Академический Документы

Профессиональный Документы

Культура Документы

Project Management Success Criteria

Загружено:

Matthew PhillipsАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Project Management Success Criteria

Загружено:

Matthew PhillipsАвторское право:

Доступные форматы

THE CRITERIA OF PROJECT MANAGEMENT SUCCESS AT CHEVRONS CAPE

TOWN REFINERY: A CASE STUDY

ZENITH MOSES MITCHELL

Research report presented in partial fulfilment

of the requirements for the degree of

Master of Business Administration

at the University of Stellenbosch

Supervisor: Prof C Brown

Degree of confidentiality: A

December 2010

ii

Declaration

By submitting this research report electronically, I, Zenith Moses Mitchell, declare that the entirety

of the work contained therein is my own, original work, that I am the owner of the copyright thereof

(unless to the extent explicitly otherwise stated) and that I have not previously in its entirety or in

part submitted it for obtaining any qualification.

ZM Mitchell

September 2010

Copyright 2010 Stellenbosch University

All rights reserved

iii

Acknowledgements

I acknowledge God as the Almighty Father of heaven and earth. Through His wisdom and

guidance, I managed to achieve great things and I believe that there is still more to come. I also

want to acknowledge my late father, Norman Mitchell for bringing me into this world.

Much appreciation goes to mother who plays a vital role in all my success stories and

achievements.

To my wife, no amount of words can describe my sincere appreciation for the support that you

gave me right from the beginning. This has been three amazing years for us: getting married and

expecting our first child. Wow, what more can a man ask for?

Lastly, I want to share my sincere thanks for my supervisor, Prof C Brown, who supported me even

in difficult times.

iv

Abstract

The Chevron Cape Town refinery was constructed in 1996 with a crude capacity of 100,000 barrels

per day (bpd). The focus of the unit is production and meeting the nameplate market demand. The

project environment for the refinery is that of maintenance and gradual upgrade. The majority of

projects handled are small capital projects.

The aim of this research is to identify what the success criteria for project management should be

for projects carried out within the small capital projects department of Chevrons Cape Town

refinery.

An important distinction to make is that this study looks at project management success and not

project success, although the aspects of project success will be discussed to highlight how closely

related the two concepts are. Project success is not directly proportional to project management

success and neither is project management success directly proportional to project success.

In the past decades, project management success was usually indicated by the project completion

within the time, cost and performance constraints (Kerzner, 2004:29). This has now evolved to

understanding all the objectives of the project. Project management can still be deemed successful

even if it did not meet all the objectives of the project and vice versa, as long as there are mutual

trade-offs agreed to by the developer (project manager) and the client.

White and Fortune (2002:1-11) conducted a survey to identify common criterion used for defining

project management success.

The three criteria identified for judging project success are

completion on time, within the budget and to performance (specification).

Project management success has been found to be a very difficult topic to define. This research

report shown that project management success needs to be moved beyond the iron-triangle to

other criteria like safety and meeting the objectives of the client. What was evident was that

criteria, factors, dimensions and measures are concepts widely used by researchers and it is

hoped that these topics. A very interesting discovery during my first interview was that project

management success comes in three phases or parts, which are pre-delivery, delivery and postdelivery.

What was evident from this research was that the criteria for project management success need to

be established up front before the project gets to the delivery phase. There is no way that one can

measure project management success when the success criteria one is looking for at the end of

the project have not been established up front.

The case study is summarised using the diagram in chapter five showing the new project

management success criteria that needs to be adopted by the refinery.

Future research into project management success criteria could include a survey which could go

out the whole refinery and not just the representative sample who were interviewed for this report

which could confirm the project management criteria found in this report.

vi

Opsomming

Die Chevron Kaapstad raffinadery is in 1996 gestig met n ruolie kapasiteit van 100,000 vate per

dag. Die fokus van die eenheid is produksie en om aan die marknavraag te voldoen. Die

projekomgewing van die raffinadery is instandhouding en mettertydse opgradering van die

raffinadery. Die meerderheid van projekte wat hanteer word is klein-kapitaalprojekte.

Die doel van hierdie navorsing is om te identifiseer wat die sukseskriteria vir projekbestuur behoort

te wees vir projekte wat binne die klein-kapitaaldepartement van Chevron se Kaapstad raffinadery

behartig word.

n Belangrike onderskeid om te maak is dat hierdie studie na projekbestuursukses kyk en die

projeksukses nie, alhoewel die aspekte van projeksukses ook bespreek sal word om uit te lig hoe

naby verwant die twee konsepte aan mekaar is. Projeksukses is nie direk proporsioneel tot

projekbestuursukses nie en omgekeerd.

In die afgelope dekades was projekbestuursukses gewoonlik aangedui deur die afhandeling van

die projek binne die tydsraamwerk, koste en prestasiebeperkinge (Kerzner, 2004:29). Hierdie

konsep het intussen uitgebrei na n verstaan van al die doelwitte van die projek. Projekbestuur kan

steeds as suksesvol beskou word al het dit nie aan al die doelwitte van die projek voldoen nie, en

omgekeerd, solank as wat daar wedersydse toegewings deur beide die ontwikkelaar

(projekbestuurder) en die klint gemaak word.

White en Fortune (2002:1-11) het n opname gemaak om die algemene kriteria te identifiseer wat

gebruik word om projekbestuursukses te definieer. Die drie kriteria wat uitgewys is om n projek te

evalueer, is afhandeling van die projek binne die tydsraamwerk, koste en prestasiebeperkinge.

Projekbestuursukes is n baie moeilike onderwerp om te definieer. Hierdie navorsingsverslag wys

dat projekbestuursukses verby die yster-driehoek moet beweeg om ander kriteria soos veiligheid

en die voldoening aan die klint se doelwitte, in te sluit. Wat duidelik na vore gekom het is dat

kriteria, dimensies en metings konsepte is wat wyd deur navorsers gebruik word. n Baie

interessante ontdekking gedurende die eerste onderhoud was dat projekbestuursukses in drie

fases of dele voorkom, naamlik voor-lewering, lewering en na-lewering

Wat duidelik uit die navorsing is, is dat die kriteria vir projekbestuursukses voor die aanvang van n

projek vasgestel moet word, voordat die projek die afleweringsfase bereik. Daar is geen manier

wat projekbestuursukes gemeet kan word wanneer die sukseskriteria wat aan die einde van n

projek gesoek word, nie aan die begin vasgestel is nie.

vii

Die gevallestudie word opgesom deur die diagram in hoofstuk vyf te gebruik wat die nuwe

projekbestuursukseskriteria aandui wat deur die raffinadery aanvaar moet word.

Toekomstige navorsing in projekbestuursukseskriteria kan n opname insluit wat aan die hele

raffinadery gestuur kan word en nie net die verteenwoordigende steekproef met wie daar vir

hierdie verslag se doeleindes onderhoud gevoer is om die projekbestuurkriteria van hierdie verslag

te bevestig nie.

viii

Table of contents

DECLARATION ................................................................................................................... II

ACKNOWLEDGEMENTS .................................................................................................. III

ABSTRACT ....................................................................................................................... IV

OPSOMMING .................................................................................................................... VI

LIST OF TABLES .............................................................................................................. XI

LIST OF FIGURES ........................................................................................................... XII

LIST DEFINITIONS ......................................................................................................... XIII

CHAPTER 1

ORIENTATION .......................................................................................... 1

1.1

Introduction ............................................................................................................. 1

1.2

Project environment at the refinery ......................................................................... 2

1.3

Problem statement.................................................................................................. 5

1.4

Research objectives ............................................................................................... 7

1.5

Literature review ..................................................................................................... 7

1.5.1

Project life cycle ......................................................................................................... 7

1.5.2

Project life cycle used by the refinery ......................................................................... 9

1.6

Research design and methodology ...................................................................... 10

1.7

Chapter summary ................................................................................................. 10

CHAPTER 2

LITERATURE REVIEW ........................................................................... 11

2.1

Introduction ........................................................................................................... 11

2.2

Project management process ............................................................................... 12

2.2.1

Initiation ................................................................................................................... 12

2.2.2

Planning .................................................................................................................. 12

2.2.3

Executing ................................................................................................................. 12

2.2.4

Monitoring and controlling ........................................................................................ 13

2.2.5

Closing .................................................................................................................... 13

2.3

Project management functions ............................................................................. 13

2.3.1

Project integration management .............................................................................. 13

2.3.2

Project scope management ..................................................................................... 14

2.3.3

Project time management ........................................................................................ 15

2.3.4

Project cost management ........................................................................................ 15

2.3.5

Project performance management ........................................................................... 15

ix

2.3.6

Project human resource management ..................................................................... 16

2.3.7

Project communication management ....................................................................... 17

2.3.8

Project risk management ......................................................................................... 18

2.3.9

Project procurement management ........................................................................... 18

2.4

Criteria for project management success ............................................................. 19

2.4.1

The concept of project success................................................................................ 19

2.4.2

Project management success criteria ...................................................................... 20

2.4.2.1

Indicator 1: Completion within budget ................................................................................. 21

2.4.2.2

Indicator 2: Satisfying the project schedule ......................................................................... 21

2.4.2.3

Indicator 3: Adequate performance standard ...................................................................... 21

2.4.2.4

Indicator 4: Meeting project objectives. ............................................................................... 21

2.4.3

Indicator 5: Optimising trade-offs ............................................................................. 22

2.4.4

Project success criteria ............................................................................................ 22

2.5

Project management success factors ................................................................... 23

2.6

Role of the project manager towards project management success..................... 25

2.7

Organizational structure for projects ..................................................................... 27

2.8

Project management tools/techniques .................................................................. 28

2.8.1

Traditional methods (Gantt charts and wall charts) .................................................. 28

2.8.2

Concurrent engineering/management ...................................................................... 29

2.8.3

Project management information systems (PMIS) ................................................... 29

CHAPTER 3

3.1

RESEARCH FINDINGS AND ANALYSIS ............................................... 30

Introduction ........................................................................................................... 30

3.1.1

Core effluent project background ............................................................................. 30

3.1.2

The project management process used by the refinery ............................................ 31

3.2

Findings from interviews and project data ............................................................ 35

3.2.1

Interview 1: Drawing office supervisor ...................................................................... 35

3.2.2

Interview 2: Reliability and maintenance representative ........................................... 36

3.2.3

Interview 3: Electrical and Instrumentation stakeholder............................................ 39

3.2.4

Interview 4: Project manager ................................................................................... 40

3.2.5

Interview 5: Interview with customer (operations department) .................................. 42

3.2.6

Interview 6: Interview with mechanical contractor .................................................... 44

CHAPTER 4

SUMMARY, CONCLUSION AND RECOMMENDATIONS ..................... 46

4.1

Introduction ........................................................................................................... 46

4.2

Summary of main findings .................................................................................... 46

4.2.1

Interview 1: Drawing office supervisor ...................................................................... 46

4.2.2

Interview 2: Reliability and maintenance representative ........................................... 46

4.2.3

Interview 3: Electrical and instrumentation stakeholder ............................................ 46

4.2.4

Interview 4: Project manager ................................................................................... 47

4.2.5

Interview 5: Interview with customer (operations department) .................................. 47

4.2.6

Interview 6: Interview with mechanical contractor .................................................... 47

4.5

Recommendations ................................................................................................ 48

4.6

Further research ................................................................................................... 50

REFERENCES .................................................................................................................. 51

xi

List of Tables

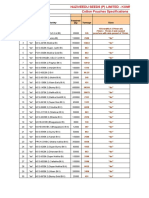

Table 1.1: Project management success criteria for Chevron projects ............................................ 5

Table 2.1: Individual competency model ....................................................................................... 17

Table 2.2: Critical factors in the project management life cycle ..................................................... 25

Table 2.3: Organisational structure and the project characteristics ............................................... 27

Table 3.1: Capital stewardship expectation table .......................................................................... 33

Table 3.2: Results of interview number 1 ...................................................................................... 36

Table 3.3: Results of interview number 2 ...................................................................................... 38

Table 3.4: Results of interview number 3 ...................................................................................... 40

Table 3.5: Results of interview number 4 ...................................................................................... 42

Table 3.6: Results of interview number 5 ...................................................................................... 44

Table 3.7: Results of interview number 6 ...................................................................................... 45

xii

List of Figures

Figure 1.1: Different types of projects undertaken at refinery (Refinery Project Data Base, 2007 2010) .............................................................................................................................................. 1

Figure 1.2: Typical structure for field projects at Chevron Refinery ................................................. 3

Figure 1.3: Typical structure for small capital projects at Chevron Refinery..................................... 3

Figure 1.4: Project life cycle .......................................................................................................... 8

Figure 1.5: Basic CPDEP road map ................................................................................................ 9

Figure 2.1: The Iron Triangle ...................................................................................................... 12

Figure 2.2: Definition of success over time .................................................................................... 19

Figure 4.1: Proposed project management success criteria for Chevrons Cape Town refinery

based on this research paper ........................................................................................................ 48

xiii

List definitions

Project

A project is a temporary endeavour undertaken to create a unique product or service

(PMBOK GUIDE, 2000:4).

Project

management

The application of knowledge, skills, tools and techniques to project activities to meet

project requirements (PMBOK GUIDE, 2000:5).

Munns and Bjeirmi defines it as the process of controlling the achievement of the

project objectives (1996:81). Project Management is accomplished through the use

of processes such as:

Initiating

Planning

Executing

Controlling

Closing

Project

management

success

The successful accomplishment of a project with regards to cost, time and

performance. The three dimensions indicate the degree of the efficiency of project

execution (Pinkerton, 2003:337)

Project success

In the modern project management era project success is define as the

accomplishment of a project within time, cost and quality and the project must be

accepted by the customer.

Field projects

Field projects are all capital projects with a project value of less than two million rand

(R2 million), regardless of the complexity of the project (Global Manufacturing

Capital Stewardship Expectations, 2009)

Small capital

projects

Small capital projects are all projects with a project value of more than two million

rand (R2 million) and less than twenty five million dollars ($25 million) regardless of

the complexity (Global Manufacturing Capital Stewardship Expectations, 2009).

Project life

cycle

Project life cycle defines the phases that connect the beginning of a project to its end

(Guide to the PMBOK, 2004:19). Burke (2007:273) on the other hand states that

project life cycle provides and informative overview of how the level of risk changes

as the project progresses through the project phases (concept, design, implement

and commission).

World class

performance

Project was within budget and schedule, meets client needs and was delivered injury

and incident free (Chevrons Project Managements Handbook, 2007:203).

CHAPTER 1

1.1

ORIENTATION

INTRODUCTION

The Chevron Cape Town refinery was constructed in 1996 with a crude capacity of 100,000 barrels

per day (bpd). The focus of the unit is production and meeting the nameplate market demand. The

project environment for the refinery is that of maintenance and gradual upgrade. The majority of

projects handled are small capital projects.

The majority of the projects at the refinery are undertaken due to five reasons namely

sustainability, replacement, growth, compliance and study. Figure 1.1 categories the different type

of projects undertaken at the refinery.

Category

8, 8%

34, 35%

25, 25%

26, 26%

Compliance

Growth

6, 6%

Replacement

Sustian

Study

Figure 1.1: Different types of projects undertaken at refinery (Refinery Project Data Base, 2007 - 2010)

Safety, which is supported at all management levels, is one of the core values of the Chevron

Corporation ensuring the safety of all employees. There is a general feeling amongst all project

managers that project management focuses more on safety in terms of costs and schedule and as

a result, Chevron projects take longer and costs are slightly higher than benchmarked projects in

other industries.

In the early 1990s, Chevron developed and deployed the Chevron Project Development and

Execution Process (CPDEP). Since then, additional processes and tools have been generated

and are continuously improved upon and refined to support and complement the CPDEP. The

CPDEP and its related processes and tools have evolved into the Chevron Project Management

(CPM) System, which is an organised and coordinated methodology that promotes and sustains

the successful execution of projects. Moving from a process to a system perspective is crucial to

Chevrons sustained success with major capital projects.

By moving from a process focus to a system focus, Chevron is enabling a more cohesive

integration of the various processes and tools to manage capital projects effectively.

It also

provides an opportunity to implement continuous improvement across the entire system and

ensures sustained organisational capability by applying the processes and tools to Chevrons

portfolio of projects.

The CPM System is comprised of five key components:

Project Management Process CPDEP provides the core process and framework, which

coordinates and aligns the other components.

Decision Making The decision making process and behaviours that guide the project

team and decision makers in making good quality decisions.

Project Assurance The reviews and assurance checks that are used to assess the

readiness of the project to proceed and help assure the project team is achieving a high

level of decision and execution quality.

Organisational Capability The people, processes, and practices that provide a means

to, develop organisational plans, acquire staff, and develop and lead an effective project

team.

Tools and Practices - The policies, standards, procedures, best practices, supporting

processes, and templates that enable the project team to plan and execute the project.

Chevron became the outright owner of the Cape Town refinery in 2002 and with it came the

expectation that the Chevron Project Development and Execution Process (CPDEP) would be

adopted for their projects.

The refinery has a project portfolio made up of a large number of field (short-term projects) and

small capital projects (long term projects). Chevron has introduced a project governance model for

projects that are linked to the CPDEP process.

Projects are categorised by value and the

expectation is that the higher the value, the more complex the project. Field projects are all

projects with a project value (total cost) of less than R2 million and small capital projects are all

projects with a project value of more than R2 million and less than R25 million . All projects above

the R250 million threshold are categorised as major capital projects. Major capital projects

normally involves stakeholders and clients outside the refinery fence, hence these projects are

managed and monitored on a corporate level.

1.2

PROJECT ENVIRONMENT AT THE REFINERY

The organisation follows a matrix structure, with team members seconded to projects from different

departments.

This in itself creates challenges for project managers to ensure that project

alignment and project integration management are maintained at the required levels to deliver

successful project management practices.

Figure 1.2 illustrates the team members of a typical project in the field projects department:

Figure 1.2: Typical structure for field projects at Chevron Refinery

Source: Chevron Project Management Manual (2007:103)

Within the field projects group, project managers usually fulfil a dual function - that of a project

manager and the discipline engineer (mechanical, electrical, instrumentation, information

technology, etc.) for most projects within the field category. This means that the field engineers are

fulfilling a project-engineering role, instead of a pure project management role.

Field projects are managed with a weak matrix team and the authority normally lies with the

functional manager of the operations group. Per definition, the project manager fulfils this coordinating role. The operations department is the most important client of the field group.

Figure 1.3 illustrates the team members of a typical project for the small capital project department:

Figure 1.3: Typical structure for small capital projects at Chevron Refinery

Source: Chevron Project Management Manual (2009:104)

Small capital projects are managed with a weak matrix team and the authority is equally spread

amongst the technical department, operations and external stakeholders. External stakeholders

refer to the sponsors and end users (commercial and sales department).

Most of the team

members are dedicated to a specific project on a full-time basis, but still reports to a separate line

manager. Much better alignment between functional departments is visible within the small capital

project department than the field project group.

The project support office provides services for both the field and small capital project

departments. The objectives of this department are as follows:

Routinely compare actual performance to cost, schedule and resource baseline.

Estimate/re-estimate cost, duration and resources needed to complete the project, by early

identification of changes to the project scope and proactively analysing performance.

Implement corrective actions when performance trends deviate from the baseline.

Promote accountability for meeting business plan and project objectives.

Develop an execution driven culture throughout the business unit.

Provide a summary level dashboard for tracking rolled-up performance of the refinerys

total project portfolio.

The construction department is an independent entity that provides services to the project manager

(field and small capital projects) concerning the execution of the project. For field projects, the

value added by the construction department is noticeable from phase three of the project cycle and

for small capital projects, the value added is visible from much earlier in the project cycle.

The procurement department provides services to the project manager through the entire project

cycle. The procurement department has has the reputation of causing bottlenecks for projects and

has implications on delivering projects on time and to some extent, on budget.

The refinery procurement department provides project managers with the following services:

Procurement / buying

Warehouse / stores management

Contracts management / legal contracts writing

Strategic sourcing / category management (high level strategic approach)

Business enablement / best practices

Starting a project is one of the key elements of a successful project.

The Chevron Project

Management System starts the process by making certain that the opportunity is aligned with the

strategic interests of the business unit and that it creates value, as well as assuring alignment

among the participants.

A high-level project plan is develop and communicated to the

stakeholders, followed by a detailed project execution plan.

In the early stages, project

alternatives are analysed to select the option that provides the optimal value for the

project.

1.3

PROBLEM STATEMENT

The aim of this research is to determine what the project management success criteria are for

refinery projects and how projects should be set up for future success. The success criteria

derived from this research should be useful to improve future projects.

Currently, Chevrons project management success criteria are somewhat traditional in their

expectations and are based on safety, cost, quality, and schedule. An additional criterion that is

important to take into consideration is operability. The project management success criteria are

mentioned in Table 1.1 below. The expectation is that each project puts up a world-class

performance and the measures to achieve this are also mentioned in Table 1.1 below.

Table 1.1: Project management success criteria for Chevron projects

Performance criteria

Success measure

Cost performance

Within a maximum tolerance of 10% of the authorised

value.

Scheduled performance

Within a maximum tolerance of 10% of the authorised

duration.

Zero recordable injuries and days away from work.

Safety performance

Operability

Within a maximum tolerance of 5% of the design

requirements.

Source: Chevrons Project Management Handbook (2009:203)

The cost performance criteria show that all projects need to come in under budget to achieve

world-class performance. The debate around this topic has been quite interesting at the refinery

because it uses a P50 (50% probability) cost estimation, which means that there is a fifty percent

chance that the project will under run and a fifty percent chance that the project will over run its

budget. The result is that if the corporation expects projects to come in under budget, the cost

estimate could no longer be a P50 but something a little higher and there is a chance that project

estimators will build an additional contingency into project estimates in order to come in under

budget. The schedule estimates are also based on the cost estimate but there is greater leniency

regarding the schedule so it has the chance of coming in both under and over schedule, which

seems to be it in the P50 range.

Safety is a core value at the corporation and safety performance expects to have zero incidents

and injuries. Project management staff is expected to introduce Chevrons safety standards for

every project undertaken at the refinery. These include following the incident and injury free safety

programme, which is based on behavioural observations. This means that peers observe each

other at the workplace and identify risky behaviour. An example of this is when a civil engineering

contractor lifts a steel reinforcement into an excavation for a column base but the weight of the

base is too heavy for the steel fixing team to lift. The observer would stop the job and expect a

mobile crane to help the team complete the task. The risky behaviour in this instance would be

damage to the teams backs if they lifted the reinforcement. Although it may not be painful in the

near future, too much exertion could create long-term back pain.

The operability (customer needs) criteria expects that if a plant upgrade was expected to deliver

10,000 barrels of crude oil a day, it would be acceptable to run 9,000 barrels a day. Chevron

expects all four criteria to be achieved to maintain a world-class performance.

With the tight schedule and cost pressures in the small project environment, the project

management practices and execution of small projects are accelerated or neglected.

In an

organisation where small capital projects are the main focus it is important to execute these

projects effectively.

For the purposes of this project, the research will look at the following problems within the small

capital project department:

The dual function of the project managers poses to be a career development problem for

them because project managers for small capital projects have to fulfil both a technical and

a project management role. This has been an issue for years at the refinery.

The support provided by the project support office concerning cost estimates, estimate

assurance, schedules, change control and reporting. Scheduling as a subject is not a main

stream course at tertiary institutions, one normally comes across it by chance. The result is

that most people have not received professional training in scheduling. At the same time,

employing experienced planners and keeping the existing ones is proving to be a difficult

task, especially in this industry. Various tools exist to assist the project support office.

These tools are stand-alone systems and a certain level of expertise is required to provide

quality reports to project managers and management.

Scope creep has resulted in large scheduling and costs overruns in the past and major

delays in projects.

The procurement department has been the cause of major bottlenecks for several years.

Several attempts have been made to improve the performance of the procurement

department, especially regarding service provision to the small capital project department.

Most of these attempts resulted in significant performance improvements in the

procurement department, but a lot still needs to be done.

Small capital projects represent approximately 90% of the refinerys capital budget and far exceed

the number of major capital projects. Why then is it important to execute and manage small

projects effectively?

The reasons are:

that small capital projects have short schedules, and performance changes have a quick

impact on project outcomes;

that building competency in small projects helps to grow large project competency.

Refinery operations are well known for tight profit margins and with the crude oil price reaching

record high levels in 2008, effective project management processes and practices became more

and more essential.

1.4

RESEARCH OBJECTIVES

The aim of this research is to identify what the project management success criteria should be for

projects carried out within the small capital projects department of Chevrons Cape Town refinery.

An important distinction to make is that this study looks at project management success and not

project success, although the aspects of project success will be discussed to highlight how closely

related the two concepts are. Project success is not directly proportional to project management

success and neither is project management directly proportional to project success.

Effective project management within the small capital project department is imperative for older

refineries where growth projects form the minority of the departments project portfolio, with

compliance and sustain projects forming the majority of the projects.

Chevrons focus on project management is based on the drive to improve the return on capital

employed (ROCE) and to achieve superior long-term shareholder returns.

Effective project

management will enable the refinery to:

Select investments with a higher return more value for money spent

Execute the same projects for less money than the competitors do.

1.5

LITERATURE REVIEW

1.5.1

Project life cycle

A number of different life cycle models exist in project management. Gray and Larson (2009:6)

state that some project managers find it useful to use the project life-cycle as the cornerstone for

managing projects. According to Gray and Larson (2009:6) the project life cycle plays a vital role

in:

recognising that any project has a limited life span;

ensuring that there are predictable changes in the level of effort and focus over the life of

the project.

The starting point begins the moment the project has been given the go ahead. For most projects

the efforts in the beginning start slowly, builds to peak, and then declines to the delivery of the

projects (see figure 1.4 below).

Figure 1.4: Project life cycle

Source : Gray and Larson (2009:6-7)

In practice, the project life-cycle is used by some project groups to estimate or re-estimate the

timing of major tasks over the life of the project, like when the team plan a major commitment of

resources in the defining stage.

A driving force behind the rapid demand for project management in todays world is the shortening

of the product life-cycle (Gray and Larson, 2009:7). Today, high-tech industries have product life

cycles averaging 1 to 3 years, compared with 30 years ago when product life cycles averaged 10

to 15 years. A common rule of thumb in the world of high-tech product development is that a sixmonth product delay can result in a 33 percent loss in product revenue. Emphasising how effective

project management can provide businesses with a competitive advantage.

1.5.2

Project life cycle used by the refinery

The Chevron Development and Execution Process (CPDEP) is the core process for project

management within the Chevron Project Management System. CPDEP is a phase-gated process

designed to improve decision-making and execution of projects by fostering better planning,

collaboration, and communication.

The key objectives of the CPDEP phase-gated process are to:

Improve project decision making

Improve project execution

Create better alignment of team members, decision makers and shareholders

The phase-gated process is a team-orientated process that provides overall structure and a

sequence of work steps that are consistent across all types of projects. The most common

representation of CPDEP is the five-phase road map shown in Figure 1.5 below.

BASIC CPDEP ROAD MAP

PHASE 1

Identify and Assess

Opportunities

Decisions

Deliverables at

Major Reviews

These deliverables

provide the information

needed for decision

makers to make their

decisions. The key

deliverables are

collated into a

comprehensive

Decision Support

Package (DSP) to

ensure a high quality

decision.

Focus Items

Focus items can be

shown on the Road Map,

or simply documented in

the PEP. These Focus

Items indicate work that

will be completed to

produce deliverables

necessary for effective

decision making.

PHASE 5

Operate and Evaluate

To Phase 1

STOP, HOLD,

or RECYCLE

STOP, HOLD,

or RECYCLE

Endorser(s) ______________

Decision Executive ________

Decision Review Board_____

Endorser(s)______________

Decision Executive ________

Decision Review Board_____

Endorser(s) ___________________

Decision Executive _____________

Decision Review Board__________

Endorser(s) ______________

Decision Executive ________

Decision Review Board_____

Proceed

with

Development of

Preferred Alternative

& Approve Phase 3

Plan?

Framing Document,

Preliminary Assessment,

Forward Plan

Project Manager/Team Leader

________________________

Work Team_______________

________________________

Develop Frame

Discovery

Definition

Structure

Preliminary Assessment

Project Management

Practices & VIPs

Phase 1 DEQ Assessment

Seek and Incorporate

Lessons Learned

CPDEP for Change

Assessment

Others as needed

Developed the Business Case

Develop Project Execution

Plan (PEP) for Phase 2

Road Map

PEP Objectives& Strategies

Detailed Plans as needed

Overall Project Schedule

Other Focus Items

______________________

______________________

Recommended

Alternative(s)

Project Manager/Team Leader

________________________

Work Team ______________

________________________

Update Frame

Refine & add further detail

Generate Alternatives

Define Scope for Alternatives

sufficiently to support

evaluation

Analyze Alternatives

Value/Benefits

Costs

Schedule

Uncertainties & Risks

Narrow and Select

Alternatives

Update the Business Case

Project Management Practices

& VIPs

Phase 2 DEQ Assessment

Seek and Incorporate

Lessons Learned

Others as needed

Develop Project Execution

Plan (PEP) for Phase 3

Road Map

PEP Objectives& Strategies

Detailed Plans as needed

Overall Project Schedule

Other Focus Items

__________________________

Accept

Plan?

Proceed

with

Operations &

Approve

Operating

Plan?

Proceed

with Execution,

Approve Funding

and Phase 4

Plan?

Fully

Defined

Scope

Execution Plan,

Funding Request

Project Manager/Team Leader ____

_____________________________

Work Team ___________________

_____________________________

Endorser(s) ______________

Decision Executive ________

Decision Review Board_____

Pursue

New

Opportunities?

DSP Document

Opportunity

Identified

Proceed

with

Generating Alternatives

& Approve

Phase 2 Plan?

NEW OPPORTUNITIES

DSP Document

The decision makers,

as defined in CSOC,

responsible for project

decisions and ultimate

project outcomes.

PHASE 4

Execute

STOP, HOLD,

or RECYCLE

DSP Document

Decision

Makers

PHASE 3

Develop Preferred

Alternative

STOP, HOLD,

or RECYCLE

DSP Document

The decision diamond

represents key

decisions and serves to

delineate phases. The

decision can be to stop,

hold, recycle or

proceed.

PHASE 2

Generate and Select

Alternative(s)

Project Manager/Team Leader

________________________

Work Team ______________

________________________

Execute Business Plan

Fully Define and Freeze Scope

Complete Detailed Design

Begin Detailed Design

Consistently Execute defined Operate Asset

Plans

Monitor and Evaluate

Performance

Finalize Business Plan

Project Management Practices &

VIPs

Phase 3 DEQ Assessment

Seek and Incorporate Lessons

Learned

Others as needed

Develop Project Execution Plan

(PEP) for Phase 4

Road Map

PEP Objectives& Strategies

Detailed Plans as needed

Overall Project Schedule

Develop Funding Request

Other Focus Items

_____________________________

_____________________________

Finalize Operating Plan

Identify New Opportunities

Project Management

Practices & VIPs

Seek and Incorporate

Lessons Learned

Others as needed

Other Focus Items

Project Management

Practices & VIPs

Seek and Incorporate

Lessons Learned

Others as needed

Other Focus Items

_________________________

_________________________

The process does not

end here! Secondary

opportunities and

projects will loop

back into the

appropriate phase.

Operations

Metrics

New

Opportunities

Operable

Assets

Project Manager/Team Leader

________________________

Work Team ______________

________________________

New

Opportunities

Work Team

The multifunctional

work team carries out

the work under the

guidance of the

project manager or

team leader.

Expectations of the

decision makers are

met through frequent

communication and

alignment checks.

________________________

________________________

Chevron Project Development and

Execution Process (CPDEP) Principles:

Focus on key value drivers for the opportunity

Use of integrated multifunctional teams

Effective input, communication and alignment between

teams, decision makers, and stakeholders

Decision driven, not activity driven - do the work

necessary to support the next decision

Consistent use of best practices and tools

Rev_14-Jan-2010

2010 Basic CPDEP Roadmap.ppt

Figure 1.5: Basic CPDEP road map

Source: Chevrons Project Manual Handbook (2009)

10

1.6

RESEARCH DESIGN AND METHODOLOGY

The outcome of this research will be qualitative in nature resulting from a proposed case study.

The mode of observation or sources of data will be participant observation, with semi-unstructured

individual or group interviews and the use of documentary sources and other existing data. The

unstructured interview process will be carried out with six individuals who are stakeholders in

projects carried out at the refinery. The discussions with the participants will play a key role in

identifying project management success criteria as projects move through the project management

life cycle.

The interview process will develop a table which can be used to represent project success criteria

at the refinery. Once these criteria have been identified, the discussion will involve the importance

that these criteria have as different categories of project are concerned.

The semi-unstructured interviews will start by asking senior project managers what they think the

main problems are that needs attention in this research study. The literature study will then focus

around these problem areas, followed by an in-depth study on the documentary sources available

and the unstructured interviews with the six participants.

The main problem is that each project is unique and the question arises whether different category

projects should be managed in different ways or is whether each project is so different that their

uniqueness needs to be respected even at the project management level. Another consideration

would be whether elapsed time has an impact on the criteria identified

1.7

CHAPTER SUMMARY

The velocity of change required to remain competitive or simply keep up has created an

organization climate in which hundreds of projects are implemented concurrently. Sharing and

prioritizing resources across a portfolio of projects in a multiproject environment like at the Cape

Town refinery has proven to be a major challenge for senior managers at the refinery. It as to be

highlighted that many firms has no idea of the problems involved with the inefficient management

of small projects.

A question that this research is trying to address is how to create an

organizational environment that supports mulitproject management. The criteria developed for

project management success in this research should assist the organization with achieving more

accountability, flexibility, innovation, speed, and continuous improvement with regards to project

management.

11

CHAPTER 2

2.1

LITERATURE REVIEW

INTRODUCTION

Kerzner (2004:1) states that for more than 35 years project management was viewed as a process

that might be nice to have, but not one that was necessary for the survival of the firm. Project

management was viewed as a threat to established lines of authority and, in most cases, only

partial project management was used. In the 1950s, project management was defined as the

application of a collection of tools and techniques to direct the use of diverse resources toward the

accomplishment of a unique, complex, one-time task within time, cost and performance. By the

mid-1990s companies started to change this mentality largely due to two reasons:

Companies were under severe competitive pressure to create quality products in a shorter

period of time.

The importance of developing long-term relationships with the customers had come to the

forefront, the survival of the company was now at stake.

Each task requires a particular mix of these tools and techniques structured to fit the task

environment and project life cycle from conception to completion of the task (Atkinson, 1999:337342). The main criteria identified from what is commonly known as the iron triangle (shown in

Figure 2.1) is still used to this day even though it is considered inadequate because of other criteria

like safety and meeting the objectives of the client.

Project management is a field of practice that promotes a normative approach to the management

of projects. It is codified in standards, tools and techniques, based primarily on experiences of

practitioners in developed Western economies and relies extensively on assumptions of economic

rationality (Muriithi & Crawford, 2003:310). Project management applies knowledge, skills, tools

and techniques to project activities to achieve project requirements. The art of project management

is accomplished through the application and integration of the project management processes of

initiating, planning, executing, monitoring, controlling and closing (PMBOK Guide, 2004:8).

Project management varies from project to project, which makes it imperative to define what a

project is. A project involves a single, definable purpose, end-item, result or outcome, usually

specified in terms of cost, schedule, and performance requirements. Turner (1993:44) defines a

project as an endeavour in which human, material and financial resources are organised in a

novel way, to undertake a unique scope of work of given specification within constraints of cost and

time so as to achieve beneficial change defined by quantitative and qualitative objectives.

12

Figure 2.1: The Iron Triangle

Source: Atkinson, 1999:340

2.2

PROJECT MANAGEMENT PROCESS

According to Cleland and Ireland (2004:53) project management involves five processes: initiating,

planning, executing, controlling and closing. These processes are based on the assumption that

project managers are rational problem solvers who are able to identify and apply rational problem

solving models to projects. These processes follow the sequence in which they are listed. In the

event that a project goes off course, re-planning comes into play, and if a project is found to be in

serious trouble, it may have to go all the way back to the initiating process to be re-started.

2.2.1

Initiation

In this stage, a project is launched after the decision has been made to undertake a project. The

project sponsor creates a project charter that defines what needs to be done in order to meet the

customers requirements. The charter should be used to authorise work on the project, define the

authority, responsibility, and accountability of the project team, and establish scope boundaries for

the job (Cleland & Ireland, 2004:53).

2.2.2

Planning

Planning is the most crucial part of the project, as it determines the outcome of the project. Lack of

planning or no planning at all results in project failure. Failure to plan makes it impossible to control

the project in cases of hiccups (Cleland & Ireland, 2004:53).

2.2.3

Executing

The execution stage has two aspects to it. The first is the technical aspect where the focus is on

execution to create the product. The second aspect is implementing the project plan. This

13

facilitates easy control of the project when encountering difficulties. It is easy to take corrective

measures to get back on track when following a well laid out plan (Cleland & Ireland, 2004:53).

2.2.4

Monitoring and controlling

Control is exercised by comparing where project work is to where it is supposed to be, then taking

action to correct any deviations from the target. Controlling is done by monitoring progress. In

monitoring, the quantity and performance are assessed with the tools available for the particular

project. The results of the assessment are compared to the plan and if there are major deviations,

mitigation plans are applied to put the project back in line. (Cleland & Ireland, 2004:54).

In every project that goes well there are always minor deviations, which are usually ignored unless

they exceed the pre-established threshold or if they could potentially drift further off course.

2.2.5

Closing

Cleland and Ireland (2004:53) stated the in many cases, once the product is produced to the

customers satisfaction, the project is considered finished which should not be the case. A final

lessons-learned review should be done before the project is considered complete. Failing to do a

lessons-learned review means that future projects will likely suffer the same headaches

encountered on the one just done.

2.3

PROJECT MANAGEMENT FUNCTIONS

In project management, there are nine broad project management functions or knowledge areas

(Artto, Lehtonen & Saranen, 2001:255). These include the management of integration, scope, time,

cost, risk, quality, human resources, communications and procurement. These nine functions are

managed through the project management life cycle. Thus the knowledge, skills, tools and

techniques are applied to manage scope, organisation, quality, cost, time and risk, from initiation

and concept through to hand-over (termination) in a rolling, iterative process.

2.3.1

Project integration management

The guide to the PMBOK (2004:337) state that project integration management includes the

processes and activities needed to identify, define, combined, unify and coordinate the various

processes and project activities within the project management process groups. In the project

management context, integration includes characteristics of unification, consolidation, articulation

and integrative actions that are crucial to project completion, successfully meeting customer and

stakeholder requirements and managing expectations.

processes include:

The project integration management

14

Develop project charter developing the project charter that formally authorises a project.

Develop preliminary project scope statement developing the preliminary project scope

statement that provides a high-level scope narrative .

Develop project management plan documenting

the actions necessary to define,

integrate, and coordinate all subsidiary plans into a project management plan.

Direct and manage project execution executing the work defined in the project

management plan to achieve the projects requirements defined in the project scope

statement.

Monitor and control - monitoring and controlling the processes required to initiate, plan,

execute, and close a project to meet the performance objectives defined in the project

management plan.

For the project to produce the desired outcomes, it should be well coordinated. The project

integration management ensures that coordination by guaranteeing that the project is properly

planned, executed and controlled.

2.3.2

Project scope management

The guide to the PMBOK (2004:338) states that project scope management includes the

processes required to ensure that the project includes all the work required, and only the work

required, to complete the project successfully. Project scope management is primarily concerned

with defining and controlling what is and is not included in the project.

The Project scope

management processes include:

Scope planning creating a project scope management plan that documents how the

project scope will be defined, verified, and controlled, and how the work breakdown

structure (WBS) will be created and defined.

Scope definition developing a detailed project scope statement as the basis for future

project decisions.

Create a WBS subdividing the major project deliverables and project work into smaller,

more manageable components.

Scope verification formalising acceptance of the completed project deliverables.

Scope control controlling changes to the project scope.

Burke (2007:116) states that effective scope management as one of the key factors determining

project success. Failure to accurately interpret the clients needs or problems will produce a

misleading scope of work, therefore project management success could be limited.

15

2.3.3

Project time management

The guide to the PMBOK (2004:338) states that project time management includes the processes

required to accomplish timely completion of the project. The project time management processes

include:

Activity definition identifying the specific schedule activities that need to be performed to

produce the various project deliverables.

Activity sequencing identifying and documenting dependencies among activities.

Activity resource estimating estimating the type and quantities of resources required to

perform each schedule activity.

Activity duration estimating estimating the number of work periods that will be needed to

complete individual scheduled activities.

Schedule development analysing activity sequences, durations, resource requirements,

and schedule constraints to create the project schedule.

2.3.4

Schedule control controlling changes to the project schedule.

Project cost management

The guide to the PMBOK (2004:338) states that project cost management involves estimating of

project cost by covering cost of all resources such as human, material, equipment, plant, travelling

expenses and other support details. These expenses are budgeted and tracked to ensure that the

project is running within budget. The project cost management process include:

Cost estimating developing an approximation of the costs of the resources needed to

complete project activities.

Cost budgeting aggregating the estimated costs of individual activities or work packages

to establish a cost baseline.

Cost control influencing the factors that create cost variances and controlling changes to

the project budget.

2.3.5

Project performance management

The Guide to the PMBOK (2004:339) states that project performance management includes the

processes and activities of the performing organisation that determine performance policies,

objectives and responsibilities so that the project will satisfy the needs for which it was undertaken.

It implements the quality management system through policy and procedures, with continuous

process improvement activities conducted throughout, as appropriate. The project performance

management processes include:

Performance planning identifying which quality standards are relevant to the project and

determining how to satisfy them.

16

Performance assurance applying the planned, systematic quality activities to ensure that

the project employs all processes needed to meet requirements.

Performance control monitoring specific project results to determine whether they comply

with relevant quality standards and identifying ways to eliminate causes of unsatisfactory

performance

Project performance management covers two aspects: performance assurance and performance

control. Performance assurance is achieved through intensive planning to meet the performance

requirements while performance control involves following certain steps to monitor results and

check if they conform to the specified requirements. If performance management is overlooked, it

can result in project failure.

2.3.6

Project human resource management

This refers to the identification of people required to execute the job, defining their roles and

responsibilities and relationships. After identifying these people, they should be acquired and

managed to execute the project.

Cleland and Ireland (2004:11-17) states that project management competency is an essential

building block for an organisations future growth and profitability. Competency depends on the

personal characteristics of an individual, reflected in his or her knowledge, skills, and attitude,

where knowledge consist of suitable familiarity, awareness and comprehension acquired by

experience and study. Skill on the other hand is the ability of the individual to apply the knowledge,

with attitude referring to the persons state of mind or feeling.

The challenge that most companies have is that competency is expressed in so many ways within

organisations, and different levels of positions within an organisation may apply different

definitions.

The following table indicates an individual competency model that can be used to determine the

competency of a project manager and a method of promoting understanding and appreciation of

top performers. It can also be used as a guideline to define job grades of project managers within

organisations.

17

Table 2.1: Individual competency model

Knowledge + Skills + Attitude = Competency

Knowledge:

Skills:

Attitude:

Familiarity, awareness, or

comprehension acquired by study

The ability to apply

knowledge

A state of mind or feeling

Project Technology

Strategic management

Project management theory

and practice

Project management

process

Project management

systems model

Interpersonal skills

Maslows needs

Communication

skills

McGregors

Theory X and Y

Systems

applications

Authority &

Responsibility

Political sensitivity

Emotional

Intelligence

Building conceptual

models

Source: Cleland and Ireland (2004:17)

2.3.7

Project communication management

The guide to the PMBOK (2004, 340) states that project communication management includes the

processes required to ensure timely and appropriate generation, collection, distribution, storage,

retrieval, and ultimate disposition of project information. The project communication management

processes provide the critical links among people and information that are necessary for

successful communication.

Project managers can spend an inordinate amount of time

communicating with the project team, stakeholders, customer, and sponsor. Everyone involved in

the project should understand how communication effects the project as a whole.

Project

communication management processes include:

Communication planning determining the information and communication needs of the

project stakeholders.

Information distribution making the needed information available to project stakeholders

in a timely manner.

Performance reporting collecting and distributing performance information, including

status reporting, progress measurement, and forecasting.

Manage stakeholders managing communication to satisfy the requirements, and resolve

issues with project stakeholders.

Any information that effects the project and the needs of the project stakeholders such as the

project status, accomplishments and relevant events needs to be communicated. Communication

management involves planning, executing and controlling the acquisition and broadcasting of all

relevant information required by the stakeholders.

18

2.3.8

Project risk management

The guide to the PMBOK (2004:340) states that Project risk management includes the processes

concerned with conducting risk management planning, identification, analysis, responses,

monitoring and the control of a project. The objectives of project risk management are to increase

the probability and impact of positive events and decrease the probability and impact of events

adverse to the project objectives. Project risk management processes include:

Risk management planning deciding how to approach, plan, and execute the risky

management activities for a project.

Risk identification determining which risks might affect the project and documenting their

characteristics.

Quality risks analysis prioritising risks for subsequent further analysis or action by

assessing and combining their probability of occurrence and impact.

Quantitative risks analysis - numerically analysing the effect on overall project objectives of

identified risks.

Risk response planning developing options and actions to enhance opportunities and to

reduce threats to project objectives.

Risk monitoring and control tracking identified risks, monitoring residual risks, identifying

new risks, executing risk response plans, and evaluating their effectiveness throughout the

project life cycle.

2.3.9

Project procurement management

The guide to the PMBOK (2004:341) states that project procurement management includes the

processes to purchase or acquire the products, services, or results needed from outside the project

team to perform the work.

Project procurement management includes the contract management and change control

processes required to administer contracts or purchase orders issued by authorised project team

members.

Project procurement management also includes the administration of any contract

issued by an outside organisation (the buyer) that is acquiring the project from the performing

organisation (the seller) as well as administrating the contractual obligations placed on the project

team by the contract. Procurement management processes include:

Plan purchases and acquisitions determining what to purchase or acquire and

determining when and how to do this.

Plan contracting documenting products, services, and result requirements and identify

potential sellers.

19

Request seller response obtaining information, quotations, bids, offers, or proposals, as

appropriate.

Select sellers reviewing offers, choosing from amongst potential sellers, and negotiating a

written contract with a seller.

Contract administration managing the contract and the relationship between the buyer

and seller, reviewing and documenting how a seller is performing or has performed to

establish the required corrective actions and provide a basis for future relationships with the

seller, managing contract related changes and, when appropriate, managing the

contractual relationship with the outside buyer of the project.

Contract closure completing and settling each contract, including the resolution of any

open items, and closing each contract.

2.4

CRITERIA FOR PROJECT MANAGEMENT SUCCESS

2.4.1

The concept of project success

This research is conducted to determine the project management success criteria of capital

projects at the Chevron Cape Town refinery, but the fundamentals of project management and

project success criteria and success factors needs to be established first.

Kerzner (2004:29-32) states that during the traditional period, project success was measured in

technical terms only. This mainly occurred because the project objectives were also defined in

technical terms only. During the renaissance period, cost and quality became equally important as

technology. The definition of success changed to a project being finished in time, within cost and at

the appropriate technical level or quality. The modern project management includes the need of

the customer and not the manufacturer. With this definition one realises that acceptable

performance is determined by the customer and not by the manufacturer.

The definition of project success has changed over the years, as shown in figure 2.2.

Figure 2.2: Definition of success over time

Source : (Kerzner, 2004:29-33)

20

2.4.2

Project management success criteria

In the past decades, project management success was usually indicated by the project completion

within the time, cost and performance constraints (Kerzner, 2004:29). This has now evolved to an

understanding of all the objectives of a project. Project management can still be deemed

successful even if it did not meet all the objectives of the project and vice versa, as long as there

are mutual trade-offs agreed upon by the developer (project manager) and the client.

White and Fortune (2002:1-11) conducted a survey to identify common criteria used for defining

project management success.

The three criteria identified for measuring project success are

completion on time, within budget and according to performance specification.

However, these are not the sole principles by which success is determined - the fit between the

project and the organisation and the coincidences of the project for the performance of the

business were also reported as important criteria. Furthermore, the survey revealed that factors

such as a realistic schedule, adequate funds and resources as well as clear objectives play a

significant role in the project management success.

On the other hand, project management success is also dependent on the abilities of a project

manager. The attributes of a project manager that contributes to project management success of

the project are his/her abilities to plan, solve problems, monitor, network, inform, motivate, solve

conflicts, support , consult, develop, reward and delegate. According to Hyvaris (2006:216-225)

study, it seems that planning/organising, networking and forming are the most significant

managerial practices in the leadership behaviour of project managers.

The overall findings of Hyvaris (2006:216-225) study implies that technical project management

tools and methods are so developed and widely used that now that it is time to turn the focus on

developing leadership skills. The most important factors in project management success are

classified into three categories, namely project participants, communication and information

exchange and the system development process.

The common project management success indicators are completion to budget, satisfying the

project schedule, adequate quality standard and meeting project objectives (Munns & Bjeirmi,

2001:81-87). But the project manager (pm) cannot be held responsible if the objectives were

incorrectly defined. In which case, the project will be a failure but the project management is still

successful.

21

2.4.2.1 Indicator 1: Completion within budget

The budget refers to the allocation of monetary resources to the project. Completion of a project

within the estimated budget is a good indication of project management success. According to the

Chevron Basic Project Management Manual (2009:3), cost estimation is the predicting or

forecasting of the cost of constructing and equipping a facility to manufacture goods, or to provide

a service. Cost estimation also provides the project manager and management with a realistic

representation of the final project costs at any stage of project development to meet a specific

project objective.

Chevron expects that the actual project cost be within 10 percent of the

authorised value for a project to be declared successful concerning cost management.

2.4.2.2 Indicator 2: Satisfying the project schedule

The schedule portion projects the desired completion date of the project, using the exact date for

the day of completion. The purpose of the schedule is to create a systematic process for creating a

project schedule, which is likely to be predictable and credible. This promotes effective

management with specific, tactful decisions about the task, sequence and time for project

completion.

Chevron expects that the actual project cost be within 10 percent of the authorised value for a

project to be declared successful concerning cost management.

2.4.2.3 Indicator 3: Adequate performance standard

This indicator captures the portion of the desired result relative to the (set) required standards of

the quality of the completed work.

2.4.2.4 Indicator 4: Meeting project objectives.

The fourth indicator comprises of the first three. It describes what the project is to accomplish,

when it is to be accomplished and how much it will take to accomplish it. To be able to use this

indicator, the project objective statement is set to be clear, concise and quite effective.

The

objectives should clearly define major deliverables as the primary project outcomes as they will be

used as the basis for judging the success of the project (Harvard Business School, 1997). Major

deliverables serve as a primary tool that focuses managements attention on the key project

outcomes.

22

2.4.3

Indicator 5: Optimising trade-offs

The essence of effective optimisation is examining the entire project plan and developing creative

means for making it more efficient (Harvard Business School, 1997). Any component of the

project can be changed or adjusted as long as the changes are done in a systematic way, visible to