Академический Документы

Профессиональный Документы

Культура Документы

Us 20130109068

Загружено:

FebrianFAАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Us 20130109068

Загружено:

FebrianFAАвторское право:

Доступные форматы

US 20130109068Al

(19) United States

(12) Patent Application Publication (10) Pub. N0.2 US 2013/0109068 A1

Ellis et al.

(54)

(43) Pub. Date:

METHODS FOR PRODUCING ACETONE,

BUTANOL, AND ETHANOL

Publication Classi?cation

(51)

(71) Applicant: Utah State University, North Logan, UT

(US)

(72) Inventors: Joshua T. Ellis, Logan, UT (US);

May 2, 2013

Int. Cl.

C12P 7/28

C12P 7/06

C12P 7/16

(52) us CL

Charles M111, Nonh Logan UT ([58);

CPC

(2006.01)

(2006.01)

(2006.01)

C12P 7/28 (2013.01); C12P 7/16 (2013.01);

Ronald Sims, Logan, UT (US); Ashlk

C121, 7/065 (201301)

sathsh Logan UT (Us)

USPC .......................... .. 435/150; 435/160; 435/161

(73) Assignee: Utah State University, North Logan, UT

(Us)

(21) Appl. No.: 13/663,002

(22) Filed:

ABSTRACT

Oct. 29, 2012

Related U-s- Application Data

(60)

(57)

Provisional application No. 61/552,317, ?led on Oct.

27, 2011.

Methods of producing solvents frorn algae, Where the meth

ods 1nclude processing algae to yield processed biomass,

fermenting the processed biomass With a Closlridium bacte

ria to yield solvents.

Patent Application Publication

May 2, 2013 Sheet 1 0f 8

US 2013/0109068 A1

F1igure

Patent Application Publication

May 2, 2013 Sheet 2 0f 8

US 2013/0109068 A1

NwBmE

E

WE

Patent Application Publication

May 2, 2013 Sheet 3 0f 8

US 2013/0109068 A1

3Figure

w

m

ii;

Patent Application Publication

May 2, 2013 Sheet 4 0f 8

US 2013/0109068 A1

Eutmw?

igu

F

4

re

{*imae}

Patent Application Publication

May 2, 2013 Sheet 5 0f 8

US 2013/0109068 A1

F5igure

w

{:13

M

w

w;

N

w,

at:

33

inTime

Patent Application Publication

May 2, 2013 Sheet 6 0f 8

US 2013/0109068 A1

6Figure

{ima }

gsmwmwwwmmwm

Patent Application Publication

May 2, 2013 Sheet 7 0f 8

US 2013/0109068 A1

gugm

Figu

7re

{Timae}

Patent Application Publication

May 2, 2013 Sheet 8 0f 8

US 2013/0109068 A1

$1. x4. . Eur

wwEwE

May 2,2013

US 2013/0109068 A1

METHODS FOR PRODUCING ACETONE,

BUTANOL, AND ETHANOL

prising processing algae to yieldprocessed biomass, ferment

ing the processed biomass With a Closlridium bacterium to

yield solvents.

CROSS-REFERENCE TO RELATED

APPLICATIONS

[0001] This application claims priority to US. Provisional

Patent Application No. 61/552,317, ?led Oct. 27, 2011, the

entirety of Which is herein incorporated by reference.

BRIEF DESCRIPTION OF THE DRAWINGS

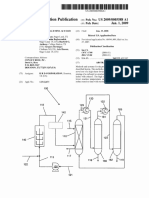

[0008]

FIG. 1 illustrates a How diagram according to an

exemplary embodiment.

[0009]

FIG. 2 illustrates production yields according to an

exemplary embodiment.

GOVERNMENT SPONSORED RESEARCH

[0002] This invention Was made, at least in part, With gov

ernment support under contract DE-EE00031 14 awarded by

the United States Department of Energy. The government has

certain rights in the invention.

TECHNICAL FIELD

[0010]

FIG. 3 illustrates production yields according to an

exemplary embodiment.

[0011]

FIG. 4 illustrates production yields according to an

exemplary embodiment.

[0012]

FIG. 5 illustrates production yields according to an

exemplary embodiment.

[0013]

FIG. 6 illustrates production yields according to an

exemplary embodiment.

[0003] The present disclosure relates to methods for pro

ducing solvents, more particularly, it relates to methods of

making acetone, butanol, and ethanol (ABE) from algal bio

mass.

[0014]

FIG. 7 illustrates production yields according to an

exemplary embodiment.

[0015]

FIG. 8 illustrates production yields according to an

exemplary embodiment.

BACKGROUND

DETAILED DESCRIPTION

[0004] Many clostridia species such as Closlridium beijer

inckii, Closlridium saccharoperbulylacelonium, and C.

acelobuzylicum are anaerobic, saccharolytic, spore forming,

and ABE producing bacteria that have been previously iso

ciated methods for producing ABE from algal biomass. In the

folloWing description, numerous speci?c details are provided

lated from a variety of environments. Saccharolytic clo stridia

have been isolated from, for example, soils, lake sediments,

Well Water, human feces, and canine feces. Closlridia are

gram-positive, rod-shaped, motile (via ?agella), and are obli

gate anaerobes.

[0005] ABE fermentation using C. acelobuzylicum, as Well

as other ABE fermenting clostridia, along With various bio

logical feedstocks have been investigated in the past. HoW

ever, to meet the needs of reneWable biofuels, improved meth

ods for producing ABE from inexpensive, reneWable

feedstocks are needed.

SUMMARY

[0006]

The polysaccharides in algae biomass offers a tre

mendous amount of energy that can be harvested in the form

of biofuels. The fermentation of carbohydrates to C2, C3, and

C4 compounds such as ethanol, acetone, isopropanol, and

butanol are de?nite in certain saccharolytic Closlri di um spp.,

such as Closlridium acelobulylicum, Closlridium saccharop

erbulylacelonium, and Closlridium beljerinckii. Acetone-bu

tanol-ethanol (ABE) fermentation, utiliZing algae as sub

strate, could be employed at industrial scales for the

production of these high value solvents. Algal biomass Would

serve as an advantageous substrate due to its ubiquitous

nature, as Well as its advantages in application and biocon

version. Algae are considered to be the most important sub

strate for future production of clean and reneWable energy.

See, e.g., Demirbas, A., Use of algae as biofuel sources,

Energy Conversion and Management, 51:2738-2749 (2010)

Elsevier Ltd. Additionally, the use of algal biomass from

WasteWater treatment facilities Would provide a cheap and

reneWable substrate, that could be continuously harvested, for

the production of ABE.

[0007] The present disclosure in aspects and embodiments

addresses these various needs and problems by providing

methods of producing solvents from algae, the method com

[0016]

The present disclosure covers apparatuses and asso

for a thorough understanding of speci?c preferred embodi

ments. HoWever, those skilled in the art Will recognize that

embodiments can be practiced Without one or more of the

speci?c details, or With other methods, components, materi

als, etc. In some cases, Well-knoWn structures, materials, or

operations are not shoWn or described in detail in order to

avoid obscuring aspects of the preferred embodiments. Fur

thermore, the described features, structures, or characteristics

may be combined in any suitable manner in a variety of

alternative embodiments. Thus, the folloWing more detailed

description of the embodiments of the present invention, as

illustrated in some aspects in the draWings, is not intended to

limit the scope of the invention, but is merely representative

of the various embodiments of the invention.

[0017] In this speci?cation and the claims that folloW, sin

gular forms such as a, an, and the include plural forms

unless the content clearly dictates otherWise. All ranges dis

closed herein include, unless speci?cally indicated, all end

points and intermediate values. In addition, optional or

optionally refer, for example, to instances in Which subse

quently described circumstance may or may not occur, and

include instances in Which the circumstance occurs and

instances in Which the circumstance does not occur. The

terms one or more and at least one refer, for example, to

instances in Which one of the subsequently described circum

stances occurs, and to instances in Which more than one of the

subsequently described circumstances occurs.

[0018] The present disclosure covers methods, composi

tions, reagents, and kits for making acetone, butanol, and

ethanol (ABE) from algal biomass. A How diagram of at least

one embodiment is illustrated in FIG. 1.

[0019] I. Feed Stocks

[0020] As a feedstock, any suitable algae, cyanobacteria, or

combination thereof may be used. In the description herein

the terms algae or algal include algae, cyanobacteria, or

combinations thereof. In embodiments, algae that produce

high concentrations of polysaccharides may be preferred. In

May 2,2013

US 2013/0109068 A1

many embodiments, algae produced in Waste Water may be

used. The algae may be lyophiliZed, dried, in a slurry, or in a

paste (With for example 10-15% solid content).

[0021]

After identi?cation of a feedstock source or sources,

[0032] Acid hydrolysis may be permitted to take place for a

suitable period of time depending on the temperature of the

slurry and the concentration of the hydrolyZing agent. For

example, the reaction may take place for up to 72 hours, such

as from about 12-24 hours. If the slurry is heated, then

the algae may be formed into a slurry, for example, by adding

Water, adding dried or lyophiliZed algae, or by partially dry

hydrolysis may occur at a faster rate, such as from about

ing, so that it has a solid content of from about 1-40%, such as

15-120 minutes, 30-90 minutes, or about 30 minutes.

about 4-25%, about 5-15%, about 7-12%, or about 10%.

[0022] The various steps to the process, according to some

adding to the slurry a hydrolyZing agent, such as an acid. Any

[0033]

Hydrolysis of the algal cells may be achieved by

embodiments, are described in more detail beloW. The meth

suitable hydrolyZing agent, or combination of agents, capable

ods described herein may be accomplished in batch processes

of lysing the cells and breaking doWn complex carbohydrates

and lipids may be used. Exemplary hydrolyZing acids may

or continuous processes.

[0023] II. Algal Biomass Processing

[0024] The feedstock may be directly processed according

to the ABE production described beloW. Alternatively, in

some embodiments, the feedstock may optionally be pro

cessed into a processed biomass prior to ABE production as

set forth in Us. application Ser. No. 13/660,161, ?led on Oct.

25, 2012, the entirety of Which is herein incorporated by

reference in its entirety. This processing to yield processed

biomass may include cell lysis, and solid/liquid separation as

described, for example, beloW.

[0025] A. Algal Cell Lysis

[0026] The algal cells may be optionally lysed by any suit

able method, including, but not limited to acid and/or base

hydrolysis (described beloW). Other methods may include

mechanical lysing, such as smashing, shearing, crushing, and

grinding; sonication, freeZing and thaWing, heating, the addi

tion of enZymes or chemically lysing agents.

[0027] In some embodiments, the algal cells may be lysed

by acid hydrolysis folloWed by an optional base hydrolysis.

include strong acids, mineral acids, or organic acids, such as

sulfuric, hydrochloric, phosphoric, or nitric acid. These acids

are all capable of accomplishing the goals stated above. When

using an acid, the pH of the slurry should be less than 7, such

as from about 1-6, about 1.5-4, or about 2-2.5.

[0034] In addition to strong acids this digestion may also be

accomplished using enZymes alone or in combination With

acids that can break doWn plant material. HoWever, any such

enZymes or enZyme/ acid combinations Would also be capable

of breaking doWn the complex polysaccharides to their

respective oligosaccharides or monosaccharides as Well as

complex lipids to free fatty acids.

[0035]

In some embodiments, the acid or enZymes, or a

combination thereof, may be mixed With Water to form a

hydrolyZing solution. HoWever, in other embodiments, the

hydrolyZing agent may be directly added to the slurry.

[0036] (2) Base Hydrolysis

[0037] After the initial acidic hydrolysis, a secondary base

hydrolysis may be performed to digest and break doWn any

[0028] (1) Acid Hydrolysis

remaining Whole algae cells; hydrolyZe any remaining com

plex polysaccharides and lipids and bring those polysaccha

[0029]

rides and lipids into solution; convert all free fatty acids to

their salt form, or soaps; and to break chlorophyll molecules

To degrade the algal cells (or other cells present), to

bring cellular components into solution, and to break doWn

complex components, such as polysaccharides to their

apart.

include, but are not limited to, starch, cellulose, and xylan.

[0038] In this secondary hydrolysis, the biomass in the

slurry is mixed With a basic hydrolyZing agent to yield a pH of

greater than 7, such as about 8-14, about 11-13, or about

12-12.5. Any suitable base may be used to increase in pH, for

example, sodium hydroxide, or other strong base, such as

The degradation of these complex polysaccharides from the

acid hydrolysis Will yield oligosaccharides or monosaccha

pH may be varied to achieve more e?icient digestion.

respective monosaccharide components as Well as lipids to

free fatty acids, a slurry of Water and algae described above

may be optionally heated and hydrolyZed With at least one

acidic hydrolyZing agent. Complex carbohydrates may

rides that can be readily used for ABE production. These

complex lipids may include, for example, triacylglycerols

(TAGs), glycolipids, etc. In addition to degrading algal cells

and complex lipids, the acidic environment created by addi

tion of the hydrolyZing agent removes the magnesium from

the chlorophyll molecules.

[0030] When heated, the slurry may reach temperatures of

from about 1-200o C., such as about 20-1000 C., about 50-950

C., or about 900 C. When temperatures above 1000 C., or the

boiling point of the solution are used, an apparatus capable of

Withstanding pressures above atmospheric pressure may be

employed. In some embodiments, depending on the type of

algae, the type and concentration of acid used for hydrolysis,

the outside temperature conditions, the permissible reaction

time, and the conditions of the slurry, heating may be omitted.

Heating may occur prior to, during, or after addition of a

potassium hydroxide may be used. Temperature, time, and

[0039] This basic slurry may be optionally heated. When

heated, the slurry may reach temperatures of from about

1-200o C., such as about 20-1000 C., about 50-950 C., or

about 900 C. When temperatures above 1000 C., or the boiling

point of the solution are used, an apparatus capable of With

standing pressures above atmospheric pressure may be

employed. In some embodiments, depending on the type of

algae, the type and concentration of acid used for hydrolysis,

the outside temperature conditions, the permissible reaction

time, and the conditions of the slurry, heating may be omitted.

Heating may occur prior to, during, or after addition of a

hydrolyZing agent.

[0040]

In addition, the basic slurry may be optionally

mixed either continuously or intermittently. Alternatively, a

hydrolysis reaction vessel may be con?gured to mix the slurry

by convection as the mixture is heated.

hydrolyZing agent.

[0041]

[0031]

In addition, the slurry may be optionally mixed

a suitable period of time depending on the temperature of the

either continuously or intermittently. Alternatively, a

hydrolysis reaction vessel may be con?gured to mix the slurry

slurry and the concentration of the hydrolyZing agent. For

example, the reaction may take place for up to 72 hours, such

as from about 12-24 hours. If the slurry is heated, then

by convection as the mixture is heated.

Basic hydrolysis may be permitted to take place for

May 2,2013

US 2013/0109068 A1

hydrolysis may occur at a faster rate, such as from about

-continued

15-120 minutes, 30-90 minutes, or about 30 minutes.

T-6 Medium (Approximate formula per liter)

[0042] During this basic hydrolysis, chlorophyll is hydro

lyzed to the porphyrin head and phytol side chain, as Well as

complex polysaccharides are hydrolyzed to oligosaccharides

Component

Amount

or their respective monosaccharide component.

KH2PO4

0.5 g

[0043] B. Biomass and Aqueous Phase Separation

[0044] Under the condition of elevated pH, the biomass

may be separated from the aqueous solution. This separation

is performed While the pH remains high to keep the lipids in

MgSO47H20

0.3 g

their soap form so that they are more soluble in Water, thereby

remaining in the Water, or liquid, phase. Once the separation

is complete, the liquid phase is kept separate and the remain

ing biomass may be optionally Washed With Water to help

remove any residual soap molecules. This Wash Water may

also be collected along With the original liquid phase. Once

FeSO4 7H20

Ammonium acetate (38.9 mM)

Cysteine hydrochloride

Glucose or Algae or other substrate

10 mg

3.0 g

0.5 g

5.0-15.0% (W/v)

Adjust pH to 6.5 With NaOH

[0052]

The medium may be formulated to contain about 1

to about 20% processed algae by Weight per liter of medium,

such as about 4 to about 15%, 5 to about 8%, or 6%.

the biomass is Washed it may be taken to the next phase of the

[0053]

process. The liquid phase may be processed further to derive

varied and adjusted based upon desired groWth parameters

and/or culturing conditions. In addition, other suitable medi

other useful products, such as biodiesel as described in US.

application Ser. No. 13/660,161, ?led on Oct. 25, 2012.

[0045] The resulting biomass, containing sugars, may then

be taken through the exemplary ABE production process

The other components of the T-6 medium may be

ums may include RCM media and TYA media, both of Which

have been shoWn to provide suitable nutrients for ABE fer

mentation With algae as substrate.

described beloW, or some other suitable ABE production

method.

[0046] III. ABE Production

[0047] A. Bacterial Producers

from about 10 to about 250 units of enzyme. Suitable sugars

[0048] Any suitable bacteria or microorganism capable of

metabolizing algal biomass into solvents may be used. At

amounts ranging from about 0.1% to about 1.0%. In some

least one Closlridium species or group of species may be used

embodiments, cheese Whey or Whey permeate may be used to

[0054] The medium may be supplemented With enzymes

and/or sugars to help initate primary groWth. Suitable

enzymes include cellulases and xylanases in amounts ranging

include glucose, starch, arabinose, galactose, and xylose in

to ferment the algal biomass into ABE. For example, suitable

substitute or augment media components. These nutrient

Closlridium species may include, Closlridium saccharoper

bulylacelonium, Closlridium acelobulylicum, Closlridium

sources have advantages because they are a Waste stream of

beijerinckii, or any suitable Closlridium bacteria isolated

from the environment.

[0049]

[0050]

B. Fermentation

ABE fermentation is typically characterized by tWo

distinct phases of metabolism, acidogenesis and solventoge

nesis. Acidogenesis occurs during log phase of groWth,

Whereas solventogenesis occurs late log phase to early sta

tionary phase of groWth. The primary acids produced during

acidogenesis are acetic and butyric acid. Clostridia re-assimi

milk product processing and, as such, may have cost advan

tages over other nutrient sources.

[0055] Once T-6 media constituents are mixed to homoge

neity, the media may be neutralized to a pH of about 7, such

as about 6.5. The medium may then be modi?ed by any

suitable technique to create an anaerobic environment. Suit

able techniques for creating such an environment include

bubbling the medium With O2 -free N2 gas for a suitable period

of time.

late the acids produced during acidogenesis and produce

[0056]

acetone, butanol, and ethanol as metabolic byproducts. The

pH-acid effect from acidogenesis plays a key role in the onset

of solventogenesis. See, Li et al., Performance of batch, fed

batch, and continuous A-B-E fermentation With pH-control,

ronment, the medium may be optionally sterilized.

102 Bioresource Technology.4241-4250 (2011).

[0051] Any suitable culture medium may be used. Culture

medium is used to support the groWth of microorgani sms, and

can be modi?ed to support microbial groWth or derive pro

duction of certain bio-products. Medium recipes contain vita

mins, minerals, buffering agents, nitrogen sources, and car

bon sources necessary for bacterial groWth. The

carbohydrates Within algal cells are the carbon source used to

drive ABE production throughout the claims. For example,

the folloWing culture medium, referred to as T-6, may be used.

T-6 Medium (Approximate formula per liter)

[0057]

Prior to or after the creation of the anaerobic envi

The medium may be inoculated With at least one

Closlridium species. The concentration of bacteria may be

varied, depending on the culture vessel and scale of the fer

mentation. Prior to or after inoculation, the bacterium may be

heat shocked to a temperature of about 700 C. for a suitable

period of time to germinate the spores. The bacterium may

also be incubated in a groWth medium at optimal temperature

prior to inoculation to alloW the spores to become vegetative

prior to transferring to the groWth medium. After inoculation,

the fermentation vessel head space, if any, may be ?ushed

With N2 gas to ensure optimal anaerobic groWth conditions.

[0058]

The culture may be incubated at about 350 C.

throughout. Typically, 48 hours is needed for T-6 glucose

cultures containing spores of Closlridium saccharoperbuzy

lacelonium to reach mid-log phase, though fermentation

times may vary depending on the vessel size, inoculation

concentration, and temperature. T-6 algae media fermenta

Component

Amount

Tryptone

6.0 g

Yeast extract

2.0 g

tions may be conducted for about 96 hours to reach optimal

ABE production. T-6 glucose fer'mentations may be used as

the positive control, Whereas T-6 media Without a carbon

source may be used as the negative control throughout.

May 2,2013

US 2013/0109068 A1

[0059]

C. ABE Puri?cation

[0060] Any suitable puri?cation method may be employed.

In some embodiments, distillation may be used for purifying

the various fermentation products. Distillation is used Widely

for alcoholic beverages, as Well as for other types of fer

mented solutions, particularly acetone, butanol, and ethanol.

When distillation is employed, puri?cation is accomplished

pH 6.5, and the media Was then dispensed into serum vials.

These vials Were then bubbled With O2 free N2 gas for 10

minutes to remove any O2 (thus generating an anaerobic

environment). Once this Was performed, the vials Were

sealed, crimped, and steriliZed. After sterilization, 1 ml of a

concentrated spore suspension containing Closlridium sac

charoperbuzylacelonium Was transferred to T-6 glucose

based on different boiling points from one compound to

another. By heating a mixture to a temperature just above each

media anaerobically. After inoculation, the groWth media

solvents boiling point, the desired compound evaporates and

then condenses independently to acquire puri?ed solvents.

to germinate spores and incubated at optimal temperature.

This step alloWed the spores to become vegetative prior to

transferring into T-6 algae media. After the T-6 glucose cul

ture reached mid-log phase, a 10% inoculum of mid-log

phase cells Was transferred into T-6 algae media (containing

[0061]

In some embodiments, each of the fermentation

products may be puri?ed; hoWever, in other embodiments,

only a select product or group of products may be puri?ed. In

particular, because the yield for acetone and butanol are

higher than that of ethanol, some puri?cation processes only

purify acetone and butanol, While other fermentation prod

ucts are ?ared off or otherWise discarded.

[0062] Other suitable puri?cation methods may be

employed, such as absorption, membrane pertraction, extrac

tion, and gas stripping. See, e.g., Kaminski et al., Biobutanol

- Production and Puri?cation Methods, Ecological Chemistry

containing spores Was heat shocked at 70 C. for 10 minutes

10% processed algae) anaerobically. After fermentation

media Was inoculated, the headspace Was ?ushed With O2 free

N2 gas for 5 minutes to ensure optimal groWth conditions and

O2 removal. The culture Was then incubated at 35 C.

throughout for 48 hours to reach mid-log phase. The fermen

tation Was conducted for 96 hours to reach optimal ABE

production. The mean yield results of tWo replicates of are

illustrated in FIG. 2.

and Engineering S., Vol. 18, No: 1 (2011).

[0063]

The folloWing examples are illustrative only and are

Example 3

not intended to limit the disclosure in any Way.

ABE Production using Processed Biomass and

EXAMPLES

Example 1

Biomass Processing

[0064]

To a glass test tube 100 mg of lyophiliZed algal

biomass Was added. One mL of a 1 Molar Sulfuric acid

solution is added to the test tube and the test tube Was then

sealed using a PTFE lined screW cap and gently mixed to

create a homogenous slurry. This slurry Was then placed in a

Hach DRB-200 heat block pre-heated to 90 C. This slurry is

alloWed to digest for 30 minutes With mixing at the 15 minute

mark.

[0065] Once the ?rst 30 minute digestion period Was com

pleted, the test tube Was removed from the heat source and

0.75 mL of a 5 Molar Sodium Hydroxide solution Was added

to the test tube. The test tube Was immediately resealed and

returned to the heat source for 30 minutes. Mixing at 15

minutes Was again provided.

[0066] Once the base hydrolysis above Was completed, the

test tube Was removed from the heat source and alloWed to

cool in a cold Water bath. Once cooled the test slurry Was

centrifuged using a Fisher Scienti?c Centri?c Model 228

centrifuge. The upper aqueous phase Was removed and col

lected in a separate test tube. To the remaining biomass 1 mL

of deionized Water as added and vigorously mixed. The slurry

Was re-centrifuged, and the liquid phase collected and added

to the previously collected liquid phase. The liquid phase Was

then removed from the process and processed biomass Was

taken for further processing.

EnZymes

[0068]

10% algal biomass Was processed according the

parameters described in Example 1. The process biomass Was

fermented as described in Example 2 With the supplementa

tion of 250 units of xylanase and 100 units of cellulose added

to the fermentation. The yield results are illustrated in FIG. 3.

Example 4

ABE Production using Processed Biomass and Sugar

[0069]

The same process as described in Example 2 Was

repeated, this time supplementing only With 1% dextrose. The

yield results are illustrated in FIG. 4.

Example 5

ABE Production using Pretreated Algae and

EnZymes

[0070] Dried algae Was crushed using a blender and then

pretreated With 250 mM sulfuric acid for 30 min at 120 C.

Acid and solvent production from Closlridium saccharoper

buzylacelonium using 10% algae supplemented With xylanase

and cellulase enZymes as described in Example 2 Was under

taken. The yield results are illustrated in FIG. 5.

Example 6

ABE Production using Pretreated Algae and

Example 2

EnZymes

ABE Production using Processed Biomass and No

[0071] Dried algae Was crushed using a mortar and pestle

and then pretreated With 250 mM sulfuric acid for 30 min at

120 C. Acid and solvent production from Closlridium sac

Supplementation of EnZymes or Sugar

[0067]

10% algal biomass Was processed according the

charoperbuzylacelonium using 10% algae supplemented With

parameters described in Example 1. The T-6 media constitu

xylanase and cellulase enZymes as described in Example 2

ents Were mixed to homogeneity, and the media neutraliZed to

Was undertaken. The yield results are illustrated in FIG. 6.

May 2,2013

US 2013/0109068 A1

Example 7

improvements therein may be subsequently made by those

skilled in the art, and are also intended to be encompassed by

ABE Production using Non-Pretreated Whole Cell

Algae

[0072] Dried algae Was used in T-6 media Without any

chemical or mechanical modi?cations to the algae cells. The

algae Was fermented according to the fermentation conditions

outlined in Example 2, except that dried, unprocessed algae

Was used and a 5% inoculum Was used for a 24 hour culture in

RCM media. The yield results are illustrated in FIG. 7.

the folloWing claims.

What is claimed is:

1. A method of producing solvents from algae, the method

comprising:

processing algae to yield processed biomass,

fermenting the processed biomass With a Closlridium bac

teria to yield solvents.

2. The method of claim 1, Wherein processing algae com

prises:

hydrolyZing a slurry comprising algae and Water by adding

Example 8

an acidic hydrolyZing agent to yield an acidic slurry,

hydrolyZing the acidic slurry by adding a basic hydrolyZ

Gas Chromatography (GC)

[0073]

A GC chromatogram, used to measure or quantify

ABE, using clari?ed culture supernatant the method

described in Example 4 is shoWn in FIG. 8. The protocol for

measuring ABE via GC analysis is as folloWs:

[0074]

Instrument: Agilent Technologies 7890A GC sys

content of about 4-25%.

4. The method of claim 2, Wherein the acidic hydrolyZing

agent is selected from the group consisting of a strong acid, a

mineral acid, sulfuric acid, hydrochloric acid, phosphoric

tem.

[0075]

ing agent to yield a basic slurry, and

separating biomass from an aqueous phase to yield pro

cessed biomass.

3. The method of claim 2, Wherein the slurry has a solid

Column specs: Restek StabiWax-DA, 30 m, 0.32

mmlD, 0.25 um df column.

[0076] Inlet: initial 30 C for 1 min; ramp 5 C/min up to

100 C; ramp 10 C/min up to 250 C.

acid, and nitric acid.

5. The method of claim 2, Wherein the acidic slurry has a

pH of from about 1.5-4.

6. The method of claim 2, Wherein the acidic slurry is

[0077] Column: How 4 ml/min; pressure 15.024 psi, Avg

velocity 53.893 cm/ sec; holdup time 0.92777 min.

heated to a temperature of from about 50-120 C.

[0078] Oven: initial 30 C for 1 min; ramp 5 C/min up to

100 C (no hold time); ramp 20 C/min up to 225 C (no

hold time); ramp 120 C/min up to 250 C and hold for 2

sodium hydroxide, and potassium hydroxide.

min.

7. The method of claim 2, Wherein the basic hydrolyZing

agent is selected from the group consisting of a strong base,

8. The method of claim 2, Wherein the basic slurry has a pH

of from about 8-14.

9. The method of claim 2, Wherein the basic slurry is heated

[0079] FID: Heater at 250 C; H2 ?oW at 30 ml/min; Air

?oW at 400 ml/min; makeup How (He) at 25 ml/min.

to a temperature of from about 50-120 C.

[0080] Miscellaneous: 1 [1.1 injection volume, and

prises mechanically shearing the algae.

Helium as carrier gas.

Example 9

10. The method of claim 1, Wherein processing algae com

11. The method of claim 1, Wherein the Closlridium bac

teria are selected from the group consisting of Closlridium

saccharoperbulylacelonium, Closlridium acelobulylicum,

and Closlridium beljerinckii.

ABE Production using Whey

[0081] Cheese Whey or Whey permeate may be used to

substitute media components. Acid and solvent production

from Closlridium saccharoperbulylacelonium using 6%

Whey, instead of 10% algae, Was undertaken under the culture

conditions described in Example 2. The ?nal ABE yields

Were as folloWs: approximately 15 g/l butanol, 4 g/l acetone,

and 1 g/l of ethanol.

12. The method of claim 1, Wherein the solvents are

selected from the group consisting of butanol, acetone, and

ethanol.

13. The method of claim 1, further comprising purifying

the solvents.

14. The method of claim 13, Wherein purifying comprises

distillation.

15. The method of claim 1, Wherein fermenting the pro

cessed biomass comprises suplementing the biomass With a

suplement selected from the group consisitng of sugar, dex

Example 10

trose, lactose, Whey, Whey permeate, and chesse Whey.

ods for producing ABE. Supplementing algae using similar

methods as in Example 2, Example 3, Example 4, Example 5,

16. The method of claim 1, Wherein fermenting the pro

cessed biomass comprises suplementing the biomass With an

enZyme selected from the group consisitng of xylanase and

cellulase.

17. A method of of producing solvents from algae, the

method comprising fermenting the algae With a Closlridium

bacteria to yield solvents.

18. The method of claim 17, Wherein the solvents comprise

and Example 6 With Whey permeate or cheese Whey is a viable

at least one of acetone, butanol, and ethanol.

option to producing ABE.

19. A method of of producing solvents from Whey, the

method comprising fermenting the Whey With a Closlridium

bacteria to yield solvents.

20. The method of claim 19, Wherein the solvents comprise

ABE Production using Whey and Pretreated Algae

[0082]

ABE production using Whey as media constituents

as oppose to T6 media components, or any other viable

media, With algae as additional substrate are additional meth

[0083]

It Will be appreciated that various of the above

disclosed and other features and functions, or alternatives

thereof, may be desirably combined into many other different

systems or applications. Also, various presently unforeseen

or unanticipated alternatives, modi?cations, variations or

at least one of acetone, butanol, and ethanol.

*

Вам также может понравиться

- Advances in Biofeedstocks and Biofuels, Volume 2: Production Technologies for BiofuelsОт EverandAdvances in Biofeedstocks and Biofuels, Volume 2: Production Technologies for BiofuelsLalit Kumar SinghОценок пока нет

- United States Patent: Sullivan Et Al. (10) Patent N0.: (45) Date of PatentДокумент17 страницUnited States Patent: Sullivan Et Al. (10) Patent N0.: (45) Date of PatentAhmed AliОценок пока нет

- Transition Metal Catalyzed Furans Synthesis: Transition Metal Catalyzed Heterocycle Synthesis SeriesОт EverandTransition Metal Catalyzed Furans Synthesis: Transition Metal Catalyzed Heterocycle Synthesis SeriesОценок пока нет

- Us 7851663 - PETROLEUM JellyДокумент21 страницаUs 7851663 - PETROLEUM JellyAbbas AliОценок пока нет

- United States: (12) Patent Application Publication (10) Pub. No.: US 2009/0005588 A1Документ10 страницUnited States: (12) Patent Application Publication (10) Pub. No.: US 2009/0005588 A1sariОценок пока нет

- EP2540692A2Документ10 страницEP2540692A2Aide SyafiqОценок пока нет

- Umted Stiltes Patent (19) (11) Patent Number: 5,689,025: Abichandani Et A) - (45) Date of Patent: Nov. 18, 1997Документ9 страницUmted Stiltes Patent (19) (11) Patent Number: 5,689,025: Abichandani Et A) - (45) Date of Patent: Nov. 18, 1997aliОценок пока нет

- United States Patent: 4,837,360 Patent Number: Date of Patent: EtДокумент6 страницUnited States Patent: 4,837,360 Patent Number: Date of Patent: EtorogenidaОценок пока нет

- US4115424Документ6 страницUS4115424Muhammad Akbar FahleviОценок пока нет

- WO2017209126A1 (Inggris)Документ22 страницыWO2017209126A1 (Inggris)rachmahwati ningrumОценок пока нет

- United States Patent: (10) Patent No.: US 7,910,784 B2Документ5 страницUnited States Patent: (10) Patent No.: US 7,910,784 B2Chandra AdityaОценок пока нет

- Silva 2012Документ7 страницSilva 2012Brian Oro BeltránОценок пока нет

- Us20110065939a1 PDFДокумент17 страницUs20110065939a1 PDFniralОценок пока нет

- 1263 3507 1 PBДокумент5 страниц1263 3507 1 PBJohn TorrezОценок пока нет

- United States Patent: (10) Patent N0.: (45) Date of PatentДокумент24 страницыUnited States Patent: (10) Patent N0.: (45) Date of PatentAlberto BuenoОценок пока нет

- United States Patent (10) Patent N0.: US 6,743,952 B2Документ8 страницUnited States Patent (10) Patent N0.: US 6,743,952 B2Rizka AndhikaОценок пока нет

- TOLUENEДокумент7 страницTOLUENEAlzahra AliОценок пока нет

- United States: (12) Patent Application Publication (10) Pub. No.: US 2009/0163744 A1Документ8 страницUnited States: (12) Patent Application Publication (10) Pub. No.: US 2009/0163744 A1Zaky YanwarОценок пока нет

- Patents US20110087038A1Документ10 страницPatents US20110087038A1Esteban HenaoОценок пока нет

- Patent Application Publication (10) Pub. No.: US 2012/0083611 A1Документ9 страницPatent Application Publication (10) Pub. No.: US 2012/0083611 A1martinОценок пока нет

- KristalisasiДокумент9 страницKristalisasiAgnesHubertaОценок пока нет

- AquaДокумент297 страницAquaTrafalgarSeieiОценок пока нет

- Pretreatment and Hydrolysis of Cellulosic Agricultural Wastes With A Cellulase-Producing Streptomyces For Bioethanol ProductionДокумент7 страницPretreatment and Hydrolysis of Cellulosic Agricultural Wastes With A Cellulase-Producing Streptomyces For Bioethanol ProductionAndré Felipe SilvaОценок пока нет

- Effect of Aeration and Agitation Rates and Scale-Up On Oxygen Transfer Coefficient, Kla in Exopolysaccharide Production From Enterobacter Cloacae WD7Документ13 страницEffect of Aeration and Agitation Rates and Scale-Up On Oxygen Transfer Coefficient, Kla in Exopolysaccharide Production From Enterobacter Cloacae WD7Alen AgicОценок пока нет

- US20090008268A1Документ17 страницUS20090008268A1hankyb14Оценок пока нет

- US4113780 AsetonasetilenisopropilДокумент4 страницыUS4113780 AsetonasetilenisopropilIrfan WahyudinОценок пока нет

- United States Patent (191: Z2 20) Woter - I 18JДокумент7 страницUnited States Patent (191: Z2 20) Woter - I 18JZulfi ZumalaОценок пока нет

- Hydrogen Production by The Hyperthermophilic Eubacterium, Using Cellulose Pretreated by Ionic LiquidДокумент15 страницHydrogen Production by The Hyperthermophilic Eubacterium, Using Cellulose Pretreated by Ionic LiquidkimlinhОценок пока нет

- TEPZZ 65 46ZA - T: European Patent ApplicationДокумент24 страницыTEPZZ 65 46ZA - T: European Patent ApplicationIrfan LutfiantoОценок пока нет

- Jurnal Analitik Jahlela Sari Kimia Bahasa InggrisДокумент14 страницJurnal Analitik Jahlela Sari Kimia Bahasa InggriskhairiyatiОценок пока нет

- TroxirutinДокумент4 страницыTroxirutinTeodoro KaufmanОценок пока нет

- AcetylacetoneДокумент5 страницAcetylacetoneac_76_pxОценок пока нет

- United States Patent (19) 4,487,831: Day Et A1. Dec. 11, 1984 (11) Patent Number: (45) Date of PatentДокумент8 страницUnited States Patent (19) 4,487,831: Day Et A1. Dec. 11, 1984 (11) Patent Number: (45) Date of PatentCrystal Joy MacababbadОценок пока нет

- United States: (12) Patent Application Publication (10) Pub. No.: US 2002/0147318 A1Документ6 страницUnited States: (12) Patent Application Publication (10) Pub. No.: US 2002/0147318 A1Khoi Nguyen DangОценок пока нет

- Ethanol 5ad Aafsdfastfwqfas Sacaxvava AxcvvvvvvvvvvvvvvvvasdddddddddddДокумент7 страницEthanol 5ad Aafsdfastfwqfas Sacaxvava AxcvvvvvvvvvvvvvvvvasdddddddddddNiko Ava DaaОценок пока нет

- United States Patent 0. ": Patented Def. 5, 1965Документ6 страницUnited States Patent 0. ": Patented Def. 5, 1965Ersa Nurul YarizsaОценок пока нет

- ?nite States Tent n91: AssigneeДокумент3 страницы?nite States Tent n91: AssigneeererОценок пока нет

- United States: (12) Patent Application Publication (10) Pub. No.: US 2015/0018589 A1Документ7 страницUnited States: (12) Patent Application Publication (10) Pub. No.: US 2015/0018589 A1Lily DianaОценок пока нет

- Logan - 2002 - Biological Hydrogen Production Measured in Bath Anaerobic RespirometersДокумент6 страницLogan - 2002 - Biological Hydrogen Production Measured in Bath Anaerobic RespirometersMaythee SaisriyootОценок пока нет

- Glycerol Fermentation by (Open) Mixed Cultures: A Chemostat StudyДокумент11 страницGlycerol Fermentation by (Open) Mixed Cultures: A Chemostat StudyjazorelОценок пока нет

- 2008 March 4 Acetaldehyde From Ethylene OxidationДокумент4 страницы2008 March 4 Acetaldehyde From Ethylene OxidationameymurudkarОценок пока нет

- Laboratory Manual and GuidelineДокумент27 страницLaboratory Manual and GuidelineFatih Rushdi100% (1)

- Patent Asam Asetat 2015Документ22 страницыPatent Asam Asetat 2015Nyimas Ulfatry100% (1)

- Separare Clorofila Cromatografie in ContracurentДокумент6 страницSeparare Clorofila Cromatografie in ContracurentramonadiОценок пока нет

- Continuous Fermentation Process For Producing Ethanol: ZusammenfassungДокумент7 страницContinuous Fermentation Process For Producing Ethanol: ZusammenfassungBrebeanu AndreiОценок пока нет

- United States: (12) Patent Application Publication (10) Pub. No.: US 2010/0197959 A1Документ19 страницUnited States: (12) Patent Application Publication (10) Pub. No.: US 2010/0197959 A1sariОценок пока нет

- Fermentors Bioreactors - Protocol - 039 - BioFlo 320 - Measuring Oxygen Transfer Rate OTR Eppendorf Fermentation VesselsДокумент4 страницыFermentors Bioreactors - Protocol - 039 - BioFlo 320 - Measuring Oxygen Transfer Rate OTR Eppendorf Fermentation VesselsTommy HiroОценок пока нет

- Process For Ethyl Acetate ProductionДокумент9 страницProcess For Ethyl Acetate ProductionMuhammad Yanuar AnantaОценок пока нет

- RMIQ Vol8 No3 4Документ6 страницRMIQ Vol8 No3 4Rose Niño LunaОценок пока нет

- Acetoacetic Acid - Diketene React With AmineДокумент3 страницыAcetoacetic Acid - Diketene React With AmineLaila Ambar SariОценок пока нет

- US20160280908A1Документ20 страницUS20160280908A1Mathilda PasaribuОценок пока нет

- Effect of Nutrient Limitation and Two-Stage Continuous Fermentor DesignДокумент7 страницEffect of Nutrient Limitation and Two-Stage Continuous Fermentor DesignkanonОценок пока нет

- Journal of The Taiwan Institute of Chemical Engineers: Kuan-Ming Lu, Si-Yu LiДокумент5 страницJournal of The Taiwan Institute of Chemical Engineers: Kuan-Ming Lu, Si-Yu LiDaniel MurilloОценок пока нет

- Characterization of The Degree of Polymerization of Xylooligomers Produced by Flow Through Hydrolysis of Pure Xylan and Corn Stover With WaterДокумент7 страницCharacterization of The Degree of Polymerization of Xylooligomers Produced by Flow Through Hydrolysis of Pure Xylan and Corn Stover With WaterJoerg BittnerОценок пока нет

- United States Patent (19) 11 4,083,889: 51 Int. Cl. ........................ Coic 1/24 Co7.c 11/04 ''Документ8 страницUnited States Patent (19) 11 4,083,889: 51 Int. Cl. ........................ Coic 1/24 Co7.c 11/04 ''irfan mahierОценок пока нет

- Wu 2012Документ7 страницWu 2012f20221437Оценок пока нет

- DR - Wang ResearchДокумент8 страницDR - Wang ResearchMahesh ParitОценок пока нет

- Electrochemical FertilizerДокумент24 страницыElectrochemical Fertilizerpakde jongkoОценок пока нет

- United States Patent: Reimann Patent No.: Date of PatentДокумент5 страницUnited States Patent: Reimann Patent No.: Date of PatentFernando Beer FrenkelОценок пока нет

- Molecular Sieve CalculationДокумент11 страницMolecular Sieve CalculationNanasaheb Patil100% (1)

- Perhitungan HEДокумент39 страницPerhitungan HEFebrianFAОценок пока нет

- DensityДокумент2 страницыDensityFebrianFAОценок пока нет

- DensityДокумент2 страницыDensityFebrianFAОценок пока нет

- Tube Chart CharacteristicsДокумент3 страницыTube Chart CharacteristicsHussain FakhruddinОценок пока нет

- B WG Tube Wall Conversion ChartДокумент1 страницаB WG Tube Wall Conversion ChartFebrianFAОценок пока нет

- Power FlowsДокумент42 страницыPower FlowsRaturi DeepankarОценок пока нет

- A2 44 CapacitanceДокумент22 страницыA2 44 CapacitanceHany ElGezawyОценок пока нет

- LV CapacitorsДокумент22 страницыLV CapacitorsFlo MircaОценок пока нет

- Biomass and Bioenergy - LectureДокумент58 страницBiomass and Bioenergy - LectureCarl Jan SolitoОценок пока нет

- The Future of Energy StorageДокумент387 страницThe Future of Energy StorageGheorghe FrigioiuОценок пока нет

- Fujiaire DuctedДокумент6 страницFujiaire Ductedbudikarya11810% (1)

- BFBC or StrokerДокумент6 страницBFBC or StrokerkichasОценок пока нет

- Lecture PPT - 20Документ22 страницыLecture PPT - 20Kawsar Jahan Binti 1511787030Оценок пока нет

- Atita EngineДокумент36 страницAtita EngineSara AzamОценок пока нет

- Work & Energy Daily Home Assignment 02 Work & Energy Daily HomeДокумент2 страницыWork & Energy Daily Home Assignment 02 Work & Energy Daily HomePooja KuchhalОценок пока нет

- Enhanced Control of A Photovoltaic Water Pumping System by DTC-SVMДокумент67 страницEnhanced Control of A Photovoltaic Water Pumping System by DTC-SVMsouad laribiОценок пока нет

- Marine PropulsionДокумент74 страницыMarine PropulsionbrufpotОценок пока нет

- Climeon Tech Product SheetДокумент3 страницыClimeon Tech Product Sheetcasda73Оценок пока нет

- Encon Tea Sep 2011Документ8 страницEncon Tea Sep 2011Pawan TiwariОценок пока нет

- Testing and Performance Assessment of 1Kwp Solar Rooftop SystemДокумент5 страницTesting and Performance Assessment of 1Kwp Solar Rooftop Systemlaw100% (1)

- BLDC Motor Speed Control by ZETA ConverterДокумент4 страницыBLDC Motor Speed Control by ZETA ConverterInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Omw 052Документ16 страницOmw 052api-355877355Оценок пока нет

- Chapter 3 PS, PSM, TmsДокумент32 страницыChapter 3 PS, PSM, Tmskishansai100% (2)

- Performance and Emission Characteristics of Commercial Kerosene Stoves Using Waste Cooking Oil-Kerosene BlendsДокумент8 страницPerformance and Emission Characteristics of Commercial Kerosene Stoves Using Waste Cooking Oil-Kerosene BlendsPrakash SpОценок пока нет

- VanosДокумент2 страницыVanosalexmarieiОценок пока нет

- Pump Performance Datasheet: Operating Conditions LiquidДокумент1 страницаPump Performance Datasheet: Operating Conditions Liquidmsh16000Оценок пока нет

- Hazards in The Installation and Maintenance of Solar PanelsДокумент5 страницHazards in The Installation and Maintenance of Solar PanelsSingAnnОценок пока нет

- Yelahanka DG Plant Presentation FinalДокумент50 страницYelahanka DG Plant Presentation FinalNishath Ilyas100% (1)

- Em Ii PDFДокумент76 страницEm Ii PDFRavi SharmaОценок пока нет

- AHU Design BasicsДокумент29 страницAHU Design BasicsHari Babu Dharmavarapu100% (2)

- BSL XXXX Projects Report 2014 - 2015Документ6 страницBSL XXXX Projects Report 2014 - 2015DesОценок пока нет

- Grendia S4Q2 Diesel EngineДокумент64 страницыGrendia S4Q2 Diesel EngineJoaquina_JoaquinaОценок пока нет

- Bombas CUTESДокумент6 страницBombas CUTESCarlos Andres Gonzales VerasteguiОценок пока нет

- GEA Chapter1 LowresДокумент52 страницыGEA Chapter1 LowrescarecaОценок пока нет

- كتاب صيانة نظم القوى الكهربائيةДокумент141 страницаكتاب صيانة نظم القوى الكهربائيةJaber HakamiОценок пока нет