Академический Документы

Профессиональный Документы

Культура Документы

Articles - Why We Need Quality Management in Maintenance - ReliabilityWeb - Com - A Culture of Reliability

Загружено:

mianabdulОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Articles - Why We Need Quality Management in Maintenance - ReliabilityWeb - Com - A Culture of Reliability

Загружено:

mianabdulАвторское право:

Доступные форматы

Articles | Why We Need Quality Management in Maintenance | Reliabil...

1 of 5

http://reliabilityweb.com/index.php/articles/why_we_need_quality_man...

Visite nuestro sitio en Espaol: Confiabilidad.net

RSS | Contact

Advertisement

Join the conversation

Subscribe to our mailing list

Productivity Inc.

Why We Need Quality

Management in Maintenance

Subscribe

by Bill Keeter

Add comment

During recent presentations, I asked the

View comments

audiences how many of their organizations had

quality management systems in place within

their maintenance departments. On average,

about two percent of the attendees raised their

hands. I asked the same audiences how many

of their organizations had quality management systems for their

manufacturing processes. The response was somewhere in the 95

percent range.

IR Windows: Compare and Save with

Exiscan

New AT33IND Perfect for QC &

Troubleshooting

Free eBook: 5 Critical Components in

Your RCA Program

That is a very interesting comparison when we consider that between 50

percent and 70 percent of equipment failures are likely due to infant

failures resulting from either maintenance or commissioning errors.

Job Postings for Maintenance and

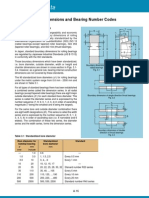

An April 1999 study of misalignment versus bearing life by the University of

Tennessees Maintenance and Reliability Center showed that as little as 5

mils/inch of misalignment when using a grid coupling could reduce bearing

life by as much as 50 percent.

Facilitator

Reliability Professionals

Become an Aladon Certified RCM2

Noise and Vibration Measurement &

Analysis Solutions

Request Your Des-Case Complimentary

It could be said that the most important periods in any assets life are the

installation and commissioning phases. Equipment will achieve 100 percent

of its design capability if the job is done well. Conversely, equipment will

start life in a degraded state if the job is done poorly.

Breather Now

R300SR for When Good Enough Isnt

Enough!

THE PURPOSE OF QUALITY MANAGEMENT

Join The Association For Maintenance

A quality management system (QMS) consists of two types of activities.

Quality assurance (QA) is activities designed to ensure that quality is built

into the process. Quality control (QC) is activities designed to ensure that

desired quality levels are actually achieved by the process. It takes both

types of activities to reach desirable quality goals. It is unreasonable to

expect that quality assurance will be 100 percent effective in preventing

maintenance and commissioning errors. The activities are a human

endeavor, which means mistakes will be made regardless of how rigorous

the procedures are. It is also uneconomical to inspect every defect using

quality control methods.

Professionals

Aircraft

Naval Vessels

Manufacturing

1968 1973

1993

2001

2005

UAL Broberg Surface** Submarine* Plucknette

Failure

Curve

ABathtub 4%

BWearout 2%

CFatigue 5%

D7%

Break-In

ERandom 14%

FInfant 68%

Allied Reliability Group Inspired Training:

Hard-Hitting, Impactful Courses and

Des-Case Corporation

Workshops

Belt/Sheave Alignment Laser, Custom

Shim and Gaskets

Integrating Your CBM Just Makes Sense

Total Productive Maintenance Books

The One-Stop Source for Lubricants &

Reliability Solutions

Reliability Performance

Institute

Motor Testing Books

3%

3%

2%

3%

1%

17%

10%

3.5%

4%

3%

17%

6.5%

11%

6%

9%

7%

Way? Try the Smart Way.

15%

42%

56%

13%

Commtest - Affordable Vibration Analysis

66%

29%

6%

67%

Spending the right amount on

maintenance?

MRO Inventory and Purchasing Books

Performing Condition Monitoring the Old

Table 1: Results of Reliability vs. Age Studies (Nowlan and Heap, Nicholas,

Pau, Allen, et al.)

*The data was gathered after over 30 years of implementing the SUBSAFE

Program

**The data was gathered approximately 15 years after the naval surface

force adopted maintenance strategies similar to those used in submarines.

Reliability Engineering Services

Foreman, Industrial Equipment Mechanic

GRADE 15 -Washington,DC

Supervisor, Reliability Engineer, GRADE

17 -Washington, DC

Reliability Project Engineer - Nashville, TN

4/14/2015 7:26 AM

Articles | Why We Need Quality Management in Maintenance | Reliabil...

2 of 5

http://reliabilityweb.com/index.php/articles/why_we_need_quality_man...

Deputy Chief Mechanical Officer Manhattan - Midtown

Asst. Chief Mechanical Officer - RCM/EAM

-Manhattan - Midtown

Maintenance Manager - Manufacturing

Senior Manager - Reliability Maintenance

& Technical Services - Lorain, OH

Reliability Manager - Nazareth, PA

Senior Reliability Consultant

Figure 1: Percent Bearing Life Achieved

Reliability Consultant

April 14

Apollo Root Cause Analysis Facilitator

Course - Auckland, New Zealand

April 14

Risk-Based Asset Management

April 15

Failure Mode and Effects Analysis and Root

Cause Analysis in Maintenance

Management

April 20

Apollo Root Cause Analysis Facilitator

Course - Perth, Australia

April 20

Figure 2: The Equipment Lifecycle

Maintenance Planning and Scheduling

PRECISION MAINTENANCE AND QUALITY

ASSURANCE

April 21

Precision maintenance is achieved by well-trained people using precision

methods and well-written procedures. Quality assurance is achieved by

inserting steps in the procedures that require the person doing the work to

record a number and the person supervising the work to approve the

number. This is not an easy assignment. It will probably make jobs last a

bit longer, which nobody likes, but if it makes the installation (I) to

potential failure (P) interval longer, it will be well worth it.

April 22

ISO 55000: Asset Management System

RCA301 Incident Investigation for Root

Cause Investigators

April 22

Apollo Root Cause Analysis Facilitator

Course - Seattle, WA

April 24

Taming the Beast to Win Webinar by Jeff

Shiver, CMRP, CPMM, CRL, RCM2

Practitioner

April 24

6 Components to Amazing Value in

Maintenance Planning and Scheduling by

Jeff Shiver, CMRP, CPMM, CRL

Is Your Equipment Telling You When It

Needs PM?

Doing It Right in Maintenance

Figure 3: I-P-F curve from Doug Plucknette

QUALITY CONTROL IN MAINTENANCE

Quality control means having the discipline to come back at the completion

of the job to take what have been referred to over the years as baseline

readings for condition monitoring. Admittedly, this is an important step for

the condition monitoring program, but changing the focus from just getting

baseline readings to quality control of the work done will result in a greater

return on those condition monitoring tools. The use of vibration analysis,

thermography and ultrasonic tools will enhance your organizations ability

to find misalignment, close couplings, leaking fittings, missing insulation,

loose electrical connections and other installation faults after maintenance

work.

WHERE TO START

Equipment Reliability Assessment by

Sampling Standard Information from

Operations

A Sustainable & Effective Approach to

Vibration Analysis

Understanding Criticality: Myths and Pitfalls

to Avoid

Asset Management and Servitization

As Advancements in Big Data, the Cloud

and IoT Transform APM, Who Will Own the

Data?

4/14/2015 7:26 AM

Articles | Why We Need Quality Management in Maintenance | Reliabil...

3 of 5

http://reliabilityweb.com/index.php/articles/why_we_need_quality_man...

Chasing the Checkered Flag

The Six Pieces Needed to Start Designing a

Planning and Scheduling Program

A Reliable Plant Good for Personal and

Process Safety

More articles

Figure 4

Decide to Do It

The first step in making any change is to decide to make the change.

Nothing happens without this critical step.

Build Organizational Support

Support from all levels of the organization is crucial to the success of this

program. Management has to be shown the potential value, and the rank

and file has to be shown what is in it for them. Evidence from a 1986

Electric Power Research Institute study suggests that a precision

maintenance program has significantly lower costs than either preventive

or predictive maintenance alone (see Figure 5).

Figure 5

ENGINEERING ASSET MANAGEMENT

AN INSURANCE PERSPECTIVE

By Ian Barnard

Create Policies & Procedures

Policies and procedures are an important way of institutionalizing any new

program. They establish what will be done, how it will be done and who will

do it. Everyones roles, goals and responsibilities will flow from these, so

they should include a RAS/CI table to summarize responsibilities. The

RAS/CI table is a quick visual summary of the responsibility level of

different organizational roles for a given process.

Determine Critical Jobs

Jobs, like equipment, have some level of criticality. Criticality is a function

of probability of occurrence and business impact. High impact jobs that are

performed frequently would pop to the top of your list and should be

examined for improvement using QA and QC methods to ensure reliable

performance.

Write and Implement New Procedures

Pick a procedure and begin working on it. The procedure writing process

should be an inclusive, facilitated process that includes the people who will

actually have to perform the work. The beginning of this process is a visual

breakdown of the job called a job map. A job map is similar to a work

breakdown structure for the job, but it has steps that identify dangers to

people and equipment, job impediments, resources and job performance

standards. The actual writing of the procedure can take place once the

team agrees that the map is complete.

Ian Barnard's unique book, Engineering Asset

Management an Insurance Perspective, is a

compilation of experiences and observations

in the fields of asset management,

engineering consulting and insurance. He has

been exposed to asset management systems

from all parts of the world and from all types

of industry. His book presents the best of the

best in asset management systems and

highlights common pitfalls which prevent

these systems from achieving excellence. The

underlying theme of the book is that it is not

technology that defines an effective asset

management system, but rather people.

While this book presents an insurance

perspective on engineering asset

management systems, a central tenet of

insurance is that if it saves the insurance

company money, it will save the client

money.

Monitor and Adjust

Quality management is a continuous improvement process. It is important

to monitor both the process and the work product to ensure the new

program is working. Establish key performance indicators (KPIs) to

measure progress in creating and implementing the new procedures and to

measure whether or not the procedures are effective.

CONCLUSION

4/14/2015 7:26 AM

Articles | Why We Need Quality Management in Maintenance | Reliabil...

4 of 5

http://reliabilityweb.com/index.php/articles/why_we_need_quality_man...

There is a lot of evidence showing that the quality of maintenance and

commissioning of equipment needs to improve in almost every industry.

Hardly any manufacturing or service organizations create their products

and services without some sort of QMS in place to ensure the customers

get a quality product at a reasonable price. The maintenance department is

a service organization whose goal is to deliver uptime at a reasonable

price. A well-designed QMS will enable them to do that.

Bill Keeter is the owner of BK Reliability in Titusville, Florida. Bill

is an experienced maintenance professional who provides

reliability training and consulting services around the world. He

is passionate about helping organizations understand and

eliminate system failures so they can achieve better safety,

environmental, operational and financial performance.

Add comment

Comments (1)

Bill, I enjoyed your discussion centered around various areas of

quality. I can relate to the percentage of organizations not

endorsing quality. If I were to poll companies within SW Florida

area I would readily see that an effective QMS has only been

implemented within a very small percentage of any organization.

Without endorsing / implementing an effective QMS, an

organization can operate in a state of chaos without any

realization. Being a certified ISO lead assessor for Orion Registrar

and a lead quality engineer/manager for Lockheed Martin, Loral

Space Systems, and IBM, I know how important it is for an

organization to develop an effective process infrastructure

covering many key elements of ISO or the Capability Maturity

Model if a software development organization. I also know from

experience that an effective / respected process architecture can

help an organization win contracts.

I would change your "Where to Start" flow where you need to

also initiate an effective "gap analysis" against an effective,

quality-based international standard.

Thank you again for your contribution.

Regards,

Ed Gardner, President

Value Management Services, LLC

9009 Prosperity Way

Fort Myers, Florida 33913

Telephone: (239) 322-7283

E-mail: valuems@comcast.net

Web Site: http://www.value-ms.com

1) Posted 6:49 pm, 15 April 2014 by Edward Gardner

Have your say

Comments are moderated prior to publication.

Please fill out the fields below.

Email addresses will never be published.

Name (required):

Email (required):

4/14/2015 7:26 AM

Articles | Why We Need Quality Management in Maintenance | Reliabil...

5 of 5

http://reliabilityweb.com/index.php/articles/why_we_need_quality_man...

URL:

Comment guidelines

You can use basic HTML (a, strong, em, blockquote).

Links automatically use the nofollow attribute.

Off-topic or inappropriate comments will be edited or deleted.

Your comment (required):

Remember my personal information

Please enter the word you see in the image below (required):

2015 Reliabilityweb.com

Articles

Feedback

About us

RSS

Privacy Policy

Contact us

Terms of service

Trademark notice

Advertise with ReliabilityWeb.com

4/14/2015 7:26 AM

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Car Maintenance TipsДокумент23 страницыCar Maintenance TipsmianabdulОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Bearing Damage AnalysisДокумент12 страницBearing Damage AnalysisZulfahmi IrhamdaniОценок пока нет

- Presentation On Condition MonitoringДокумент71 страницаPresentation On Condition MonitoringShahin Manjurul AlamОценок пока нет

- Control Valve CharacteristicsДокумент65 страницControl Valve CharacteristicsAzar DeenОценок пока нет

- ORBIT v30n1 2010 r15Документ60 страницORBIT v30n1 2010 r15mathewaj100% (1)

- Lesson 01 PDFДокумент12 страницLesson 01 PDFAbuubakr Abdelwhab HassanОценок пока нет

- A2U8A2 - KBR Quality Plan For Phase Two Mechanical and Electrical Work PDFДокумент53 страницыA2U8A2 - KBR Quality Plan For Phase Two Mechanical and Electrical Work PDFMOST PASONОценок пока нет

- A2U8A2 - KBR Quality Plan For Phase Two Mechanical and Electrical Work PDFДокумент53 страницыA2U8A2 - KBR Quality Plan For Phase Two Mechanical and Electrical Work PDFMOST PASONОценок пока нет

- Plant Performance Assessment QuestionnaireДокумент27 страницPlant Performance Assessment QuestionnairesoumitrabanОценок пока нет

- Woody 2000 ProjectДокумент36 страницWoody 2000 ProjectRobert Luggard100% (6)

- Condition Monitoring Forum Qatar 2015Документ16 страницCondition Monitoring Forum Qatar 2015SyedNadeemAhmedОценок пока нет

- Power Transformer Condition Monitoring and Assessment ForДокумент6 страницPower Transformer Condition Monitoring and Assessment ForsureshnfclОценок пока нет

- Integrity ManagementДокумент8 страницIntegrity Managementgurdeepsarora8738Оценок пока нет

- Mobius Institute Vibration Brochure AlliedДокумент12 страницMobius Institute Vibration Brochure AlliedIslam BirgeОценок пока нет

- Bearing Condition Monitoring Using Acoustic Emission and VibrationsДокумент227 страницBearing Condition Monitoring Using Acoustic Emission and VibrationslucastcОценок пока нет

- Condition Monitoring of Steam Turbines by Performance AnalysisДокумент4 страницыCondition Monitoring of Steam Turbines by Performance Analysissppram100% (1)

- Car RPRДокумент20 страницCar RPRsandiego100% (1)

- Parts2008 KCG-5000DESДокумент9 страницParts2008 KCG-5000DESmianabdulОценок пока нет

- DK1915 CH12Документ70 страницDK1915 CH12gao379100% (1)

- Car Maintenance How To Change Car Fluids Like A Pro Without Breaking A Sweat PDFДокумент4 страницыCar Maintenance How To Change Car Fluids Like A Pro Without Breaking A Sweat PDFmianabdulОценок пока нет

- Top Summer Car Maintenance Tips PDFДокумент7 страницTop Summer Car Maintenance Tips PDFmianabdulОценок пока нет

- Liquid FuelДокумент5 страницLiquid FuelmianabdulОценок пока нет

- Klbove enДокумент2 страницыKlbove enmianabdulОценок пока нет

- Bearing NumbersДокумент6 страницBearing NumbersonlineojОценок пока нет

- ConstructionandCharacteristicsof RollingBearingsДокумент4 страницыConstructionandCharacteristicsof RollingBearingsmianabdulОценок пока нет

- SS0018 A - 3, 5, 10 KW Gas 5, 10, 15 KW Diesel Generator SetДокумент11 страницSS0018 A - 3, 5, 10 KW Gas 5, 10, 15 KW Diesel Generator Setanon-114619100% (1)

- Emails Opening ClosingДокумент2 страницыEmails Opening ClosingmianabdulОценок пока нет

- Problems CPMДокумент1 страницаProblems CPMmianabdulОценок пока нет

- User Instructions: Installation Operation Maintenance Edward ValvesДокумент16 страницUser Instructions: Installation Operation Maintenance Edward ValvesmianabdulОценок пока нет

- Hidden Features of Windows 7 That 95% Windows Users Don't KnowДокумент6 страницHidden Features of Windows 7 That 95% Windows Users Don't KnowmianabdulОценок пока нет

- Section 1 Heat Exchanger Level 1Документ1 страницаSection 1 Heat Exchanger Level 1mianabdulОценок пока нет

- Articles - Why We Need Quality Management in Maintenance - ReliabilityWeb - Com - A Culture of ReliabilityДокумент5 страницArticles - Why We Need Quality Management in Maintenance - ReliabilityWeb - Com - A Culture of ReliabilitymianabdulОценок пока нет

- Section 2 CV PSV & NRV Level 1Документ1 страницаSection 2 CV PSV & NRV Level 1mianabdulОценок пока нет

- Physics Fill in The BlanksДокумент3 страницыPhysics Fill in The BlanksmianabdulОценок пока нет

- 09 Unit ConvertionДокумент1 страница09 Unit ConvertionmanbkkОценок пока нет

- In Determining The Amount of Float in A Task, You Need To Look at Both Types of Float. Other Words, When Activities Converge On A Network DiagramДокумент4 страницыIn Determining The Amount of Float in A Task, You Need To Look at Both Types of Float. Other Words, When Activities Converge On A Network DiagrammianabdulОценок пока нет

- Problems CPMДокумент1 страницаProblems CPMmianabdulОценок пока нет

- 09 Unit ConvertionДокумент1 страница09 Unit ConvertionmanbkkОценок пока нет

- Pag. 228 235 - A REVIEW OF FAULT DIAGNOSISIN MECHATRONICS SYSTEMSДокумент8 страницPag. 228 235 - A REVIEW OF FAULT DIAGNOSISIN MECHATRONICS SYSTEMSSelahadin Al AyubОценок пока нет

- 7126-Plus en WebДокумент2 страницы7126-Plus en Webtrung2iОценок пока нет

- 1Документ84 страницы1Turgut Arslan100% (1)

- Machine Diagnostics Toolbox: Industrial SolutionsДокумент8 страницMachine Diagnostics Toolbox: Industrial SolutionsIbnu HajarОценок пока нет

- COREWIND D4.1 Identification of Floating Wind Specific O&M Requirements and Monitoring TechnologiesДокумент98 страницCOREWIND D4.1 Identification of Floating Wind Specific O&M Requirements and Monitoring TechnologiesadeshinexxОценок пока нет

- Unit 5 Maintenance TypesДокумент13 страницUnit 5 Maintenance TypesaishwaryaОценок пока нет

- Sensonics - Intelligent Machinery ProtectionДокумент5 страницSensonics - Intelligent Machinery ProtectionMuhammad Rizki SetiawanОценок пока нет

- SNL Plumer BlockДокумент108 страницSNL Plumer Blockpapathsheila100% (1)

- Meherwan P Boyce - Gas Turbine Engineering Handbook-Elsevier Butterworth-Heinemann (2012) 4Документ5 страницMeherwan P Boyce - Gas Turbine Engineering Handbook-Elsevier Butterworth-Heinemann (2012) 4amir moniriОценок пока нет

- Oil Condition Monitoring BrochureДокумент4 страницыOil Condition Monitoring BrochureLubrexcel LubrifiantiОценок пока нет

- Me Automation & Robotics SyllabusДокумент27 страницMe Automation & Robotics SyllabusweenniiОценок пока нет

- ME6012 Maintenance EngineeringДокумент8 страницME6012 Maintenance EngineeringBhuvanesh KumarОценок пока нет

- Condition Monitoring Techniques For Electrical Equipment-A Literature SurveyДокумент10 страницCondition Monitoring Techniques For Electrical Equipment-A Literature SurveymuhammedОценок пока нет

- Vasavipower.com.docxДокумент9 страницVasavipower.com.docxabdulyunus_amirОценок пока нет

- CBM ManualДокумент88 страницCBM ManualZdenko SemanОценок пока нет

- Rotor Dynamic Modelling As A Powerful Support Tool For Vibration Analysis On Large Turbomachinery - Murilo CamisãoДокумент7 страницRotor Dynamic Modelling As A Powerful Support Tool For Vibration Analysis On Large Turbomachinery - Murilo Camisãojoao batista alvesОценок пока нет

- Bro Imv OctДокумент2 страницыBro Imv Octabdulwadi84Оценок пока нет

- Protect Your Machine and ToolingДокумент12 страницProtect Your Machine and Toolingdaniel ornelasОценок пока нет

- HVPD Kronos Permanent 4-Page Product CardДокумент4 страницыHVPD Kronos Permanent 4-Page Product CardppОценок пока нет

- UG 4-1 Mechanical Engineering R16-SyllabusДокумент23 страницыUG 4-1 Mechanical Engineering R16-SyllabusSunkari rameshОценок пока нет