Академический Документы

Профессиональный Документы

Культура Документы

2015 ISO World Conference Brochure

Загружено:

Anonymous AlhzFE9EVNОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

2015 ISO World Conference Brochure

Загружено:

Anonymous AlhzFE9EVNАвторское право:

Доступные форматы

The Worlds Leading Conference on ISO 9000 & QMS Standards

AS9100 for

Aviation, Space,

and Defense

ISO 13485 for

Medical Devices

ISO 14001 for

Environmental

Management

Hank Moore

Corporate Strategist

Author of the

Business Tree

Nigel Croft, Ph.D.

Lorri Hunt

Chair, ISO

Subcommittee

ISO/TC176/SC2

U.S. Lead to

ISO 9001 Revision

Susan Briggs

Randy Dougherty

Alan Daniels

Team Leader for

AS9100 Standards

Development

ISO/TS 16949 for

the Automotive

Industry

Risk Management

& ISO 9001

Revision

Jack West

Past Chair US TAG to TC 176

& Member of

SC2 WG on the QMPs

eAudits & Audits

EARLY REGISTRATION GIFTS

Early Registration Deadline: FEBRUARY 5, 2015

Tablet PC: 7" Dual Core Android 8GB Tablet

PC with Camera

iPod Shuffle

$50 ASQ Gift Certificate

Apple TV: Only if you are registered for both

conferences.

Please see the Registration Guidelines for further

information

Chair, U.S. TAG to

ISO TC 207 on EMS

Vice-President

ANSI-ASQ National

Accreditation Board

Duke Rohe

Quality Improvement Education

Specialist,

M.D. Anderson Cancer Center

The Worlds Leading Conference on ISO 9000 & QMS Standards

Conference Chairs Message

2015 is on target to be a year with the most

impact to professionals that implement and

audit to quality management system

standards as well as other standards in the

world. ISO 9001, ISO 14001, and ISO 13485 are

scheduled to be published in 2015 with ISO

45001, the new standard that replaces OHSAS

18001, the standard on occupational safety

and health, following close behind. Changes

to ISO 9001 will also impact the sector specific

standards AS9100 and TS16949.

Exhibits

JW Marriott Houston, TX, USA

Bexar/Travis/Nueces Rooms

The 2015 ISO 9000 conference list of speakers includes technical

experts participating in the management systems standards that

are currently in the revision process. This provides the unique

opportunity to get information directly from the source. The large

list of standards that are currently under revision also brings to

the forefront concerns related to transitioning to the revisions. The

conference has included speakers who will provide the most upto-date information on what your organization must do to

transition to ISO 9001 or one of the other standards.

The goal of the ISO 9000 conference has always been to provide

an experience to conference attendees that provides value. This

years conference has been structured to not only provide

speakers that are international experts who are top in their field

and actively participating in the revisions to these management

system standards, but to include industry experts with hands-on

experience in implementing management system standards. Case

studies provide examples of something you can take back to your

organization.

The conference will also focus on networking opportunities by

providing an infrastructure where you can network not only with

your colleagues at the conference but some of the key speakers

participating in the revision.

In short, the 2015 ISO 9000 Conference is set to be the best

opportunity to learn not only about the revision to ISO 9001, but

many of the other management system standards in development

at one time.

See you in Houston!

Warm Regards,

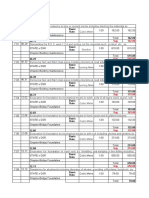

$1,495 until February 5, 2015

$1,595 after February 5, 2015

$1,695 after March 2015

Early Registration Deadline: February 5,

2015

Each 8 x 10 booth will be set with 8 high blue and green back

drape 3 high blue side dividers, one 6 table draped blue, two side

chairs, one wastebasket, and a 7 x 44 one-line identification sign.

The exhibit area is carpeted. Electricity is additional.

With an Exhibit Booth, you are entitled to bring two booth

personnel. One of the booth personnel will receive complimentary

conference attendance. Each additional Exhibit Personnel must

register as regular conferees in order to attend the technical

sessions. Exhibitors are not eligible for Early Registration Gifts.

Freeman Move-In

Sunday, March 8, 2015, 11:30 AM-3 PM

Exhibitor Move-In

Sunday, March 8, 2015; 3 PM-6 PM

Show Days

Monday, March 9, 2015; 7:30 AM-5 PM

Tuesday, March 10, 2015; 7:30 AM-1 PM

Exhibitor Move-Out

Tuesday, March 10, 2015; 1 PM-2 PM

Freeman Move-Out

Tuesday, March 10, 2015; 1 PM-3 PM

ISO Conference Bags: $3,000

ISO Conference Reception: $2,500

ISO Conference Folders: $2,000

One-Page Insert in Conference Bags: $1000

Lorri Hunt, 2015 Conference Chair

Conference Registration

Phone: 1-412-782-3383 or 1-888-236-9940

Fax:

1-866-500-9081

E-mail: info@aqi.org

Visit:

www.iso9000conference.com

Register online: regonline.com/aqi

Conference Mailing List will be available for purchase in an

electronic format exclusively for our exhibitors. Cost: $800.

The mailing lists will contain mailing information only. Attendee

emails and phone numbers will not be provided. Attendee

mailing list can only be used once to promote the exhibiting

companys products and the list must not be entered into a

database for other purposes or for continued uses.

2015 American Quality Institute. All right reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from the American Quality Institute.

Page ISO-2

The year 2015 is one of

the biggest years in

recent times for

standards. ISO 9000,

ISO 9001, ISO 14001,

ISO 13485, and ISO 45001

are all in the final stages

of development. With this

many standards set for

publication this year,

organizations are faced

with many questions.

These organizations must

consider when to make

the transition to the new

revisions, and what kind

of changes are needed.

They must also consider what to do when they have an integrated management system

and the standards are not being published at the same time.

The Conference will feature a panel discussion with top-experts who are leaders in their

respective fields in writing the new revisions. Brief overviews of some of the most

common standards and the current status of their publication will be presented.

Challenges and key changes will be discussed. The interactive panel discussion will

conclude with the opportunity for you to ask questions related to the standards and

obtain value-added information for your organization.

In it's 23rd year, ISO 9000 World Conference has become the most important annual

gathering in the world bringing together leaders in the field of ISO 9001, ISO 14001,

ISO 3485, ISO 9000, AS9100, and QMS Standards.

With three keynotes, 50+speakers, and hands-on workshops, this years conference

promises to be the must-attend event of 2015 for every Quality Mangement Standard

professional.

Early Registration Gifts

ISO 9001/QMS Networking Luncheons

Early Registration Deadline:

February 5, 2015

12:00 PM-1:15 PM (on both conference days)

If you register for the ISO 9000 World

Conference, using the registration code

A2015 before the early registration

deadline, your early registration gift selection

includes the following:

iPod Shuffle

Tablet PC

$50 ASQ Gift

Certificate

If you register for

both the ISO 9000

World Conference

and the Lean & Six Sigma

World Conference by the

early registration deadline,

you may combine your gifts

and receive:

Apple TV

Please note that early registration gifts are available only if

you register by phone and not available if you register

online. Please see the Conference Registration Guidelines

for further information. Please also note that the ASQ Gift

certificates must be used during the exhibit hours.

Join us for this fun activity! During this Networking Luncheon, you may select to be

seated depending on your area of interest or expertise. Please note that group seating

is limited and will be assigned on a first-come, first-served basis. Following is a partial

list of Networking Groups. Please sign up using the conference registration form using

this link: regonline.com/aqi. Please note that you must register for the Conference

in order to participate in the Networking Luncheons.

Monday, March 9, 2015

Tuesday, March 10, 2015

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

Accredited Certification

AS9100

Auditing

Being Audited

Context of the Organization

Documented Information

Energy

Healthcare

Innovation

Integrated Management Systems

ISO 13485

ISO 9001:2015 Revision

18.

19.

20.

21.

22.

23.

Management Commitment

Management Review

Manufacturing Industries

Monitoring & Measurement

Process Management & Systems

Thinking

Regulated Industries

Risk

Service industries

Transitioning to the new ISO Standard

TS 16949

Understanding & Using Data

Page ISO-3

23rd Annual ISO 9000 World Conference

7:30 AM-8:00 AM

Continental Breakfast

8:00 AM-8:10 AM

Opening Remarks -- Lorri Hunt, Conference Chair

Session #ISO-011

8:10 AM-8:50 AM

The Future Has Moved and Left No Forwarding Address

MONDAY March 9, 2015

Keywords: Growth

Strategies, Vision,

Planning, Leadership

Industry: All

Level: All

Hank Moore, Corporate Strategist, Management Resource Institute, Houston, TX, USA

The opening keynote speaker is Hank Moore, Futurist and Corporate Strategist. He will cover trends,

challenges, and opportunities for business to survive and thrive. Hank Moore is the highest level business

overview expert and is in that rarified circle of experts such as Peter Drucker, Tom Peters, Steven Covey, Peter

Senge and W. Edwards Deming. Drucker termed Hank Moore's Business Tree as the most original business

model of the past 50 years. The Business Tree is his trademarked approach to growing, strengthening, and

evolving business, while mastering change. He advises companies about growth strategies, visioning, planning,

leadership development, futurism, and Big Picture issues that profoundly affect the business climate. He has

presented Think Tanks for five U.S. Presidents and has spoken at six Economic Summits.

Hank Moore has provided senior level advising services for more than 5,000 client organizations (including 100

of the Fortune 500), companies in transition (startup, re-engineering, mergers, going public), public sector

entities, professional associations, and non-profit organizations. He has worked with all major industries over a

40-year career. He advises at the Executive Committee and Board levels, providing Big Picture ideas.

Session #ISO-012

8:50 AM-9:30 AM

Keywords: ISO 9001,

Revision, Quality

Management System

Industry: All

Level: All

A New Era of Management System Standards Implications of

the ISO 9001 Revision

Nigel Croft, Ph.D., Chairman of ISO/TC176/SC2

This presentation will explain the important role of a Quality Management system in the context of sustainable

development initiatives, and the implications for the current revision of the ISO 9001 standard. It will discuss

the implications for ISOs portfolio of management system standards and relate these to the core elements of

a sustainable development philosophy, namely economic development, environmental integrity, and social

responsibility. The presentation will review the three core recurring themes: define the processes; take into

consideration the risks associated with those processes; and manage the processes and the system as a whole

using the Plan-Do-Check-Act cycle.

Dr. Croft holds a first class honors degree in Natural Sciences from Cambridge University, England, and a

Doctorate in Materials Science from Sheffield University. He is a Chartered Engineer and Chartered Quality

Professional in the UK, a Fellow of the Chartered Quality Institute, and a Senior Member of ASQ.

Session #ISO-013

9:30 AM-10:00 AM

Keywords: ISO

9001:2015 Revision,

Transition,

Accreditation

Industry:

Manufacturing

ISO 9001:2015 Separating the Facts from Fiction

Lorri Hunt, President, Lorri Hunt & Associates, Inc., Kansas City, MO, USA

The revision to ISO 9001 is scheduled for late 2015. Thats a fact. Beyond that, there continues to be a great

deal of information available from quality journals, social media, or simply I heard this from fill-in-the-name

of an expert. Some of this information is fact, some is fiction, and some of the information is somewhere in

the middle. Because this vast amount of information can at times be confusing and even contradictory, it can

lead to frustration. This session will review the facts from the fiction for some of the most frequently discussed

clauses in the marketplace. It will highlight the changes in requirements for leadership, documented

information, and risk-based thinking. It will focus on ensuring you are getting the right information to

understand the revised requirements and manage the transition to the ISO 9001:2015 revision.

Lorri Hunt is the leading authority in the United States in the area of the ISO 9001:2015 Revision. She currently

serves as the head of delegation for ISO TC176/SC2. In this role, she is responsible for overseeing the

development of consensus positions for the United States related to ISO 9001 and 9004. She is a United States

expert and Task Group Monitor for the next revision to ISO 9001 that is currently planned for 2015.

Level: Intermediate

10:00 AM-10:20 AM

Page ISO-4

Coffee Break

TO REGISTER CALL

888-236-9940 O R 412-782-3383 O R E - M A I L : INFO@AQI.ORG

The Worlds Leading Conference on ISO 9000 & Related Standards

Changes to Standards Affecting Accredited

Certification

Randy Alan Dougherty, VP, ANSI-ASQ National Accreditation Board, Chairman and President, IAF,

Milwaukee, WI, USA

ISO/IEC 17011 is the international standard for accreditation bodies. A revision of this standard was initiated

in 2014. ISO/IEC 17021 is the international standard for certification bodies for management systems,

including, but not limited to, ISO 9001 and ISO 14001. This standard has been under revision since 2012 with

the revision likely to be published in 2015. This will change some of the requirements for certification bodies.

Session # ISO-021

10:20 AM-11:00 AM

Keywords: ISO, IAF,

Accreditation,

Transitions

Industry: Service

Level: Intermediate

ISO 9001:2015 - Panel Discussion

Panel Lead: Lorri Hunt, President, Lorri Hunt & Associated, Inc., Kansas City, MO, USA

The year 2015 is one of the biggest years in recent times for standards. ISO 9000, ISO 9001, ISO 14001, ISO

13485, and ISO 45001 are all in the final stages of development. With this many standards set for publication

during the next year, organizations are faced with many questions. Organizations must consider when to

make change and what kind of change might be needed in their organization. They must also consider what

to do when they have an integrated management system and the standards are not publishing at the same

time. This presentation will include brief overviews of some of the most common standards and the current

status of their publication. Challenges and key changes will be discussed with the standards by some of the

leading experts in standards development in the world. This interactive panel discussion will conclude with

the opportunity for you to ask questions related to the standards and obtain value-added information for

your organization.

Session #ISO-022

11:00 AM-12:00 PM

Keywords: ISO

9001:2015 Revision,

ISO, 14001, AS9100, ISO

9000, Accreditation,

Transition

Industry:

Manufacturing

Level: Intermediate

The panel will feature top-experts from around the world:

John E. (Jack) West, Past Chair US TAG to TC176 and Member of SC 2 WG on the QMPs, Silver

Fox Advisors, The Woodlands, TX, USA

Nigel Croft, Ph.D., Chairman of ISO/TC176/SC2, UK

Alan W. Daniels, Process and Systems Manager, The Boeing Company; ISO International

Organization for Standardization, Lake Stevens, WA, USA

Susan K. Briggs, Chair, U.S. TAG to ISO TC 207 on Environmental Management, Reading, MA, USA

Randy Alan Dougherty, President, IAF and VP ANAB, Milwaukee, WI, USA

ISO 9001/QMS Networking Luncheon

Join us for this fun activity! During this Networking Luncheon, you may select to be seated depending on

your area of interest or expertise. Group sign-in will be made on-site. Please note that group seating is

limited and will be assigned on a first-come, first-served basis. Following is a partial list of Networking

Groups:

Accredited Certification

Energy

AS9100

Healthcare

Auditing

Innovation

Being Audited

Integrated Management Systems

Context of the Organization

ISO 13485

Documented Information

ISO 9001:2015 Revision

TO REGISTER ONLINE:

Monday, March 9, 2015

12:00 PM-1:15 PM

REGONLINE.COM/AQI OR V I S I T WWW.AQI.ORG

Page ISO-5

MONDAY March 9, 2015

Several technical specifications have been published in the last few years: ISO/IEC TS 17021-2, ISO/IEC TS

17021-3, and ISO/IEC TS 17021-4 through to ISO/IEC TS 17021-7. These establish additional competence

requirements for management systems certification bodies. Revisions to ISO 9001 and ISO 14001 to conform

to the new high level structure for management systems standards are likely to be published in 2015. What

are the implications to accredited certification? Randy A. Dougherty is Vice President, ANAB for the ANSIASQ National Accreditation Board in Milwaukee, WI. Dougherty oversees the activities of a staff of 5 and 25

contract auditors. Dougherty holds a masters degree in public health administration from the University of

Michigan in Ann Arbor, and earned his bachelors degree from Lake Superior State College.

23rd Annual ISO 9000 World Conference

Session #ISO-031

1:15 PM-1:50 PM

MONDAY March 9, 2015

Keywords: ISO

9001, ISO 14001,

Environmental

Managements

Systems (EMS)

Industry: All

Level: Intermediate

Changes Coming for the ISO 14001 Environmental Management

Systems

Susan K. Briggs, Chair, U.S. TAG to ISO TC 207 on Environmental Management, Convenor,

ISO TC207/SC1/WG5 on Environmental Management Systems, Reading, MA, USA

Since its origination in 1996, more than 250,000 organizations in 155 countries around the globe have adopted

the International Organization for Standardization (ISO) standard on Environmental Management Systems, ISO

14001, with uptake continuing to grow. The standard underwent revision in 2004; however, changes were

limited to clarifying the original requirements. During this period, new developments have arisen in the field of

environmental management and stakeholder expectations have evolved, resulting in strong international

support for substantive changes to ISO 14001. This revision has been undertaken to ensure the standard

continues to be relevant over the next two decades.

A study completed in 2010 by TC 207/SC1, Future Challenges for EMS, made 25 recommendations to address

the evolving developments and expectations. In addition to the technical changes resulting from these

recommendations, changes in design and layout of the standard have occurred in response to the ISO mandate

to impose a common structure and minimum set of requirements on all management system standards (MSS).

This presentation will provide an overview of the new requirements and outline the transition process for

organizations seeking to have their systems certified to the new standard.

Session #ISO-032

1:50 PM-2:25 PM

ISO 50001 Energy Management

Keywords: ISO

50001:2011, Energy

Management

Systems

Industry:

Manufacturing

Level: Intermediate

In this session, Deann Desai will make a presentation about the new ISO 50001 standard for energy

management. ISO 50001 is based on the management system model of continual improvement also used for

other well-known standards such as ISO 9001 or ISO 14001. This makes it easier for organizations to integrate

energy management into their overall efforts to improve quality and environmental management.

Deann Desai, Georgia Tech, Atlanta, GA, USA

ISO 50001:2011 provides a framework of requirements for organizations to: develop a policy for more efficient

use of energy; fix targets and objectives to meet the policy; use data to better understand and make decisions

about energy use; measure the results; review how well the policy works; and continually improve energy

management.

ISO 50001 gives organizations the requirements for energy management systems (EnMS), provides benefits for

organizations large and small, in both public and private sectors, in manufacturing and services, in all regions of

the world. Targeting broad applicability across national economic sectors, it is estimated that the standard could

influence up to 60 % of the worlds energy use.

Session #ISO-033

2:25 PM-3:00 PM

Update on TL 9000 R6.0 Requirements & ISO 9001:2015

Keywords: QuEST,

ICT, ISO 9001,

Telecommunications,

TL 9000

Industry: Electronics

Level: Advanced

ISO 9001:2015 its coming! Its changing! What will it mean to the information and communication

technologies (ICT) industry? ISO 9001:2015 is being revised and it is expected to be very different with a new

structure and new requirements. TL 9000 is a management system standard that is built on ISO 9001 to meet the

supply chain quality requirements of the ICT industry.

Sheronda Jeffries, TL 9000 Program Manager, QuEST Forum, Durham, NC, USA

This presentation will review the current status of the ISO 9001:2015 revision, along with the key changes such

as the High Level Structure for 'Annex SL found in the Draft International Standard (DIS). We will review the plan

to update TL 9000 R6.0 to incorporate ISO 9001:2015 and discuss the transition period for ISO 9001:2015 and TL

9000 R6.0 Requirements.

During this presentation, You will learn: the plan to update TL 9000 R6.0 to incorporate ISO 9001:2015; the

transition period for ISO 9001:2015 and TL 9000 R6.0 Requirements before changes become mandatory; and

what you can do to prepare for TL 9000 R6.0 Requirements!

3:00 PM-3:30 PM

Page ISO-6

Refreshment Break

TO REGISTER CALL

888-236-9940 O R 412-782-3383 O R E - M A I L : INFO@AQI.ORG

The Worlds Leading Conference on ISO 9000 & Related Standards

Interlinking Performance Excellence & Multiple ISO Standards

Kevin Lee Griffin, Quality Contractor and Kathy D. Boardman, R.Ph., M.S., Associate Center Director, Division of

Clinical Trial Operations, VA Cooperative Studies Program Clinical Research Pharmacy Coordinating Center,

Albuquerque, NM, USA

Changes to ISO 13485 - Are You Ready?

Bill Enos, Microbiology Team Leader, Americas, BSI Medical Devices, Ludlow, MA, USA

As the medical device marketplace continues to expand globally, there is an ever growing need to harmonize

compliance requirements across the board. ISO 13485 is the standard by which medical device manufacturers

demonstrate compliance and this standard is undergoing a significant revision. This revision will not only

directly link this standard to other global device requirements, but also seeks to align itself with other global

initiatives designed to harmonize requirements for all manufacturers. This update represents a major revision

and must be understood in detail in order to maintain compliance domestically and around the world.

Keywords: Multiple

Integrated Standards,

ISO 9001, ISO 15378,

ISO, 21500, ISO 19011,

Malcolm Baldrige, NQA,

ISO, CAP, GCP, Cgmp,

Regulatory Standards

Industry: Government

Level: Intermediate

Session #ISO-042

1:50 PM-2:25 PM

Keywords: ISO 13485,

Medical Devices

Industry: Healthcare

Level: Intermediate

The goal of this presentation is to update the attendees with regard to the most recent changes to the ISO

13485 QMS requirements. This revision directly affects all areas of medical device manufacturing, from

concept to post market follow up. In a global setting, it is critical to understand the interaction between

quality systems, device requirements, and all other regulatory requirements.

The Current State of Quality in the Automotive Industry

Craig Williams, US TAG to ISO/TC 176, ISO/TC 176, VP, Quality , Johnson Controls Power Solutions, Glendale,

WI, USA and Scott A. Gray, Sr. Program Manager, AIAG, Southfield, MI, USA

This presentation will give the audience an update on the challenges facing the automotive industry and

corresponding initiatives underway at the Automotive Industry Action Group (AIAG). AIAG is the industry

association responsible for the development and publication of many of the recognizable documents that

support the Quality, Supply Chain, and Corporate Responsibility activities between the supply partners of the

automotive sector. In particular, the AIAG publishes the Core Tools and ISO/TS 16949 reference manuals.

Session #ISO-043

2:25 PM-3:00 PM

Keywords: ISO/TS

16949

Industry: Automotive

Level: Intermediate

The speakers will be covering the following topics during the session:

Results of the Current State of Quality Survey

Updates on recently released guidelines and training

Status of TS 16949 and AIAGs supporting reference materials

Interactive discussion on Perspectives on the Future of Automotive QMS

There are many changes that are taking place that will impact the Quality Management System of the OEMs

and the associated supply base. The continued collaboration of the OEMs and suppliers on the AIAGs Board

and Steering Committees is a key to the ongoing success of the industry. This session will highlight the

accomplishments of recent volunteer project teams and identify opportunities for the audience to participate

in the collaborative efforts that are underway at the AIAG in support of the automotive industry.

Refreshment Break

3:00 PM-3:30 PM

TO REGISTER ONLINE:

REGONLINE.COM/AQI OR V I S I T WWW.AQI.ORG

Page ISO-7

MONDAY March 9, 2015

The VA Cooperative Studies Program Clinical Research Pharmacy Coordinating Center (PCC) supports and

manages drug/device, regulatory, and patient safety-related aspects of multicenter clinical trials (MCTs).

MCTs study the effectiveness and safety of drugs/devices in humans. The PCC participates in more than 100

clinical trials, each lasting from a few months to over 15 years, with over 200,000 patients per year at over

2,200 participating sites, using >250 drugs/devices. The PCC operates in a highly regulated environment and

thrives through visionary leadership, strategic planning, innovation, focus on customers, employee

engagement, and systems approach. It implements the approach-deployment-learning-integration (ADLI)

model into its Quality Management and performance excellence system. This presentation will describe the

use of multiple standards in this initiative, provide a successful strategy for embedding multiple standards,

guidance, and criteria into a complex organization that functions simultaneously in R&D, cGMP, GCP, and

services; best practices for efficiently integrating multiple performance tools, such as ISO, MBNQA, and Lean;

lessons learned in integrating multiple ISO quality standards and performance excellence strategies to create

a MBNQA recipient organization; and benefits of a variety of external assessments to validate complex, multidisciplinary processes as well as identifying best practices and benchmarks

Session #ISO-041

1:15 PM-1:50 PM

23rd Annual ISO 9000 World Conference

Session #ISO-051

1:15 PM-1:50 PM

Will ISO 9001-2015 Really Eliminate Preventive Actions?

Keywords: Planning,

Mitigation, Risk

Preventive Action

Industry:

Manufacturing

Level: Basic

The take-away for those attending this presentation will be an understanding that, while the Preventive Action

clause in the 2008 version of ISO 9001 will be eliminated in the 2015 version, preventive actions will still be

necessary to mitigate potential problems exposed during the planning process. Planning is included in the

current version of ISO 9001, but the 2015 version expands the planning requirements with a focus on risk

identification and the mitigation of those risks.

William Houser, President, Eagle Force, Inc., Spring, TX, USA

MONDAY March 9, 2015

Risk mitigation is, by it is very nature, proactive preventive action. On the other hand, risk that is not mitigated

until non-conformances occur, is reactive and corrective. The ISO 9001:2015 requirement to identify and

mitigate risks prior to their occurrence means that preventive actions will be necessary. Those attending this

presentation will learn the practical application of the revised planning, risk evaluation, and mitigating actions

requirements in avoiding problems.

This presentation will focus on a practical approach to the ISO 9001:2015 planning process that will expose

significant risks that require mitigating (preventive) action to eliminate the problems before they have an

impact on customers and the organization.

Session #ISO-052

1:50 PM-2:25 PM

The Single Management System

Keywords: RiskMatrix, Technology,

ISO 9001:2015,

Regulatory

Compliance, Process

Map, Corrective

Action

Industry: Software

Level: Advanced

The IRCA certification Officer in INFORM issue 42, states that the expectation for ISO 9001:2015, is a single

management system. The question is, how do organizations accomplish that?

Session #ISO-053

2:25 PM-3:00 PM

Reaching Beyond Quality

Keywords: ISO 9001,

Maturity, Annex SL,

Risk

Industry:

Manufacturing

Level: Intermediate

More than 1.2 million organizations are certified to ISO 9001, making it the most widely used management

system standard in the world. When finalized, the 2015 revisions to ISO 9001 will create a tectonic shift which

will reverberate across many organizations striving to maintain compliance. Designed to increase applicability

to businesses that provide services, the revision will break down internal silos with its renewed focus on risk

and bring increased responsibility to top management. ISO 9001:2015 will compel organizations to look

beyond immediate quality concerns to incorporate enterprise-wide strategies to mitigate or avoid risks that

could potentially jeopardize various aspects of the product or service.

Jeffrey Lewis, CEO, Safety In Your Hand, Inc., Palo Alto, CA, USA

This presentation aims to share the mechanism, which drives a seamlessly integrated management system with

appropriate controls, to facilitate on-going conformity, and statutory / regulatory compliance. 'What if' risk

matrix sets up the risk treatments as it is applicable to the product, process and assets, considering the severity

of impact and the likelihood of occurrence from the identified risk.

The Management System Process Map, sets up the flow of the management system through to corrective

actions. It will identify the statutory/regulatory implementation points. The corrective action form with three

options of planned, condition monitoring, emergency. Determining the type of corrective action will facilitate

an analysis towards an improvement of only planned events.

John DiMaria, ISO Product Manager, British Standards Institution, Herndon, VA, USA

ISO 9001:2008 made no mention of the word risk. In practice, however, risk has always been considered

reactively through the CAPA process. This has involved establishing root cause of what happened to affect the

products quality, correcting the issue, and then arriving at an action that will prevent additional quality issues

that may arise from that threat.

Upon conclusion of this session, participants will learn the ten clauses of the new ISO Management System

Annex SL; understand how the global risk analysis will affect your organization; have an overview of how

changes may affect the audit process; and be presented with best practices for a smooth transition.

3:00 PM-3:30 PM

Page ISO-8

Refreshment Break

TO REGISTER CALL

888-236-9940 O R 412-782-3383 O R E - M A I L : INFO@AQI.ORG

The Worlds Leading Conference on ISO 9000 & Related Standards

Take Charge of Change with Self-Assessment

Susan E. Moore, Compliance & Self-Assessment SME, Lockheed Martin Missiles and Fire Control, Arlington,

TX, USA

Embracing change and mitigating risk at the same time can be challenging. This presentation will share an

outlook any organization can use to take charge of change using a self-assessment program. Youll leave

with resources to improve the bottom line by reducing escapes, creating awareness, and improving

customer/registrar satisfaction. Insight will be shared on how this proactive approach has improved the

performance in a $5B organization and Malcolm Baldrige recipient.

Session #ISO-061

3:30 PM-4:05 PM

Keywords: Mitigating

Risk, Self-Assessment,

Audits

Industry:

Defense/Military

Level: Intermediate

Hands on training ideas will be shared to make a self-assessment program easy to implement for any

company. Take-away will include the following:

Audit success stories, Lessons Learned, and Self-Assessment

Templates pamphlet will be available

Dan Reid, Director of Consulting, Omnex, Ann Arbor, MI, USA

The global auto industry in recent years has come to recognize risks inherent in its long and diffuse supply

chain. Now it's starting to face an almost 40 percent bottleneck in the ability to make vehicles.

ISO TS16949 defines the global automotive supplier requirements for a quality management system.

Supplier management in the automotive supply chain continues to be a key concern of automakers and tier

one suppliers alike. It was such a concern that several tier one suppliers developed a sub-tier supplier

management process published through the Automotive Industry Action Group (AIAG). TS 16949

supplements the base ISO 9001 requirements for Control of Purchased Products with specific requirements

for sub-tier supplier certification and development.

Session #ISO-062

4:05 PM-4:40 PM

Keywords: TS 16949,

QS-9000, IWA 1, FMEA,

PPAP, APQP, Sub-tier

Supplier Management,

Problem Solving

Industry: Automotive

Level: Intermediate

In this session, Dan Reid, the first Delegation Leader of the International Automotive Task Force (IATF)

responsible for ISO TS 16949 and the automotive third party certification scheme, explains the automotive

supplier management requirements and offers tips based on industry best practices.

WORKSHOP 4

ISO 9001: 2015 Revision

What is New?

Jack West, Silver Fox Advisors,

The Woodlands, TX, USA

2-Hour Workshop

0.2 CEU/REU

Great workshop if you need a

comprehensive overview of the changes

Fee: Workshop registration fee is $95 if you are

registered for either the ISO or LSS Conference, for

Speakers & Exhibitors, $195 if you are registering for the

workshop only. The fee includes course materials, and a

certificate. Please note that space is limited.

TO REGISTER ONLINE:

An overview of the contents of this workshop is

as follows:

When will ISO 9001 2015 become reality?

Setting the foundation; QMPs, vision, mission,

objectives, organization

How long a transition period after release of

ISO 9001:2015

Implications of the New footprint i.e. Annex

SL for users?

Change to less specificity of requirements?

More generic?

Change in wording: different words but same

meaning? Different words with broader or

more restrictive meaning?

Are there new requirements?

Existing requirements expressed in a new way

What are the areas I should be contemplating

now and why?

6:30 PM-8:30 PM

(2 hour workshop)

Keywords: Revision

Industry: All

Level: All

Understanding the concepts of the organization

and its context, the needs and expectations of

interested parties and how to determine the

scope of the quality management system

REGONLINE.COM/AQI OR V I S I T WWW.AQI.ORG

Page ISO-9

MONDAY March 9, 2015

TS16949: Automotive Supply Chain Management

MONDAY March 9, 2015

23rd Annual ISO 9000 World Conference

Session #ISO-071

3:30 PM-4:05 PM

CTQ (Critical to Quality) Case Study Textile Manufacturing

Keywords: Synthetic

Fibers, CTQ, Critical to

Quality

Industry:

Manufacturing,

Textiles

Level: Intermediate

When you're developing new products and services, quality is important not only to satisfy your clients, but

also to help you stand out from your competitors. However, defining quality can be a challenge, and it's easy

to overlook factors that customers care about. This is when Critical to Quality (CTQ) trees are useful. They help

you understand what drives quality in the eyes of your customers, so that you can deliver a product or service

that they are genuinely pleased with. Opportunity to understand the potential paths for effective long-term

achievements and successes using process steps and interaction diagrams for effective Critical to Quality

events and projects. By first identifying what the customer critical values are, defining the supplied product

attributes (measures), and predicting product quality and customer satisfaction based on critical points

identified and controlled within the supplier's manufacturing process.

Carl A. Labbe, Senior Quality Manager, and Charlie Stiner, Plant Manager, Propex, Chattanooga, TN, USA

In this session, you will learn the critical steps for effective CTQ events / projects, Flow chart for quick decision

making during CTQ event or project, using long-term tools to maintain improvement gains, such as mistake

proof, controls, Critical Xs, etc. You will learn to continually measure and challenge the improvement cycle for

long-term customer improvement relationship.

Session #ISO-072

4:05 PM-4:40 PM

Product Realization Planning in a Build to Print Environment

Keywords: ISO 9001,

Planning, Product

Realization

Industry:

Manufacturing

Level: Basic

Product realization is the term used to describe the work that the organization goes through to develop,

manufacture, and deliver the finished goods or services. An effective Quality Management System (QMS)

includes a comprehensive approach to getting from the product concept to the finished product. This

approach, sometimes called a quality plan, includes the following: product requirements and quality

objectives, creation of the processes, documents, and resources needed for product realization, required

verification, monitoring, inspection, and test activities including the records to be kept.

Jay Matthews, Quality Manager, Flanders, Lynnville, IN, USA

This session will cover how to implement planning in a build to print environment by discussing various

methods to implement a successful planning function. It will address how to define quality objectives for the

product, establishing processes and documents, how to verify the product meets criteria, and deal with the

records of planning. It will also cover how to plan for succession planning and maintaining an agile workforce.

Participants will learn different methods to successfully plan for build to print and all jobs in accordance to ISO

9001, section 7.1 Planning of Product Realization. This session will address common pitfalls and how to avoid

them. It will show that by performing the proper planning, significant cost savings can be achieved.

P a g e I S O - 10

TO REGISTER CALL

888-236-9940 O R 412-782-3383 O R E - M A I L : INFO@AQI.ORG

The Worlds Leading Conference on ISO 9000 & Related Standards

Building Customer Intimacy: Integrating Innovation into How

We Listen

Bob Norris, Senior Client Partner, BMGI, Denver, CO, USA

Listening to the Voice of the Customer (VOC) is essential for business success. While most organizations have

started to listen to their customers, these efforts are neither effective nor efficient. They rarely result in positive

outcomes, such as new products and services that are demanded by customers or the business strategy

needed to drive breakthrough results. Most organizations are continuing to do surveys as their primary way to

listen without exploring other ways to connect the customer.

Session #ISO-081

3:30 PM-4:05 PM

Keywords: Voice of

the Customer (VOC),

Innovation

Industry: Service

Level: Basic

Disruptive Technologies - Should Quality Care?

Session #ISO-082

4:05 PM-4:40 PM

A disruptive technology is new technology that unexpectedly displaces an established technology.

Technology can be separated into two categories: sustaining and disruptive. Sustaining technologies are

based on incremental improvements to an established technology. On the other hand, disruptive

technologies can be identified as a technology that displaces a sustaining technology and shakes up the

industry or a ground-breaking product that creates a completely new industry. Examples include Mobile

Internet, Automation of Work Knowledge, the Internet of Things, Advanced Robotics and Additive

Manufacturing.

Keywords:

Technology,

Innovation, Process

Improvement

Industry:

Manufacturing

Level: Intermediate

Alan Lund, Principal, CORE Business Management, Milford, MI, USA

Should Quality care? Yes, because disruptive technologies can be a source of cost savings and enhanced

customer satisfaction, How? By incorporating the innovative use of disruptive technologies to improve

process performance, enhance data capture/analysis and to streamline qualitys accountability and

responsibility. Attendees for this session will learn:

What are Disruptive Technologies

How Disruptive Technologies can be used to enhance the Quality function

Steps to identifying and incorporating Disruptive Technology

How to utilize Disruptive Technology as a value-added approach to improve quality

How Disruptive Technology can drive quality function visibility

ISO 9000 Speed Networking

5:00 PM-6:00 PM

Brian Clark, Engines, Inc., Jonesboro, AR, USA

Last year, the number one request from attendees according to our survey was

networking. Space is limited so please sign up in advance. Speed networking

will be in a round robin model, facilitating the meeting of individuals with

similar goals, and the opportunity to exchange information in a structured

environment. Each attendee is guaranteed to meet more people than they

would in a traditional networking session. Sometimes individuals with a propensity for mastering the concepts of quality

management, Six Sigma, and SPC may have less propensity for social interaction.

Whether you are an introvert or extrovert, starting out your career in the quality field or a seasoned professional, you will

enjoy this format of meeting other professionals. Typically, participants are randomly paired, the signal is given for a three

minute discussion. This is enough time for introductions and to gain a quick impression.

Youll be amazed at the results from a short meeting with someone youve never met in this quick and simple networking

setup. Meaningful conversations, clients, projects, jobs, and friendships can develop from connections started at a speed

networking session!

TO REGISTER ONLINE:

REGONLINE.COM/AQI OR V I S I T WWW.AQI.ORG

P a g e I S O - 11

MONDAY March 9, 2015

This presentation will address how to develop and implement a refreshed VOC strategy focused on building

customer intimacy. It will provide an approach to identify the Job To Be Done for, by, and with the customer to

determine the outcomes from the value of the products and services they purchase. With actual success

stories as the bulk of the presentation, it will also demonstrate how to implement a structured, disciplined,

and innovative listening approach by getting up close and personal with customers to actually experience

how they use the products and/or services, how to process data to interject information into new product

development, and using this information to rapidly enhance process performance.

TUESDAY

March 10, 2015

23rd Annual ISO 9000 World Conference

7:30 AM-8:00 AM

Continental Breakfast

8:00 AM-8:05 AM

Opening Remarks

Session #ISO-101

8:05 AM-8:40 AM

Organizational Transformation: Sustaining High Performance

Keywords:

Organizational

Transformation,

Sustainability, High

Performance,

Leadership

Industry:

Manufacturing

Level: Advanced

This concise and practical presentation will guide attendees to apply GPS-based methods to mobilize

operations while incorporating destination-focused initiatives. The presenter will explain why the companies

who merit the descriptor high-performing devote such enormous energy toward three vital components:

goals, people, and systems. And while the worlds most profitable corporations all share a clearly-defined vision

and mission, whats often missing is a direct link between tactical operational goals and strategic direction.

Attendees will learn to incorporate measurable goals into their companys daily regimen. Plus, they will have

the management tools to maintain teams that are engaged, focused, accountable, - and poised to drive results.

Session #ISO-102

8:40 AM-9:15 AM

Keywords: Customer

Satisfaction, Metrics,

Employee

Satisfaction, Data

Driven Decision

Making

Industry: Software

Level: Intermediate

Shane Yount, Principal/Author, Competitive Solutions, Inc., Alpharetta, GA, USA

Attendees will discover everything from defining corporate direction and design for leadership parameters, to

the smartest ways to create and maintain workplace behavioral expectations. Additionally, the presenter offers

critical insight on hot-button topics like cultural and generational diversity, communication styles, and listening

processes among employees. Attendees will learn to incorporate measurable goals into their companys daily

regimen. Plus, they will have the management tools to maintain teams that are engaged, focused, accountable,

and poised to drive results.

Customer Satisfaction: Using Metrics to Drive Change

Beth Leonard, VP, Corporate QA, DMI, Bethesda, MD, USA

As business leaders we tend to pay a lot of attention to the metrics important to the business: revenue, cash

flow, profitability, growth, and so on but the real drivers of these business outcomes are customers. So the

obvious question becomes what customer metrics should you be tracking to make sure business metrics

continue to head in the right direction?

This presentation will focus on how to set up an effective customer and employee satisfaction and metrics

program and provide best practices for practitioners. Ms. Leonard will discuss how DMIs internal metrics

program has been implemented as a tool to steer data-driven decision making across all levels of management

including the executive team.

The presentation will be delivered in an informal manner and will include lessons learned and examples from a

real world application. Questions and discussions will be considered a welcome part of the presentation.

Session #ISO-103

9:15 AM - 9:50 AM

ISO 9001 Implementation: Added Challenges During Acquisition

Keywords: ISO 9001,

Implementation,

Acquisition, Change

Management

Industry:

Manufacturing

Level: Intermediate

This presentation is a case study in implementing an ISO 9001 QMS and getting it certified during an

unexpected and sudden company acquisition. Implementation is always full of surprises, but an acquisition

offers an additional layer of anxiety, uncertainty, and stress to the organization and its associates. The timing

could not have been worse. Or was it? Could the acquisition actually have been a blessing in disguise? This

presentation will explore the journey how a very successful privately owned company is acquired by a global

and publicly traded company just two months prior to its scheduled ISO certification audit.

Laura Denktash, Performance Excellence Manager, Video Gaming Technologies, Tulsa, OK, USA

This presentation will offer information through slides that contain charts and forms that include information

about how to successfully navigate an ISO 9001 implementation with the added twist of an acquisition. Lessons

learned and keys to success in this especially volatile and stressful situation will be shared. Anyone who is

going through an implementation or planning an implementation can benefit from this presentation. Change

management skills will also be highlighted.

P a g e I S O - 12

TO REGISTER CALL

888-236-9940 O R 412-782-3383 O R E - M A I L : INFO@AQI.ORG

The Worlds Leading Conference on ISO 9000 & Related Standards

Continental Breakfast

7:30 AM-8:00 AM

Opening Remarks

8:00 AM-8:05 AM

Quality and Process Improvement Initiatives in Healthcare

Session #ISO-111

8:05 AM-8:40 AM

There are many approaches to quality management ISO, Lean and Six Sigma, Baldrige, TQM, and others.

Similarities exist among them albeit with different names, e.g. CA/PA in ISO, Control Phase in Six Sigma

similar but not the same. Enduring success of project outcomes depends on adherence to standardized

procedures and work instructions for the defined processes. As these processes evolve and continually

improve, revisions to the documents must be maintained and training updated in order to sustain a consistent

quality standard.

Keywords: Strategic

Planning, Control

Plan, Sustainability,

STEEEP, Lean & Six

Sigma, Baldrige, TQM

Industry: Healthcare

Level: Intermediate

Valentine Boving, Sr. Quality Engineer, U.T. MD Anderson Cancer Center, Houston, TX, USA

ISO 9001 Providing the Basis for Integrated Performance Base

Session #ISO-112

8:40 AM-9:15 AM

This session will first address the gaps in healthcare and review the current healthcare accreditation model as

well as the Conditions of Participation to highlight key points for the system based references and identify key

aspects that continue to impact healthcare performance.

Keywords:

Healthcare, ISO 9001

Industry: Healthcare

Level: Intermediate

William Metzcar, CEO, ISO Consultants for Healthcare, Greenville, OH, USA

Successful Organizational Change

Duke Rohe, Quality Improvement Education Consultant, U.T. MD Anderson Cancer Center, Houston, TX, USA

Organizational change is happening in almost every healthcare organization but success has been elusive.

Senior leaders know that changes are needed not only system-wide but in their own organization. They know

the kinds of changes their organizations need and when they are needed. And certainly they know that the

responsibility for change rests squarely on their shoulders.

Session #ISO-113

9:15 AM-9:50 AM

Keywords: QMS,

Healthcare, PI, QI

Industry: Healthcare

Level: Intermediate

Executives know that their boards of directors expect more than day-to-day performance; those board

members expect the executives they support to make the changes needed to ensure a profitable, long-term,

future for the organization. In short, todays leaders must both run the business well all the time and change

the business well every time.

Changing the way an organization works is no longer an occasional exercise; change is no longer the

exception. It is now the rule. Changing the way an organization operates is central to organizational

improvement. In todays world change management is the most important role of organizational leadership.

The paramount problem with organizational change today is that change initiatives are rarely successful. The

often-quoted statistic is that only 30% of organizational change attempts are successful. Topics will include:

Introduction to Organizational Change Management; Transitioning with a clear, communicated Vision, and

Altering Processes and Procedures.

Coffee Break

9:50 AM-10:15 AM

TO REGISTER ONLINE:

REGONLINE.COM/AQI OR V I S I T WWW.AQI.ORG

P a g e I S O - 13

March 10, 2015

Secondly, the presenter will cover key ideas from each ISO 9001 clause from a healthcare perspective. These

requirements will be interpreted using healthcare examples and language to bring an understanding of the

essential requirements for performance enhancement. Thirdly, Mr. Metzcar will review the pursuit of ISO 9001

by healthcare and the different approaches utilized to gain certification or compliance. Comparison of these

models to the industry accepted Four Phase approach will be provided to convey a practical, efficient, and

effective model for ISO 9001 implementation within healthcare.

TUESDAY

Quality is driven by the customer, and what the customer requires is defined by the quality improvement team

with endorsement from top management. At our healthcare institution the customer is typically identified as

the patient, clinical services, and operations. A diverse sampling of improvement projects, whose outcomes

have been sustained, will be presented with discussion on why their success has continued into the present.

Further discussion will center on possible causes why many improvement projects have not been sustained.

23rd Annual ISO 9000 World Conference

Session #ISO-121

10:15 AM-10:50 AM

TUESDAY

March 10, 2015

Keywords: Lean,

Quality Manual,

Revisions, Transition,

ISO/TR 10013

Industry:

Manufacturing

Level: Intermediate

The Four-Page Quality Manual

Kristin Case, Consultant, CaseConsults, Tulsa, OK, USA

It is not uncommon to see quality manuals, often 20 60 pages long that were prepared for the purpose of ISO

9001 certification. In some cases, the verbiage and numbering scheme of the manual is similar (or nearly

identical) to the ISO 9001:2008 standard itself. With the ISO 9001 standard going through a significant revision,

there has never been a better time to review and improve your quality manual.

This presentation will address what is required by ISO 9001:2008 to be in the quality manual as well as what is

recommended by ISO/TR 10013, Guidelines for quality management system documentation. It will also address

how to manage the changes in requirements between the 2008 and 2015 revisions of ISO 9001 (because

throwing your old quality manual away probably isnt in the best interest of the organization).

Multiple real-life examples will be provided to meet the requirements for contents of the quality manual (clause

4.2.2(a c) in ISO 9001:2008). Emphasis will be placed on the importance of quality objectives (clause 5.4.1) and

include these in the manual while simultaneously minimizing the need for revisions to the manual. Tips for

eliminating redundancy with other levels of quality documentation (e.g., procedures and work instructions), and

guidelines for deciding what information should be kept, revised, and removed to make the quality manual

more reader-friendly will be presented.

Session #ISO-122

10:50 AM-11:25 AM

Keywords: Internal

Audit, Quality Audit,

Environmental Audit

Industry:

Manufacturing

Level: Intermediate

Combining Internal Audits for ISO 9001 and ISO 14001

Patsy L. Brown, Consultant/Trainer, Brown & Associates Quality Consulting, Inc., Pine Bluff, AR, USA

This presentation is directed at those organizations who are registering both the quality management system

and environmental management system and wish to combine the internal audits of both systems for improved

efficiency in the audit process. Each section of the ISO 9001 and 14001 standards that have similar or identical

requirements will be summarized, and the different requirements for each standard will be highlighted. Where

one standard does not require the same level of detail, participants will be presented with options for

implementation of the audit process.

The presenter will address the knowledge and skills needed to accomplish combined quality and environmental

audits -- knowledge of quality management systems, knowledge of environmental management systems, and

knowledge of basic auditing skills. Most internal auditor training classes are delivered with specialization in only

one standard. This usually results in a lack of specific knowledge of the other management system for

prospective internal auditors. As a result, auditors must have additional training to bridge this gap. The session

will provide recommendations to efficiently provide this additional training.

Session #ISO-123

11:25 AM-12:00 PM

Customer Audit Innovation

Keywords:

Customer Audits,

Supplier Audits,

Customer Relations

Industry: Service

Level: Intermediate

This presentation will provide an in-depth look at innovation in customer auditing. Customers often reserve the

right to audit under supplier management, and often a company can be visited by many customers throughout

the year, creating substantial costs and investments to successful support each requested customer audit.

Sami Brown, Quality Systems Specialist, and Douglas Potter, Western Hemisphere Quality Manager, Jeppesen

Sanderson, Inc., Englewood, CO, USA

Most customer requested audits require a variety of production staff be available to answer process questions

and demonstrate the processes to the auditors satisfaction. Each time an employee must be removed from

production work to address an auditor, there is lost efficiency and increased costs to the business.

This presentation will introduce an innovative customer audit technique using a Customer Audit Conference

format. This method allows majority of customers requesting an audit to arrive on site for a single audit event,

reducing the cost and interruption to business.

12:00 PM-1:15 PM

P a g e I S O - 14

Networking Luncheon

TO REGISTER CALL

888-236-9940 O R 412-782-3383 O R E - M A I L : INFO@AQI.ORG

The Worlds Leading Conference on ISO 9000 & Related Standards

Clinically Led Improvement

Tim O'Hanlon, Partner, GE Healthcare Finnamore, Birmingham, West Midlands, UK

The UK government has set a target that 95% of patients attending the Accident and Emergency

Department (A&E) should be treated and either be admitted to the hospital or be discharged from the

department within 4 hours. Many hospitals in the UK struggle to consistently meet this target. Patients are

defaulting to A&E because of convenience, a belief that they will see a better clinician, and because they

struggle to get appointments with their family doctor. In these case study organizations, the leadership

teams understood that there was variation in performance and this gave the opportunity improvement.

Session #ISO-131

10:15 AM-10:50 AM

Keywords: Rapid

Improvement,

Emergency Room,

Clinical Engagement

Industry: Healthcare

Level: Intermediate

This presentation will show how to engage the unconvinced in improvement change attitudes to team

based change prove the need for investment and not just savings.

Improving the QMS in Healthcare Organizations

Mickey Christensen, President, TQM Systems, Baton Rouge, LA, USA

With all of the changes occurring in the healthcare industry in the USA (and other countries), an

organization will have to make sustainable improvements to survive. Implementing a good management

system to institutionalize the changes that show good results will aid in sustaining the organization.

Keywords: Process

Improvement, QMS

Improvement, Healthcare

Industry: Healthcare

Level: Basic

The bottom line is implementing/changing to a system that is agile and effective. Attendees will take away

an awareness of the urgency to improve and will be able to view improving the Quality Management

system in different ways.

Facilitation Football - Managing Group Process to its Best

Duke Rohe, Quality Improvement Education Consultant, U.T. MD Anderson Cancer Center; Houston, TX, USA

Meeting facilitation is an essential skill for every improvement professional. We may know the pieces of it,

but do we know what we don't know? This session attempts to provide the tips, tricks, and traps of

facilitating group process...and do it in an engaging manner. Every participant will receive a Facilitation

Football placemat to scribe the important aspects of facilitation. They will determine what's on the playing

field (during the meeting), what's out of bounds, and what happens after the touchdown.

Session #ISO-133

11:25 AM-12:00 PM

Keywords: QMS,

Healthcare, PI, QI

Industry: Healthcare

Level: Intermediate

Shared will be distinctions between leading and facilitating a meeting. Sixteen attributes of an effective

team, roles/goals/secrets/tools/weapons of facilitation, great ground rules, ten most common traps you to

fall into, a universal agenda that works when there is no agenda, and how to keep from personally getting

sucked into the content of a meeting. There are also pointers and roles to facilitate large meetings when

there more than eight members.

If you want to learn all this in a simulation manner that can be transferred to others, come check it. It's

good for new learners who want to know and seasoned professionals who want to remember.

Networking Luncheon

12:00 PM-1:15 PM

TO REGISTER ONLINE:

REGONLINE.COM/AQI OR V I S I T WWW.AQI.ORG

P a g e I S O - 15

March 10, 2015

Changes are occurring in the processes involved with patient and employee safety, quality of care provided,

reduction of HAIs, reduction of returns within 30 days, HIPAA, reduction of reimbursements, and many

other changes.

Session #ISO-132

10:50 AM-11:25 AM

TUESDAY

GE Healthcare Finnamore was invited to initiate this change management improvement program. While

patients were never in an unsafe situation, what became very clear from the range of projects that emerged,

was that the leaders were right; there was variation in use of procedures. Each area/shift was adapting their

way of working and some best practice was not being shared as quickly as it might have been. Many of the

tasks within the project teams therefore focused on developing new procedures and then ensuring effective

implementation every shift, every day.

23rd Annual ISO 9000 World Conference

Session #ISO-141

10:15 AM-12:00 PM

Keywords: Risk, Risk

Based Thinking

Industry: All

Level: Basic

Risk-Based Thinking: A Major Element of ISO 9001:2015

William Levinson, President, Levinson Productivity Systems PC, Wilkes Barre, PA, USA

"Identification of risks and opportunities" is perhaps the foremost major change in ISO 9001:2015. General Carl

von Clausewitz's On War, in fact, summarized the basic concept in a single sentence. "Countless minor

incidentsthe kind you can never really foreseecombine to lower the general level of performance, so that

one always falls far short of the intended goal." He cited examples such as bad roads, lack of fresh horses, fog,

and bad weather, and defined them with the single word, "Friction," which in todays language is defined as

Risk

March 10, 2015

Success in warfare depended as much, if not more, on a general's ability to overcome friction as it did on his

combat skills. The same principle carries over into industry where friction encompasses the entire set of

unanticipated and undesirable events that cause projects to finish late, order fulfillments to be late, actual

capacity to fall short of theoretical capacity, and so on. Tom Peters later wrote in Thriving on Chaos, "The

accumulation of little items, each too trivial to trouble the boss with, is a prime cause of miss-the-market

delays," and the concept "for want of a nail" also is applicable.

Henry Ford, in fact, addressed risk both internally and externally. Purportedly minor machine stoppages, the

industrial counterparts of Clausewitz's "countless minor incidents," were simply not tolerated even if the workers

could clear them within minutes; the workers also looked for the root causes to eliminate them.

TUESDAY

The attendee will learn how to teach the concept of risk to the entire workforce, which empowers each

employee to recognize potential safety, quality, and throughput issues. This also supports lean manufacturing

because friction is, by definition, muda or waste (and vice versa). As stated by J.F. Halpin in Zero Defects (1966),

"They turned out to be the little things that get under a worker's skin but are never quite important enough to

make him come to management for a change." Any chronic annoyance or frustration (e.g. having to clear

purportedly minor stoppages), workplace inefficiency, wasted effort, or doing it over because it wasn't done

right the first time, is friction that should be the target of closed loop corrective action.

Ford added in My Life and Work (1922), "If transportation were perfect and an even flow of materials could be

assured, it would not be necessary to carry any stock whatsoever. That would save a great deal of money, for it

would give a very rapid turnover and thus decrease the amount of money tied up in materials. With bad

transportation one has to carry larger stocks." This reinforces the connection between friction and lean

manufacturing because this risk (materials not arriving on schedule) requires the carriage of inventoryone of

the Toyota production system's Seven Wasteswhich, in turn, increases cycle times. Ford, therefore, vertically

integrated his supply chain to prevent interruptions by unreliable suppliers or railroads, and included

contingency plans for catastrophes as major as a flooded rail line.

While any worker should be able to identify workplace friction (risk), it is primarily up to management to

identify external risks such as supply chain breakdowns, natural disasters, loss of business continuity, and

technological changes that could endanger the organization's existence. This workshop will provide several

real-world examples of these risks, and the consequences of failure to anticipate and/or mitigate them.

12:00 PM-1:15 PM

ISO 9001/QMS Networking Luncheons

Join us for this fun activity! During this Networking Luncheon, you may select to be seated depending on your

area of interest or expertise. Group sign-up will be made on-site. Please note that group seating is limited and

will be assigned on a first-come, first-served basis. Following is a partial list of Networking Groups.

P a g e I S O - 16

Management Commitment

Management Review

Manufacturing Industries

Monitoring & Measurement

Process Management & Systems Thinking

Risk

Service industries

Transitioning to the new ISO Standard

TS 16949

Understanding & Using Data

Regulated Industries

TO REGISTER CALL

888-236-9940 O R 412-782-3383 O R E - M A I L : INFO@AQI.ORG

The Worlds Leading Conference on ISO 9000 & Related Standards

Data Analysis for Small Businesses - Missed Opportunities

David Ross, Quality Consultant, TMAC, Arlington, TX, USA

As a TMAC employee for the past 10 years, Mr. Ross had the opportunity to observe (up close) how many

small businesses collect and analyze data affecting key processes such as Customer Satisfaction,

Nonconforming Product, and Job Quoting. More times than not, real opportunities for improvement are

overlooked resulting in little or no real benefit to the organization. Contributing factors include:

Treating data affecting small and large revenue customers equally

Data collection instruments omit key variables needed for effective decision making (i.e. processes,

Session #ISO-151

1:15 PM-1:50 PM

Keywords: Analysis of

Data, Data Collection,

Improved

Performance

Industry:

Manufacturing

Level: Intermediate

groups/departments

Cost of Poor Quality: Purpose-Built Tools to Address Quality

Carl Mead, Director, Business Improvement Solutions, BSI; Herndon, VA, USA

Technology in the form of purpose-built software tools can help address quality challenges, help improve

customers perceptions, and help businesses to be liked. In todays social media savvy, ultra-connected

world, noteworthy quality is a very desirable goal. When noteworthy becomes comment-worthy or tweetworthy, ones quality reputation is enhanced. Participants will walk away from this session with a simple

formula: quality management = quality product. Examining the traditional aspects of Cost of Poor Quality

(COPQ) may provide a structured approach on how to manage and improve performance. Key points include:

Keywords: Software

Tools, Quality

Management,

Measure, Cost of Poor

Quality, Performance

Improvement

Industry:

Manufacturing

Level: Intermediate

mitigating risk, driving continual improvement, and improving customer satisfaction

How to leverage technology to streamline quality management, reduce the cost of poor quality,

identify and correct problems in your supply chain and effectively track customer complaints

Shifting focus to the analysis that is key to continual improvement: trend reporting, tracking,

transparency

Using the Cloud to Deploy QMS Solutions

Session #ISO-153

2:25 PM-3:00 PM

This session will present the trends surrounding cloud computing undefined what it is, what to look for, and

some of the benefits of deploying QMS in the cloud. It will discuss Software as a Service and how companies

can leverage the latest methods of deployment for their QMS solution. The following concepts will be

discussed:

Keywords: Quality,

Cloud Technology,

Quality Software

Industry: Software

Level: Intermediate

Tim Lozier, Director of Product Strategy, VERSE, Farmingdale, NY, USA

How Quality Management Systems can be deployed to the cloud as a cost-effective dedicated

environment for your organization.

Types of deployment of enterprise software

Benefits of cloud-based technology

What to look for in cloud deployment

How QMS fits into the cloud computing scheme

Selecting a solution, with cloud in mind

Refreshment Break

3:00 PM-3:30 PM

TO REGISTER ONLINE:

REGONLINE.COM/AQI OR V I S I T WWW.AQI.ORG

P a g e I S O - 17

March 10, 2015

The era of (quality) management systems 2.0

Best practices and technology that can facilitate this culture change and ensure the focus is on

Session #ISO-152

1:50 PM-2:25 PM

TUESDAY

employees, product types, disposition types for nonconforming product, etc.)

Once designed, data collection and analysis tools tend not to change and evolve with the business

Limiting data collection/analysis to business and production processes and omitting functional

23rd Annual ISO 9000 World Conference

Session #ISO-161

1:15 PM-1:50 PM

TUESDAY

March 10, 2015

Keywords: Strategy,

Lean, Hoshin Kanri,

Policy Deployment

Industry:

Manufacturing

Level: Intermediate

Hoshin Kanri: Engaging the Workforce to Achieve Goals

Chris Hayes, CEO, Impact Performance Solutions; Morgan, UT, USA

Many employees and leaders struggle to understand how they contribute to organizational objectives and how

daily activities impact the big picture. Planned use of Hoshin Kanri and the X-matrix can help create a visible

link for everyone to understand their personal contribution. Once understood, employee engagement and

productivity easily increase allowing change to become easier. Hoshin Kanri, when applied effectively in any

industry, is the most powerful tool to effectively align an organizations activities to its true north. This

methodology ensures that everyone in an organization knows the strategic direction of the organization and

focuses each person in a common direction. A catch-ball environment is supported where goals, strategies,

and action items are tossed back and forth between management levels to insure that each level is engaged

and proactively working towards achieving planned results at a higher level. Learning outcomes from this

presentation include:

Understand strategy deployment

Learn how Hoshin Kanri simplifies strategy deployment

Identify the likely challenges as well as the likely benefits of using Hoshin Kanri

Get a solid overview and path forward for considering alignment of the organization towards meeting

top-level goals

Session #ISO-162

1:50 PM-2:25 PM

Keywords: ISO, Lean,

Project Management

Industry:

Education/Training

Level: Basic

How to Achieve Buy-In

Terra Vanzant Stern, Six Sigma Master Black Belt, SSD Global Solutions, Inc., Conifer, CO, USA

As ISO or Lean Six Sigma professionals it is often necessary to enlist employees who do not directly report to

our position to help in promoting a program. Often there are responsibilities within each department that

require support.

Setting the team's direction is often the easy part. Getting an employee to buy in to the concept of working

collaboratively can be more difficult. Some people simply like to work independently. Others may not be

convinced of the true benefits of working as a group. Therefore, when you present the idea of working on a

team, you'll want to emphasize the positive aspects of the experience in order to achieve team buy-in.