Академический Документы

Профессиональный Документы

Культура Документы

SoucyBandTrackInstallationA 654RB

Загружено:

sohail749Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

SoucyBandTrackInstallationA 654RB

Загружено:

sohail749Авторское право:

Доступные форматы

M113 VEHICLE FAMILY

RUBBER TRACK

INSTALLATION INSTRUCTIONS

SOUCY TRACK SYSTEM

04-M113-1ENS

(SPLIT IDLER)

04-M113-1ENS

A-654 (2003/09/18) Rv. B

Lithod in Canada

M113 VEHICLE FAMILY / RUBBER TRACK INSTALLATION INSTRUCTIONS

SOUCY TRACK SYSTEM

04-M113-1ENS

TABLE OF CONTENTS

List of parts and tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Installation of complete kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

A. Vehicle preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

B. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

C. Tensionning the track . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Vehicle operation with rubber track . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

04-M113-1ENS

A-654 (2003/09/18) Rv. B

Lithod in Canada

M113 VEHICLE FAMILY / RUBBER TRACK INSTALLATION INSTRUCTIONS

SOUCY TRACK SYSTEM

04-M113-1ENS

LIST OF PARTS AND TOOLS

Assembly Components

Please refer to assembly drawing No. E1030022

Special Tools

2 Sprocket guide pins

Standard Tools Required

General mechanics tool kit

Adequate lifting equipment

2 Jack stands

Air wrench

Grease gun with pressure gauge

Torque wrench

Lift truck (if available)

16 ft string (for measuring)

04-M113-1ENS

A-654 (2003/09/18) Rv. B

Lithod in Canada

M113 VEHICLE FAMILY / RUBBER TRACK INSTALLATION INSTRUCTIONS

SOUCY TRACK SYSTEM

04-M113-1ENS

WARNING

Always take safety precautions before attempting any work

on your vehicle.

04-M113-1ENS

A-654 (2003/09/18) Rv. B

Lithod in Canada

M113 VEHICLE FAMILY / RUBBER TRACK INSTALLATION INSTRUCTIONS

SOUCY TRACK SYSTEM

04-M113-1ENS

INSTALLATION OF COMPLETE KIT

WARNING

All instructions below are sequential. All operations requires the preceeding ones to be

safe and complete.

A.

VEHICLE PREPARATION

a.1) Position the vehicle on a hard flat surface. Ensure adequate clearance to move and work

around the vehicle easily.

a.2) Block the vehicle.

a.3) Remove track shrouds and covers.

a.4) Empty grease completely from track tension adjuster (one side at a time only).

a.5) Remove pin and separate the metal track.

a.6) Roll vehicle off metal track and store away.

a.7) Ensure proper alignement of road wheels and idler wheels.

a.8) Jack one side at a time. Lift the vehicle and secure with two jack stands (minimum of 10 tons

each). (See fig. 1)

a.9) Remove idler and road wheels.

a.10) Remove idler and road wheel studs.

a.11) Remove drive sprockets.

6,5 inches

min.

fig. 1

04-M113-1ENS

A-654 (2003/09/18) Rv. B

Lithod in Canada

M113 VEHICLE FAMILY / RUBBER TRACK INSTALLATION INSTRUCTIONS

SOUCY TRACK SYSTEM

B.

04-M113-1ENS

INSTALLATION

b.1) Install (8) 5/8 nc X 33/4 long wheel

studs on each of the six road wheels.

Remove hubs and press new studs in. If

a press is not available, use a road

wheel spacer for take-up and tighten

nuts to pull the stud into the flange.

(See fig. 2)

fig. 2

b.2) Remove idler hubs. Install the new

threaded ring inside on the idler flange.

Align the ring with the existing holes

and drill/counter sink 5/16 holes.

(See fig. 3)

fig. 3

b.3) Put the inner road wheel first, then the

spacers and complete installation with

the outer road wheels. Insert flat

washers and nylon lock nuts and torque

to 160 10 ft-lb (210 15 Nm).

(See fig. 4)

fig. 4

04-M113-1ENS

A-654 (2003/09/18) Rv. B

Lithod in Canada

M113 VEHICLE FAMILY / RUBBER TRACK INSTALLATION INSTRUCTIONS

SOUCY TRACK SYSTEM

04-M113-1ENS

b.4) Install (2) guide pins on the final drive.

No torque is required but all the threads

need to be fully engaged. (See fig. 5)

fig. 5

b.5) NOTE : The right side (106 pitches) of

the track system is shown on this

picture. Perform the same steps for the

left side but use the 105 pitches track.

Count the number of pitches to make

sure you have the proper track length.

Lay the track closely by the road wheels

without touching them. Ensure proper

orientation. (See fig. 6)

FORWARD

DIRECTION OF

BELTING

fig. 6

b.6) Lift the top run of the track over the

road wheels. Slide the track under the

road wheels. Make sure the track

guides are properly aligned with the

road wheels, and lower the vehicle.

(See fig. 7)

WARNING

Before lowering the vehicle, thoroughly

check all components and remove any

objet that interferes with the vehicle.

04-M113-1ENS

A-654 (2003/09/18) Rv. B

Lithod in Canada

M113 VEHICLE FAMILY / RUBBER TRACK INSTALLATION INSTRUCTIONS

SOUCY TRACK SYSTEM

04-M113-1ENS

fig. 7

b.7) Move the vehicle back (or pull the track by hand forward) to leave as little space as possible

between the track and the last road wheel. (See fig. 8)

fig. 8

b.8) Install the first half-sprocket on the guide

pins. Do not push all the way in.

(See fig. 9)

GUIDE

NOTCH

DO NOT PUSH

HALF-SPROCKET

ALL THE WAY

IN YET !

fig. 9

04-M113-1ENS

A-654 (2003/09/18) Rv. B

Lithod in Canada

M113 VEHICLE FAMILY / RUBBER TRACK INSTALLATION INSTRUCTIONS

SOUCY TRACK SYSTEM

04-M113-1ENS

b.9) Install the track over the first halfsprocket. Install the second half-sprocket

on the guide pins. Make sure the

sprockets are properly timed.

(See fig. 10)

ALIGN GUIDE

NOTCHES

TOGETHER

fig. 10

b.10) Secure the sprocket with 1/8 thick

outer ring (10 hole washers 61/2 dia)

and 5/8 nc x 3 long cap screws. Do

not use any other type of washers.

Remove the guide pins and screw the

last 5/8 nc x 3 long cap screws.

WARNING : You may damage the

final drive seal if :

A) You do not use outer ring;

B) You use longer screw.

Torque at 210 10 ft-lb (285 15

Nm). (See fig. 11)

fig. 11

b.11) With engine power, rotate the sprocket backward to obtain tension under the sprocket, and

simultaneousely slide the track behind the idler hub. Lock sprocket with hand brake. (See fig. 12)

fig. 12

04-M113-1ENS

A-654 (2003/09/18) Rv. B

Lithod in Canada

M113 VEHICLE FAMILY / RUBBER TRACK INSTALLATION INSTRUCTIONS

SOUCY TRACK SYSTEM

04-M113-1ENS

b.12) Align the first half-idler in position

towards the front of the vehicle (as

shown on fig. 13). Install the retaining

ring first then lock washers and screws.

Hand tighten only, do not torque at this

point.

(See fig. 13)

fig. 13

b.13) Move the vehicle forward to rotate the half-idler in position, then install the second half-idler

wheel (the same way as in b.12). Install cap screws and lock washers. Torque rearmost half

only at 160 10 ft-lb (210 15 Nm), rotate again to move other half-idler into rear position

and then torque the four remaining screws. (See fig. 14 and 15)

A

B

fig. 14

fig. 15

04-M113-1ENS

A-654 (2003/09/18) Rv. B

Lithod in Canada

10

M113 VEHICLE FAMILY / RUBBER TRACK INSTALLATION INSTRUCTIONS

SOUCY TRACK SYSTEM

C.

04-M113-1ENS

TENSIONNING THE TRACK

c.1) With the grease gun, pump grease in

the cylinder until a pressure of 2500

psi is obtained (See fig. 16)

OR

measure the distance between a tight

string and the track as shown below.

Loop one end of the wire and attach

around inside track pad at sprocket

end. Pull tight and bind with a heavy

object suspended at the other end.

Pump grease until dim is 17/8 (1/8)

over the center wheel (No. 3).

(See fig. 17).

fig. 16

17/8 (1.875)

kg

fig. 17

c.2) Road test vehicle to verify that track is properly installed. Re-check the tension 2 or 3 times after

complete track rotations (approx. 200 yards) until it maintains its nominal pressure.

04-M113-1ENS

A-654 (2003/09/18) Rv. B

Lithod in Canada

11

M113 VEHICLE FAMILY / RUBBER TRACK INSTALLATION INSTRUCTIONS

SOUCY TRACK SYSTEM

04-M113-1ENS

MAINTENANCE

Check track tension periodically :

Track will bed-in during the first 20 hours of operation and may require daily or weekly tension

adjustments. Track will not stretch much during its life but vehicle load and suspension sag will affect track

tension. Always inspect before running.

STORAGE

Track and components can sustain A1 & C2 climatic cycling as described in QSTAG-360 for a period of

minimum 5 years. Recommended temperatures range is : Minus 40 to 60 degrees Celsius (-40 to

+140F). Track life should improve when temperature and humidity are kept close to 0 degree Celsius

(32F) and 40% humidity.

OPERATING CONDITIONS

Track and components can sustain A1 & C2 climatic cycling as described in QSTAG-360 for a period of

minimum 5 years. Recommended temperatures range is : Minus 40 to 50 degrees Celsius (-40 to

+122F). Track life should improve when temperature and humidity are kept close to 15 degrees Celsius

(60F) and 40% humidity.

VEHICLE OPERATION WITH RUBBER TRACK

Ratcheting :

It is possible that the track will jump teeth under certain limit conditions such as panic stops and/or

negotiating very steep downward slopes under brakes. This condition is deemed normal and will not

entail any degradation or loss of performance for the life cycle of the track.

04-M113-1ENS

A-654 (2003/09/18) Rv. B

Lithod in Canada

12

Вам также может понравиться

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Tesla Profiles UpworkДокумент1 страницаTesla Profiles Upworksohail749Оценок пока нет

- If You Want To Test A Mans Character Give Him Power Abraham LiДокумент134 страницыIf You Want To Test A Mans Character Give Him Power Abraham Lisohail749Оценок пока нет

- Then and NowДокумент25 страницThen and Nowsohail749Оценок пока нет

- Lincoln Leadership: Bob Avery Baraboo School DistrictДокумент35 страницLincoln Leadership: Bob Avery Baraboo School Districtsohail749Оценок пока нет

- The Servant Leadership of Abraham LincolnДокумент7 страницThe Servant Leadership of Abraham Lincolnsohail749Оценок пока нет

- Abraham Lincoln-The Power of Personal ExampleДокумент68 страницAbraham Lincoln-The Power of Personal Examplesohail749Оценок пока нет

- Abraham Lincoln and The Art of Collaborative Leadership: ForumДокумент3 страницыAbraham Lincoln and The Art of Collaborative Leadership: Forumsohail749Оценок пока нет

- Abraham Lincoln Management Guru! Lessons For Library LeadershipДокумент8 страницAbraham Lincoln Management Guru! Lessons For Library Leadershipsohail749Оценок пока нет

- Electric Circuit Connections For Renault RadioДокумент1 страницаElectric Circuit Connections For Renault Radiosohail749Оценок пока нет

- Exama SchedualsДокумент1 страницаExama Schedualssohail749Оценок пока нет

- Eipm Emba Programme 2013-14Документ2 страницыEipm Emba Programme 2013-14sohail749Оценок пока нет

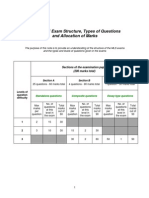

- MLS-SCM Exam StructureДокумент1 страницаMLS-SCM Exam Structuresohail749Оценок пока нет

- Retirement Speeches EbookДокумент21 страницаRetirement Speeches Ebooksohail749Оценок пока нет

- Intelligent LogisticsДокумент4 страницыIntelligent LogisticsAnand Khisti.Оценок пока нет

- Importance of Logistics Management and Emerging TrendsДокумент52 страницыImportance of Logistics Management and Emerging Trendsmadhuharidas100% (2)

- Logistics Transformation - Phase II: Defense Science Board Task Force OnДокумент57 страницLogistics Transformation - Phase II: Defense Science Board Task Force Onsohail749Оценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Calculating The Pathlength of Liquid Cells by FTIR PIKEДокумент1 страницаCalculating The Pathlength of Liquid Cells by FTIR PIKEMoises RomeroОценок пока нет

- Installation InstructionsДокумент3 страницыInstallation InstructionsRosaLovaОценок пока нет

- Pre Joining Formalities Campus Medical FormДокумент18 страницPre Joining Formalities Campus Medical Formrafii_babu1988Оценок пока нет

- AMS BreakerДокумент4 страницыAMS Breakerkuttu9703Оценок пока нет

- ANTENASДокумент10 страницANTENASGreo HernandezОценок пока нет

- Etic HackДокумент31 страницаEtic HackJOrdi CrespoОценок пока нет

- Composition Code ExampleДокумент3 страницыComposition Code ExampleREBEL USMANОценок пока нет

- 3M Scotchkote - Custom Coating GuideДокумент16 страниц3M Scotchkote - Custom Coating GuideUgoRibeiroОценок пока нет

- Chapter Two History and Vision of Digital LibrariesДокумент16 страницChapter Two History and Vision of Digital LibrariesakliluОценок пока нет

- Full Marks: 50 Duration: 3 HoursДокумент2 страницыFull Marks: 50 Duration: 3 HoursK JaiswalОценок пока нет

- Sheet 3Документ5 страницSheet 3Yasmin RedaОценок пока нет

- Promat Promapaint dc1 Hvac Ducts Technical Manual en 2019 12Документ6 страницPromat Promapaint dc1 Hvac Ducts Technical Manual en 2019 12mohammad faldi fauziОценок пока нет

- Civil Engineering Interview QuestionsДокумент12 страницCivil Engineering Interview Questionsjadgug100% (1)

- BTW-ST300MW Pure Sine Wave Inverter ManualДокумент15 страницBTW-ST300MW Pure Sine Wave Inverter ManualCarlos ZubietaОценок пока нет

- PowerMaxExpress V17 Eng User Guide D-303974 PDFДокумент38 страницPowerMaxExpress V17 Eng User Guide D-303974 PDFSretenОценок пока нет

- Co-Ordinate Measuring Machines & It's Applications: Introduction ToДокумент65 страницCo-Ordinate Measuring Machines & It's Applications: Introduction Toshiva dОценок пока нет

- Indicsoft ProfileДокумент13 страницIndicsoft ProfileMahmood AkhtarОценок пока нет

- CBSE Class 12 Political Science WorksheetДокумент2 страницыCBSE Class 12 Political Science WorksheetKamal BhardwajОценок пока нет

- Founder-CEO Succession at Wily TechnologyДокумент12 страницFounder-CEO Succession at Wily TechnologyMayank Saini100% (1)

- Lewmar Marine Equipment Guide Ed 14Документ224 страницыLewmar Marine Equipment Guide Ed 14Renato Fonseca100% (1)

- M6 L11 FinalДокумент12 страницM6 L11 FinalUrban EcoLab CurriculumОценок пока нет

- A140Документ104 страницыA140hungchagia1Оценок пока нет

- Harden's Spices Model For Biochemistry in Medical CurriculumДокумент10 страницHarden's Spices Model For Biochemistry in Medical CurriculumGlobal Research and Development Services100% (1)

- Software: Measurlink Is An Easy-To-Use, Windows-Based Family of Quality Data Management Software ApplicationsДокумент8 страницSoftware: Measurlink Is An Easy-To-Use, Windows-Based Family of Quality Data Management Software ApplicationsBrandi DaleОценок пока нет

- P287 SCIL Programming BasicsДокумент78 страницP287 SCIL Programming BasicsOscar GarciaОценок пока нет

- Installation & Stock Detail of Ignition Modules & Magnetos of Gas Compressor Units (All Fields)Документ4 страницыInstallation & Stock Detail of Ignition Modules & Magnetos of Gas Compressor Units (All Fields)Atiq_2909Оценок пока нет

- TDSC Tpus420 enДокумент23 страницыTDSC Tpus420 encatalind_cdОценок пока нет

- Vulnerability Management PolicyДокумент6 страницVulnerability Management PolicySerdar AktaşОценок пока нет

- C ElanchezhianДокумент8 страницC ElanchezhiankeshavuvceОценок пока нет

- Wavin QuickStream Specification Oct 14Документ6 страницWavin QuickStream Specification Oct 14Syahrisal SaputraОценок пока нет