Академический Документы

Профессиональный Документы

Культура Документы

Fichier 21

Загружено:

Shriram AvasarkarОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Fichier 21

Загружено:

Shriram AvasarkarАвторское право:

Доступные форматы

Column Internals

High-Quality Service of Design, Manufacture and Installation

Mass Transfer & Reactor Internals

Company

Company

About Euroslot Kdss

Beyond technology - creating value

The Euroslot Kdss group was formed from the merger of two

companies in order to provide a unique breadth and depth of

expertise across a range of industry sectors from petrochemicals

and refineries to water treatment, filtration, food processing and

the paper industry.

The new group has the financial muscle, the international reach

and depth of expertise to be that supplier. We are also unique in

the breadth of range of products and our very comprehensive

installation and site services. Through its Mass Transfer & Reactor

Internals Division, Euroslot Kdss will, in fact, be the only company

to design, manufacture and site install the full range of reactor

and column internals. For many clients that is an unbeatable

combination.

The synergy between the merged companies is much more

than industry focus, product set or customer base. We share the

same business ethics, the same approach to problem solving

and working in partnership with clients. Clients really value our

responsiveness and the way we become a seamless part of their

team, rather than the traditional supplier/client relationship.

Add to that our network of more than 25 sales agents worldwide,

as well as manufacturing facilities in Europe, Middle East, China,

India and South Africa. Euroslot Kdss is in a unique position to

provide end-to-end services wherever they are required.

All over the world, refineries, petrochemical, chemical and gas companies trust Euroslot Kdss expertise to deliver

mass transfer solutions, safely, on time, on budget.

We specialize in process simulation, design, manufacture, installation and plant reinstatement. With a depth of

expertise in distillation plant, we always deploy our own in-house professionals.

Clients value more than just our technical skills and site-based installation expertise. They value our business

agility, our responsiveness and our willingness to own the problem.

Sharing our expertise

Euroslot Kdss has earned a reputation for leadership in our field, bringing quality, safety and innovation across

the sector. Thats why we are licensed by major companies to design, manufacture and install both standard and

specialized mass transfer equipments.

So, if you are looking to maximize capacity of a column or to de-bottleneck a complete train, our process

engineering team can help you with your project definition.

And in the event of unplanned downtime, you can trust us to diagnose, carry out stress and process engineering

designs, manufacture and re-install. A quality solution will be implemented in record time.

Let us share our hugeness of expertise

Our clients recognize the benefits of working with a partner who has a proven scope and depth of expertise

across a whole choice of process applications.

Euroslot Kdss brings that richness of experience to design, manufacture, installation and support across:

Crude Distillation Units

Demethanisers

Depropanisers

De-Isobutanisers

Methanol Distillation

Benfield Units

Amine Absorbers

Vacuum Distillation

FCCU Main Fractionators

FCCU Primary Absorbers

Condensate Stabilizers

Sour Water Strippers

Nitric Acid Absorbers

Chlorine & HCl Scrubbing

SO2 & H2S Scrubbing

Liquid/Liquid Amine Contactors

Condensate Stabilizers

De-Ethanisers

Debutanizers

Ethanol Distillation

Vetrocoke Units

Crude Fractionators

Amine Regenerators

Vacuum Lube Units

FCCU Strippers

FCCU Secondary Absorbers

Glycol Contactors

Direct Contact Coolers

Sulphuric Acid Absorbers

NOX Scrubbing

De-aerating Towers

Ammonia unit

All covered by our strict quality control methodology.

Mass Transfer & Reactor Internals

Mass Transfer & Reactor Internals

All starts with process and engineering design

We manufacture tower internals with quality

engineered in

Whether its a completely new process, a complicated upgrade or just a check on performance of your existing

unit, we understand that reliable front-end process design gives you the confidence to select the optimum process

equipment for your application. Euroslot Kdss can design, manufacture and install the tower distillation trays for

you. Our offer includes as well replacement of nearly all kind of conventional trays no matter their dimensions.

Simulation

Globally recognized process simulation packages are used to perform rigorous mass and energy balances for

chemical applications and separation and reactive distillation for oil/gas applications.

What a better way to ensure the highest quality components than to design and manufacture whole ranges in

house. From our own modern manufacturing facilities we develop and produce ESP (Enhanced Separation

Performance) internals with the highest quality standards.

ESP (Enhanced Separation Performance) is the brand name of Euroslot Kdss equipment with advanced

features designed in. All is developed from our own practice, hands on industry expertise.

Hydraulic and Mechanical

Hydraulic and mechanical design is built around our own software, proven over hundreds of installations to

accurately predict both hydraulic capability and mechanical strength/integrity for any chosen application.

Mass Transfer & Reactor Internals

Mass Transfer & Reactor Internals

Distillation Trays

Distillation trays

Introduction .............................................................................................................................................

Mobile Valve Tray ...................................................................................................................................

Fixed Valve Tray .....................................................................................................................................

Other Distillation Trays ...........................................................................................................................

Page 7

Page 8

Page 9

Page 10

High Performance Random Packing

ESP Metal Packing ................................................................................................................................ Page 12

ESP Plastic Packing, Support, Bed Limiters ........................................................................................... Page 13

High Performance Structured Packing

ESP Structured Packing, Support ......................................................................................................... Page 14

Distributors, Feed Devices and Collector Trays

Introduction ............................................................................................................................................ Page 16

ESP Brand Liquid Distributors ................................................................................................................ Page 17

ESP Brand Liquid Feed Devices and Collector Trays .............................................................................. Page 19

Liquid / Gas and Liquid / Liquid Separator Internals

The two main classes of column internals used today are trays and

packing. Distillation Trays reveal many advantages, for example:

Easy maintenance and cleaning possibility, good fouling

resistance

Can carry wide range of liquid flows by changing number of

tray sections or passes, weir length and type of tray

Easy distribution

Very good turndown and flexibility

Over pressure good handling.

Euroslot Kdss can design and supply their own ESP valve trays, and also other conventional trays, such as bubble

cap trays, sieve trays, etc.

Trays allow intimate contact between vapor and liquid phases. The Principle of a distillation process is defined by

the following steps:

Vapor and liquid mix to form froth

Mass transfer occurs within the froth

The froth overflows across a weir

The vapor is released and moves to the upper tray

The bulk liquid flows down the downcomer to the next tray

The steps repeat on the next tray

ESP Mesh Mist Eliminators .................................................................................................................... Page 20

ESP Vane Mist Eliminators, Plate Pack Coalescers ................................................................................ Page 21

V n+1

Euroslot Kdss Quality Insurance System .......................................................................................... Page 22

Site Service .......................................................................................................................................... Page 23

Contact Euroslot Kdss ........................................................................................................................ Page 24

V n+1

Vn

Ln

V n-1 L n

n+1

Vn

n

V n-1

n+1

n

Depending on feed rates and column diameter, the number of passes can vary from 1 to 4.

(a)

(b)

(c)

Figure 1. Flow passes on trays: (a) Single-pass (b) Two-pass (c) Four-pass

Mass Transfer & Reactor Internals

Mass Transfer & Reactor Internals

Mobile Valve Tray

Fixed Valve Tray

The Mobile Valve Tray is a flat perforated plate, with each perforation

equipped with a movable disk. At low vapor rates, the disk may settle

intermittently over the perforation and covers it to avoid liquid weeping.

As the vapor rate is increased, the disk rises vertically. The height of

restrictive valve legs or a caging structure determines the upper limit

of open area.

The fixed valve tray is a low cost stationary assembly which imitates the

shape of a valve. The fixed valves are directly extruded from tray deck.

The absence of moving parts eliminates wear and sticking, but at the

expense of lower turndown than other valve trays. However, the fixed

valve tray can present higher turndown ratio and improved capacity

than sieve tray.

Standard float valves are the pillar of valve tray configurations available

today. They offer high turndown flexibility (5:1) and a choice of valve

thicknesses to accommodate most requirements.

ESP Fixed Valves

ESP Float Valves

ESP mobile valves can be round or rectangular and the different leg heights are available

according to pressure and gas flow rates. Unlike the conventional float valve, our ESP Float Valve

incorporates unique features that result in a very robust design to reduce valve loss, a built-in

anti-rotation mechanism, easy in-situ replacement, fixed orientation for maximum turndown ratio.

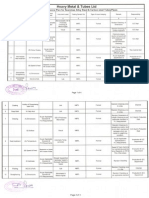

The table below summarizes the various types of ESP float valves that can be designed and

supplied by Euroslot kdss.

ESP-DV (ESP-MDV)

ESP-RV

ESP-BV/CV

Standard size for DV

and high capacity

design for Mini DV

Anti-rotation design

Very high turndown

Rectangular form,

parallel to liquid flow

No valve spinning,

resistant to popping

out

Similar capacity and

efficiency to round

valve

Conventional round

valve with three legs

Supplied for

replacement or on

request

Option: venture

orifice for reduced

pressure drop

ESP-SV

Round valve with

four snap-in legs

Available in most

metal alloys

High turndown

ESP fixed valves, designed by Euroslot Kdss, are generally round, but could be other shapes like

rectangular upon request of clients. Leg heights could also be customized. Our ESP fixed valve

trays provide low liquid entrainment due to lateral vapor orientation compared to sieve trays. Below

in the table ESP fixed valves are presented for meeting your project requirement.

ESP mini fixed valve offers a low cost option, having a wider operating range than sieve trays. It is

an intermediate solution between sieve and mobile valves. They offer a higher capacity than sieve

trays by 10 ~15% and a slightly higher performance and flexibility compared to these last ones.

ESP-FV

ESP-MFV

ESP-FTV

ESP-MFTV

Round shape

Standard size design

with hole diameters of

about 40mm

Very high fouling

resistance

Round shape

Mini size design with

hole diameter of

about 20 mm

Higher capacity

compared to standard

size design

High fouling

resistance

Rectangular shape,

parallel to liquid flow

Option: Tapered shape

in valve plate for

optimization of flow

orientation

High fouling

resistance

Small rectangular

fixed valve

Option: Tapered shape

in valve plate for

optimization of flow

orientation

High performance

Mass Transfer & Reactor Internals

Mass Transfer & Reactor Internals

Other Distillation Trays

Baffle Trays

Euroslot Kdss is also capable of designing and supplying conventional trays besides ESP valve trays, such as,

cage valve tray, sieve tray, bubble cap tray, dual flow tray, and baffle tray, etc.

These plates achieve high fouling in spite of their low effectiveness. They have large open areas approaching

50%, however an ESP high performance tray normally has an open area of less than 15%. Baffle trays are

employed in applications requiring high capacity and low pressure drop. Contact between vapor and liquid is

carried out when vapor passes through a curtain of liquid falling between trays or through liquid streams crossing

the tray perforations. Three major types of baffle trays are:

Sieve Trays

This perforated flat plate design probably provides the majority of

installed tray types used in the process industry and are widely accepted

due to their excellent operating characteristics, low cost investment

and low maintenance requirements. This is the simplest design among

the various tray types because there are no mechanical moving parts.

Sieve trays are resistant to heavy fouling services and offer high

capacities. However, their performances are ranked from low to

moderate and the flexibility is very low.

Dual Flow Trays

Dual flow trays dont have weirs

or downcomers thus vapor rate

maintains the plate liquid level.

Hole size will be defined for

optimizing the performance.

However, smaller holes can be

plugged up more easily.

Euroslot Kdss can fabricate

specific dual flow trays called

"Ripple Tray" licensed by Stone & Webster.

These wave shape dual flow trays reduce fouling without disturbing the vapor/liquid distribution,

and they are fabricated from perforated sheet with large surface area for vapor and liquid traffic.

Experience has demonstrated that smaller holes achieve higher tray capacities at the same

open area. This kind of trays has lower performances and flexibilities than conventional trays with

downcomers. Nevertheless, these ripple trays have greater capacities and are high resistant to

corrosion and fouling.

Bubble Cap Trays

Shed Decks

Shed decks are essentially angle iron beams of various sizes from

50mm to 250mm that are placed in rows across the column. They

are typically located at 610mm tray spacing. They may be set in

overlapping rows or rotated 90 degrees from tray to tray.

Side to side trays

The Side-to-side trays allow the liquid to splash

from side to side. The decks can be sloped. Fouling

resistance is high.

Disk and donut trays

Disk and donut trays are slightly sloped trays that allow

the liquid to splash from inner circle ring to outer circle

ring. They have high fouling resistance.

Cartridge Trays

This type of tray configuration is commonly used for small diameter columns, less than 900 mm.

Installation and assembly of standard trays on site inside a column is not practical. Thus trays are

pre-assembled into manageable cartridge packages. Then each cartridge package can be slide

down by the open vessel flange.

It is a well-tested device for use in many applications requiring high operating flexibility. It has

been widely used since the 50s, but less and less used due to a much higher cost than sieve or

valve trays.

Construction can be made suitable for leak-tight performance or for standard assembly methods,

using a wide range of materials and designs. This type of devices proposes a very high flexibility

(10:1). Bubble caps are available in a range of diameter from 30 to 200 mm.

10

11

Mass Transfer & Reactor Internals

Mass Transfer & Reactor Internals

High Performance Random Packing

ESP Plastic Rings

For more than a century, random packing has been successfully

employed in distillation, absorption, stripping, heat transfer and

scrubbing columns - an inexpensive means of increasing capacity and

efficiency. Random Packing is recommended when pressure drop and

residence time have no significant influence on column operation,

such as in gas washing towers.

Euroslot Kdsss ESP random packing will match your budget and your

performance needs. ESP Random Packing is an inexpensive boost to

capacity and productivity. Regular availability of Euroslot Kdss random

packing is a key benefit in unplanned downtime.

In addition to our industry-leading ESP brand of products and components, we also manufacture a comprehensive

range of industry-standard packing, built upon a history of well documented operational performance. Our random

packing includes: Pall Rings (Thermoplastics, Metals), Raschig Rings (Ceramics, Metals) and Saddles (Ceramics,

Thermoplastics).

reducing drag, maximizing mass transfer

Our ESP range also includes high performance thermoplastic random

packing that retains the basic slotted ring heritage, with an open skeletal

structure.

You could choose an enhanced version, designed to maximize

available contact surface and mechanical strength. Its conical shape is

proven to reduce drag, resulting in lower pressure drop while increasing

accessibility to the inner surface. All designed to achieve higher mass

transfer efficiency.

Random Packing Support

Packing supports perform the following functions:

ESP Metal Rings

Physically support the packed bed

Incorporate sufficient open area to allow unrestricted flow

of liquid and vapor

Prevent downward migration of random packing pieces

third generation high performance, high capacity

random packing

The ESP Metal Packing is our range of high performance column packing. The basic shape bears

resemblance to other high performance packing elements but with particular enhancements

to improve randomness, liquid spreading and mechanical strength. The result is a robust and

cost effective 3rd generation high capacity random packing solution. ESP Metal Packing can be

supplied in most metallic materials, such as carbon steel, stainless steel, aluminum, titanium,

zirconium and high nickel alloys. Design integrity hydraulic and mechanical - is all part of the

ESP promise.

ESP-R Ring

ESP-P Ring

ESP-C Ring

ESP-I Ring

Replacement of

Raschig Ring

Great strength-toweight ratio

Wall thickness can

be as large as 1 mm

for the application in

corrosive media

Available size at 16,

25, 38, 50, 90 mm

Replacement of

Pall Ring, highest

industry experience

worldwide

Strength-to-weight

ratio stronger than

most other random

packing

Available size at 16,

25, 38, 50, 90 mm

Replacement of CMR

Lower ratio of

diameter to height

than pall ring

High mechanical

strength

Available size at 16,

25, 38, 43, 50, 63,

90, 127 mm

Replacement of IMTP

30% lower pressure

drop than Pall Ring

Design in geometry

enhances greater

capacity & efficiency

than other random

packing

Available size at 15,

25, 40, 50, 60, 70,

90 mm

The ESP range of packing support plates has a high open

structure. These supports offer an open area up to equivalent to

entire column cross section (100%).

In case of flooding, pressure surges at high gas velocities, thus

the packing support is fastened by special clamps to support

ring.

ESP random packing support plates are available in a wide range

of materials as requested by clients. Multiple beam designs are

also available.

Hold Down Plates / Bed Limiters

Retaining devices are used to avoid bed movement in the event of pressure surge or a major upset.

It will limit damage of packing and avoid particles fluidization and carrying over.

Hold down plates are used with ceramics and carbon random

packing to prevent fluidization and minimize packing movement,

due to high gas loading or pressure surges which may break

packing particles. Hold down plate usually rests directly on the

packing.

Packing bed limiters are used with plastic and metal random

packing. Bed limiters dont rest on the packing, but they are

fastened to column by means of support rings and bolting.

Alternatively it can be jointed to the liquid distributor by tie-rods.

Bed limiters will be designed for each special case.

12

13

Mass Transfer & Reactor Internals

Mass Transfer & Reactor Internals

High Performance Structured Packing

ESP Brand Structured Packing

Structured packing is the self-standing element made of inclined

45 or 60 corrugated sheets channels. These channels could be

eventually perforated. This packing is particularly adapted for low

pressure and low liquid load applications, by reducing pressure drop

and energy consumption.

ESP Structured Packing

ESP EM-R/S/HC

Engraved sheet metal design, with or without perforation

Style R for most distillation applications, Style S for high liquid rate

applications and our recently developed Style HC for enhanced capacity

with no loss of efficiency

Operation range: vacuum to high pressure, liquid load 0.2 to more than

200 m3/(m2 h)

Surfaces ranging from below 100 m/m to 750 m/m

ESP WG-R/S

It is manufactured in a wide range of sizes by varying the crimp altitude. Packing surface ranges

from 50 m/m (lowest efficiency, highest capacity) to 750 m/m (highest efficiency, lowest

capacity).

Style R - a 45 crimp for most distillation applications

Style S - a 60 crimp for high liquid rate applications, such as heat transfer beds

Style HC - an optimized fine dimple pattern embossed on the surface to maximize

liquid spreading and wetting ability

All types of ESP structured packing are summarized in the next page.

WIRE GAUZE TYPE STRUCTURED PACKING

Fabricated with corrugated wire gauze sheets to provide improved

liquid wetting, to offer enhanced separation characteristics for fine

chemicals separations

Operation range: 1 mbar to normal pressure

High separation efficiency, minimum pressure drop

Available in Style R and S with a very high surface area (i.e. 350, 400,

500 and 750 m/m)

may be constructed from almost any commercial metal, including carbon steel, stainless steels (type 410, 304 &

316), duplex steels, aluminum, copper alloys, nickel alloys, titanium and zirconium.

ESP structured packing is manufactured with two standard crimp angles and the available styles

are as follows:

EMBOSSED METAL STRUCTURED PACKING

ESP EP-R/S

THERMOPLASTIC STRUCTURED PACKING

Thermoplastic version of the Type ESP EM, for use in corrosive

services, as it is resistant to many chemicals

Operation range: vacuum to high pressure, maximum temperature at

110C for PP, and at 150C for PVDF

Available in plastic of PP, PVC-C, PVDF, and Teflon

Available in Style R and S with surface areas at 125, 250 m/m , etc.

ESP EC-R/S

CERAMIC STRUCTURED PACKING

Ceramic material, for application in high corrosive services (such as in

sulfuric acid media), and for high operation temperature till 700 C

Diameter: minimum at 150 mm

Operation range: vacuum to high pressure

Construction design similar to the Type ESP EM

Available in Style R and S with various surface areas

ESP Packing Support

Packing support grids for structured Packing has the same functions as the random packing

support (physical support of packing, large open area not to restrict flow of liquid and gas,

prevent packing moving downward). These supports offer an important free cross section and

are compatible with the layer design of structured packing.

Structured Packing support grid is available in various metal or thermoplastic materials.

With a special design, it can be supplied also for supporting random packing.

ESP GP

HEAVY DUTY COLUMN PACKING - OPEN, ROBUST GRID

DESIGN

Rigid, open and robust design, 60 corrugation angle, relatively large

corrugations and a smooth surface, designed to minimize liquid holdup

Suitable for fouling services (solids contamination, polymer formation

and coking) , and for services from vacuum to high pressure

Having a high liquid rate capacity, ESP Grid Packing also performs well

in heat transfer applications where separation efficiency is not critical

Available in most grades of stainless steel (1mm thick standard gauge),

other materials and gauge thicknesses available on request

14

15

Mass Transfer & Reactor Internals

Mass Transfer & Reactor Internals

Distributors, Feed Devices and Collector Trays

ESP Brand Liquid Distributors

Apart from the high efficiency ESP trays or packing, the performance

of distillation column shall be guaranteed by distributors, feed devices

and other internals inside the column.

ESP EKD-101

ESP EKD-102

PAN TYPE (OPEN ORIFICE)

Design for installation as one piece assembly, diameter up to 1200mm

Liquid level balanced by orifices located in the pan bottom

Vapor flow through circular gas riser, as well as via the gap between the

pan and the vessel wall

Maximum operation turndown ratio at 2:1

For clean liquid service

Not suitable for serving as a liquid redistributor

Euroslot Kdss design these column internals with an accurate fluid

distribution in distillation columns. Most applied design features in

industry are Pan, Pipe, Chimney Tray and Trough type

ESP High Efficiency Liquid Distributors

Liquid distributors are used in packed towers above each bed of packing they should guarantee a uniform liquid

distribution. Packing efficiency may decrease due to misdistribution and it tends to low packing turndown.

PAN TYPE (DRIP TUBE)

Alternative design to the type EKD-101, diameter up to 1000mm

Liquid level balanced by orifices located in drip tubes fitted to the pan

Vapor flow through circular gas riser, as well as via the peripheral

section between the pan and the vessel wall

Standard design for an operation turndown ratio at 2:1, and with an

optimized design a high turndown ratio at 4:1 by using multiple level of

orifices in the drip tubes

Low to moderate fouling tendency

Metering of the liquid is by orifices punched in the trough sidewalls, above the level of the holder

bottoms. ESP Trough Type (Orifice Guide) liquid distributor allows solids to settle out on the floor of

the trough. This makes the design particularly suitable for use in low to moderate fouling services.

The number of distribution points per unit area can be designed as required. Drip guides, fitted

to the exterior of the troughs it also effectively eliminate liquid misdistribution and entrainment

induced by the effects of vapor flow.

ESP High Efficiency Liquid Distributors ensure high quality liquid distribution across the complete

tower cross section.

ESP EKD-201

Available for any diameter, custom designed chimney arrangement for

various application requirements of liquid distribution and pressure

drop

Liquid flow through orifices located on the tray deck, vapor flow

through chimneys

Standard operation turndown ratio at 2:1

Standard design for clean liquid service; lower fouling tendency when

using larger bottom orifices for higher liquid flow rate

This distributor is suitable for liquid redistribution

ESP High Performance Feed Devices

They are designed and supplied by

Euroslot Kdss when the feed requires

uniform distribution in order to obtain

an overall desirable performance of

the distillation column. The feed can be

liquid only, mixed phases of liquid/vapor

(flash feed), and also vapor. The most

applied design of inlet feed device are in

pipe, vane, and deck, etc. Euroslot Kdss

will be able to choose the appropriate

inlet feed distribution system at your

request.

ESP High Performance Liquid Collectors

Liquid collectors are frequently applied between packed beds for partial liquid draw-off and/or to

feed a liquid distributor below. They are also often required for total liquid draw-off to product or

reboiler, or used for liquid mixing.

16

CHIMNEY TRAY (OPEN ORIFICE)

ESP EKD-202

CHIMNEY TRAY (DRIP TUBE)

Alternative design to the type of EKD-201, available for any diameter

Liquid flow through orifices located in drip tubes fitted to the tray deck,

vapor flow through chimneys

Standard operation turndown ratio at 2:1, and high turndown ratio at

4:1 available by using multiple level of orifices in the drip tubes

Low and moderate fouling tendency

This distributor is suitable for liquid redistribution

17

Mass Transfer & Reactor Internals

Mass Transfer & Reactor Internals

ESP Brand Liquid Distributors

ESP Brand Feed Devices and Collector Trays

ESP EKD-301

ESP EKD-302

ESP EKD-303/304

TROUGH TYPE (OPEN ORIFICE)

ESP EKF-101

Design for accommodating mixed liquid/vapor or flashing feed

For vessel diameters greater than 900mm

The gallery is around the perimeter of the distributor above the

distributor floor, it is installed on a support ring in the standard design;

the sidewall of the gallery has normally a polygonal form

The feed entering tangentially against the column wall, and then the

liquid collected into a pool below along the gallery while the vapor

phase being disengaged

Design for accurate liquid distribution, diameter greater than 900mm

Liquid metering through orifices located on the bottom of the troughs

Vapor passage supplied by the gap between the troughs

Liquid fed to the upper central parting box, and then into the troughs

below; optional design: a central trough (same level as lateral troughs)

to provide structural support and liquid equalization between troughs

Maximum turndown ratio at 2:1

For clean liquid service (limited fouling resistance)

TROUGH TYPE (DRIP TUBE)

ESP EKF-201

ESP EKF-301

Diameter greater than 900mm, possibly up to 4000mm

Liquid flow through orifices located in the trough sidewalls, vapor

through the gap between the troughs

Guided drip tubes fitted to the exterior of the troughs conducting the

liquid from drip points to decrease entrainment and to eliminate liquid

misdistribution; overflow holes provided at each guided tube

Alternative liquid conduction design with large holes in the trough

sidewalls accompanied by thin plate discharge system will provide a

high fouling resistance

Standard turndown ration at 2:1, ratio up to 10:1 is achievable with this

configuration

ESP EKD-401/402

PIPE TYPE (OPEN ORIFICE/SPRAY NOZZLE)

Design with inlet basic pipe and lateral ones

Liquid flow through orifices located in the wall of lateral pipes,

alternative design via spray nozzles

Spray nozzle design for complete liquid coverage and wetting of the bed

Maximum turndown ratio at 2:1

Standard design for clean liquid service

18

VANE TYPE FEED INLET DEVICE

Design of curved vanes, arranged in a heavy duty housing, to reduce

inlet momentum and to promote initial separation of vapor-liquid feeds

Used for mixed phase feeds

Suitable for installation in vertical and horizontal separators

Inlet devices offering the following potential advantages:

Improve vapor distribution

Reduce gas speed

Decrease fine mist

Cut liquid re-entrainment

Lower slug momentum

Alternative design to the type EKD-301, diameter greater than 900mm

Liquid flow through orifices located in drip tubes fitted to the troughs,

vapor through spaces between troughs

Standard operation turndown ratio at 2:1, higher turndown ratio at 4:1

achievable by using multiple level of orifices in the drip tubes

For low to moderate fouling services

TROUGH TYPE (GUIDED LATERAL TUBE/ PLATE)

FLASH GALLERY (MIXED PHASE FEED)

HALF OPEN PIPE FEED DEVICE

It is commonly used to initiate gas/liquid separation

Allowable inlet momentum lower than that of vane type feed inlet

device, normal design standard: m Vm2 2100 kg/ (m.s2). Where m is

the mean density of the mixture in the feed pipe in kg/m and Vm is the

velocity of the mixture in the inlet nozzle in m/s

The choice between Vane type inlet device and half open pipe is a tradeoff between the required separation efficiency and the costs

For the vessel diameter less than 0.5 m, standard design is the feed

nozzle fitted with a half open pipe inlet device, with the opening directed

downwards

For vessel diameters over 0.5 m and inlet nozzle sizes larger than 6, a

Vane Type Feed Inlet Device is recommended

ESP EKC-101

CHIMNEY TRAY LIQUID COLLECTOR

Chimney collector trays proposed for partial or full liquid removal at a

specific point in the column, for mixing feed with refluxed liquid, and

for vapor distribution

Risers can be round, wide/narrow rectangular

Design options: downcomers, downpipes, and sumps for liquid

passage

Generally available for all diameter, ideally for applying in the large

column with high liquid loads

Available in metal and thermoplastic material

19

Mass Transfer & Reactor Internals

Mass Transfer & Reactor Internals

Liquid/Gas and Liquid/Liquid Separators

ESP Vane Mist Eliminators

Based on well established industry standard design

concepts, our range of ESP Separator Internals

have developed unique mechanical enhancements

to ensure effective and reliable performance.

Rigorous separation efficiency and capacity

modeling takes full account of both equipment

geometry, as well as system physical properties, to

further enhance their performance.

Specially profiled chevron style baffle plates are the secret of our ESP

range of vane mist eliminators. These mist eliminators remove liquid

droplets from a vapor stream by the inertial impact of droplets with

the baffle plate. Meanwhile, the gas follows a zigzag path between the

baffles.

Vane mist eliminator provides higher capacity of handling gas load. Moreover,

if vanes are installed in a horizontal flow instead of vertical gas flow, it can

handle still higher gas velocities. It is less efficient in removing very small

droplets compared to mesh type. Standard design is for removal of droplets

larger than 30 m, and we can propose special design of high efficiency for

removal of droplets around 15 m.

Liquid/Gas Separator :

ESP Mesh Mist Eliminators

Features include:

The most common mist eliminator used in production is the knitted-wire-mesh

type. The mesh mist eliminators include a pad of knitted wire mesh packed

between two rigid grids to provide support. Liquid droplets are collected on

the wires and the vapor flows up through the pad. The liquid drains from the

mesh because of gravity.

Our ESP high efficiency knitted mesh pads can be used for many services.

A necessary pad area is proposed from our hydraulic calculation based on

the requirements of your process, and then the best configuration will be

designed suitable for the dimensions of the separator to get the maximum

efficiency. They can be circular, rectangular, cylindrical, V-shaped, etc. They

can remove 100% of liquid droplets larger than 5 m in diameter.

No Drainage Channels

Open Drainage Channels (Single Pocket)

Enclosed Drainage Channels (Double Pocket)

Fouling resistance can be accommodated within the range.

Liquid/Liquid Separator :

ESP Plate Pack Coalescers

All are offered with top and bottom grids and fixing hardware.

Liquid-Liquid separators are commonly employed to remove oil or other

hydrocarbon components from water.

Euroslot Kdss can provide you the plate coalescer design to aid in coalescing

oil droplets in the water and water droplets in the oil. If your process requires the

separation of two or three phases, ESP Coalescers perform very effectively.

The following list summarizes some ESP types of mesh mist eliminator designed and supplied by Euroslot Kdss.

ESP TYPE

20

ED-158

ED-210

ED-280

ED-375

ED-460

ED-500

ED-905

ED-1780

Specific area

(m2/m3)

158

210

280

375

460

500

905

1780

Density

(Kg/m3)

80

120

144

193

128

160

220

432

Designed and manufactured for easy installation and removal for maintenance, ESP Coalescers are well proven

across many applications.

21

Mass Transfer & Reactor Internals

We design, develop,

manufacture and install with quality built in

Quality doesnt just happen. Its engineered into our

manufacturing and into our services.

That means using the latest laser technology, including

laser welding techniques. Using modern production

control systems to ensure the highest visibility, while

improving efficiencies in the workshops.

And we invest heavily in the development of

sophisticated software solutions to optimize processes

and to ensure strength, safety and integrity throughout

our projects.

Software solutions that range from process simulation

to hydraulic and mechanical design.

We are constantly reviewing and employing new

approaches, new technologies, to improve function,

quality, and flexibility. For you, that all adds up to peace

of mind.

Accreditation Includes

OHSAS 18001 (September 2013)

ISO14001 (September 2013)

ISO9001 v2008 (Certification renewal February

2013)

UIC N1

UIC N2

Company

Site Services

Thank you, Euroslot Kdss, for being so reactive in our

hour of need. We just love your can do attitude.

Whether its planned maintenance or emergency

callout, its good to have a partner you can trust.

24 hours a day, on site, on call.

Installation

Installation of plant and equipment in the petrochemical

and refining industries can be uptight. For many buyers and

technicians it becomes a career limiting experience. Or it can be

performed professionally, on time, to budget every time.

Clients value our partnership approach, whether we are the

lead contractor or part of their team. Our specialist supervisors

meld with the client team, adding real value with their depth of

experience, ensuring a trouble-free installation.

Our customers also value our ability to take on new projects and

ideas, where more traditional companies can be bound by rigid

procedures or menu solutions.

Maintenance, Shutdown or Revamping

Our planned maintenance services mean you have access to

highly experienced engineers and technicians, all adopting the

Euroslot Kdss philosophy of thinking from your side of the table.

Our experienced Site Managers provide a single or multiple

discipline approach that ranges from pre-shutdown planning

to shutdown completion. We work closely with our clients in

all elements of a shutdown necessary to complete the works

safely and efficiently. They can be resident on-site, sharing their

expertise to help you plan and monitor the whole process. Keeping

you informed of the latest preventive maintenance techniques to

minimize unplanned downtime. On site, our team will strip down,

diagnose, re-engineer and replace defective components fast

often improving the design in the process.

And when an unplanned shutdown does occur, you can be

confident that our rapid response teams will be on the plane.

Our full time management supervisors have the highest level

of skills in the industry, coupled with the necessary certification

required to work in the most demanding of environments. Our

site teams are UIC N1 and UIC N2 Certifications.

Full back up and strategically sited spares

One very simple measure of any companys ability to provide

effective site services is its strategy for spares. Ours is very

simple - a full range of off the shelf spares and hardware where

it is needed. Our huge based storage facilities are supported by

strategically located spares and plant stores across Europe.

22

23

Mass Transfer & Reactor Internals

Filtration

Your local contact is:

Well Screens

Mass Transfer & Reactor Internals

Site Services

Contact Euroslot Kdss

Euroslot Kdss India

No.12 Gautam House M.G Road

Naupada Thane (W)

40 0602 India

Tel: +33 (0)5 49 93 93 93

Fax: +33 (0)5 49 93 86 71

Email: frsales@euroslotkdss.com

Tel: +91 (0)22 25 396872

Fax: +91 (0)22 25 438212

Email: insales@euroslotkdss.com

Euroslot Kdss China

3153 Heping Village

Lvxiang Town

Jinshan District

Shanghai

201518 China

Euroslot Kdss South Africa

37 Main Road

Eastleigh

Edenvale

1610

South Africa

Tel: +86 (0)21 5401 0993

Fax: +86 (0)21 5401 0992

Email: cnsales@euroslotkdss.com

Tel: +27 (0)11 663 4950

Fax: +27 (0)11 609 0662

Email: zasales@euroslotkdss.com

Euroslot Kdss Pars

No. 25 Unit 3 West 26th Street

(Haq Talab) South Allameh Ave

Sa' adatabad Area

Iran

Tel: +98 (0)21 8868 6942

Fax: +98 (0)21 8868 4605

Email: sales@euroslotkdsspars.com

Euroslot Kdss Vers. 12-2012

Euroslot Kdss France

ZA Les Pridons

86140 SCORB CLAIRVAUX

France

Вам также может понравиться

- Carbon Alloy Steel Seamless Straight TubesДокумент4 страницыCarbon Alloy Steel Seamless Straight TubesShriram AvasarkarОценок пока нет

- ISO/IEC 17020 Checklist ReviewДокумент29 страницISO/IEC 17020 Checklist ReviewJoher100% (1)

- STD 152Документ39 страницSTD 152Shriram AvasarkarОценок пока нет

- STD 141Документ31 страницаSTD 141Shriram AvasarkarОценок пока нет

- STD 181Документ27 страницSTD 181Shriram AvasarkarОценок пока нет

- 2 Casting FormingДокумент56 страниц2 Casting FormingMohana KrishnanОценок пока нет

- STD 154Документ55 страницSTD 154Shriram Avasarkar100% (3)

- STD 183Документ51 страницаSTD 183Shriram Avasarkar100% (1)

- STD 153Документ15 страницSTD 153Shriram AvasarkarОценок пока нет

- OISD Standard for Propane Tank Truck DesignДокумент29 страницOISD Standard for Propane Tank Truck DesignShriram AvasarkarОценок пока нет

- Pressure Control ValvesДокумент55 страницPressure Control ValvesShriram AvasarkarОценок пока нет

- STD 150Документ27 страницSTD 150Shriram Avasarkar100% (1)

- Design For Over PressureДокумент168 страницDesign For Over PressurebryandownОценок пока нет

- Design For Over PressureДокумент168 страницDesign For Over PressurebryandownОценок пока нет

- Piping Design InfoДокумент265 страницPiping Design InfoPedro Luis Choque MamaniОценок пока нет

- Maharashtra Factories Rules, 1963Документ210 страницMaharashtra Factories Rules, 1963Jatin Shah100% (4)

- Steel Work Inspection ReportДокумент3 страницыSteel Work Inspection ReportAhmad Hasnan100% (1)

- Gas TurbineДокумент60 страницGas TurbineezeОценок пока нет

- Code For PV & HEДокумент23 страницыCode For PV & HEShriram AvasarkarОценок пока нет

- Commonly Used Material StandardsДокумент1 страницаCommonly Used Material StandardsShriram AvasarkarОценок пока нет

- HPCL Vendor - ListДокумент106 страницHPCL Vendor - ListShriram Avasarkar67% (6)

- Asme 31 GДокумент48 страницAsme 31 GShriram Avasarkar100% (2)

- JokesДокумент85 страницJokesShriram AvasarkarОценок пока нет

- West Texas Gas Distribution Pipeline IMP 2012 6-22-12Документ45 страницWest Texas Gas Distribution Pipeline IMP 2012 6-22-12Shriram AvasarkarОценок пока нет

- MethodologyДокумент1 страницаMethodologyShriram AvasarkarОценок пока нет

- Welding SymbolДокумент52 страницыWelding SymbolShriram Avasarkar100% (4)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Lighting and AcousticsДокумент18 страницLighting and Acousticsmahira bhatiaОценок пока нет

- Dry Putty 111Документ2 страницыDry Putty 111mahmoud badrОценок пока нет

- Comparing antioxidant assays for estimating activity in guava extractsДокумент7 страницComparing antioxidant assays for estimating activity in guava extractsFira KuswandariОценок пока нет

- Atmospheric Water GeneratorДокумент3 страницыAtmospheric Water GeneratorKhusnil MujibОценок пока нет

- Cell Organelles and Their Functions - RS' ScienceДокумент1 страницаCell Organelles and Their Functions - RS' ScienceMishaОценок пока нет

- 72 Had DadДокумент6 страниц72 Had DadthestupiddogОценок пока нет

- He's Got The Whole World in His Hands: African-American Spiritual 120 120Документ1 страницаHe's Got The Whole World in His Hands: African-American Spiritual 120 120kcpsОценок пока нет

- The Fundamental Building Block: The CellДокумент12 страницThe Fundamental Building Block: The CellTanish JenaОценок пока нет

- Using Pumps As Power Recovery TurbinesДокумент4 страницыUsing Pumps As Power Recovery TurbinesKali CharanОценок пока нет

- DrillersManual Chapters 1 12Документ192 страницыDrillersManual Chapters 1 12Hugo MoralesОценок пока нет

- Emerging Pollutants in The EnvironmentДокумент10 страницEmerging Pollutants in The EnvironmentVita Maryam H.Оценок пока нет

- Bradford White Hot Water Tank Cut SheetДокумент2 страницыBradford White Hot Water Tank Cut SheetmaxxhaloОценок пока нет

- Mysore Road Plastic Industry ListДокумент6 страницMysore Road Plastic Industry ListjafarptrОценок пока нет

- MiniProject Stage 3 - Process Dynamic & ControlДокумент8 страницMiniProject Stage 3 - Process Dynamic & ControlFarihah Eyfa100% (2)

- ISO 17746-2016 Steel Wire Rope Net Panels and RollsДокумент24 страницыISO 17746-2016 Steel Wire Rope Net Panels and RollsOctavian Miclescu100% (1)

- 10.1016 J.jallCOM.2005.10.048 Extraction of Titanium From Different Titania Precursors by The FFC Cambridge ProcessДокумент9 страниц10.1016 J.jallCOM.2005.10.048 Extraction of Titanium From Different Titania Precursors by The FFC Cambridge ProcessHooman BaghbanОценок пока нет

- APL - Emulsifiers Products ListДокумент2 страницыAPL - Emulsifiers Products Listshreeket3953Оценок пока нет

- Building electricity vocabularyДокумент9 страницBuilding electricity vocabularyChan PhakkdeyОценок пока нет

- Carbomer 940: Information SheetДокумент3 страницыCarbomer 940: Information SheetrendyОценок пока нет

- FC WellheadДокумент32 страницыFC WellheadEfe Alexander Orieka100% (2)

- FoodDrug Interactions Careful Drug Selection Patient CounselingДокумент6 страницFoodDrug Interactions Careful Drug Selection Patient CounselingmelodythОценок пока нет

- Himani Bansal Jayant Negi Ritesh Kumar Uday PratapДокумент7 страницHimani Bansal Jayant Negi Ritesh Kumar Uday PratapJayant NegiОценок пока нет

- 9472761Документ23 страницы9472761Emerson KohlrauschОценок пока нет

- Essential Guide to Compressed Air SystemsДокумент35 страницEssential Guide to Compressed Air SystemsvmramakrishnanОценок пока нет

- Lab Technician Interview QuestionsДокумент3 страницыLab Technician Interview QuestionsCandra AprizalОценок пока нет

- Copy of Pharmacognosy-and-Plant-ChemistryДокумент25 страницCopy of Pharmacognosy-and-Plant-ChemistryDecemae FuentesОценок пока нет

- BC34.1 E9 Determination of Acid Value of FatsДокумент3 страницыBC34.1 E9 Determination of Acid Value of FatsGlenn Vincent Tumimbang96% (26)

- 1995Документ283 страницы1995Robert BataraОценок пока нет

- ACROLEIN MSDSДокумент6 страницACROLEIN MSDSzaedmohd50% (2)

- 2019 Cre Ii L24-26Документ32 страницы2019 Cre Ii L24-26Aman PrasadОценок пока нет