too see a real-time animated virtual environment showing the gyroscope and its

movement when being simulated under a user-defined controller.

The

Simulink

model

that

will

be

used

in

this

section

is

named

s_gyro_position_control_nonlinear.mdl and is depicted in Figure 8. The Ref_Command block sets

the desired gyroscope angle to a square wave with amplitude 20 (deg) and frequency 0.1 Hz. The

Continuous Sigmoid block has been used to have control over the maximum velocity and acceleration

that the reference signal can acquire. Notice the Switch block that has been used on the output of the

Continuous Sigmoid block. This switch has been used to ensure that for the first 10 seconds after the

simulation has been started no reference input is applied to the gyro. This is done because the

gyroscope disk requires some time to get to its set-point RPM. If references are applied before this

RPM is reached, the closed-loop system will go unstable since not enough angular momentum has been

acquired for the gyroscopic effect to take place. After the first 10 seconds have passed the reference is

applied to the system and responses can be monitored.

The Gyroscope Non-Linear Plant block implements the non-linear model of the gyroscope to which

you will apply the controller you have designed in the previous section. The input to the plant is a four

element vector. The first two elements of this vector are zero since there is no actuating device present

in the plant that corresponds to these entries. The third element of this vector represents the control

input to the plant which is the torque to be applied about the gyroscope y-axis as explained in section

4.1. The fourth element of this vector is the input to the gyroscope disk motor. This input applies a setpoint RPM of 2000 to the gyroscope disk in order to acquire the required angular momentum for the

gyroscopic effect to take place. The outputs of the Gyroscope Non-Linear Plant block consist of the

gyroscope angles about z and y axes ( and respectively), the current disk position and their

velocities.

The Controller block takes the reference signal and the current value of as inputs. The block

implements the LEAD controller that you have designed in the previous section. The output of this

controller is the motor torque and is hence input to the Gyroscope Non-Linear Plant block. The Linear

Simulation block implements the same simulation as was ran in the previous section and has been

Document Number 807 Revision 1.0 Page 33

Gyroscope Position Control Laboratory Student Manual

included here to compare the controller performance when acting on the linear and non-linear model.

Finally the Psi scope block plots the reference signal versus the gyroscope angle on both the linear

and non-linear models. The Torque scope block plots the control command when acting on both the

linear and non-linear models.

Figure 8: Simulink Model of Non-Linear Gyroscope Plant and LEAD Controller

The VRML block contains the virtual reality simulation that was mentioned earlier. This sub-system

contains a block named VR Sink. You can double-click on this block to see a real-time updated

animation of the gyroscope when being driven by your controller. This lets you monitor gyro's stability

as well as its movements when the model is running.

Document Number 807 Revision 1.0 Page 34

Gyroscope Position Control Laboratory Student Manual

Follow the steps below to apply your earlier designed controller to the non-linear gyroscope plant:

1. If you have closed MATLAB or cleared the workspace since finishing the previous section rerun the setup script named gyro_model_params.m. In the above case your controller transfer

function C(s) is deleted. Therefore enter it again using the MATLAB command prompt under

the variable C as was done in step 1 of section 5.4. When running the above setup script make

sure that the parameter CONTROL_TYPE is set to 'MANUAL'.

2. Using the MATLAB current directory open the Simulink model named

s_gyro_position_control_nonlinear.mdl.

3. Make sure the Ref_Command block has been set to produce a square wave with amplitude

20(deg) and frequency 0.1 Hz.

4. Click on the Incremental build button found in the Simulink toolbar. This can alternatively be

done by selection QUARC and then Build from the menu or pressing ctrl + b while the Simulink

model is the active window.

5. Once the code is successfully built, click on the Connect To Target button found in the

Simulink toolbar and then on the Start real-time code button. Note that selecting QUARC then

Start from the Simulink menu bar also performs the same action.

6. The simulation should now start. Remember that no output should be produced for the first 10

seconds as the gyro disk gets to its set-point RPM. After the first 10 seconds have passed the

reference is applied to the controller. You can open the Psi scope block to see a simultaneous

plot of the reference signal (in blue), response under the controller and linearized plant (in

purple) and response under the controller and non-linear plant (in yellow). Notice that

although the reference signal is set to a square wave, the scopes show a saw-tooth shaped

signal for the reference. This is due to the use of the Continuous Sigmoid block that sets a

maximum speed and acceleration that the reference signal is allowed to acquire.

The response under the linearized plant should be stable as you have already tuned this controller in

the previous section. However as mentioned at the beginning of this section satisfying a set of

specifications on a linearized model does not guarantee that all those specifications will be met on the

non-linear model under the same controller. Therefore you might notice that your controller does not

satisfy the requirements outlined in section 5.4 or is not even stable. If this is the case you should

further tune your controller using the same procedure as followed in the previous section and then try it

on the non-linear plant as instructed above. To do this, first stop the model by clicking on the Stop realtime code button. Now run the siso-tool and import the variable C from the workspace into the SISO

Design Task environment. Open the real-time updated step response window by clicking on Analysis in

the SISO Design Task window and selecting Response to Step Command. Now you can tune your

controller to further satisfy specifications and when you are ready you can enter its new transfer

function in MATLAB as before. You can then re-run the s-gyro_position_control_nonlinear.mdl

model to see the effects of your new controller on the nonlinear model. Each time that you apply your

controller to the non-linear model open the Torque scope block and make sure that the value of the

control command applied to the non-linear plant (yellow plot) stays below the saturation value of 1.5 as

set by the Saturation1 block at the output of the Controller block. If this signal saturates you should try

to decrease the amplitude of the controller step response (green plot) in the LTI Viewer for SISO Design

Task window when tuning your controller. Once you have a stable controller you can open the VRML

sub-system and double-click on the VR Sink block to see the simulated gyroscope virtual environment.

Document Number 807 Revision 1.0 Page 35

Gyroscope Position Control Laboratory Student Manual

1. If your previous controller did not require any further tuning provide its transfer function below.

Also use the Time Figure and Time Figure1 blocks found in the Simulink model to print plots

of reference versus and the control command and attach them to your report. Do the above

with your new controller if your old one required tuning. Show that the control command is

below the saturation value of 1.5. You can use the data cursor by clicking on the Data Cursor

button found above each time figure plot.

0 1 2

Document Number 807 Revision 1.0 Page 36

Gyroscope Position Control Laboratory Student Manual

5.5.1. Non-Minimum Phase Zeros

Consider the following LEAD controller:

C( s ) =

1.41 ( 1 0.38 s )

[19]

1 + 0.04 s

Applying this controller to the open loop plant G that was obtained in question 2 of section 4.1 leaves

us with the following open-loop and closed-loop transfer functions:

G( s ) =

ol

G( s ) =

cl

1.5355 ( 1 0.38 s )

0.3556 10

-5 4

3

2

s + 0.00008892 s + 0.474 s + 1.1861 s

[20]

1.5355 ( 1 0.38 s )

0.3556 10

[21]

-5 4

3

2

s + 0.00008892 s + 0.0474 s + 0.6026 s + 1.5355

Plotting the step response of this closed-loop system using the siso-tool's Response to Step Command

we obtain what is depicted in Figure 9. The blue plot shows the closed-loop system step response from

the reference input to system output which is the gyroscope angle in our case. The green plot shows

the controller step response from its input (error signal) to its output (control command applied to gyro

plant).

Figure 9: Closed-Loop Step Response Under Controller [19]

Document Number 807 Revision 1.0 Page 37

Gyroscope Position Control Laboratory Student Manual

Look more closely to the closed-loop step response in the time interval between zero and about 0.4

seconds. As shown above, the response takes on negative values for a short time interval before

becoming positive again and finally settling at about 1.2 seconds. This is a property of a class of

systems called Non-Minimum Phase systems. In general when the open-loop system has a right-half

plane zero as in [20], the step response takes on negative values for some time before becoming

positive. This is known as a Non-Minimum Phase response or an Inverse Response. Since zeros of the

open-loop forwards transfer function G(s)ol appear as closed-loop zeros as in [21], it is concluded that

whenever G(s)cl has right half plane zeros, the system's step response will exhibit undershoot, taking on

negative values. If there are two or more right half plane zeros the form of the Non-Minimum Phase

response becomes more complex.

Figure 10 below shows a plot of the reference signal versus gyro angle when the controller in [19] is

applied to the non-linear gyro model in the Simulink model s_gyro_position_control_nonlinear.mdl.

The reference signal was set to a square wave with an amplitude of 20 degrees and frequency of 0.1 Hz.

The blue plot shows the reference command while the green plot shows the gyro angle .

Figure 10: Reference vs. Gyro Angle Under Controller [19]

As expected and seen above the non-minimum phase effect is present in the system. In this section you

will try to eliminate or minimize this effect by tuning the controller in [19]. Follow the steps below:

1. If you have closed MATLAB or cleared the workspace since finishing the previous exercise, run

the setup script gyro_model_ params.m.

2. Enter the controller defined in [19] into the MATLAB workspace under the variable C in the

Document Number 807 Revision 1.0 Page 38

Gyroscope Position Control Laboratory Student Manual

same fashion as was done in step 1 of section 5.4.

3. Type sisotool(G) in the MATLAB command prompt and hit the enter key.

4. In the SISO Design for SISO Design Task window click on File and select Import.

5. In the System Data window that pops up change the Data value of the system variable C from 1

to C by double-clicking on the 1 in front of this variable and changing it to C.

6. Click on OK. The SISO Design for SISO Design Task window will show the root locus resulting

by applying this controller to the gyro plant.

7. Click on Analysis and select Response to Step Command in the SISO Design for SISO Design

Task window. This will open the step response plots shown in Figure 9.

8. Begin tuning the controller as before to eliminate the Non-Minimum Phase response. Try to

keep the other specifications outlined in section 5.4 satisfied as well.

9. Once you see a step response that satisfies the specifications without showing a non-Minimum

Phase response click on File in the SISO Design for SISO Design Task window and select

Export.

10. In the SISO Tool Export window that pops up, select the Compensator C component and click

on Export to Workspace. Make sure that the Export As column corresponding the the

compensator has the value C. This will make sure that the compensator is saved in the

workspace under the variable name C that out models are set to use. A Variable Name Conflict

window may open. You can click on Yes.

11. If you have closed the s_gyro_position_control_nonlinear.mdl Simulink model open it using

the MATLAB current directory. If it is still open skip this step.

12. Go to the MATLAB command prompt and type qc_update_model; and hit the enter key. This

will download the new C transfer function to the Simulink model.

13. Set the Ref_Command block to output a square wave with amplitude 20 degrees and frequency

0.1 Hz.

14. Start the simulation by clicking on QUARC in the Simulink model toolbar and selecting Start.

You can now look at various scopes in the model to see the effect of your controller tuning on the nonlinear system response. Remember that as it was mentioned in section 5.5 although a satisfactory

response may be obtained when tuning a controller on the linearized plant, when this controller is

applied to the non-linear model, the closed-loop response will change. If some specifications are not

met or the Non-Minimum Phase response is still present repeat the steps above. Once you come up with

a controller that satisfies the specifications and shows no Non-Minimum Phase response, stop the

model by clicking on the Stop real-time code button.

1. Print a copy of the LTI Viewer for SISO Design Task page showing the closed-loop step

response, rise time and maximum amplitude of your tuned controller and attach it to this report.

Also provide the transfer function of your controller. Show that your controller is satisfying the

specifications of section 5.4 and no non-minimum phase response is present. Is the NonMinimum Phase response removed compared to Figure 9?

Document Number 807 Revision 1.0 Page 39

Gyroscope Position Control Laboratory Student Manual

0 1 2

2. Using the Time Figure and Time Figure1 blocks in s_gyro_position_control_nonlinear.mdl

print plots of the reference versus gyro angle and the torque commanded by the controller

when the reference signal is a square wave with amplitude 20 (deg) and frequency 0.1 Hz.

Attach these plots to your report. Show that the control command is below the saturation

threshold of 1.5. Is the Non-Minimum Phase response removed compared to Figure 10?

Document Number 807 Revision 1.0 Page 40

Gyroscope Position Control Laboratory Student Manual

0 1 2

Document Number 807 Revision 1.0 Page 41

Gyroscope Position Control Laboratory Student Manual

5.6. LQR Simulation on Non-Linear

Plant

Up until this section you have been working with a LEAD controller and have tuned an initial

compensator to satisfy a set of requirements and also to remove the effects of non-minimum phase

response. It was shown in section 4.5.1 that the gyroscope plant is controllable using state-feedback. In

this section you will begin with a state-feedback controller designed using LQR that has nonsatisfactory response. This controller computes a control command of the form u = -Kx, where x is the

state vector as defined in [10] and K is the state-feedback gain, designed using LQR. Using the intuition

you should have developed in section 4.5.1, you are asked to tune the weighting parameters of this LQR

design (Q and R weighting matrices) to improve the controller's performance. The Simulink model that

you will use to perform this section is named s_gyro_position_control_lqr.mdl and shown in Figure

11.

Figure 11: Simulink Model Used to Simulate LQR Controller on Non-Linear Gyro Plant

Document Number 807 Revision 1.0 Page 42

Gyroscope Position Control Laboratory Student Manual

The main structure of this model is similar to that of s_gyro_position_control_nonlinear.mdl. The

only difference is that the Controller block in s_gyro_position_control_nonlinear.mdl held a LEAD

controller for which you would design and enter a transfer function C, in the MATLAB command

prompt. In the model depicted in Figure 11 however, the LQR Controller block implements a statefeedback controller with gain K. Recall that in section 4.5 we defined our state-vector x in the following

form:

x=

[22]

This is why in addition to the reference command, the states defined in [22] are also fed into the

controller under signal names dTheta, Psi and dPsi respectively.

As mentioned in section 4.5.1, in the LQR design process the Q and R weighting parameters are first set

to their corresponding identity matrices and are then tuned to meet some specifications. This is the

same procedure that will be followed in this section starting with the following Q and R factors:

1 0 0

Q= 0 1 0

0 0 1

and R = 1

[23]

Follow the steps outlined below to design and simulate the initial LQR controller on the non-linear

Gyro plant:

1. If you have closed MATLAB or cleared the workspace since finishing the last exercise, open

the MATLAB software, set the current directory to the folder where experiment files are saved,

and run the setup script named Gyro_model_params.m. When running this file make sure that

the parameter CONTROL_TYPE is set to 'MANUAL'. Otherwise skip to step 2.

2. Open the Simulink model named s_gyro_position_control_lqr.mdl. This is the model

depicted in Figure 11.

3. Double-click on the LQR Controller block. This should open the sub-system depicted in Figure

12.

Figure 12: LQR Controller Sub-system

Document Number 807 Revision 1.0 Page 43

Gyroscope Position Control Laboratory Student Manual

As dictated by our state vector x defined in [10], the state feed-back gain K, is a three element

vector [K1, K2, K3], with K1 being the gain on , K2 being the gain on , and K3 acting on

. You can verify this by double-clicking on each of the Gain blocks and checking the gain

values set.

4. Without modifying any of the gain parameters set in the above sub-system, go to the MATLAB

command prompt and enter the A and B model matrices that you calculated in question 1 of

section 4.5 into the MATLAB workspace using the following format and variable names:

A=[a 11 a 12 a13 ; a 21 a22 a 23 ; a 31 a 32 a33 ] ; and

B=[b1 ; b2 ; b 3];

where aii and bii entries correspond to the entry values you have calculated.

5. Our system output is the gyro angle which is the second entry in our state vector defined in

[10]. Therefore enter the C and D matrices into the MATLAB workspace as follows:

C=[0 1 0]; and

D=0 ;

6. With the Simulink model named s_gyro_position_control_lqr.mdl still open type the

following command in the MATLAB command prompt and hit the enter key:

d_gui_lqr_tuning('A', A, 'B', B, 'C', C, 'D', D);

This should open a window similar to the one depicted in Figure 13.

Figure 13: LQR Tuning GUI

Document Number 807 Revision 1.0 Page 44

Gyroscope Position Control Laboratory Student Manual

This is a graphical tool that you will use to perform on-line tuning on the LQR controller that is

applied to the non-linear gyro plant in s_gyro_position_control_lqr.mdl. As seen in Figure 13,

you can vary the diagonal entries in the Q weighting matrix as well as R. Every time that you

make a change, clicking on the Apply button will cause a new gain K to be calculated and

applied to the model automatically. This calculated K is the three element vector that was

mentioned earlier and is obtained using the MATLAB 'lqr' function and the Q and R weighting

parameters that you choose. As seen in Figure 13 and equations in [23] the controller you will

begin with has the identity matrices as its Q and R weighting parameters.

7. Click on Apply. The calculated state-feedback gain K will be calculated and is shown below:

K = [1.03 1.00 0.41]

8. Without closing the LQR Tuning GUI, go back the Simulink model

s_gyro_position_control_lqr.mdl. Make sure that the Ref_Command block is set to output a

square wave with amplitude 20 (deg) and frequency 0.1 Hz. Click on the Incremental build

button found in the Simulink toolbar. This can be alternatively done by selecting QUARC and

clicking on Build or holding ctrl + B while the Simulink model is the active window.

9. Once the model real-time code is built, click on the Connect To Target button and then on the

Start real-time code button to start the simulation. This can be alternatively done by selecting

QUARC and clicking on Start or holding ctrl + J while the Simulink model is the active

window.

10. Once the first 10 seconds have passed (during which the gyroscope disk is being brought up to

desired RPM), the reference is applied and you can monitor the system response by looking at

the Ref vs. Psi and Torque scopes. Figures 14 and 15 show these two plots.

Figure 14: Reference vs. Gyro Angle

Response (Initial LQR Controller)

Figure 15: Control Command (Initial LQR

Controller)

You can open the VRML sub-system and double-click on the VR Sink block, to see a real-time

virtual environment simulation of the gyroscope and its movement in response to the reference

input. Again notice that we are controlling the gyro angle about the z-axis, by only

Document Number 807 Revision 1.0 Page 45

Gyroscope Position Control Laboratory Student Manual

commanding the y-axis which is a direct result of the gyroscopic effect. As seen in Figure 14,

the system response is fairly poor and the steady-state error is clearly much greater than zero.

11. Keep the Simulink model running. Go back to the LQR Tuning GUI. You can now begin tuning

the weighting parameters using the text boxes corresponding to each entry. Once you click on

Apply, the new gain will be calculated and applied to the controller in real-time so you can see

the effect of your tuning immediately on the scopes. Tune the controller until you get zero

steady state error. Also make sure that the torque generated by your controller is not saturated at

the threshold level of 1.5 as set by the Saturation block in the Simulink model.

12. Once you obtain a response in gyro angle that has zero steady-state error stop the model by

clicking on the Stop real-time code button in the Simulink toolbar or clicking on QUARC and

selecting Stop. Provide your tuned Q and R weighting parameters and the resulting statefeedback gain vector K. How does changing each parameter in the Q weighting matrix affect the

resulting K? Does this agree with your answer to question 2 in section 4.5.1?

0 1 2

13. Using the Time Figure blocks in the Simulink model s_gyro_position_control_lqr.mdl print

plots of the Reference versus gyro angle and the torque commanded by the controller when

the non-linear plant is driven by your tuned LQR controller and the Ref_Command block is set

to output a square wave with amplitude 20 (deg) and frequency 0.1 Hz. Attach these prints to

your report.

Document Number 807 Revision 1.0 Page 46

Gyroscope Position Control Laboratory Student Manual

0 1 2

Document Number 807 Revision 1.0 Page 47

Gyroscope Position Control Laboratory Student Manual

5.7. LEAD and LQR Controllers Actual

Implementation

During the previous in-lab exercises you have worked with the linearized as well as the non-linear gyro

plant in simulation and have tuned a LEAD controller and an LQR controller to satisfy a set of

specifications. In this section you will implement these controllers on the actual gyroscope hardware.

You can then monitor the response of each controller when acting on the actual plant. If necessary you

can perform more tuning on your controllers to obtain desired results with the actual hardware. The

Simulink model used in this section is named q_gyro_position_control.mdl and is depicted in Figure

16.

Document Number 807 Revision 1.0 Page 48

Gyroscope Position Control Laboratory Student Manual

Figure 16: Simulink Model Used to Implement LEAD and LQR Controllers on Actual Gyro Plant

The HIL Interfacing block, implements an interface between the Simulink model and the data

acquisition device and eventually the actual gyro hardware. Reading of encoder counts and applying the

control command to gyroscope motors takes place in this block. Included in the HIL Interfacing subsystem, are two position-velocity controllers labeled Wheel Controller and Theta Controller. The

Wheel Controller block sets a reference RPM for the gyroscope disk and applies the required torque to

the disk such that the desired RPM is reached. As explained earlier the reference on the gyro angle is

set to be zero while the disk is acquiring the desired RPM to avoid instability. This is implemented in

the HIL Interfacing sub-system where there is a switch implemented on the Psi torque input to the

DAQ. The wait time before applying references on is set by the parameter DISK_RPM_DELAY in the

setup script Gyro_model_params.m which is set to 10 seconds by default. The reason for having the

Theta Controller block will become clear as you implement you controllers on the actual plant.

Document Number 807 Revision 1.0 Page 49

Gyroscope Position Control Laboratory Student Manual

The Psi LEAD Controller block contains the same sub-system as the one found in the Controller block

of the Simulink model s_gyro_position_control_nonlinear.mdl that you used earlier to simulate a

LEAD controller on the non-linear gyro plant. It takes the reference signal and the current value for the

gyro angle as inputs. The output of this block is the control command calculated by the LEAD

controller defined in the Compensator block. Later in this section you will be prompted to enter the

transfer function of the LEAD controller you have designed in section 5.5.1 to the MATLAB work

space to be used as this compensator.

The Psi LQR Controller block contains the same sub-system as the one found in the LQR Controller

block of the Simulink model s_gyro_position_control_lqr.mdl that you used earlier to simulate an

LQR controller on the non-linear gyro plant. It takes the reference signal, and current values for ,

and as inputs. The output of this block is the control command calculated by the LQR controller.

This controller has a three-element gain K. Later in this section you will be prompted to enter the LQR

gain K, you have designed in part 12 of section 5.6 to the MATLAB work space to be used as this

controller.

The Simulation block contains a sub-system with the same structure as the Simulink models

s_gyro_position_control_nonlinear.mdl and s_gyro_position_control_lqr.mdl that you have used

earlier. Parallel to the actual control implementation running in the above blocks, the Simulation block

simulates the same controllers on the non-linear modeled plant for comparison purposes. The same

reference signal is passed through the same Sigmoid block in both the simulation and actual

implementations. The outputs of this block consist of the simulated gyro angle , LEAD controller and

LQR controller commands. These signals, as well as their actual implementation values are passed to

the Plotting & Scopes sub-system where you can monitor actual versus simulated values for these

parameters. Notice the switch labeled LEAD/LQR found in the top model as well as the Simulation subsystem. This switch select between the two controllers and you need to make sure that both switches are

set to the same controller whenever you are looking at a plot to compare simulation and actual

implementation values.

Finally the Continuous Sigmoid blocks found in both the top model and Simulation sub-system are set

to a maximum velocity and acceleration dictated by the variables SIGMOID_VEL_MAX and

SIGMOID_ACCEL_MAX respectively. These variables are defined in the setup script

Gyro_model_params.m.

Follow the steps below to implement the LEAD and LQR controllers you designed in the previous

sections on the actual gyro plant. Please note that it is assumed that the gyro device is wired to the

AMPAQ unit and the data acquisition card as described in [4].

1. If you have closed the MATLAB software since finishing the last exercise, re-load it.

2. Using the MATLAB current directory browse to the folder where the experiment files are saved

and open the setup script Gyro_model_params.m. Make sure the variable CONTROL_TYPE

is set to 'MANUAL' and run the script.

3. Enter the A and B matrices that you calculated in question 1 of section 4.5 into the MATLAB

work space under the variables A and B.

4. Enter the C and D matrices given in step 5 of section 5.6 into the MATLAB work space under

the variables C and D.

Document Number 807 Revision 1.0 Page 50

Gyroscope Position Control Laboratory Student Manual

5. Enter the transfer function of the LEAD controller you designed in section 5.5.1 into the

MATLAB workspace under the variable name C_s. Use the same syntax as the one given in

step 1 of section 5.4.

6. Using the MATLAB current directory Open the Simulink model named

q_gyro_position_control.mdl which is depicted in Figure 16.

7. Configure DAQ: Open the HIL Interfacing sub-system and double-click on the HIL Initialize

block. Ensure that this block is configured for the DAQ device that is installed in your system.

By default it is setup for the Quanser Q8 Hardware-in-the-Loop board. See [5] for more

information on configuring the HIL Initialize block.

8. Now type the following command in the MATLAB command prompt and hit the enter key:

d_gui_lqr_tuning('A', A, 'B', B, 'C', C, 'D', D);

9. The LQR Tuning GUI shown in Figure 13 comes up. Enter the diagonal entries of the Q

weighting matrix you obtained in step 12 of section 5.6 in the appropriate boxes. Also enter the

value of weighting parameter R you obtained in the same question as above.

10. Click on the Apply button. The LQR gain will be calculated and displayed on the MATLAB

command prompt.

11. Using the MATLAB current directory open the Simulink model named q_gyro_calibrate.mdl.

This model simply consists of a HIL Initialize block that is configured to reset the encoders on

the gyro device. Make sure simulation mode is set to External in the Simulink toolbar and build

the real-time code by clicking on the Incremental build button or selecting QUARC/Start from

the Simulink menu.

12. Once the code is successfully built make sure that the gyro device is in an alignment similar to

the one shown in Figure 17. With the gyro aligned as described above, select QUARC/Start

from the Simulink menu. The code will run for 2 seconds and stop automatically. You can now

close the simulink model q_gyro_calibrate.mdl.

Document Number 807 Revision 1.0 Page 51

Gyroscope Position Control Laboratory Student Manual

Figure 17: 3 DOF Gyroscope Starting Configuration

13. Go back to the Simulink model q_gyro_position_control.mdl and make sure that the

Reference block in the top model and the Ref_Command block in the Simulation sub-system are

both set to output a square wave with amplitude 20 (deg) and frequency 0.1 Hz.

14. Make sure that both LEAD/LQR blocks in the top model and the Simulation sub-system are

switched to the LEAD controller.

15. Make sure the simulation mode is set to External in the Simulink toolbar and build the real-time

code by clicking on the Incremental build button or selecting QUARC/Build from the Simulink

menu.

16. Once the code is successfully built, click on the Connect To Target button and then the Start

real-time code button. This can be alternatively done by selecting QUARC/Start from the

Simulink menu. Make sure to hold the gyroscope in the configuration shown in Figure 17

when starting the code and release it 3-4 seconds after the gyroscope disk has started

rotating. Avoid touching the wheel with your fingers and hold blue and red frames only.

17. The real-time code will now begin running and the gyroscope disk will start rotating and

speeding up to desired RPM. After the first 10 seconds have passed the references set earlier are

applied and the your controller kicks in.

If at any point during the time that the real-time code is running the system

becomes unstable, stop the model immediately by clicking on the Stop real-time

code button and consult a teaching assistant.

Document Number 807 Revision 1.0 Page 52

Gyroscope Position Control Laboratory Student Manual

18. The gyro angle should be now tracking a reference square wave of amplitude 20 (deg) and

frequency 0.1 Hz. Open the Plotting & Scopes sub-system and double-click on the Reference vs.

Simulated vs. Actual Psi scope. The red plot is showing the reference input, the blue plot is

showing the simulated gyro angle and the purple plot is showing the actual gyro angle .

Notice that although the reference is set to a square wave the reference plot does not have the