Академический Документы

Профессиональный Документы

Культура Документы

BS 6231 PDF

Загружено:

Thomas OrИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

BS 6231 PDF

Загружено:

Thomas OrАвторское право:

Доступные форматы

Specification for

PVC-insulated cables

for switchgear and

controlgear wiring

ICS 29.060.20

NO COPYING WITHOUT BSI PERMISSION EXCEPT AS PERMITTED BY COPYRIGHT LAW

Copyright British Standards Institution

Reproduced by IHS under license with BSI - Uncontrolled Copy

No reproduction or networking permitted without license from IHS

Licensee=University of Hong Kong/5910986001

Not for Resale, 08/08/2005 20:45:40 MDT

| BS 6231:1998

|

| Incorporating

|

| Amendment No. 1

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

--``,,,,,,,,,,,,,``,,,,`,,``,,`-`-`,,`,,`,`,,`---

BRITISH STANDARD

BS 6231:1998

Committees responsible for this

British Standard

The preparation of this British Standard was entrusted by Technical Committee

GEL/20, Electric cables, to Subcommittee GEL/20/1, Wiring cables, upon which the

following bodies were represented:

Association of Consulting Engineers

Association of Manufacturers Allied to the Electrical and Electronic Industry

(BEAMA Ltd)

British Approvals Service for Cables

British Cable Makers Confederation

British Plastics Federation

British Retail Consortium

Chartered Institution of Building Services Engineers

Department of Trade and Industry Consumer Safety Unit, C A Division

Electricity Association

ERA Technology Ltd.

Electrical Installation Equipment Manufacturers Association (BEAMA Ltd.)

Engineering Industries Association

Institution of Incorporated Executive Engineers

Lift and Escalator Industries Association

London Underground Ltd.

Portable Electric Tool Manufacturers Association

Transmission and Distribution Association (BEAMA Ltd.)

--``,,,,,,,,,,,,,``,,,,`,,``,,`-`-`,,`,,`,`,,`---

This British Standard, having

been prepared under the

direction of the Electrotechnical

Sector Board, was published

under the authority of the

Standards Board and comes into

effect on

15 August 1998

BSI 17 June 2005

First published, as BS 1231,

July 1945

Second edition, November 1958

Third edition, February 1963

Fourth edition, as BS 6231,

August 1969

Fifth edition, May 1978

Sixth edition, December 1981

Seventh edition, October 1990

Eighth edition, August 1998

Amendments issued since publication

Amd. No.

Date

15648

17 June 2005 Certification notice in Foreword changed and deleted

on inside back cover

Text affected

The following BSI references

relate to the work on this

standard:

Committee reference GEL/20/1

Draft for comment 96/215021 DC

ISBN 0 580 29572 9

Copyright British Standards Institution

Reproduced by IHS under license with BSI - Uncontrolled Copy

No reproduction or networking permitted without license from IHS

Licensee=University of Hong Kong/5910986001

Not for Resale, 08/08/2005 20:45:40 MDT

BS 6231:1998

Contents

Page

Committees responsible

Inside front cover

Foreword

ii

1 Scope

1

2 Normative references

1

3 Definitions

1

4 Temperature ratings

1

5 Voltage designations

1

6 Identification

2

7 Marking

2

8 Conductors

2

9 Insulation

3

10 Construction and overall dimensions

3

11 Dimensional test methods

3

12 Electrical requirements and test methods

3

13 Durability of colours and marking

5

14 Test under fire conditions

5

Annex A (informative) Guidance on installation and operating temperatures

12

Bibliography

Inside back cover

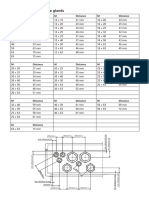

Table 1 Constructional details and maximum resistance for small circular

tinned annealed copper conductors not included in BS 6360

2

Table 2 Spare

4

Table 3 Voltage values for voltage test

4

Table 4 Thermal endurance test voltage

5

Table 5 Types AU and AK PVC-insulated cables

6

Table 6 Types BU and BR PVC-insulated rigid cables

7

Table 7 Type BK PVC-insulated flexible cables

8

Table 8 Types CU and CR PVC-insulated rigid cables

9

Table 9 Type CK PVC-insulated flexible cables

10

Table 10 List of tests applicable to the various types of cable

11

--``,,,,,,,,,,,,,``,,,,`,,``,,`-`-`,,`,,`,`,,`---

Copyright British Standards Institution

Reproduced by IHS under license with BSI - Uncontrolled Copy

No reproduction or networking permitted without license from IHS

BSI 17 June 2005

Licensee=University of Hong Kong/5910986001

Not for Resale, 08/08/2005 20:45:40 MDT

BS 6231:1998

Foreword

This new edition of BS 6231 has been prepared by Technical Subcommittee

GEL/20/1 and supersedes BS 6231:1990 which is withdrawn. It introduces technical

changes but does not reflect a full review or revision of this standard, which will be

undertaken in due course.

As specified in the previous edition, this standard adopts the voltage designation for

some types of harmonized single-core PVC-insulated cables in CENELEC

Harmonization Document HD 21.

--``,,,,,,,,,,,,,``,,,,`,,``,,`-`-`,,`,,`,`,,`---

Although CENELEC has now agreed to a 600/1 000 V rating for some cables of the

types specified in BS 6004 when installed inside equipment in protected conditions, the

electrical controlgear industry has requested continuation and revision of BS 6231,

rather than its withdrawal, because some requirements cannot always be fulfilled by

the use of cables conforming to other British Standards.

To meet the requirements of the electrical switchgear and controlgear industry, a new

range of cables, types CR, CU and CK, has been introduced for operation at a

designated temperature of 85 8C. These cables are dimensionally similar to the existing

types BR, BU and BK.

The opportunity has also been taken to align types AU and AK cables contained in this

standard with those of BS 4808-2.

Annex A (informative) gives guidance on installation and operating temperatures.

Cables conforming to this standard are deemed also to conform, for corresponding

sizes, to the requirements of the corresponding classes of BS 4808, BS 6004 and BS

6500. Because of the more stringent requirements of this standard, the converse is

not necessarily true.

Product certification/inspection/testing. Users of this British Standard are

advised to consider the desirability of third-party certification/inspection/testing

of product conformity with this British Standard. Users seeking assistance in

identifying appropriate conformity assessment bodies or schemes may ask BSI to

forward their enquiries to the relevant association.

A British Standard does not purport to include all the necessary provisions of a

contract. Users of British Standards are responsible for their correct application.

Compliance with a British Standard does not of itself confer immunity

from legal obligations.

Summary of pages

This document comprises a front cover, an inside front cover, page i and ii,

pages 1 to 12 and a back cover.

Copyright British Standards Institution

Reproduced by IHS under license with BSI - Uncontrolled Copy

No reproduction or networking permitted without license from IHS

ii

Licensee=University of Hong Kong/5910986001

Not for Resale, 08/08/2005 20:45:40 MDT

BSI 17 June 2005

BS 6231:1998

1 Scope

This British Standard specifies requirements for

single-core non-sheathed cables, including flexible

cables, used for the wiring of switch, control,

metering, relay and instrument panels of power

switchgear, and for such purposes as internal

connections in rectifier equipment and in motor

starters and controllers.

The types of cable specified in this standard are as

follows:

Type

AU

AK

BR

BU

BK

CR

CU

CK

Form of conductor

Rigid, round,

Flexible

Rigid, round,

Rigid, round,

Flexible

Rigid, round,

Rigid, round,

Flexible

Designated

temperature

70 8C

70 8C

stranded 70 8C

solid

70 8C

70 8C

stranded 90 8C

solid

90 8C

90 8C

solid

Rated

voltage

60 V

60 V

600/1 000 V

600/1 000 V

600/1 000 V

600/1 000 V

600/1 000 V

600/1 000 V

2 Normative references

--``,,,,,,,,,,,,,``,,,,`,,``,,`-`-`,,`,,`,`,,`---

The following normative documents contain

provisions which, through reference in this text,

constitute provisions of this British Standard. For

dated references, subsequent amendments to, or

revisions of, any of these publications do not apply.

For undated references, the latest edition of the

publication referred to applies.

BS 2011:1981, Environmental testing

Part 2.1T: Test T Soldering.

BS 4066-1, Tests on electric cables under fire

conditions Part 1: Method of test on a single

vertical insulated wire or cable.

BS 4066-2, Tests on electric cables under fire

conditions Part 2: Method of test on a single

small insulated wire or cable.

BS 4727, Glossary of electrotechnical, power,

telecommunication, electronics, lighting and colour

terms Part 2: Terms particular to power

engineering Group 08 Electric cables.

BS 5099, Spark testing of electric cables.

BS 6360, Specification for conductors in insulated

cables and cords.

BS 7655-3.1, Specification for insulating and

sheathing materials for cables Part 3: PVC

insulating compounds Section 3.1: Harmonized

types.

Copyright British Standards Institution

Reproduced by IHS under license with BSI - Uncontrolled Copy

No reproduction or networking permitted without license from IHS

BSI 17 June 2005

BS 7655-3.2, Specification for insulating and

sheathing materials for cables Part 3: PVC

insulating compounds Section 3.2: Hard grade

types.

BS EN 60811-1-1:1995, Insulating and sheathing

materials for electric cables. Common test

methods Part 1-1: General application

Measurement of thickness and overall dimensions.

Tests for determining the mechanical properties.

PD 2379, Register of colours of manufacturers'

identification threads for electric cables and cords .

3 Definitions

For the purposes of this British Standard the

definitions relating to electric cables given in

BS 4727 apply.

4 Temperature ratings

The designated temperatures quoted are the

temperatures assigned to the same materials in

BS 6004, BS 6500 and BS 7655. The combination of

ambient temperature and temperature rise due to

load should not result in a conductor temperature

exceeding the designated temperature.

NOTE Attention is drawn to annex A which gives guidance on

installation and operating temperatures.

5 Voltage designations

5.1 Types AU and AK cables shall be designated by

the rated voltage, which is 60 V. They are intended

for use where the operating voltage to earth does not

exceed 60 V. They are suitable for wiring circuits

which are tested with d.c. at a voltage not

exceeding 500 V.

NOTE Where the fault power is low and adequate mechanical

protection is provided, these types may be used at voltages higher

than 60 V by agreement between the purchaser and the

manufacturer.

5.2 Types BU, BR, BK, CU, CR and CK cables shall

be designated by the rated voltages U0 and U

expressed in the form U0/U, where U0 is the

power-frequency voltage to earth for which the cable

is designed, and U is the power-frequency voltage

between phase conductors for which the cable is

designed.

The rated voltage for these cables is 600/1 000 V.

These cables are intended for use at alternating

voltages not exceeding 600 V to earth, and direct

voltages not exceeding 1 000 V to earth. They are

suitable for wiring circuits for which the prescribed

alternating test voltage, when installed in the

equipment, does not exceed 4 kV r.m.s. for 1 min.

Licensee=University of Hong Kong/5910986001

Not for Resale, 08/08/2005 20:45:40 MDT

BS 6231:1998

6.1 All cables shall be identified by colour as listed

in Tables 5, 6, 7, 8 and 9. The colour shall be either

throughout the whole of the insulation or on its

surface.

6.2 For types AU and AK cables, the colours of

bi-colour combinations shall be uniform and the

form shall be either continuous helical marking or

ring marking which, when viewed from any side,

shall be readily identifiable within every 15 mm of

length.

6.3 On types BU, BR, BK, CU, CR and CK cables

marked with the bi-colour combination green/yellow,

the distribution of these colours shall conform to the

following condition.

On the core marked with the bi-colour combination

green/yellow, the distribution of the colours shall be

such that for every 15 mm length of core, one of

these colours shall cover at least 30 % and at

most 70 % of the surface of the core, while the other

colour covers the remainder of the surface.

NOTE 1 In cases of dispute and where appropriate to the

method of colour marking of the insulation, a suitable test for

checking conformity is given in BS 6469-99.1:1992, clause 8.

NOTE 2 Information on the use of the colours green/yellow. It is

understood that the colours green and yellow when they are

combined as specified above are recognized exclusively as a

means of identification of the core intended for use as earth

connection or similar protection.

6.4 The colours of the cables shall be durable and

easily discernible.

Conformity shall be checked by the test described in

clause 13.

7 Marking (not applicable to types AU and AK)

7.1 Types BU, BR, BK, CU, CR and CK cables shall

be provided with an indication of origin consisting of

either an identification thread or the continuous

marking of the manufacturer's name or trade mark.

This marking may be by printing, indenting or

embossing.

7.2 If coloured threads are used, the colours shall

be in accordance with those registered in PD 2379.

The colours of identification threads shall be easy to

recognize or shall become recognizable by cleaning

with petrol or any other suitable solvent, if

necessary.

7.3 The designated temperature shall be indicated

on types CU, CR and CK cables in the following

form:

HEAT RESISTING 90

The marking shall be by printing, indenting or

embossing, and shall be legible and easily

discernible.

7.4 Each specified mark shall be regarded as

continuous if the distance between the end of the

mark and the beginning of the next identical mark

does not exceed 275 mm.

7.5 Any marking by printing shall be durable.

Conformity shall be checked by the test prescribed

in clause 13.

8 Conductors

8.1 The conductors shall be circular, plain or

tinned, annealed copper conductors as specified

in 8.2 to 8.6.

8.2 For type AU cables, the conductors shall be

tinned annealed copper conductors. The number and

nominal diameter of wires and the maximum

resistance at 20 8C shall conform to the appropriate

requirements given in Table 1.

8.3 For type AK cables, the conductors shall be

tinned annealed copper conductors. They shall

conform to the appropriate requirements of

BS 6360 for class 5 conductors.

8.4 For types BK and CK cables, the conductors

shall be either plain annealed or tinned annealed

copper conductors. They shall conform to the

appropriate requirements of BS 6360 for

class 5 conductors.

8.5 The conductors of types AU and AK cables, and

of types BK and CK when tinned annealed copper

conductors are used, shall conform to the

requirements for solderability when tested in

accordance with Test Ta, Method 1 : Solder bath

at 235 8C, given in BS 2011-2.1T:1981.

8.6 For all other types of cable the conductors shall

be plain annealed copper conforming to the

appropriate requirements of BS 6360 for class 1 or

class 2 conductors.

Table 1 Constructional details and

maximum resistance for small circular tinned

annealed copper conductors not included in

BS 6360

Nominal

cross-sectional

area

Number and

nominal diameter

of wires

Maximum

resistance of

conductor at 20 8C

mm2

mm

V/km

0.2

0.28

0.5

1/0.50

1/0.60

1/0.80

92.2

64.1

36.0

NOTE This marking may be combined with the marking

specified in 7.1.

Copyright British Standards Institution

Reproduced by IHS under license with BSI - Uncontrolled Copy

No reproduction or networking permitted without license from IHS

Licensee=University of Hong Kong/5910986001

Not for Resale, 08/08/2005 20:45:40 MDT

BSI 17 June 2005

--``,,,,,,,,,,,,,``,,,,`,,``,,`-`-`,,`,,`,`,,`---

6 Identification

BS 6231:1998

9.1 The insulation shall be PVC compound of the

following types as designated in BS 7655 and shall

conform to the appropriate requirements of that

standard, as follows:

Types AU and AK cables: PVC type 2 or type TI 1

conforming to BS 7655-3.2 or -3.1 respectively, as

specified in Table 5.

Types BU, BR and BK cables: PVC type TI 1

conforming to BS 7655-3.1.

Types CU, CR and CK cables, PVC type TI 3

conforming to BS 7655-3.1.

Conformity shall be checked by performing the tests

indicated in the appropriate column of Table 10.

9.2 The insulation shall be closely applied to the

conductor. It shall be possible to remove the

insulation easily without damage to the insulation

itself, to the conductor or to any tin coating.

Conformity shall be checked by examination and by

a manual test.

9.3 For types AU and AK cables, the radial

thickness of insulation shall be not less than the

appropriate minimum value given in Table 5.

For all other types of cable, the mean value of

thickness of insulation shall be not less than the

value specified for each type and cross-sectional

area of cable in Tables 6, 7, 8 and 9. The thickness

at any measured place may be less than the mean

value specified, but the difference shall not

exceed 0.1 mm +10 % of the mean value specified.

Conformity shall be checked by the test method

described in 11.1.

10 Construction and overall

dimensions

10.1 The construction shall be as given in

Tables 5, 6, 7, 8 or 9, as appropriate. Conformity

shall be checked by examination and by

measurement.

10.2 The mean overall diameter shall not exceed

the appropriate upper limit given in Table 5, 6, 7, 8

or 9. Conformity shall be checked by the method

prescribed in 11.2.

11 Dimensional test methods

11.1 Measurement of insulation thickness.

Take a sample of cable from three different places,

separated by at least 1 m.

Prepare the samples and take six thickness

measurements on each sample, in accordance with

BS EN 60811-1-1, 8.1, including the minimum

thickness

Copyright British Standards Institution

Reproduced by IHS under license with BSI - Uncontrolled Copy

No reproduction or networking permitted without license from IHS

BSI 17 June 2005

Take the mean of the 18 values, after rounding, as

the mean value of insulation thickness. For a

specified mean thickness of 0.5 mm or above, round

the calculated mean value to one decimal

place, 0.05 being rounded upwards. For a specified

mean thickness of below 0.5 mm, round the

calculated mean value to two decimal

places, 0.005 being rounded upwards.

Take the smallest of the 18 values as the minimum

thickness of insulation at any point.

11.2 Measurement of overall diameter.

Take a sample of cable from three different places,

separated by at least 1 m.

Take diameter measurements in accordance with

BS EN 60811-1-1:1995, 8.3.

For diameters not exceeding 25 mm, take the mean

of the six measurements as the mean overall

diameter

For diameters exceeding 25 mm, take the mean of

the three measurements as the mean overall

diameter.

When embossing in accordance with 7.1 or 7.3 is

used, the points at which measurements are made

shall not coincide with the embossing.

--``,,,,,,,,,,,,,``,,,,`,,``,,`-`-`,,`,,`,`,,`---

9 Insulation

12 Electrical requirements and test

methods

12.1 Requirements

12.1.1 Types AU and AK

These cables shall be subjected at the manufacturer's

works to the spark test prescribed in 12.2.2 and

shall withstand the test voltage without failure of the

insulation.

When tested in accordance with 12.2.3, the

insulation shall not break down. When tested in

accordance with 12.2.4, the insulation resistance

shall be not less than the appropriate value given in

Table 5.

These cables shall also be capable of withstanding

the thermal endurance test prescribed in 12.2.6

without breakdown of the insulation.

12.1.2 Types BU, BR, BK, CU, CR and CK

These cables shall be subjected at the manufacturer's

works to the spark test prescribed in 12.2.2 and

shall withstand the test voltage without failure of the

insulation.

When tested in accordance with 12.2.3, the

insulation shall not break down. When tested in

accordance with 12.2.4, the insulation resistance

shall be not less than the appropriate value given in

Tables 6, 7, 8 or 9. When tested in accordance

with 12.2.5, the exterior of the insulation shall show

no signs of damage nor suffer electrical breakdown

(discoloration of the insulation shall be ignored).

Licensee=University of Hong Kong/5910986001

Not for Resale, 08/08/2005 20:45:40 MDT

BS 6231:1998

12.2 Test methods

12.2.4 Insulation resistance test

12.2.1 General

Tests shall be performed at an ambient temperature

of (20 15) 8C unless otherwise specified in the

details for the particular test.

Unless otherwise specified in the particular test, the

frequency of the alternating test voltages shall be in

the range of 49 Hz to 61 Hz. The waveform shall be

substantially sinusoidal.

12.2.4.1 General

When an insulation resistance test is made, it shall

be performed in accordance with 12.2.4.2

or 12.2.4.3, as appropriate. The test given in 12.2.4.2

shall normally be performed with the water at

ambient temperature, but in case of dispute the

temperature of the water shall be (20 5) 8C.

The test given in 12.2.4.3 shall be performed with

the water at a temperature of (70 2) 8C for

types BU, BR and BK, or (90 2) 8C for types CU, CR

and CK.

12.2.2 Spark test

The core insulation shall conform to the

requirements for spark testing given in BS 5099 when

tested in accordance with the a.c. or d.c. test

methods specified in that standard.

Table 2 Spare

12.2.3 Voltage test

12.2.3.1 Types AU and AK.

Immerse in water, for not less than 24 h, a

sample 5 m in length. Earth the water and maintain it

at (20 5) 8C. With the cable still immersed, apply

between the conductor and the water the

appropriate test voltage given in Table 3. Raise the

voltage gradually and maintain it at the full value

for 5 min.

Table 3 Voltage values for voltage test

Type

Nominal

cross-sectional area

Test voltage r.m.s.

mm2

AU

0.2

0.28

0.5

1 000

1 000

1 500

AK

0.22

0.5

0.75

1 000

1 500

2 000

12.2.3.2 Types BU, BR, BK, CU, CR and CK

Immerse in water, for not less than 1 h, a sample

between 10 m and 20 m in length. Earth the water.

With the cable still immersed, apply an alternating

voltage of 3 500 V between the conductor and the

water. Raise the voltage gradually and maintain at

the full value for 5 min.

12.2.4.2 Types AU and AK

Immerse a sample, 5 m in length, in water for not

less than 1 h. Allow a length of approximately

250 mm at each end of the sample to project above

the water.

Apply a d.c. voltage of between 80 V and 500 V

between the conductors and the water.

Measure the insulation resistance 1 min after

application of the voltage. Present the value in terms

of MVkm

12.2.4.3 Types BU, BR, BK, CU, CR and CK

Immerse for 30 min a loosely coiled sample of the

cable, between 5 m and 10 m in length, in water

previously heated in accordance with 12.2.4.1.

Apply a d.c. voltage of between 80 V and 500 V

between the conductors and the water.

Measure the insulation resistance 1 min after

application of the voltage. Correct the value

to MVkm

12.2.5 Long term resistance of PVC insulation

to d.c. (for types BU, BR, BK, CU, CR and CK,

see 12.1.2)

Immerse a sample, approximately 5 m in length, in an

aqueous solution of sodium chloride of

approximately 10 g/l which has previously been

raised to, and is maintained at, a temperature of

(60 5) 8C. Allow a length of approximately 250 mm

at each end of the sample to project above the

solution.

Connect the negative pole of a 220 V d.c. supply to

the conductor of the sample and the positive pole to

a copper electrode immersed in the solution. Apply

the voltage for a period of 10 days.

--``,,,,,,,,,,,,,``,,,,`,,``,,`-`-`,,`,,`,`,,`---

Copyright British Standards Institution

Reproduced by IHS under license with BSI - Uncontrolled Copy

No reproduction or networking permitted without license from IHS

Licensee=University of Hong Kong/5910986001

Not for Resale, 08/08/2005 20:45:40 MDT

BSI 17 June 2005

BS 6231:1998

12.2.6 Thermal endurance (for types AU and AK,

see 12.1.1)

Wind a sample of cable, without undue tension, for

four turns around and in contact with a metal

mandrel, the diameter of which is approximately

four times the maximum specified overall diameter

of the cable. Maintain the assembly at (85 2) 8C for

not less than 1 000 h. Earth the mandrel and apply

the test voltage given in Table 4 between the

conductor and the mandrel continuously throughout

the period.

Cool the assembly to room temperature and apply

the test voltage given in Table 3 between the

conductor and the mandrel for a further period of

not less than 5 min.

13 Durability of colours and marking

Conformity to the requirements of 6.4 and 7.5 shall

be checked by trying to remove the colours of the

cables, the marking of the manufacturer's name or

trade mark, and the designated temperature, by

rubbing them lightly 10 times with a piece of cloth

soaked in water.

14 Test under fire conditions

Types BU, BR, BK, CU, CR and CK shall be tested in

accordance with BS 4066-1 and -2, as applicable, and

shall conform to the requirements of that standard.

Table 4 Thermal endurance test voltage

Test

Nominal

cross-sectional area

Test voltage r.m.s

mm2

AU

0.2

0.28

0.5

750

750

1 000

AK

0.22

0.5

0.75

750

1 000

1 500

--``,,,,,,,,,,,,,``,,,,`,,``,,`-`-`,,`,,`,`,,`---

Copyright British Standards Institution

Reproduced by IHS under license with BSI - Uncontrolled Copy

No reproduction or networking permitted without license from IHS

BSI 17 June 2005

Licensee=University of Hong Kong/5910986001

Not for Resale, 08/08/2005 20:45:40 MDT

BS 6231:1998

Table 5 Types AU and AK PVC-insulated cables

Construction

Tinned annealed copper conductor

Type AK 0.75 mm2 only:

All other cables:

PVC insulation type TI 1;

PVC insulation type 2

Colours

Single colours

Black, blue, brown, cream, green, grey, orange, pink, red, turquoise, violet, white, yellow

Bi-colours

Brown/blue, green/black, green/blue, green/brown, green/red, grey/blue, grey/brown, grey/green,

grey/orange, grey/red, orange/black, orange/blue, orange/brown, orange/green, orange/red, red/black,

red/blue, red/brown, white/black, white/blue, white/brown, white/green, white/grey, white/orange,

white/red, white/violet, white/yellow, yellow/green, yellow/violet

NOTE Base colours are indicated by bold type.

Type

Conductor

Radial thickness of insulation

Nominal

cross-sectional

area

Number/

nominal

diameter of

wires, or class

Nominal

Minimum

mm2

mm

mm

mm

Mean overall

diameter,

upper limit

Minimum

insulation

resistance

at 20 8C

mm

MVkm

AU

0.2

0.28

0.5

1/0.50

1/0.60

1/0.80

0.2

0.2

0.3

0.15

0.15

0.25

0.95

1.05

1.50

50

50

50

AK

0.22

0.5

0.75

class 5

class 5

class 5

0.2

0.3

0.6

0.15

0.25

0.50

1.05

1.65

2.45

50

50

10

--``,,,,,,,,,,,,,``,,,,`,,``,,`-`-`,,`,,`,`,,`---

Copyright British Standards Institution

Reproduced by IHS under license with BSI - Uncontrolled Copy

No reproduction or networking permitted without license from IHS

Licensee=University of Hong Kong/5910986001

Not for Resale, 08/08/2005 20:45:40 MDT

BSI 17 June 2005

BS 6231:1998

--``,,,,,,,,,,,,,``,,,,`,,``,,`-`-`,,`,,`,`,,`---

Table 6 Types BU and BR PVC-insulated rigid cables

Construction

Plain annealed copper conductor

PVC insulation type TI 1

Colours

Single colours

Black, blue, brown, grey, red, white, yellow

Bi-colour

Green/yellow (for earthing or similar protection, see 6.3)

Type

Conductor

Radial thickness

of insulation,

mean value

Mean overall

diameter, upper

limit

Minimum

insulation

resistance at 70 8C

mm

mm

MVkm

Class

Nominal

cross-sectional

area

mm2

BU

1.0

1.5

2.5

1

1

1

0.8

0.8

0.8

3.2

3.5

3.9

0.0142

0.0124

0.0103

BR

1.0

1.5

2.5

4

6

10

16

25

35

50

70

95

120

150

185

240

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

0.8

0.8

0.8

0.8

0.8

1.0

1.0

1.2

1.2

1.4

1.4

1.6

1.6

1.8

2.0

2.2

3.3

3.6

4.2

4.8

5.4

6.8

8.0

9.8

11.0

13.0

15.0

17.0

19.0

21.0

23.5

26.5

0.0126

0.0114

0.0094

0.0078

0.0066

0.0064

0.0053

0.0051

0.0044

0.0044

0.0037

0.0036

0.0033

0.0033

0.0033

0.0032

Copyright British Standards Institution

Reproduced by IHS under license with BSI - Uncontrolled Copy

No reproduction or networking permitted without license from IHS

BSI 17 June 2005

Licensee=University of Hong Kong/5910986001

Not for Resale, 08/08/2005 20:45:40 MDT

BS 6231:1998

Table 7 Type BK PVC-insulated flexible cables

Construction

Tinned or plain annealed copper conductor

PVC insulation type TI 1

Colours

Single colours

Black, blue, brown, grey, red, white, yellow

Bi-colour

Green/yellow (for earthing or similar protection, see 6.3)

Type

Conductor

Radial thickness

of insulation,

mean value

Mean overall

diameter, upper

limit

Minimum

insulation

resistance at 70 8C

mm

mm

MVkm

Class

Nominal

cross-sectional

area

mm2

BK

--``,,,,,,,,,,,,,``,,,,`,,``,,`-`-`,,`,,`,`,,`---

0.5

0.75

1.0

1.5

2.5

4

6

10

16

25

35

50

70

95

120

150

185

240

Copyright British Standards Institution

Reproduced by IHS under license with BSI - Uncontrolled Copy

No reproduction or networking permitted without license from IHS

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

0.8

0.8

0.8

0.8

0.8

0.8

0.8

1.0

1.0

1.2

1.2

1.4

1.4

1.6

1.6

1.8

2.0

2.2

3.0

3.2

3.4

3.7

4.2

4.8

6.3

7.8

9.0

11.5

13.0

15.0

17.5

19.5

21.5

24.0

26.5

30.0

Licensee=University of Hong Kong/5910986001

Not for Resale, 08/08/2005 20:45:40 MDT

0.0161

0.0141

0.0128

0.0111

0.0094

0.0077

0.0059

0.0058

0.0048

0.0047

0.0040

0.0039

0.0033

0.0032

0.0029

0.0029

0.0029

0.0028

BSI 17 June 2005

BS 6231:1998

Table 8 Types CU and CR PVC-insulated rigid cables

Construction

Plain annealed copper conductor

PVC insulation type TI 3

Colours

Single colours

Black, blue, brown, grey, red, white, yellow, orange, pink, violet, turquoise, green and cream

Bi-colour

Green/yellow (for earthing or similar protection, see 6.3).

Conductor

Radial thickness

of insulation mean

value

Mean overall

diameter, upper

limit

Minimum

insulation

resistance at 90 8C

mm

mm

MVkm

Class

Nominal

cross-sectional

area

mm2

CU

1.0

1.5

2.5

1

1

1

0.8

0.8

0.8

3.2

3.5

3.9

0.0142

0.0124

0.0103

CR

2.5

4

6

10

16

25

35

50

70

95

120

150

185

240

2

2

2

2

2

2

2

2

2

2

2

2

2

2

0.8

0.8

0.8

1.0

1.0

1.2

1.2

1.4

1.4

1.6

1.6

1.8

2.0

2.2

4.2

4.8

5.4

6.8

8.0

9.8

11.0

13.0

15.0

17.0

19.0

21.0

23.5

26.5

0.0094

0.0078

0.0066

0.0064

0.0053

0.0051

0.0044

0.0044

0.0037

0.0036

0.0033

0.0033

0.0033

0.0032

Copyright British Standards Institution

Reproduced by IHS under license with BSI - Uncontrolled Copy

No reproduction or networking permitted without license from IHS

BSI 17 June 2005

Licensee=University of Hong Kong/5910986001

Not for Resale, 08/08/2005 20:45:40 MDT

--``,,,,,,,,,,,,,``,,,,`,,``,,`-`-`,,`,,`,`,,`---

Type

BS 6231:1998

Table 9 Type CK PVC-insulated flexible cables

Construction

Tinned or plain annealed copper conductor

PVC insulation type TI 3

Colours

Single colours

Black, blue, brown, grey, red, white, yellow, orange, pink, violet, turquoise, green and cream

Bi-colour

Green/yellow (for earthing or similar protection, see 6.3).

Type

Conductor

--``,,,,,,,,,,,,,``,,,,`,,``,,`-`-`,,`,,`,`,,`---

Minimum

insulation

resistance at 90 8C

mm

mm

MVkm

mm2

0.5

0.75

1.0

1.5

2.5

4

6

10

16

25

35

50

70

95

120

150

185

240

Copyright British Standards Institution

Reproduced by IHS under license with BSI - Uncontrolled Copy

No reproduction or networking permitted without license from IHS

10

Mean overall

diameter, upper

limit

Class

Nominal

cross-sectional

area

CK

Radial thickness

of insulation,

mean value

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

0.8

0.8

0.8

0.8

0.8

0.8

0.8

1.0

1.0

1.2

1.2

1.4

1.4

1.6

1.6

1.8

2.0

2.2

3.0

3.2

3.4

3.7

4.2

4.8

6.3

7.8

9.0

11.5

13.0

15.0

17.5

19.5

21.5

24.0

26.5

30.0

Licensee=University of Hong Kong/5910986001

Not for Resale, 08/08/2005 20:45:40 MDT

0.0161

0.0141

0.0128

0.0111

0.0094

0.0077

0.0059

0.0058

0.0048

0.0047

0.0040

0.0039

0.0033

0.0032

0.0029

0.0029

0.0029

0.0028

BSI 17 June 2005

BS 6231:1998

Table 10 List of tests applicable to the various types of cable

Clause

number

Test description

Table number

5

8

12.2.2

12.2.3.1

12.2.3.2

12.2.4.2

12.2.4.3

12.2.4.3

12.2.5

12.2.6

Electrical tests

Conductor resistance

Spark test

Voltage test on cables types AU and AK

Voltage test on cables at 3500 V

Insulation resistance test at 20 8C

Insulation resistance test at 70 8C

Insulation resistance test at 90 8C

Long term resistance of PVC insulation to d.c.

Thermal endurance

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

10.1

11.1

11.2

Constructional and dimensional tests

Check on construction

Measurement of insulation thickness

Measurement of overall diameter

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

Mechanical properties of insulation

Tensile strength without ageing

Elongation at break without ageing

Cold bend test

Cold elongation test

Cold impact test

Tensile strength after ageing in air

Elongation at break after ageing in air

Loss of mass test

Hot deformation test

Hot pressure test

Heat shock test

Thermal stability test at 200 8C

Durability of colours and marking

Test under fire conditions

X

X

X

Xa

Xa

Xa

X

Xb

Xa

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

9.1

--``,,,,,,,,,,,,,``,,,,`,,``,,`-`-`,,`,,`,`,,`---

13

14

NOTE ``X'' indicates that the particular test is applicable to the cables in the table shown at the head of the column.

a

Type TI 1 insulation only

Type 2 insulation only

Copyright British Standards Institution

Reproduced by IHS under license with BSI - Uncontrolled Copy

No reproduction or networking permitted without license from IHS

BSI 17 June 2005

Licensee=University of Hong Kong/5910986001

Not for Resale, 08/08/2005 20:45:40 MDT

11

BS 6231:1998

The electrical properties of PVC compounds are not

adversely affected by low temperatures, but these

compounds become increasingly stiff and brittle at

temperatures about 0 8C. These cables should not be

manipulated or left unsupported at these, or lower

temperatures.

It is recommended that the cables should be installed

only when both the cable and the ambient temperature

are above 0 8C and have been so for the previous 24 h,

or where special precautions have been taken to

maintain the cable above this temperature.

Once installed, types AU and AK are suitable for use at

a minimum ambient temperature of 215 8C and types

BU, BR and BK at a minimum ambient temperature

of 220 8C. These cables are suitable for use where the

combination of ambient temperature and temperature

rise due to load results in a conductor temperature not

exceeding 70 8C. This is termed the designated

temperature.

Types CR, CU and CK cables, once installed, are

suitable for a limited degree of movement at a

minimum ambient temperature of 215 8C. They are

suitable for use where the conductor temperature does

not exceed the designated temperature of 90 8C.

However, adjacent to high temperature zones, cables

which are not subject to flexing or other mechanical

stresses, are suitable for 15 000 h of cumulative

operation at a temperature of 105 8C, provided that the

direct contact temperature does not exceed 85 8C. In

certain favourable conditions of service it may be

possible to operate the cables for periods longer

than 15 000 h, but attention should be paid to the

following points:

a) the possible effects of high temperature on the

softening of insulation and on its dielectric

properties, and

b) some insulants can break down chemically after

prolonged exposure to high temperatures. When this

occurs, corrosive substances are formed, which

attack the cable conductor or even the metal of

nearby enclosures, especially if moisture from

condensation is present when the circuit cools after

normal operation.

Copyright British Standards Institution

Reproduced by IHS under license with BSI - Uncontrolled Copy

No reproduction or networking permitted without license from IHS

12

Bibliography

BS 6004, PVC-insulated cables (non-armoured) for

electric power and lighting.

BS 6469-99:1992, Insulating and sheathing materials

of electric cables Part 99: Test methods used in the

United Kingdom but not specified in BS EN 60811 or

other Parts of BS 6469.

BS 6500, Insulated flexible cords and cables.

--``,,,,,,,,,,,,,``,,,,`,,``,,`-`-`,,`,,`,`,,`---

Annex A (informative)

Guidance on installation and operating

temperatures

Licensee=University of Hong Kong/5910986001

Not for Resale, 08/08/2005 20:45:40 MDT

BSI 17 June 2005

--``,,,,,,,,,,,,,``,,,,`,,``,,`-`-`,,`,,`,`,,`---

Copyright British Standards Institution

Reproduced by IHS under license with BSI - Uncontrolled Copy

No reproduction or networking permitted without license from IHS

Licensee=University of Hong Kong/5910986001

blank

Not for Resale, 08/08/2005 20:45:40 MDT

BS 6231:1998

BSI British Standards Institution

BSI is the independent national body responsible for preparing

British Standards. It presents the UK view on standards in Europe and at the

international level. It is incorporated by Royal Charter.

Revisions

British Standards are updated by amendment or revision. Users of

British Standards should make sure that they possess the latest amendments or

editions.

It is the constant aim of BSI to improve the quality of our products and services.

We would be grateful if anyone finding an inaccuracy or ambiguity while using

this British Standard would inform the Secretary of the technical committee

responsible, the identity of which can be found on the inside front cover.

Tel: +44 (0)20 8996 9000. Fax: +44 (0)20 8996 7400.

BSI offers members an individual updating service called PLUS which ensures

that subscribers automatically receive the latest editions of standards.

Buying standards

Orders for all BSI, international and foreign standards publications should be

addressed to Customer Services. Tel: +44 (0)20 8996 9001.

Fax: +44 (0)20 8996 7001. Email: orders@bsi-global.com. Standards are also

available from the BSI website at http://www.bsi-global.com.

In response to orders for international standards, it is BSI policy to supply the

BSI implementation of those that have been published as British Standards,

unless otherwise requested.

Information on standards

BSI provides a wide range of information on national, European and

international standards through its Library and its Technical Help to Exporters

Service. Various BSI electronic information services are also available which give

details on all its products and services. Contact the Information Centre.

Tel: +44 (0)20 8996 7111. Fax: +44 (0)20 8996 7048. Email: info@bsi-global.com.

Subscribing members of BSI are kept up to date with standards developments

and receive substantial discounts on the purchase price of standards. For details

of these and other benefits contact Membership Administration.

Tel: +44 (0)20 8996 7002. Fax: +44 (0)20 8996 7001.

Email: membership@bsi-global.com.

Information regarding online access to British Standards via British Standards

Online can be found at http://www.bsi-global.com/bsonline.

Further information about BSI is available on the BSI website at

http://www.bsi-global.com.

Copyright

Copyright subsists in all BSI publications. BSI also holds the copyright, in the

UK, of the publications of the international standardization bodies. Except as

permitted under the Copyright, Designs and Patents Act 1988 no extract may be

reproduced, stored in a retrieval system or transmitted in any form or by any

means electronic, photocopying, recording or otherwise without prior written

permission from BSI.

BSI

389 Chiswick High Road

London

W4 4AL

This does not preclude the free use, in the course of implementing the standard,

of necessary details such as symbols, and size, type or grade designations. If these

details are to be used for any other purpose than implementation then the prior

written permission of BSI must be obtained.

Details and advice can be obtained from the Copyright & Licensing Manager.

Tel: +44 (0)20 8996 7070. Fax: +44 (0)20 8996 7553.

Email: copyright@bsi-global.com.

--``,,,,,,,,,,,,,``,,,,`,,``,,`-`-`,,`,,`,`,,`---

Copyright British Standards Institution

Reproduced by IHS under license with BSI - Uncontrolled Copy

No reproduction or networking permitted without license from IHS

Licensee=University of Hong Kong/5910986001

Not for Resale, 08/08/2005 20:45:40 MDT

Вам также может понравиться

- BS 5308-1Документ22 страницыBS 5308-1Jeff Anderson Collins100% (2)

- BS 7655-0-2006Документ13 страницBS 7655-0-2006Surendra Mishra100% (2)

- BS 6622-2007Документ60 страницBS 6622-2007oadipphone7031100% (7)

- ANSI NEMA MW 1000-2003 Rev.1.2005Документ220 страницANSI NEMA MW 1000-2003 Rev.1.2005carlosantunez111100% (5)

- Cable GlandsДокумент20 страницCable GlandsBalaji VenkatesanОценок пока нет

- Fmds0501 - Hazardous Classification AreasДокумент49 страницFmds0501 - Hazardous Classification AreasAnonymous 1XHScfCIОценок пока нет

- BS 07655-1.1-2000Документ9 страницBS 07655-1.1-2000Reda ElawadyОценок пока нет

- Bs 6485 1999 PVC Insulated Conductors For Overhead Power LinesДокумент12 страницBs 6485 1999 PVC Insulated Conductors For Overhead Power LinesAnamulKabir100% (2)

- BS 2627-1970 Specification For Wrought Aluminum For Electrical Purposes WireДокумент12 страницBS 2627-1970 Specification For Wrought Aluminum For Electrical Purposes WireThanh Dang67% (3)

- BS 215-2-1970-Aluminium Conductors and Aluminium Conductors Steel-Reinforced For Overhead Power TransmissionДокумент16 страницBS 215-2-1970-Aluminium Conductors and Aluminium Conductors Steel-Reinforced For Overhead Power TransmissionDayan Yasaranga100% (2)

- Cable Gland - DistancesДокумент1 страницаCable Gland - DistancesalexiuteodorОценок пока нет

- Insulating and Sheathing Materials For CablesДокумент8 страницInsulating and Sheathing Materials For CablesHanh-Trang DangОценок пока нет

- BS 5000-17Документ8 страницBS 5000-17stuart3962Оценок пока нет

- En50288-1 2003Документ16 страницEn50288-1 2003namheeОценок пока нет

- Caledonian Navy Cables GuideДокумент35 страницCaledonian Navy Cables GuidePugalenthi SekarОценок пока нет

- Fire Resistant Fiber CablesДокумент43 страницыFire Resistant Fiber Cablesrose chenОценок пока нет

- Bs en 50290-2!26!2002 通信电缆 第2-26部分 通用设计规则和制造 无卤素的阻燃绝缘化合物Документ9 страницBs en 50290-2!26!2002 通信电缆 第2-26部分 通用设计规则和制造 无卤素的阻燃绝缘化合物Yayan RnsОценок пока нет

- BS 4607-3Документ20 страницBS 4607-3Jeff Anderson Collins100% (1)

- Kabel Nyfgby 2Документ1 страницаKabel Nyfgby 2dandik_dwiОценок пока нет

- (No. 90) - 11 - SDMS-04 - R0 - FinalДокумент20 страниц(No. 90) - 11 - SDMS-04 - R0 - Finalpmurali_10490025467% (3)

- CIBSE Commissioning Code A - Air Distribution Systems (1996 Confirmed 2006)Документ33 страницыCIBSE Commissioning Code A - Air Distribution Systems (1996 Confirmed 2006)Thomas Or100% (6)

- BS 7629-1Документ20 страницBS 7629-1floyd hope prieto100% (1)

- BSI Standards PublicationДокумент34 страницыBSI Standards PublicationІгор Бадюкевич100% (1)

- BS 88-2.1 1988 - Low-Voltage FusesДокумент12 страницBS 88-2.1 1988 - Low-Voltage Fusesravibraju100% (1)

- BS 6724 1997Документ42 страницыBS 6724 1997Simon Law100% (1)

- BS 6724 1997Документ42 страницыBS 6724 1997Simon Law100% (1)

- Iec60227 6 PDFДокумент7 страницIec60227 6 PDFKLN Prasad0% (1)

- Bs 6387 Catc-950deg Cel-HighlightedДокумент1 страницаBs 6387 Catc-950deg Cel-HighlightedAshik M RasheedОценок пока нет

- ( - Ekgo: TandcfrciДокумент23 страницы( - Ekgo: TandcfrciRajesh Arora100% (4)

- SOR - Vol 3-Print, ElectricalДокумент359 страницSOR - Vol 3-Print, Electricaldebabazooka100% (4)

- Key Changes in SS 638 2018 - Part 4 Protection For SafetyДокумент37 страницKey Changes in SS 638 2018 - Part 4 Protection For SafetyThomas Or100% (1)

- CIBSE Commissioning Code L - Lighting PDFДокумент30 страницCIBSE Commissioning Code L - Lighting PDFThomas Or100% (2)

- Electric and Optical Fibre Cables - Test Methods For Non-Metallic MaterialsДокумент12 страницElectric and Optical Fibre Cables - Test Methods For Non-Metallic Materialsjawad chraibiОценок пока нет

- BS 5099-2004 Electric Cables - Voltage Levels For Spark TestingДокумент7 страницBS 5099-2004 Electric Cables - Voltage Levels For Spark TestingAnamulKabirОценок пока нет

- N2XSYДокумент5 страницN2XSYRinda_RaynaОценок пока нет

- En 50525-1Документ38 страницEn 50525-1siddharth incertech100% (4)

- BS 4999-145Документ10 страницBS 4999-145Dino PedutoОценок пока нет

- 6387Документ24 страницы6387sohaib100% (3)

- Iec 60949Документ15 страницIec 60949carlos_alfaro_herrera100% (2)

- Engine Room VentillationДокумент36 страницEngine Room VentillationAnwarul Shafiq AwalludinОценок пока нет

- Irs S 76-89 PDFДокумент34 страницыIrs S 76-89 PDFGaurav Agarwal0% (1)

- BS en 50525Документ20 страницBS en 50525Dung Pham100% (1)

- Benefits of Using IEC 61439 Standard in Electrical Busbar SystemsДокумент9 страницBenefits of Using IEC 61439 Standard in Electrical Busbar SystemsMessung Power Distribution SystemsОценок пока нет

- BS 8491Документ28 страницBS 8491sohaib100% (1)

- International StandardДокумент5 страницInternational StandardKln Prasad0% (1)

- Iec 61034-2Документ22 страницыIec 61034-2sohaib100% (1)

- CIBSE Commissioning Code L - LightingДокумент30 страницCIBSE Commissioning Code L - LightingThomas Or100% (1)

- Cost Abstract for Buena Vista Resort ConstructionДокумент13 страницCost Abstract for Buena Vista Resort ConstructionAnil sainiОценок пока нет

- Iec 61439Документ17 страницIec 61439Romario DiazОценок пока нет

- BS 215 Part 1 1970Документ11 страницBS 215 Part 1 1970AnamulKabirОценок пока нет

- Catalogue Cable - Tenaga Cable IndustriesДокумент114 страницCatalogue Cable - Tenaga Cable Industriesnhasnizam197583% (6)

- Wallis Catalogue - Earthing SystemДокумент120 страницWallis Catalogue - Earthing Systemjk_173Оценок пока нет

- Signal CableДокумент27 страницSignal CableVikas Srivastav89% (9)

- LV SWG Verification IEC 61439 - 2009 (Siemens)Документ42 страницыLV SWG Verification IEC 61439 - 2009 (Siemens)RudanekОценок пока нет

- NF C 33-209 cable specsДокумент2 страницыNF C 33-209 cable specsshivam dwivedi0% (1)

- BS 07870-5-2011 (2012)Документ22 страницыBS 07870-5-2011 (2012)bean bean50% (2)

- Copper For Busbars-OrIENTAL CuДокумент27 страницCopper For Busbars-OrIENTAL Cutenk_man83% (6)

- BS - 7671 - CIBSE Lecture (Yorkshire Branch)Документ40 страницBS - 7671 - CIBSE Lecture (Yorkshire Branch)tony6sungОценок пока нет

- Bs 62230Документ22 страницыBs 62230sohaib100% (1)

- En 50575:2014 + A1:2016Документ28 страницEn 50575:2014 + A1:2016Renato100% (1)

- LSF CablesДокумент30 страницLSF CablesFrancisco M. RamosОценок пока нет

- Wireless Infrastructure Catalogue enДокумент222 страницыWireless Infrastructure Catalogue eneduardo100% (1)

- En 50618-2014Документ29 страницEn 50618-2014Dominic Santiago100% (7)

- IEC 61238-1 Compression and Mechanical Connectors For Power CablesДокумент12 страницIEC 61238-1 Compression and Mechanical Connectors For Power Cablesquarktop123456100% (3)

- BS 6007 - (0101001)Документ26 страницBS 6007 - (0101001)rommel duranОценок пока нет

- Colour Code According To DIN VDE 0815: Installation Cables Installation CablesДокумент1 страницаColour Code According To DIN VDE 0815: Installation Cables Installation CablesrocketvtОценок пока нет

- BS 07870-3.12-2011 (2012)Документ22 страницыBS 07870-3.12-2011 (2012)Fernando Sánchez RomeroОценок пока нет

- Uninyvin Cables PDFДокумент2 страницыUninyvin Cables PDFmailmanugsОценок пока нет

- PGCIL Power & Control Cable Rev-5Документ14 страницPGCIL Power & Control Cable Rev-5uttam100% (1)

- COMESA Standard for Hard-drawn Aluminium WireДокумент18 страницCOMESA Standard for Hard-drawn Aluminium WiremartinpellsОценок пока нет

- 7655 0 PDFДокумент13 страниц7655 0 PDFsohaibОценок пока нет

- B 231 - B 231M - 99 - Qjizms05oqДокумент11 страницB 231 - B 231M - 99 - Qjizms05oqAifam RawОценок пока нет

- IEC Standard RequirementsДокумент14 страницIEC Standard RequirementsjamilОценок пока нет

- BS 6622 XLPE CablesДокумент57 страницBS 6622 XLPE Cablesdanferreiro8318Оценок пока нет

- Bu1 PDFДокумент31 страницаBu1 PDFGilberto MejíaОценок пока нет

- BS 06622-2007Документ60 страницBS 06622-2007Thanh DangОценок пока нет

- RE Grid Intergration ThailandДокумент54 страницыRE Grid Intergration ThailandMontree SupaphobОценок пока нет

- CEM PT HandbookДокумент44 страницыCEM PT HandbookThomas OrОценок пока нет

- Thailand Electric Power SystemДокумент23 страницыThailand Electric Power SystemThomas OrОценок пока нет

- Medium Voltage Switching Station-VOL-2 - MVДокумент76 страницMedium Voltage Switching Station-VOL-2 - MVThomas OrОценок пока нет

- Energy Indonesia Country Report (Usaid)Документ35 страницEnergy Indonesia Country Report (Usaid)Natarajan NathanОценок пока нет

- FMDS0523 PDFДокумент25 страницFMDS0523 PDFEd OrtizОценок пока нет

- Contactor by EE Controls PDFДокумент10 страницContactor by EE Controls PDFPaul MendozaОценок пока нет

- Ari 550.590-2003Документ36 страницAri 550.590-2003Ronald阿豐Оценок пока нет

- Leviton - Cat6A Reference Guide. 051518pdf PDFДокумент89 страницLeviton - Cat6A Reference Guide. 051518pdf PDFThomas OrОценок пока нет

- Network Topologies and Distance PDFДокумент26 страницNetwork Topologies and Distance PDFThomas OrОценок пока нет

- Network Cabling Design Best PracticesДокумент40 страницNetwork Cabling Design Best PracticesThomas Or0% (1)

- EE740 PowerFlow1Документ18 страницEE740 PowerFlow1Thomas OrОценок пока нет

- MV Distribution - GMSet (MV GIS) CBДокумент26 страницMV Distribution - GMSet (MV GIS) CBThomas OrОценок пока нет

- Cooling Load Article 2015Документ4 страницыCooling Load Article 2015Edmund YoongОценок пока нет

- GeoSS Event Seminar 7 August 2012 - Slides PDFДокумент13 страницGeoSS Event Seminar 7 August 2012 - Slides PDFThomas OrОценок пока нет

- StochBioChapter3 PDFДокумент46 страницStochBioChapter3 PDFThomas OrОценок пока нет

- 21 The Exponential DistributionДокумент37 страниц21 The Exponential DistributionChandler Jiacheng LiaoОценок пока нет

- 040 051 WaterДокумент12 страниц040 051 WaterThomas OrОценок пока нет

- Fact Sheet 4 - Energy Efficiency of White LEDsДокумент2 страницыFact Sheet 4 - Energy Efficiency of White LEDsThomas OrОценок пока нет

- MV Distribution - GMSet (MV GIS) CBДокумент26 страницMV Distribution - GMSet (MV GIS) CBThomas OrОценок пока нет

- Lighting DesignДокумент1 страницаLighting DesignThomas OrОценок пока нет

- Chapter 5 - Bu2Документ4 страницыChapter 5 - Bu2mjcntn000Оценок пока нет

- CopperДокумент2 страницыCopperJega SkyОценок пока нет

- Honewell Fire Alarm Cable GuideДокумент18 страницHonewell Fire Alarm Cable GuideMark VincentОценок пока нет

- Astm B 286-07Документ5 страницAstm B 286-07Ramsi Ankzi100% (1)

- Copper CablesДокумент4 страницыCopper CablesJagpreet Singh RandhawaОценок пока нет

- Category 3 copper cable specificationsДокумент45 страницCategory 3 copper cable specificationsArman Ul NasarОценок пока нет

- UAE Sharjah private education authority Rosary school British curriculum science revision worksheetДокумент7 страницUAE Sharjah private education authority Rosary school British curriculum science revision worksheetMiral HashemОценок пока нет

- List Price W e F 1-08-11Документ14 страницList Price W e F 1-08-11balajootyОценок пока нет

- Industrial Ethernet Cat 5E: Leoni Special Cables GMBHДокумент2 страницыIndustrial Ethernet Cat 5E: Leoni Special Cables GMBHLeodoletaОценок пока нет

- Industrial Ethernet Cat.5+: Leoni Special Cables GMBHДокумент2 страницыIndustrial Ethernet Cat.5+: Leoni Special Cables GMBHLeodoletaОценок пока нет

- 9618 s22 Ms 12 PDFДокумент9 страниц9618 s22 Ms 12 PDFSunnatbek Meliqo'ziyevОценок пока нет

- Is 7404 1 1991COPPERДокумент11 страницIs 7404 1 1991COPPERRAMASHISH KUMARОценок пока нет

- Cable Selection Guide (SELECTION OF HIGH TENSION H. T. CABLES PAGE NO - 15) Page No 31Документ31 страницаCable Selection Guide (SELECTION OF HIGH TENSION H. T. CABLES PAGE NO - 15) Page No 31Shanto Chowdhury100% (1)

- E MseptSOR2022Документ239 страницE MseptSOR2022Abhishek TiwariОценок пока нет

- Screenshot 2021-06-03 at 7.27.55 PMДокумент6 страницScreenshot 2021-06-03 at 7.27.55 PMSo Mte BeОценок пока нет

- Low Voltage Electrical Works SpecificationДокумент35 страницLow Voltage Electrical Works Specificationefmartin21100% (1)

- Bahra WiresДокумент12 страницBahra WiresJoseph JoeОценок пока нет

- Earthing Chemical Analysis and ItseffectsДокумент18 страницEarthing Chemical Analysis and ItseffectsDeepak GuptaОценок пока нет

- Estimasi Biaya Jasa Pekerjaan ElectricalДокумент19 страницEstimasi Biaya Jasa Pekerjaan ElectricalHarry Priyulanda RukkaОценок пока нет

- Sutrado Kabel Catalogue - Quality cables and copper productsДокумент61 страницаSutrado Kabel Catalogue - Quality cables and copper productsRudi AlfadliОценок пока нет

- Dezire Electrical Final Bill Summary for Jaipur InstallationДокумент26 страницDezire Electrical Final Bill Summary for Jaipur Installationrudresh kumarОценок пока нет