Академический Документы

Профессиональный Документы

Культура Документы

Sapag JHP Valves Jun04 en

Загружено:

anwar01Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Sapag JHP Valves Jun04 en

Загружено:

anwar01Авторское право:

Доступные форматы

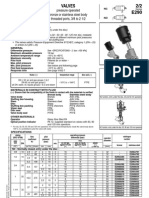

Butterfly valves JHP

The high performance butterfly valve

Features and Benefits

The design and quality of construction ensure

the highest performance, for example:

- the double offset design avoids seat wear

and a low seating torque,

- the JHP has a high flow capacity value due

to the well engineered shape of the disc and

the stub shaft design,

- the mounting plate is standardized

according to ISO 5211 to adapt any type of

actuator without any intermediate

component.

JHP complies with the following standards:

Flange adaptation:

- ISO 2084 / 7005

- EN 1092

- DIN 2501

- BS 4504

- ANSI B 16.5

- JIS B 2210

- MSS SP 44

Face to face:

- ISO 5752

- EN 558-1

- NFE 29305

- DIN 3202 (K1, K2)

- BS 5155

- API 609

- MSS SP 68

Fire safe standards:

- API 607

- BS 6755-2

Applications

General industrial utilities

Power generation

Automotive Industry

Chemical petrochemical

Food processing

Pulp and Paper

Ship building

Desalination

Off-shore

Bitume

Sugar mills

Cooling industries

Technical data

Maximum working pressure:

DN50 to DN400: PN 40

DN450 to DN600: PN 25

DN700 to DN900: PN 16

Temperature range: -50C to +400C

Vacuum: 1 Torr

JHP is suitable to be mounted with all

quarter-turn pneumatic and electric

operators.

Wafer and lugged designs are available.

Sapag reserves the right to change the contents without notice

SAHFR-0011-EN-0406

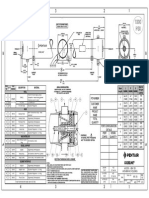

Butterfly valves JHP

The ultimate design

No leakage

1

Seat:

Tightness is unaffected by pressure

changes, or changes in flow direction as

the seat can move radially in its slot.

2

Bottom end cover:

Ensures lower stem tightness by its static

seal of expanded graphite.

3

Packing system:

The perfect internal tightness is obtained

by a conventional packing system in

expanded graphite. The excellent

temperature stability ensures 100% static

and dynamic tightness.

- The travel stop contact against the

mounting plate, thus avoiding potential

over-torque of the discstem.

- When actuator has been removed and

valve is in service, the position of the

disc is clearly shown.

12

The Sapag plant is ISO9001

approved

The JHP is in compliance with the

latest european directives:

Disc to stem connection:

Via radial taper pins (no intruding

between up- and downstream side of

the valve), which allows accurate

connection without any play between

disc and stem.

Optimized design

Easy accessible

13 Disc:

4

Standardized mounting plate:

The double eccentric disc design is

The integrally cast plate is in accordance

optimized via the finite element method

with ISO 5211. The actuator can be

so that there is no contact between the

directly mounted to it, eliminating the

seat and disc already at small angles.

need of brackets and couplings.

5

Twin column construction:

Allows easy access to the packing system

without removing the actuator.

6

Extended neck:

For easy insulation. Especially designed

for isolated pipes as it allows insulation flanges included- with easy access to the

packing system. In addition any potential

leak path is located outside the isolation

material.

7

Centering flange:

Allows precise centering of the valve on

Fig. 2: Optimized design via finite

the pipe.

element method

8

Retaining ring:

With screws outside of flange sealing

zone, which facilitates easy maintenance.

The results of this unique design are:

In addition the uninterrupted sealing

No wear and low closing torque.

surface allows the installation of spiral

A large free flow area resulting in a low

wound gaskets.

headloss and high flow values.

Perfect shaft guiding

The disc edge has a geometry which

9

Bearings:

- facilitates the contact between disc

Double corrosion resistant bearings on upper

and seat during valve closure,

and lower stem, providing low friction

- guarantees tightness through a wide

coefficient and high load capacity. The

area of contact.

bearings avoid any deflection of shaft at the

packing level, thus ensuring perfect

bidirectional tightness.

10 Disc locating shoulder:

Shrunk on the shaft during assembly. It retains

its position for the life of the valve and

prevents displacement of disc in relation to

the seat while being in service.

11 Travel stop, position indicator:

Located at the mounting plate level:

- The travel stop is set during assembly at 90

disc angle in order to avoid any over

traveling of the disc. (See fig. 1)

Fig. 1: Travel stop position indicator

Sapag reserves the right to change the contents without notice

page 2

- PED module H,

categorie 3

- TPED module H,

categorie 2

- ATEX:

II 2 G/D EEx c

The JHP range holds the following

approvals and certificates:

MARINE:

Fire safe:

11

5

3

9

12

6

7

8

13

9

1

10

2

Butterfly valves JHP

A complete range

JHP RTFE (standard)

The seat is made of filled RTFE in order to minimize cold flow effects at high temperatures. The combined action of seat geometry and the elastic

metal insert guarantees a long lasting bidirectional tight shutoff.

Pressure

P-T diagram (JHP RTFE and FS)

Bar

(psi)

Valve mounting with

shaft downstream

Non dangerous

liquids only

Saturated steam

Liquid steam

Bidirectional

valve

All fluids

DN50-300 lug

DN50-400 wafer

JHP FS (Fire Safe)

DN50-600: 25 bar max.

DN700-900: 16 bar max

The valve has been designed according fire test standards. The standard RTFE seat is mounted with a stainless steel ring. In the event of fire, it

supersedes over the RTFE seat and provides a bidirectional backup seal, according to API 607 / BS 6755 part 2.

JHP PP (Pulp and Paper)

Bar

(psi)

Recommended

flow direction

Pressure

The valve has been designed specially for the pulp and paper applications. The special seat guarantees a long life time without maintenance.

P-T diagram (JHP PP)

DN50-400

The valve integrates a metal seat in order to

be used on all applications with high pressure

and high temperature.

Bar

(psi)

Pressure

JHP HT (High Temperature)

P-T diagram (JHP HT)

Saturated steam

Liquid steam

Recommended

flow direction

DN50-250: 25 bar max.

DN300-400: 16 bar max.

Bidirectional (JHP RTFE and FS)

1 Seat downstream

In this case, the closing action of disc

leads to compression of PTFE seat

between disc and metallic insert.

Subsequently, the seat takes support

from the retaining ring, while the

energized insert delivers a sealing

pressure between disc and seat, in

radial direction.

2 Seat upstream

The fluid flowing behind the seat

increases the sealing effect.

In fact, the JHP seat offers real

dynamic tightness in both

directions.

Sapag reserves the right to change the contents without notice

page 3

Butterfly valves JHP

Hydraulic characteristics

Flow coefficients Kv and Cv

Kv is the flow in m3/h of water, at an average

temperature of 20C, crossing the valve with

creating a headloss of 1 bar.

Definitions

Simplified formula

Non

Headloss

Kv

compressible

Kv

Q

p

P1

P2

QN

Gas

fluid

p < P1

2

Cv = 1.16 Kv

QN

514

N.T

p. P2

2 QN

=

514.P1

N.T

P2 > P1

2

p > P1

2

Kv

1

p

Q

=

31,6

1

N

P2 < P1

2

: Flow coefficient of the valve

: Flow in m3/h

: Headloss in the valve in bar

: Upstream pressure in bar

: Downstream pressure in bar

: Flow in normal conditions

(0C, 760 mm Hg) in m3/h

: Temperature of the fluid in K

: Volumic weight of the fluid in kg/m3

: Volumic weight in normal conditions

Kv values

DN (mm)

50

65

80

100

125

150

200

250

300

350

400

450

500

600

700

800

Size (inch)

2"

21/2"

3"

4"

5"

6"

8"

10"

12"

14"

16"

18"

20"

24"

28"

32"

5

14

25

37

50

70

95

115

9

25

41

64

93

130

180

210

19

42

62

98

149

213

274

320

37

70

116

174

244

328

442

500

61

115

190

285

400

538

725

820

72

126

210

342

520

786

1 050

1 200

137

241

364

574

893

1 389

1 986

2 300

180

368

612

005

503

182

012

600

265

521

981

548

254

232

250

200

302

612

072

748

700

045

030

300

392

795

394

272

511

266

848

500

490

010

760

870

445

650

910

000

620

250

190

620

620

350

430

800

900

880

190

250

100

100

200

600

20

30

40

50

60

70

80

90

Headloss coefficient (K)

For liquid, the formula of the headloss with a

disc opening angle is:

V2

P = K

10 000

2g

1

1

2

3

3

1

2

3

4

5

1

1

2

4

6

7

1

2

3

5

7

9

1

1

2

4

6

9

12

1

2

3

5

8

12

14

1

3

5

8

12

18

21

1

2

4

7

11

16

25

30

250

560

450

250

250

950

220

200

1

3

5

9

15

22

34

40

700

400

970

600

220

600

250

200

900

36"

2

4

7

12

19

29

44

51

150

350

750

350

800

200

240

200

Definitions

K is the headloss coefficient according to the angle to opening in which:

P : Headloss in a valve opened to an angle expressed in bar

V : Velocity of the fluid in a pipeline of diameter equal to the one of the valve expressed in m/s

when the valve is opened to an angle

g

: Acceleration of gravity in m/s2

K : Headloss according to the angle to opening. Results in the table

: Volumic weight of the fluid (kg/m3)

H : Headloss on the valve opened to an angle a expressed in meters of water columns.

In the case of water the formula is simplified

V2

H = K

2g

K values

50

65

80

100

125

150

200

250

300

350

400

450

500

600

700

800

2"

Size (inch)

20

392

30

50

40

16

50

7.2

60

3.9

70

2

80

1.09

90

0.74

21/2"

3"

4"

5"

6"

8"

10"

12"

14"

16"

18"

20"

24"

28"

32"

36"

346 178

45

36

17

17

6.8

6.7

3.2

2.9

1.66 1.42

0.86 0.86

0.63 0.63

115

32

12

5.2

2.6

1.46

0.8

0.63

103

29

11

4.7

2.4

1.32

0.73

0.57

153

50

18

6.8

2.9

1.29

0.72

0.55

134

43

19

7.6

3.1

1.3

0.64

0.47

189

45

16

6.1

2.7

1.29

0.68

0.47

181

47

13

5.3

2.5

1.22

0.7

0.47

258

63

20

7.7

3.2

1.44

0.65

0.44

261

64

21

7.8

3.3

1.45

0.65

0.44

268

63

21

7.8

3.3

1.45

0.65

0.45

255

63

20

7.5

3.1

1.41

0.63

0.45

251

58

20

7.4

3.1

1.39

0.61

0.44

241

57

19

7.2

3

1.31

0.59

0.41

222

56

18

7

2.8

1.26

0.55

0.4

223

54

17

6.7

2.6

1.21

0.53

0.39

900

DN (mm)

900

Maximum allowable torques in Nm for standard shaft material (13% Cr)

DN (mm)

50

65

80

100

125

150

200

250

300

350

400

450

500

600

700

800

Size (inch)

2"

21/2"

3"

4"

5"

6"

8"

10"

12"

14"

16"

18"

20"

24"

28"

32"

36"

122

122

122

297

297

743

743

1 332

1 957

1 957

3 108

6 389

10 793

10 793

25 948

25 948

52 851

900

13% Cr

Notes

The maximum allowable torques are applicable for standard type valves.

Actuator sizing torques in Nm

DN (mm)

50

65

80

100

125

150

200

250

300

350

400

450

500

600

700

800

Size (inch)

2"

21/2"

3"

4"

5"

6"

8"

10"

12"

14"

16"

18"

20"

24"

28"

32"

36"

JHP RTFE/FS/PP

JHP HT

27

54

33

66

45

90

73

146

115

230

780

340

320

40

480

910

720

1 290

950

1 290

1 350

1 610

1 700

2 290

2 300

-

3 200

-

4 500

-

6 000

-

8 000

-

Sapag reserves the right to change the contents without notice

page 4

Butterfly valves JHP

Bare shaft valve - All constructions

Wafer

Lugged

DN50 - DN200

DN250 - DN900

Dimensions (mm)

DN

DN

(mm) (inch)

50

65

80

100

125

150

200

250

300

350

400

450

500

600

700

800

900

2"

21/2"

3"

4"

5"

6"

8"

10"

12"

14"

16"

18"

20"

24"

28"

32"

36"

Weight (kg)

A

175

191

197

233

245

283

307

371

399

421

453

522

550

634

720

771

878

102

116

122

149

160

193

217

251

302

324

358

392

427

485

547

598

687

43

46

46

52

56

56

60

68

78

78

102

114

127

154

165

190

241

D1

D2

E1

E2

97

117

130

158

188

212

267

321

372

431

484

534

590

689

799

900

1000

153

173

190

225

261

294

365

420

476

542

606

662

722

837

947

1070

-

26

26

26

26

26

26

26

36

36

36

43

49

63

63

81

81

-

70

70

70

90

100

100

100

110

110

110

F

11

11

11

14

14

19

19

27

27

27

32

36

46

46

55

55

-

G*

Nb

Wafer

Lugged

35

35

35

40

50

60

60

80

80

100

14

14

14

16

16

18

18

21

21

22

24

30

30

30

35

36

38

80

80

80

100

100

116

116

155

155

155

162

175

210

210

300

300

350

70

70

70

100

100

100

100

132

132

132

140

-

70

70

70

102

102

102

102

125

125

125

140

140

165

165

254

254

254

4

4

4

4

4

4

4

4

4

4

4

4

4

4

8

8

8

9

9

9

11

11

11

11

14

14

14

18

18

22

22

18

18

18

10

10

10

12

14

18

18

22

22

28

8

8

8

8

9

11

11

14

14

16

60

60

60

73

60

80

80

100

100

100

3.1

4.5

4.9

8.2

9.8

12.5

22

41

55

75

98

145

188

224

269

515

850

4.8

6.9

7.7

13.7

17

22.5

34

53

78

97

133

206

244

306

450

825

-

Notes

Dimensions and weights are given as a guide.

(G*): Sapag standard is square shafts for DN50 - DN800, key drive for DN900.

Key drive for DN250 - DN800 are available on request.

Sapag reserves the right to change the contents without notice

page 5

Butterfly valves JHP RTFE

Standard version: DN50 - DN900 (2 - 36)

Detail of the seat

Lugged

Wafer

DN50 - DN200

DN250 - DN900

Parts list

Rep. Number Designation

Steel body and disc

Stainless steel body and disc

Steel body /stainless steel disc

1

2

1

1

Body

Disc

EN GP 240 GH / A 216 Gr. WCB

EN GP 240 GH / A 216 Gr. WCB

Retaining ring

EN GP 240 GH / A 216 Gr. WCB

EN

EN

EN

EN

4

5

6

7

8

9

10

11

12

13

14

15

16

1

1

1

1

1

1

*

4

1

1

1

*

1

*

1

1

Upper stem

Lower stem

Seat

Packing gland

Gland follower

Position indicator

Packing

Bearing

Disc locating shoulder

Bottom end cover

Bottom seal

Pin

Circlips

Set screw

Indication plate

Key

Bolt

EN X20Cr13 / AISI 420

EN X20Cr13 / AISI 420

Reinforced PTFE

EN X12Cr13 / AISI 410

EN C22E / AISI 1015

EN C22E / AISI 1015

Expanded graphite

Carbon steel + PTFE

EN X2CrNi 19-11 / AISI 304 L

EN C22E / AISI 1015

PTFE

EN X2CrNiMo 17-12-2 / AISI 316 L

Carbon steel

Carbon steel

Stainless steel

EN C35E / AISI 1038

Galvanized steel

EN GX5CrNiMo 19-11-2 / A 351 Gr. CF8M

EN X5CrNiMo 19-11-2 / AISI 316

EN GX5CrNiMo 19-11-2 / A 351 Gr. CF8M

EN X5CrNiMo 19-11-2 / AISI 316

EN GX5CrNiMo 19-11-2 / A 351 Gr. CF8M

EN X5CrNiCuNb 16-4 / A 564 Gr. 630

EN X5CrNiCuNb 16-4 / A 564 Gr. 630

Reinforced PTFE

EN X2CrNi 19-11 / AISI 304 L

EN X5CrNiMo 19-11-2 / AISI 316

EN X5CrNiMo 19-11-2 / AISI 316

Expanded graphite

Stainless steel + PTFE

EN X2CrNi 19-11 / AISI 304 L

EN X5CrNiMo 19-11-2 / AISI 316

PTFE

EN X2CrNiMo 17-2-2 / AISI 316 L

Stainless steel

Stainless steel

Stainless steel

EN C35E / AISI 1038

Stainless steel

17

18

* Number dependent on valve size

Sapag reserves the right to change the contents without notice

page 6

GP 240 GH / A 216 Gr. WCB

X5CrNiMo 19-11-2 / AISI 316

GX5CrNiMo 19-11-2 / A 351 Gr. CF8M

GP 240 GH / A 216 Gr. WCB

EN X5CrNiCuNb 16-4 / A 564 Gr. 630

EN X5CrNiCuNb 16-4 / A 564 Gr. 630

Reinforced PTFE

EN X12Cr13 / AISI 410

EN C22E / AISI 1015

EN C22E / AISI 1015

Expanded graphite

Carbon steel + PTFE

EN X2CrNi 19-11 / AISI 304 L

EN C22E / AISI 1015

PTFE

EN X2CrNiMo 17-2-2 / AISI 316 L

Carbon steel

Carbon steel

Stainless steel

EN C35E / AISI 1038

Galvanized steel

Butterfly valves JHP FS

Fire Safe seat: DN50 - DN600 (2 - 24)

Detail of the seat

Lugged

Wafer

DN250 - DN600

DN50 - DN200

Parts list

Rep. Number Designation

Steel body and disc

Stainless steel body and disc

Steel body /stainless steel disc

1

2

1

1

Body

Disc

EN GP 240 GH / A 216 Gr. WCB

EN GP 240 GH Chrome /

Chrome A 216 Gr. WCB

Retaining ring

EN GP 240 GH / A 216 Gr. WCB

EN GP 240 GH / A 216 Gr. WCB

EN X5CrNiMo 19-11-2 Chrome /

Chrome AISI 316

EN GX5CrNiMo 19-11-2 Chrome /

Chrome A 351 Gr. CF8M

EN GP 240 GH / A 216 Gr. WCB

4

5

6

7

8

9

10

11

12

13

14

15

16

1

1

1

1

1

1

*

4

1

1

1

*

1

*

1

1

Upper stem

Lower stem

Seat

Packing gland

Gland follower

Position indicator

Packing

Bearing

Disc locating shoulder

Bottom end cover

Bottom seal

Pin

Circlips

Set screw

Indication plate

Key

Bolt

EN X20Cr13 / AISI 420

EN X20Cr13 / AISI 420

FS Loaded PTFE

EN X12Cr13 / AISI 410

EN C22E / AISI 1015

EN C22E / AISI 1015

Expanded graphite

Carbon steel + PTFE

EN X2CrNi 19-11 / AISI 304 L

EN C22E / AISI 1015

Expanded graphite

EN X2CrNiMo 17-12-2 / AISI 316 L

Carbon steel

Carbon steel

Stainless steel

EN C35E / AISI 1038

Galvanized steel

EN GX5CrNiMo 19-11-2 / A 351 Gr. CF8M

EN X5CrNiMo 19-11-2 Chrome /

Chrome AISI 316

EN GX5CrNiMo 19-11-2 Chrome /

Chrome A 351 Gr. CF8M

EN X5CrNiMo 19-11-2 / AISI 316

EN GX5CrNiMo 19-11-2 / A 351 Gr. CF8M

EN X5CrNiCuNb 16-4 / A 564 Gr. 630

EN X5CrNiCuNb 16-4 / A 564 Gr. 630

FS Loaded PTFE

EN X2CrNi 19-11 / AISI 304 L

EN X5CrNiMo 19-11-2 / AISI 316

EN X5CrNiMo 19-11-2 / AISI 316

Expanded graphite

Stainless steel + PTFE

EN X2CrNi 19-11 / AISI 304 L

EN X5CrNiMo 19-11-2 / AISI 316

Expanded graphite

EN X2CrNiMo 17-2-2 / AISI 316 L

Stainless steel

Stainless steel

Stainless steel

EN C35E / AISI 1038

Stainless steel

17

18

EN X5CrNiCuNb 16-4 / A 564 Gr. 630

EN X5CrNiCuNb 16-4 / A 564 Gr. 630

FS Loaded PTFE

EN X12Cr13 / AISI 410

EN C22E / AISI 1015

EN C22E / AISI 1015

Expanded graphite

Carbon steel + PTFE

EN X2CrNi 19-11 / AISI 304 L

EN C22E / AISI 1015

Expanded graphite

EN X2CrNiMo 17-2-2 / AISI 316 L

Carbon steel

Carbon steel

Stainless steel

EN C35E / AISI 1038

Galvanized steel

* Number dependent on valve size

Sapag reserves the right to change the contents without notice

page 7

Butterfly valves JHP PP

Pulp & Paper metal seat: DN50 - DN400 (2 - 16)

Detail of the seat

Wafer

Lugged

DN50 - DN200

Recommended

flow direction

DN250 - DN400

Parts list

Rep. Number Designation

Steel body and disc

Stainless steel body and disc

Steel body /stainless steel disc

1

2

1

1

Body

Disc

EN GP 240 GH / A 216 Gr. WCB

EN GP 240 GH Chrome /

Chrome A 216 Gr. WCB

Retaining ring

EN GP 240 GH / A 216 Gr. WCB

EN GP 240 GH / A 216 Gr. WCB

EN X5CrNiMo 19-11-2 Chrome /

Chrome AISI 316

EN GX5CrNiMo 19-11-2 Chrome /

Chrome A 351 Gr. CF8M

EN GP 240 GH / A 216 Gr. WCB

4

5

6

7

8

9

10

11

12

13

14

15

16

1

1

1

1

1

1

*

4

1

1

1

*

1

*

1

1

Upper stem

Lower stem

Seat

Packing gland

Gland follower

Position indicator

Packing

Bearing

Disc locating shoulder

Bottom end cover

Bottom seal

Pin

Circlips

Set screw

Indication plate

Key

Bolt

EN X20Cr13 / AISI 420

EN X20Cr13 / AISI 420

EN X2CrNiMo 17-2-2 / AISI 316 L

EN X12Cr13 / AISI 410

EN C22E / AISI 1015

EN C22E / AISI 1015

Expanded graphite

Carbon steel + PTFE

EN X2CrNi 19-11 / AISI 304 L

EN C22E / AISI 1015

Expanded graphite

EN X2CrNiMo 17-12-2 / AISI 316 L

Carbon steel

Carbon steel

Stainless steel

EN C35E / AISI 1038

Galvanized steel

EN GX5CrNiMo 19-11-2 / A 351 Gr. CF8M

EN X5CrNiMo 19-11-2 Chrome /

Chrome AISI 316

EN GX5CrNiMo 19-11-2 Chrome /

Chrome A 351 Gr. CF8M

EN X5CrNiMo 19-11-2 / AISI 316

EN GX5CrNiMo 19-11-2 / A 351 Gr. CF8M

EN X5CrNiCuNb 16-4 / A 564 Gr. 630

EN X5CrNiCuNb 16-4 / A 564 Gr. 630

EN X2CrNiMo 17-2-2 / AISI 316 L

EN X2CrNi 19-11 / AISI 304 L

EN X5CrNiMo 19-11-2 / AISI 316

EN X5CrNiMo 19-11-2 / AISI 316

Expanded graphite

Stainless steel + PTFE

EN X2CrNi 19-11 / AISI 304 L

EN X5CrNiMo 19-11-2 / AISI 316

Expanded graphite

EN X2CrNiMo 17-2-2 / AISI 316 L

Stainless steel

Stainless steel

Stainless steel

EN C35E / AISI 1038

Stainless steel

17

18

* Number dependent on valve size

Sapag reserves the right to change the contents without notice

page 8

EN X5CrNiCuNb 16-4 / A 564 Gr. 630

EN X5CrNiCuNb 16-4 / A 564 Gr. 630

EN X2CrNiMo 17-2-2 / AISI 316 L

EN X12Cr13 / AISI 410

EN C22E / AISI 1015

EN C22E / AISI 1015

Expanded graphite

Carbon steel + PTFE

EN X2CrNi 19-11 / AISI 304 L

EN C22E / AISI 1015

Expanded graphite

EN X2CrNiMo 17-2-2 / AISI 316 L

Carbon steel

Carbon steel

Stainless steel

EN C35E / AISI 1038

Galvanized steel

Butterfly valves JHP HT

High Temperature metal seat: DN50 - DN400 (2 - 16)

Detail of the seat

Wafer

Recommended

flow direction

Lugged

DN50 - DN200

DN250 - DN400

Parts list

Rep. Number Designation

Steel body and disc

Stainless steel body and disc

Steel body /stainless steel disc

1

2

1

1

Body

Disc

EN GP 240 GH / A 216 Gr. WCB

EN GP 240 GH Chrome /

Chrome A 216 Gr. WCB

Retaining ring

EN GP 240 GH / A 216 Gr. WCB

EN GP 240 GH / A 216 Gr. WCB

EN X5CrNiMo 19-11-2 Chrome /

Chrome AISI 316

EN GX5CrNiMo 19-11-2 Chrome /

Chrome A 351 Gr. CF8M

EN GP 240 GH / A 216 Gr. WCB

4

5

6

7

8

9

10

11

12

13

14

15

16

1

1

1

1

1

1

*

4

1

1

1

*

1

*

1

1

Upper stem

Lower stem

Seat

Packing gland

Gland follower

Position indicator

Packing

Bearing

Disc locating shoulder

Bottom end cover

Bottom seal

Pin

Circlips

Set screw

Indication plate

Key

Bolt

EN X20Cr13 / AISI 420

EN X20Cr13 / AISI 420

EN X2CrNiMo 17-2-2 / AISI 316 L

EN X12Cr13 / AISI 410

EN C22E / AISI 1015

EN C22E / AISI 1015

Expanded graphite

Stainless steel

EN X2CrNi 19-11 / AISI 304 L

EN C22E / AISI 1015

Expanded graphite

EN X2CrNiMo 17-12-2 / AISI 316 L

Carbon steel

Carbon steel

Stainless steel

EN C35E / AISI 1038

Galvanized steel

EN GX5CrNiMo 19-11-2 / A 351 Gr. CF8M

EN X5CrNiMo 19-11-2 Chrome /

Chrome AISI 316

EN GX5CrNiMo 19-11-2 Chrome /

Chrome A 351 Gr. CF8M

EN X5CrNiMo 19-11-2 / AISI 316

EN GX5CrNiMo 19-11-2 / A 351 Gr. CF8M

EN X5CrNiCuNb 16-4 / A 564 Gr. 630

EN X5CrNiCuNb 16-4 / A 564 Gr. 630

EN X2CrNiMo 17-2-2 / AISI 316 L

EN X2CrNi 19-11 / AISI 304 L

EN X5CrNiMo 19-11-2 / AISI 316

EN X5CrNiMo 19-11-2 / AISI 316

Expanded graphite

Stainless steel

EN X2CrNi 19-11 / AISI 304 L

EN X5CrNiMo 19-11-2 / AISI 316

Expanded graphite

EN X2CrNiMo 17-2-2 / AISI 316 L

Stainless steel

Stainless steel

Stainless steel

EN C35E / AISI 1038

Stainless steel

17

18

EN X5CrNiCuNb 16-4 / A 564 Gr. 630

EN X5CrNiCuNb 16-4 / A 564 Gr. 630

EN X2CrNiMo 17-2-2 / AISI 316 L

EN X12Cr13 / AISI 410

EN C22E / AISI 1015

EN C22E / AISI 1015

Expanded graphite

Stainless steel

EN X2CrNi 19-11 / AISI 304 L

EN C22E / AISI 1015

Expanded graphite

EN X2CrNiMo 17-2-2 / AISI 316 L

Carbon steel

Carbon steel

Stainless steel

EN C35E / AISI 1038

Galvanized steel

* Number dependent on valve size

Sapag reserves the right to change the contents without notice

page 9

Butterfly valves JHP

Actuator options

Notched lever LC

Lockable lever LF

Wormgear MK

Wafer

Wormgear MR

Compact Pneumatic Actuator

Large Pneumatic Actuator

Electric Actuator

Gearbox and Electric Actuator

Lugged

Counterweight Actuator

Sapag reserves the right to change the contents without notice

page 10

Butterfly valves JHP

Valves with handle

Notched lever LC

Wafer

Lugged

Notes

Dimensions in mm, weights in kg

Dimensions and weights are given as a

guide.

Number of locking positions: LC4 = 9,

LC12 = 9, LC20 = 7

Dimensions

DN

DN

(mm) (inch)

50

65

80

100

125

150

2

21/2

3

4

5

6

Weights

Lever

LC 4

LC 4

LC 4

LC 12

LC 12

LC 20

D1

D2

Wafer

Lugged

175

191

197

233

245

283

102

116

122

149

160

193

43

46

46

52

56

56

97

117

130

158

188

212

153

173

190

225

261

294

230

230

230

320

320

420

69

69

69

75

75

75

45

45

45

52

52

52

3.6

5

5.4

8.9

10.5

13.5

5.3

7.4

8.2

14.4

17.7

23.5

Lockable lever LF

Wafer

Lugged

Notes

Dimensions in mm, weights in kg

Dimensions and weights are given as a

guide.

Continuous adjustable.

Dimensions

DN

DN

Weights

(mm) (inch)

Lever

D1

D2

Wafer

Lugged

50

65

80

100

125

150

200

LF 4

LF 4

LF 4

LF 12

LF 12

LF 20

LF 20

175

191

197

233

245

283

307

102

116

122

149

160

193

217

43

46

46

52

56

56

60

97

117

130

158

188

212

267

153

173

190

225

261

294

365

230

230

230

320

320

420

420

69

69

69

75

75

75

75

45

45

45

63

63

65

65

4.1

5.5

5.9

9.8

11.5

14.5

24

5.8

7.9

8.7

15.3

18.6

24.5

35.7

2

21/2

3

4

5

6

8

Sapag reserves the right to change the contents without notice

page 11

Butterfly valves JHP

Gear operators

Worm gear MK

Dimensions

DN

Actuator

Nr of hand-

(mm) (inch)

DN

Type

wheel turns

50

65

80

100

125

150

200

250

300

350

400

450

MK

MK

MK

MK

MK

MK

MK

MK

MK

MK

MK

MK

2

21/2

3

4

5

6

8

10

12

14

16

18

1

1

1

1

1

2

2

3

3

3

4

4

6

6

6

6

6

7.5

7.5

12.5

12.5

12.5

20

20

Weight (Kg)

Wafer

Lugged

175

191

197

233

245

283

307

371

399

421

453

522

102

116

122

149

160

193

217

251

302

324

358

392

43

46

46

52

56

56

60

68

78

78

102

114

97

117

130

158

188

212

267

321

372

431

484

534

153

173

190

225

261

294

365

420

476

542

606

662

200

216

223

258

270

318

342

409

437

459

507

576

G

72

72

72

72

72

101

101

118

118

118

160

160

55

55

55

55

55

77

77

79

79

79

130

130

185

185

185

185

185

228

228

228

228

228

285

285

55

55

55

55

55

77

77

79

79

79

130

130

45

45

45

45

45

67

67

80

80

80

122

122

Wafer

Lugged

236

252

258

294

306

364

388

453

481

502

574

643

150

150

150

150

150

300

300

300

300

300

400

400

7.6

9

9.4

12.7

14.5

23

32.4

54

68.1

88

128

175

9.3

11.4

12.2

18.2

21.5

33

44.2

66

91

110

163

236

AB 880 N

Worm gear MR

Notes

Dimensions in mm or inches, weights in kg

Dimensions and weights are given as a

guide.

Actuator selection valid for all JHP valves

except HT series.

Dimensions

DN

DN

(mm) (inch)

50

65

80

100

125

150

200

250

300

350

400

450

500

600

700

800

900

Actuator

Nr of hand-

Type

wheel turns

2"

AB 210

21/2"

AB 210

3"

AB 210

4"

AB 210

5"

AB 210

6"

AB 210

8"

AB 210

10"

AB 550

12"

AB 550

14"

AB 550

16"

AB 880

18"

AB 880

20"

AB 1250

24"

AB 1250

28" AB 1950/SP4

32" AB 1950/SP4

36"

IW6

7.5

7.5

7.5

7.5

7.5

7.5

7.5

8.5

8.5

8.5

9.5

9.5

14

14

52

52

70

D

A

175

191

197

233

245

283

307

371

399

421

453

522

550

634

720

771

878

102

116

122

149

160

193

217

251

302

324

358

392

427

485

547

598

687

43

46

46

52

56

56

60

68

78

78

102

114

127

154

165

190

241

Wafer

Lugged

97

117

130

158

188

212

267

321

372

431

484

534

590

689

799

900

1000

153

173

190

225

261

294

365

420

476

542

606

662

722

837

947

1070

-

Sapag reserves the right to change the contents without notice

Weight (Kg)

E

202

218

224

260

272

310

334

412

440

462

495

564

598

682

775

826

948

G

73

73

73

73

73

73

73

105

105

105

126

126

148

148

260

260

295

63

63

63

63

63

63

63

69

69

69

100

100

110

110

143

143

188

171

171

171

185

185

185

185

255

255

255

301

311

496

496

437

437

410

page 12

66

66

66

66

66

66

66

83

83

83

101

101

110

110

143

143

188

45

45

45

45

45

45

45

71

71

71

86

86

105

105

211

211

242

P

235

251

257

293

305

343

367

458

486

508

543

612

649

733

841

892

1007

V

125

125

125

160

160

160

160

300

300

300

400

500

500

600

400

400

400

Wafer Lugged

7.4

8.8

9.2

12.6

14.2

16.9

26.3

51

66

85

114

162

213

250

317

563

907

9.1

11.2

12

18.1

21.4

26.9

38.1

63

88

107

150

223

269

332

498

873

-

Butterfly valves JHP

Electric actuators

Type of actuator

Quarterturn

Multiturn

OA

AS/BS

ST

ASM

X

X

X

X

X

X

on gearbox

X

X

X

on gearbox

X

X

X

Travel stops

Limit switch for open and close position

Torque switches

Handwheel for manual action

Electric quarter turn actuators

OA type

AS type

BS type

Dimensions

DN

DN

(mm) (inch)

Actuator

50

50

65

65

80

100

125

150

200

250

300

350

400

OA3

OA6

OA3

OA6

OA6

OA8

OA15

AS18

AS50

AS50

AS80

BS100

BS150

2"

2"

21/2"

21/2"

3"

4"

5"

6"

8"

10"

12"

14"

16"

175

175

191

191

197

233

245

283

307

371

399

421

453

102

102

116

116

122

149

160

193

217

251

302

324

358

C

43

43

46

46

46

52

56

56

60

68

78

78

102

Weights

wafer

lugged

97

97

117

117

130

158

188

212

267

321

372

431

484

153

153

173

173

190

225

261

294

351

420

476

542

606

228

228

244

244

250

286

298

383

407

471

530

507

539

125

125

125

125

125

125

125

226

226

226

226

284

284

160

202

160

202

202

202

260

312

340

340

340

455

455

90

90

90

90

90

90

98

167

167

167

167

172

172

65

65

65

65

65

65

65

89

89

89

89

134

134

49

49

49

49

49

49

49

59

59

59

59

96

96

390

390

406

406

412

462

474

460

484

563

606

588

620

60

60

60

60

60

60

60

100

250

250

250

250

250

wafer

8.5

8.8

9.9

10.2

11

16

18

29

40

59

75

100

126

lugged

10.2

10.5

12.3

12.6

13.4

21

25

39

52

71

98

123

161

Gearboxes and electric multiturn actuators

AS 200/400 types

IW + ASM/ST types

Dimensions

DN

DN

(mm) (inch)

450

500

600

700

800

900

D

Actuator

18"

AS 200

20"

AS 200

24"

AS 400

28" IW52R + ASM0

32" IW6R + ASM1

36" IW6R + ASM1

522

550

634

720

771

878

392

427

485

547

598

687

114

127

154

165

190

241

Weights

wafer lugged

534

590

689

799

900

1000

662

722

837

947

1070

462

497

555

785

841

948

218

218

179

231

273

273

673

708

766

996

1052

1159

258

258

280

377

377

377

188

188

148

143

188

188

470

470

497

594

594

594

130 541

130 576

120 642

143 843

188 899

188 1006

R

109

109

154

92

50

50

wafer

lugged

298

298

253

315

357

357

300

300

300

300

400

400

213

256

294

343

612

947

274

312

376

524

922

Notes

Dimensions in mm or inches, weights in kg.

Dimensions and weights are given as a guide.

Actuator selection valid for all JHP valves except for HT series.

Sapag reserves the right to change the contents without notice

page 13

Butterfly valves JHP

Pneumatic actuators

On request:

bracket

On request:

bracket

On request: manual override

On request: manual override

Dimensions double acting pneumatic actuator: 6 bar air supply

DN

(mm)

50

65

80

100

125

150

200

250

300

350

400

450

500

600

D

Actuator

DR

DR

DR

DR

DR

DR

DR

DR

DR

DR

DR

DR

DR

DR

10-2

10-2

20-2

21-4

30-0

40-0

50-0

60-1

60-1

71-0

70-0

70-0

82-0

82-0

A

175

191

197

233

245

283

307

371

399

421

453

522

550

634

B

102

116

122

149

160

193

217

251

302

324

358

392

427

485

C

43

46

46

52

56

56

60

68

78

78

102

114

127

154

Weight

Wafer Lugged

97

117

130

158

188

212

267

321

372

431

484

534

590

689

153

173

190

225

261

294

351

420

476

542

606

662

722

837

33

33

33

33

50

50

70

70

70

110

110

110

110

110

41

41

41

41

55

55

75

75

75

110

110

110

110

110

145

145

145

145

190

190

295

295

295

515

515

515

490

490

86

86

86

86

110

110

148

155

155

248

248

248

248

248

290

290

290

290

340

340

500

500

500

800

800

800

800

800

45

45

98

98

65

135

90

190

190

145

145

145

295

295

98

98

98

98

135

135

190

190

190

295

295

295

295

295

306

322

328

364

400

438

500

571

599

724

756

825

853

937

132

132

132

132

132

132

132

132

132

156

156

156

156

156

180

180

180

180

180

180

320

320

320

400

400

400

600

600

Wafer

Lugged

4.5

5.9

6.4

9.7

13.5

17.4

31.3

52.9

67.1

106.4

129.6

177

230

266

6.2

8.3

9.2

15.2

20.7

27.4

43.1

65

90

128.5

165

238

286

348

Dimensions single acting pneumatic actuator - spring to open: 6 bar air supply

DN

(mm)

Actuator

50

65

80

100

125

150

200

250

300

350

400

SR

SR

SR

SR

SR

SR

SR

SR

SR

SR

SR

175

191

197

233

245

283

307

371

399

421

453

20-2/4

30-0/4

30-0/4

40-0/4

40-0/4

50-0/4

60-1/4

71-0/4

71-0/4

81-0/3

80-0/4

B

102

116

122

149

160

193

217

251

302

324

358

C

43

46

46

52

56

56

60

68

78

78

102

Weight

Wafer Lugged

97

117

130

158

188

212

267

321

372

431

484

153

173

190

225

261

294

351

420

476

542

606

33

50

50

50

50

70

70

110

110

110

110

41

55

55

55

55

75

75

110

110

110

110

145

190

190

190

190

295

295

515

515

490

490

86

110

110

110

110

148

155

248

248

248

248

290

340

340

340

340

500

500

800

800

800

800

145

65

65

195

195

90

275

145

145

520

520

145

195

195

195

195

275

275

520

520

520

520

306

301

352

388

400

476

507

674

702

724

756

132

132

132

132

132

132

132

156

156

156

156

180

180

180

180

180

320

320

400

400

600

600

Wafer

Lugged

5.8

9.3

9.7

15.4

17

24.9

40.4

85.4

99.6

142.4

165.6

7.5

11.7

12.5

20.9

24.2

34.9

52.2

97.5

122.5

164.5

201

Dimensions single acting pneumatic actuator - spring to close: 6 bar air supply

DN

(mm)

Actuator

50

65

80

100

125

150

200

250

300

350

400

SR

SR

SR

SR

SR

SR

SR

SR

SR

SR

SR

175

191

197

233

245

283

307

371

399

421

453

20-2/4

30-0/5

30-0/5

40-0/5

50-0/5

60-1/5

60-1/7

71-0/5

81-0/5

81-0/5

80-0/7

B

102

116

122

149

160

193

217

251

302

324

358

C

43

46

46

52

56

56

60

68

78

78

102

Weight

Wafer Lugged

97

117

130

158

188

212

267

321

372

431

484

153

173

190

225

261

294

351

420

476

542

606

33

50

50

50

70

70

70

110

110

110

110

41

55

55

55

75

75

75

110

110

110

110

145

190

190

190

295

295

295

515

490

490

490

86

110

110

110

148

155

155

248

248

248

248

290

340

340

340

500

500

500

800

800

800

800

145

65

65

195

90

275

275

145

520

520

520

145

195

195

195

275

275

275

520

520

520

520

306

301

352

388

438

483

507

674

702

724

756

132

132

132

132

132

132

132

156

156

156

156

180

180

180

180

320

320

320

400

600

600

600

Notes

Actuator selection valid for all JHP valves except for HT series.

Sapag reserves the right to change the contents without notice

page 14

Wafer

Lugged

5.8

9.3

9.7

15.4

22.2

31

40.4

85.4

122.6

142.4

165.6

7.5

11.7

12.5

20.9

29.4

41

52.2

97.5

145.5

164.5

201

Butterfly valves JHP

Double or single acting pneumatic actuator

Pneumatic actuators: Accessories and Options

External limit switches

Protection to IP 67

Working temperature:

-25C to +70C

300 volts - 6 A

Limit switches or sensors in box

Box in alloyed aluminium or

polycarbonate

Protection to IP 65

Working temperature:

-25C to +80C

Adjustable cams from 0 to 90

Electricity supply all voltages,

AC or DC supply

On request:

Explosion proof switches

E Ex d

On request:

Explosion proof switches E Ex i

Pneumatic Positioners

(standard)

Working temperature:

-15C to +80C

(-40C on request)

Air supply pressure:

1.4 to 6 bar (20 to 50 psi)

Signal: 0.2 to 1 bar

(3 to 50 psi)

Electropneumatic

Positioners (standard)

Protection to IP 54

Working temperature:

-15C to +80C

Input signal: 4-20 mA

Manual acting CM type for

double or single acting pneumatic

actuators

Wafer

Accessories such as solenoid valves,

speed regulators and silencers.

Lugged

ISOBOX

Protection to IP 67

Working temperatures: -25C to +100C

Available with limit switches or sensors

Size of valve

Type

DN50 - DN200 / 2 - 8

DN250 - DN600 / 10 - 24

Isobox 1

Isobox 2

Sapag reserves the right to change the contents without notice

page 15

Butterfly valves JHP

Mounting

Assembly on line

1. Leave sufficient space between the flanges. Be sure that these edges have well aligned,

parallel, and erect sealing faces.

2. Put the seals between flanges and body.

3. The valve is closed. Center the valve by bolting the body locator first.

4. Progressively tighten diametrically opposed bolts by alternating sides until contact has been

made between body, seals and the flange faces. Tighten bolts fully.

5. Control after mounting: operate the valve from fully open position to fully closed position to

make sure that nothing is obstructing the disc.

DN (mm)

50

65

80

100

125

150

200

250

300

350

400

450

500

600

700

800

DN (inch)

21/2

10

12

14

16

18

20

24

28

32

36

D mini

49

59

74

97

122

146

194

243

289

333

381

428

477

574

676

770

860

900

Between flanges and dead end assembly for Wafer type

DN (mm)

50

65

80

100

125

150

200

250

300

350

400

450

500

600

700

800

900

DN (inch)

21/2

10

12

14

16

18

20

24

28

32

36

EN 1092

DIN 2501

BS 4504

ISO 2084

PN 6

PN 10

PN 16

PN 25

PN40

EN 1759

Class 150

Class 300

ANSI B 16.5

Class 150

ANSI B 16.5

Class 300

ANSI B 16.47 A Class 150

ANSI B 16.47 A Class 300

JIS

JIS 10 K

JIS 16 K

JIS 20 K

MSS SP 44

Class 150

MSS SP 44

Class 300

See ANSI B 16.5

See ANSI B 16.5

Between flanges and dead end assembly for Lug type

DN (mm)

50

65

80

100

125

150

200

250

300

350

400

450

500

600

700

800

900

DN (inch)

21/2

10

12

14

16

18

20

24

28

32

36

EN 1092

DIN 2501

BS 4504

ISO 2084

PN 6

PN 10

PN 16

PN 25

PN40

EN 1759

Class 150

Class 300

ANSI B 16.5

Class 150

ANSI B 16.5

Class 300

ANSI B 16.47 A Class 150

ANSI B 16.47 A Class 300

JIS

JIS 10 K

JIS 16 K

JIS 20 K

MSS SP 44

Class 150

MSS SP 44

Class 300

V

V

V

See ANSI B 16.5

See ANSI B 16.5

V

V

Notes

: Possible for all versions

: Please contact factory

V

These data are valid for raised face flanges only. For flat face flanges, please consult factory.

Please, specify requested valve drilling when ordering.

Sapag reserves the right to change the contents without notice

page 16

Butterfly valves JHP

Maintenance: packing replacement

Warning:

In all cases, the line must be with the pressure relieved.

Seat replacement

1 Remove valve from line (closed disc).

2 Remove retaining ring (item 3).

3 Extract used seat (item 6).

4 Gently clean:

- disc circle (item 2);

- seat compartment.

5 Put new seat in position (still closed disc).

6 Re-screw retaining ring.

7 Reset valve between flanges and wait 15 minutes (except PP) before any operation.

8 Valve is now ready to re-install.

Packing replacement

The operation can be done directly on the valve:

- without removing it from line

1 Unscrew gland follower (item 8) and lift packing gland (item 7).

2 Extract packing rings (item 10) with tool.

3 Clean upper stem (item 4) and packing space.

4 Refill packing rings.

5 Reset gland follower and packing gland.

6 Adjust packing compression to avoid leakage.

Parts list

Rep.

Number

Designation

Body

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

1

1

1

1

1

1

1

1

*

4

1

1

1

*

1

Disc

Retaining ring

Upper stem

Lower stem

Seat

Packing gland

Gland follower

Position indicator

Packing

Bearing

Disc locating shoulder

Bottom end cover

Bottom seal

Pin

Circlips

Bolt

* dependent on valve size

Sapag reserves the right to change the contents without notice

page 17

Butterfly valves JHP

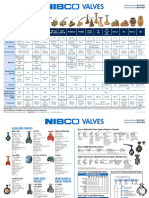

Ordering code

Ordering code

A code with the following basis information is marked on the identification plate:

- four characters defining type of body, material of body, disc and seat materials

- one character or more, defining the top works (with option(s)) and type of actuator (if applicable).

For the order, completing the above data with the following information:

- the nominal diameter (DN)

- the flange

- the working pressure

- and if applicable, the valve options

Type

37 Wafer

77 Lugged

Body and disc

0

Steel

1

Stainless steel

3

Steel body and stainless steel disc

Seat

0

Reinforced RTFE

1

Fire safe FS

2

Metal PP

3

Metal HT

Top works

0

Bare shaft

1

Handle kit, type LC

3

Gear box, type MG

4

Gear box, type GS

5

Gear box, type MR

7

Gear box, type MK

8

Handle kit, type LF

DN (mm)

DN50 (2) - DN900 (36)

Flange: Type

(For class flanges, precise the standard).

See page 16.

PS

Working pressure (CWP)

Options (Top works)

B

Padlock

T

Switches

M

Flange actuator (MG, GS, MR)

S

ISOBOX (switches)

W

Chainwheel

Valve options

R

Shaft extension

Approvals & Certificates

FS

Fire safe

M

Naval Approved

T

TPED Approved

X

ATEX Approved

Actuators

A

Pneumatic actuator

C

Electric actuator

H

Hydraulic actuator

P

Counterweight actuator

Options

Consult us

Examples

1. JHP butterfly valve with handle type LF, DN150, for mounting between flanges defined by the EN1092 in PN16

JHP 37108 - 150 PN16 PS16:

150

PN16 PS16

Working pressure (16 bar max)

Flange (EN1092 PN16)

DN (150)

Top works (lockable lever LF)

Type (Wafer)

Stainless steel (body and disc)

Seat (reinforced RTFE)

2. Same valve but with metal seat PP and pneumatic actuator, working pressure of 10 bar

JHP 37120A - 150 PN16 PS10:

A - 150 PN16 PS10

Seat (metal, PP)

Top works (bare shaft)

Working pressure (10 bar max)

Actuator (pneumatic actuator)

3. Same valve but with gear box, type MR (option: flange actuator), electric actuator, for mounting between flanges defined by EN1759,

Class 150, TPED approved

JHP 37105MC - 150 EN1759 Class 150 PS16T:

C - 150

Top works (gear box, type MR)

Top works option (flange actuator)

Actuator (Electric actuator)

Sapag reserves the right to change the contents without notice

EN1759 Class150 PS16

Flange (EN 1759 Class 150)

TPED approved

page 18

Вам также может понравиться

- Schmidt Armaturen FlowPak Class 150, 1/2” - 4” Technical DocumentДокумент12 страницSchmidt Armaturen FlowPak Class 150, 1/2” - 4” Technical DocumentMisael Castillo CamachoОценок пока нет

- Re 10223Документ26 страницRe 10223medi38Оценок пока нет

- Product Specifications for FOXTOP Control Valve System PSS 4-24A1 FДокумент0 страницProduct Specifications for FOXTOP Control Valve System PSS 4-24A1 Fcico_ctОценок пока нет

- Crane - Series.rs Center LineДокумент23 страницыCrane - Series.rs Center LinenedwestОценок пока нет

- SAPAG Butterfly ValvesДокумент22 страницыSAPAG Butterfly ValvespawelzakОценок пока нет

- Manometre Fise Tehnice 2000.i PDFДокумент2 страницыManometre Fise Tehnice 2000.i PDFGaina IOnutОценок пока нет

- Mark 50 Series Self-Operated Back Pressure RegulatorsДокумент16 страницMark 50 Series Self-Operated Back Pressure RegulatorsDarren JohnstonОценок пока нет

- Control Choke Valve 9000Документ8 страницControl Choke Valve 9000sabi_shi100% (2)

- TYPE 5611/5611Q: Elastomer Bellows SealsДокумент8 страницTYPE 5611/5611Q: Elastomer Bellows SealsLuvys Garcia MartinezОценок пока нет

- Ratio Pressure Reducing ValvesДокумент4 страницыRatio Pressure Reducing Valveskanem1Оценок пока нет

- SPO Webversion HighДокумент6 страницSPO Webversion HighchadОценок пока нет

- Re10545 2011-12Документ12 страницRe10545 2011-12katakliztmaОценок пока нет

- HYD. PumpДокумент40 страницHYD. Pumprohitbhat2345Оценок пока нет

- Series 825Y Specification SheetДокумент2 страницыSeries 825Y Specification SheetFEBCOОценок пока нет

- Valvula Mariposa Danais 150Документ15 страницValvula Mariposa Danais 150Oscar CherroОценок пока нет

- Pumps+Valves4 MudGateValves 081129Документ6 страницPumps+Valves4 MudGateValves 081129isamelgqОценок пока нет

- Axially Splitcase Pumps - HS & HST SeriesДокумент12 страницAxially Splitcase Pumps - HS & HST SeriesSuhas Natu100% (1)

- 8 Bomba Tornillo Alliweiler AebДокумент14 страниц8 Bomba Tornillo Alliweiler AebHugo Miño Carrasco100% (1)

- Local Solutions For Individual Customers Worldwide: Accumulators & AccessoriesДокумент20 страницLocal Solutions For Individual Customers Worldwide: Accumulators & Accessoriesamjed_de_enimОценок пока нет

- Catalogo - FestoДокумент66 страницCatalogo - FestoconsultachОценок пока нет

- Rotex Pneumatic Cylinder CatalogueДокумент4 страницыRotex Pneumatic Cylinder Cataloguekumar ambujОценок пока нет

- Neojv 0040 enДокумент0 страницNeojv 0040 enLuis GuevaraОценок пока нет

- Fisherr 8510 and 8510B Eccentric Disc Control Valves (EMA) : FeaturesДокумент20 страницFisherr 8510 and 8510B Eccentric Disc Control Valves (EMA) : FeaturesFabián HerreraОценок пока нет

- Visual Flow Indicator Guide from Flow-MonДокумент12 страницVisual Flow Indicator Guide from Flow-Mondhanu_aquaОценок пока нет

- Valves 2/2 E290: Pressure Operated Bronze or Stainless Steel Body Threaded Ports, 3/8 To 2 1/2Документ4 страницыValves 2/2 E290: Pressure Operated Bronze or Stainless Steel Body Threaded Ports, 3/8 To 2 1/2Velpuri RameshBabuОценок пока нет

- Three Way Valve Technical OverviewДокумент8 страницThree Way Valve Technical OverviewWalter JosephОценок пока нет

- Rotametro ABBДокумент10 страницRotametro ABBjoticamario123Оценок пока нет

- SWGДокумент25 страницSWGBilly ZununОценок пока нет

- Important DataДокумент8 страницImportant DataAbdelrahman AliОценок пока нет

- AVT Ball & Butterfly Brochure 05 Latest 12 PageДокумент12 страницAVT Ball & Butterfly Brochure 05 Latest 12 PageshalbyОценок пока нет

- (2012) Complete IELTS Bands 5-6.5 Student's BookДокумент3 страницы(2012) Complete IELTS Bands 5-6.5 Student's BookAhmed Hamdy0% (1)

- VAG Absperrklappen02-05Документ27 страницVAG Absperrklappen02-05Muhamad FajriОценок пока нет

- Donaldson Visokotlačni FilteriДокумент86 страницDonaldson Visokotlačni FilteriViktor -stОценок пока нет

- Regulador 1253 B - American M.Документ8 страницRegulador 1253 B - American M.Jheysson FloresОценок пока нет

- Dynex PF 1300 SpecsДокумент7 страницDynex PF 1300 SpecsAdeel HassanОценок пока нет

- Api Plan 11Документ6 страницApi Plan 11johnsaballaОценок пока нет

- MPVN BrochureДокумент32 страницыMPVN Brochurefernando_naciamentОценок пока нет

- KITZ DJ Series Ductile Iron Butterfly Valves E-231-06 PDFДокумент16 страницKITZ DJ Series Ductile Iron Butterfly Valves E-231-06 PDFYulita Ika PawestriОценок пока нет

- Dynaxe-En Double EccДокумент15 страницDynaxe-En Double Eccrajaj19800% (1)

- Goulds GIS Pump Data SheetДокумент6 страницGoulds GIS Pump Data Sheetjimmy0802Оценок пока нет

- Milroyal CДокумент12 страницMilroyal Croberto_divitaОценок пока нет

- Angle Seat Valve: High Cycle-Life On/Off Control ValveДокумент6 страницAngle Seat Valve: High Cycle-Life On/Off Control ValveIbhar Santos MumentheyОценок пока нет

- b3311 722-2Документ7 страницb3311 722-2Arnaldo BenitezОценок пока нет

- LMI Series G Metering Pump Datasheet PDFДокумент6 страницLMI Series G Metering Pump Datasheet PDFVkita MolinaОценок пока нет

- Butterfly Valve TorqueДокумент8 страницButterfly Valve TorqueShyam KrishnanОценок пока нет

- Series 826YD Specification SheetДокумент2 страницыSeries 826YD Specification SheetFEBCOОценок пока нет

- Oventrop Valve Technical SpecДокумент15 страницOventrop Valve Technical SpecblindjaxxОценок пока нет

- Catalogo ASCOДокумент4 страницыCatalogo ASCOIkaro MatosОценок пока нет

- Reg RedQ Specialy Regulators PDFДокумент20 страницReg RedQ Specialy Regulators PDFDavid SaldarriagaОценок пока нет

- CP Range: Redefining Flow ControlДокумент8 страницCP Range: Redefining Flow ControlSmootherОценок пока нет

- OpGL Globe ValveДокумент20 страницOpGL Globe Valvemanmohansingh1999Оценок пока нет

- Desalination pump design bookletДокумент14 страницDesalination pump design bookletBenicio Joaquín Ferrero BrebesОценок пока нет

- WaterWolf Data Sheet PDFДокумент2 страницыWaterWolf Data Sheet PDFcarlosfariasfakeОценок пока нет

- OZKAN Butterfly ValvesДокумент11 страницOZKAN Butterfly ValvesAhmed AbdelwaneesОценок пока нет

- A Guide to Vintage Audio Equipment for the Hobbyist and AudiophileОт EverandA Guide to Vintage Audio Equipment for the Hobbyist and AudiophileОценок пока нет

- Culture and PeopleДокумент20 страницCulture and Peopleanwar01Оценок пока нет

- Previous Coursework Example (Comments) PoorДокумент28 страницPrevious Coursework Example (Comments) Pooranwar01Оценок пока нет

- Data Sheet Needle Valves Date 04/2013 1 of 18: (Specifications Are Subject To Change Without Notice)Документ4 страницыData Sheet Needle Valves Date 04/2013 1 of 18: (Specifications Are Subject To Change Without Notice)anwar01Оценок пока нет

- Engineering Standards Manual - Welding Standards Manual - Volume 3 Welding Procedure SpecificationsДокумент3 страницыEngineering Standards Manual - Welding Standards Manual - Volume 3 Welding Procedure SpecificationsjacquesmayolОценок пока нет

- TocДокумент3 страницыTocanwar01Оценок пока нет

- Technical Specifications BAMULДокумент133 страницыTechnical Specifications BAMULjaya100% (1)

- SGLPG Technical Standard One Storage of LPG in Bulk (HSE-03-10)Документ39 страницSGLPG Technical Standard One Storage of LPG in Bulk (HSE-03-10)anwar01Оценок пока нет

- OISD Standard 244 DraftДокумент94 страницыOISD Standard 244 DraftSuresh GanesanОценок пока нет

- ENRAF Tank Gauging 4416650 - Rev4Документ26 страницENRAF Tank Gauging 4416650 - Rev4Joffre BourgeoisОценок пока нет

- Sprinkler AppGuide WFAG557Документ15 страницSprinkler AppGuide WFAG557anwar01Оценок пока нет

- 1 Guide For WPS PQR WPQR PDFДокумент6 страниц1 Guide For WPS PQR WPQR PDFmuhammadazhar100% (1)

- 15-Pipe Heat Tracing Application GuideДокумент6 страниц15-Pipe Heat Tracing Application Guideanwar01Оценок пока нет

- Pipeline Welding Procedure SpecificationДокумент59 страницPipeline Welding Procedure Specificationanwar01100% (1)

- Bill of Quantities: (Ref. 05-Boq-Rev1)Документ1 страницаBill of Quantities: (Ref. 05-Boq-Rev1)anwar01Оценок пока нет

- Facility Oil Handling and Design Standards RuleДокумент118 страницFacility Oil Handling and Design Standards RuleEko W Perkasa100% (1)

- Design of Pressure Vessel Using Asme Code, Section Viii, Division 1Документ7 страницDesign of Pressure Vessel Using Asme Code, Section Viii, Division 1bbmoksh100% (2)

- 04 Tender Volume IIIДокумент33 страницы04 Tender Volume IIIanwar01Оценок пока нет

- Basic Calculations Piping System Design PDFДокумент14 страницBasic Calculations Piping System Design PDFjeff_shawОценок пока нет

- Lgs GuideДокумент130 страницLgs GuidewujrhkjОценок пока нет

- Tender Documentation RFT Template PDFДокумент37 страницTender Documentation RFT Template PDFHein Zin HanОценок пока нет

- Section 6 - Bill of Quantities ("BQ")Документ104 страницыSection 6 - Bill of Quantities ("BQ")kresimir.mikoc9765Оценок пока нет

- Crane Engineering Principles of Fluid MixingДокумент20 страницCrane Engineering Principles of Fluid MixingSuphi YükselОценок пока нет

- Asme SectionsДокумент56 страницAsme SectionsalperbogaОценок пока нет

- 3 Blend Tank - Chemical Process ControlДокумент22 страницы3 Blend Tank - Chemical Process ControlAudrey Patrick KallaОценок пока нет

- Chemical Feed Positive Displacement Pumps Berschauer 060712Документ28 страницChemical Feed Positive Displacement Pumps Berschauer 060712anwar01Оценок пока нет

- 500 SP PIP 018 Rev C (Check Valve)Документ13 страниц500 SP PIP 018 Rev C (Check Valve)anwar01Оценок пока нет

- Basic Calculations Piping System Design PDFДокумент14 страницBasic Calculations Piping System Design PDFjeff_shawОценок пока нет

- CERN Clean Gas Pump SpecificationДокумент6 страницCERN Clean Gas Pump Specificationanwar01Оценок пока нет

- Inflammable Liquids and Substances Regulations 1953Документ41 страницаInflammable Liquids and Substances Regulations 1953anwar01Оценок пока нет

- Butterfly Valve Installation Guide PDFДокумент3 страницыButterfly Valve Installation Guide PDFAnonymous v5uipHОценок пока нет

- High Performance SeriesДокумент8 страницHigh Performance SeriesRonCarОценок пока нет

- Butterfly Valve T-Smart 7 GEAДокумент2 страницыButterfly Valve T-Smart 7 GEACamilaОценок пока нет

- API 609 StandarДокумент1 страницаAPI 609 StandarJavier Barrera0% (2)

- Final Series 59 - 2020 - v8 - 22-4-2021Документ6 страницFinal Series 59 - 2020 - v8 - 22-4-2021Prathamesh Pradeep MashilkarОценок пока нет

- Control Valve HandbookДокумент11 страницControl Valve Handbookshare careОценок пока нет

- Please Read These Instructions Carefully: GRW/GRL Installation & Operation ManualДокумент8 страницPlease Read These Instructions Carefully: GRW/GRL Installation & Operation ManualCn RomaОценок пока нет

- ENGINEERING - DESIGN - GUIDELINES - Control - Valve - Sizing - and - Selection by KLM PDFДокумент28 страницENGINEERING - DESIGN - GUIDELINES - Control - Valve - Sizing - and - Selection by KLM PDFSyed Waqas Haider50% (2)

- Severn Cryo Butterfly Valves V1.1Документ5 страницSevern Cryo Butterfly Valves V1.1Thắng Trần QuangОценок пока нет

- ARITA - Katalog-Produk-WaterworkДокумент24 страницыARITA - Katalog-Produk-WaterworkIqrok Himawan KusumaОценок пока нет

- Wheatley Butterfly ValveДокумент6 страницWheatley Butterfly Valvejose2525Оценок пока нет

- Fisher Control Valve Selectiion GuideДокумент16 страницFisher Control Valve Selectiion GuideVsr SudhirОценок пока нет

- BfviomДокумент4 страницыBfviomAHMEDMALAHYОценок пока нет

- Guth Mixproof Butterfly Valves: The Reliable ProgramДокумент6 страницGuth Mixproof Butterfly Valves: The Reliable ProgramВалентин КовальчукОценок пока нет

- BV242Документ1 страницаBV242FAIYAZ AHMEDОценок пока нет

- Tyco Grinnell Resilient Seat ButterflyДокумент8 страницTyco Grinnell Resilient Seat ButterflySergio Gana GonzalezОценок пока нет

- RMT DP Flow 3-Troubleshooting - Annubar - 485Документ13 страницRMT DP Flow 3-Troubleshooting - Annubar - 485Angel AvilaОценок пока нет

- Double Eccentric Butterfly Valve Data SheetДокумент15 страницDouble Eccentric Butterfly Valve Data SheetRaied AyeshОценок пока нет

- BCV Fireking VikingsДокумент2 страницыBCV Fireking VikingsPepeng GantengОценок пока нет

- Materials System SpecificationДокумент11 страницMaterials System Specificationliuyx866Оценок пока нет

- Lecture 7: Piping Drafting & Drawing: Prepared By: Nor Helya Iman Bt. Kamaludin Helya@unimap - Edu.myДокумент31 страницаLecture 7: Piping Drafting & Drawing: Prepared By: Nor Helya Iman Bt. Kamaludin Helya@unimap - Edu.myOsvaldo Junges BomfimОценок пока нет

- Types of Valve in FPSДокумент3 страницыTypes of Valve in FPSmyra.ugseОценок пока нет

- Valves - App Guide PDFДокумент40 страницValves - App Guide PDFarnoldmoyaОценок пока нет

- ACRISДокумент12 страницACRISGerard Fanner Jr.Оценок пока нет

- Premier Valves Product SelectorДокумент12 страницPremier Valves Product Selectorneelkant sharmaОценок пока нет