Академический Документы

Профессиональный Документы

Культура Документы

Sea Water Chlorination

Загружено:

E.C.MADHUDUDHANA REDDYАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Sea Water Chlorination

Загружено:

E.C.MADHUDUDHANA REDDYАвторское право:

Доступные форматы

Sea Water Chlorination

Use of chlorine for control of biological fouling in power plant cooling water system is the most effective way of controlling

bio-fouling at reasonable concentration as chlorine is available at a low cost. Chlorine Gas feeders are simple and easy to

control at low capital cost and requires minimum maintenance. The chlorine residual for shock dosing can be relatively short

and in expensive. De-toxification (dechlorination) systems can be installed at a very nominal cost to meet the environmental

requirement.

Total residual chlorine (TRC) as expressed in red book of United States of Environmental Protection Agency (EPA) specifies

0.2 mg/litres TRC. It should not exceed 160 minutes for 24 hours.

Point of chlorine dosing in Sea Water

Normally the sea water for power plant is taken deep in the sea at Sea water intake head. The sea water travels through

intake pipe and reaches the CW pump sump from where the water is pumped to the condenser.

Continuous and Shock dosing chlorination

In Sea water application both continuous and shock dosing chlorination are applied for effective bio fouling.

Continuous chlorination

At sea water intake head of inlet pipe, continuous dosing of approx. 1 - 2 ppm will be effective in control of Mollusks, algae,

slime and weed. They constrict the flow of Sea water in the intake pipe. It also prevents sea shell deposition in the pipeline

which is a most trouble-some to remove.

Continuous chlorine dosing is done near to the pump house ahead of bar racks and traveling water screen. 1-2 ppm is

recommended so that the complete bar racks and traveling water screen can be kept clean and free from any bio fouling.

This will also ensure the pump sump and pump suction side free from any slime growth. The free residual chlorine and the

condenser outlet can be measured to determine the chlorine dosing as the chlorine demand of sea water varies according to

the season and also the quality of the sea water.

Shock dosing chlorination - Dosing point No.3

Shock dosing of chlorination is done effectively at 1 - 5 ppm depending upon the quality of sea water. The recommended

dosing time is one cycle time for every 8 hours shift which would be sufficient to keep the condenser cooling surface free

from bio fouling and maintain the efficiency of the condenser and power generation.

Theory of Sea Water chlorination

In Sea water at pH 7.4 - 8.1 less than 50% of chlorine is available as fast acting Hypochlorous acid. However Sea water also

contains 60 mg/litre (ppm) bromide ion which displaces the chlorine, being a stronger oxidizing agent to produce

hypobromous acid.

Cl2 + H20 --------- HOCL + H+ + ClHOCL + Br ---------- HOBr + ClWhen chlorine is dissolved in water, it hydrolyzes rapidly according to the above equation. The rapidity of the reaction can be

expressed that the chlorine molecule reacting with hydroxyl ion rather than with the water module.

Cl2 + OH- ------- HOCL + Cl

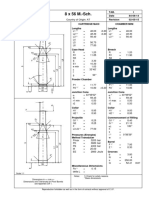

CHLORINE DOSING POINTS

This reaction is of great practical important relating to the chemistry of aqueous chlorine solution discharging from

chlorination equipment. From the chlorinator outlet the chlorine solution is always limited by design to less than 3500

mg./litre of chlorine in water. At this concentration the most highly buffered solution will result pH of not more than 3. At this

pH the amount of molecular chlorine in equilibrium with HOCl is substantial. Concentration higher than 3500 mg/l causes

excessive chlorine gas release, at the point of application which is not desired.

Considering sea water at pH 8 the reaction by addition of chlorine with sea water will result in the presence of HOCl, OCl,

HOBr and OBr and will act to create the hostile environment for living organism. We will have 70% to 90% HOBr as

extremely rapid toxicant.

The aim of chlorination is to achieve Hypochlorous acid (HOCL) and hypochlorite ion(OCl which will be effective in

preventing fouling of the cooling water circuits. The fundamental objective in water chlorination is to create hostile

environment which will discourage marine organisms from establishing themselves and growing on the internal surfaces of

PIPE WORK AND CONDENSER SURFACE. The hostile environmental is created and maintained by continuous

chlorination.

Fouling control with chlorine dosage

The control of algae and slime in the pipe work and condensers can be achieved by shock/intermittent chlorination. The level

of continuous chlorination and level of frequency and duration of intermittent shock chlorination varies from one area to

another. It also depends upon the season of the year depending on biological activity and quality of water. The optimum

treatment is achieved by operating experience.

Continuous chlorination dosing level is in the region of 0.3-2 ppm. Shock chlorination dosing level is practiced at 2-5 ppm for

1 cycle time for every 4-8 hours. The practice with natural sea water chlorination is to monitor the total 30 minutes demand.

The water is dosed with certain quantity of equivalent chlorine. The residual is measured after 30 minutes. The difference

between the initial dose level and the residual level is reported as the chlorine demand.

Only shock dosing chlorination is not sufficient for effectively treating the sea water. When shell forming organisms grow in

the water, they attach themselves to the piping. Even if the organism is killed by Shock chlorination, the dead remains

attached to the piping and subsequently can break free and clog the piping with disastrous results. Continuous chlorination

prevents settlement and growth of marine organisms. Various tests conducted indicates residual of 0.1 mg/litre will prevent

the growth of marine organisms.

Вам также может понравиться

- Diesel Engines For Vehicles D2066 D2676Документ6 страницDiesel Engines For Vehicles D2066 D2676Branislava Savic63% (16)

- The DIRKS Methodology: A User GuideДокумент285 страницThe DIRKS Methodology: A User GuideJesus Frontera100% (2)

- Power Plant Instrumentation and Control HandbookДокумент5 страницPower Plant Instrumentation and Control HandbookE.C.MADHUDUDHANA REDDYОценок пока нет

- PPM or ORP Which Should Be UsedДокумент6 страницPPM or ORP Which Should Be UsedmairaaguilarОценок пока нет

- EPMS System Guide For Subcontractor - V1 2Документ13 страницEPMS System Guide For Subcontractor - V1 2AdouaneNassim100% (2)

- Lecture 10 RCLДокумент14 страницLecture 10 RCLPinku KhanОценок пока нет

- Paper On Water TreatmentДокумент9 страницPaper On Water Treatmentiulyan007Оценок пока нет

- Session Objectives: DisinfectionДокумент23 страницыSession Objectives: DisinfectionOscar AcebalОценок пока нет

- Chlorine Effective Disinfectant in Aquaculture: Claude E. Boyd, PH.DДокумент2 страницыChlorine Effective Disinfectant in Aquaculture: Claude E. Boyd, PH.DPhu NguyenОценок пока нет

- 2.4 Disinfection by Boiling and ChlorinationДокумент8 страниц2.4 Disinfection by Boiling and Chlorinationa_mohid17Оценок пока нет

- Chlorine and Drinking Water TreatmentДокумент4 страницыChlorine and Drinking Water TreatmentRajesh CheОценок пока нет

- Chlorination and DechlorinationДокумент5 страницChlorination and DechlorinationbandarОценок пока нет

- (Ebook) (Survival) Water Purification - Drinking Water Chlorination PDFДокумент4 страницы(Ebook) (Survival) Water Purification - Drinking Water Chlorination PDFcamohunter71Оценок пока нет

- PPSPL - Olympic Size S. Pool PresentationДокумент50 страницPPSPL - Olympic Size S. Pool PresentationYUNUS SAYYEDОценок пока нет

- Dowex Ion Exchange Resins Biological Fouling Prevention LДокумент6 страницDowex Ion Exchange Resins Biological Fouling Prevention LAlgirdas BaranauskasОценок пока нет

- Disinfection SlidesДокумент29 страницDisinfection SlidesptfОценок пока нет

- Water Chlorination: Zahid HussainДокумент10 страницWater Chlorination: Zahid HussainZAHID HUSSAINОценок пока нет

- Tertiary TreatmentДокумент24 страницыTertiary TreatmentHrithik BaradiaОценок пока нет

- DisinfectionДокумент5 страницDisinfectiondave tafadzwa kuyeriОценок пока нет

- Water DisinfectionДокумент2 страницыWater DisinfectionGuy SelaОценок пока нет

- Lecture 7 DisinfectionДокумент31 страницаLecture 7 DisinfectionSgakilОценок пока нет

- Chapter 6Документ33 страницыChapter 6Solomon DesalegnОценок пока нет

- Bryce Lang The Fundamentals of Private Swimming Pool OperationДокумент25 страницBryce Lang The Fundamentals of Private Swimming Pool OperationJay SuguitanОценок пока нет

- Chlorination CalculationsДокумент23 страницыChlorination CalculationsOkwajja ClementОценок пока нет

- ChlorinationДокумент7 страницChlorinationJomer Levi PortuguezОценок пока нет

- Swimming Pool Service Technicians Study GuideДокумент11 страницSwimming Pool Service Technicians Study GuideIndikaОценок пока нет

- So, What's The Difference?Документ7 страницSo, What's The Difference?William EdwardsОценок пока нет

- CH Lori NationДокумент17 страницCH Lori NationJayraj MakwanaОценок пока нет

- Management of Potable WaterДокумент25 страницManagement of Potable WaterDedah IssaОценок пока нет

- Water Disinfection: A Practical Approach To Calculating Dose Values For Preharvest and Postharvest ApplicationsДокумент0 страницWater Disinfection: A Practical Approach To Calculating Dose Values For Preharvest and Postharvest ApplicationsAgrim KhatryОценок пока нет

- Chlorination and Optimal Chlorine Dosage For Nile Water: April 2005Документ12 страницChlorination and Optimal Chlorine Dosage For Nile Water: April 2005RobovenОценок пока нет

- Chlorine Use in Produce Packing LinesДокумент5 страницChlorine Use in Produce Packing LinesGerman Antonio Aviles OrellanaОценок пока нет

- CCEWQ 05 ChlorinationDrinkingWtrДокумент6 страницCCEWQ 05 ChlorinationDrinkingWtrPrasenjit DeyОценок пока нет

- Miscellaneous Treatment MethodsДокумент25 страницMiscellaneous Treatment Methodsjong LacОценок пока нет

- Lec 17 Week14Disinfection1Документ20 страницLec 17 Week14Disinfection1Muhammad Husnain IjazОценок пока нет

- Water Quality Tests: E. Coli Is A Group of Bacteria Whose Presence IndicatesДокумент1 страницаWater Quality Tests: E. Coli Is A Group of Bacteria Whose Presence IndicatesPanda BeruОценок пока нет

- Water DisinfectionДокумент2 страницыWater DisinfectionGuy Sela100% (1)

- AVIA BestPractice WaterChlorination 2019 enДокумент8 страницAVIA BestPractice WaterChlorination 2019 enEduardo ViolaОценок пока нет

- Groundwater ChlorinationДокумент21 страницаGroundwater ChlorinationrareszОценок пока нет

- Chlorination of Drinking Water - 4 July 2013Документ1 страницаChlorination of Drinking Water - 4 July 2013F H MughalОценок пока нет

- How To Shock The Pool 2022Документ12 страницHow To Shock The Pool 2022Kaira Patel 653Оценок пока нет

- Swimming Pool Maintenance TipsДокумент7 страницSwimming Pool Maintenance TipsSwimming Pool DubaiОценок пока нет

- Drinking Water TreatmentДокумент4 страницыDrinking Water TreatmentEuqenaej AladedoОценок пока нет

- Water Treatment Booklet White LabelДокумент18 страницWater Treatment Booklet White LabelWater supplyОценок пока нет

- Swimming Pool Maintenance: Steps To Remove Algae in Swimming PoolsДокумент7 страницSwimming Pool Maintenance: Steps To Remove Algae in Swimming PoolsRAKESH REDDYОценок пока нет

- Chemical Injection Technologies: Technical BulletinДокумент2 страницыChemical Injection Technologies: Technical BulletinacastromОценок пока нет

- What Is ChlorinationДокумент12 страницWhat Is Chlorinationcristina23Оценок пока нет

- Chlorine DoseДокумент14 страницChlorine DoseRidwan AzizОценок пока нет

- Fressure Filter, Softening &disinfectionДокумент30 страницFressure Filter, Softening &disinfectionAmirОценок пока нет

- Chlorine DioxideДокумент9 страницChlorine Dioxidejavier mascherano100% (1)

- Cooling Water Chlorination: Chlorine ChemistryДокумент4 страницыCooling Water Chlorination: Chlorine Chemistrymnasiroleslami100% (1)

- DWT SWRORedOxДокумент12 страницDWT SWRORedOxMohamed MotaweaОценок пока нет

- ChlorineДокумент4 страницыChlorinektm_kannanОценок пока нет

- Water PurificationДокумент53 страницыWater PurificationVerdah Sabih100% (1)

- Pool Diagram: Basic Explanation of Pool Circulation SystemДокумент17 страницPool Diagram: Basic Explanation of Pool Circulation SystemAnonymous x1s2CfSОценок пока нет

- Basic Chemistry of Chlorination PDFДокумент8 страницBasic Chemistry of Chlorination PDFalexmuchmure2158Оценок пока нет

- Topic 2 Chlorination & SamplingДокумент108 страницTopic 2 Chlorination & SamplingCrisnuel RamirezОценок пока нет

- Pipeline Disinfection and FlushingДокумент7 страницPipeline Disinfection and FlushingEmilAbdoОценок пока нет

- Standard methods for the examination of water and sewageОт EverandStandard methods for the examination of water and sewageОценок пока нет

- How Reverse Osmosis Works: A Look at Industrial ROОт EverandHow Reverse Osmosis Works: A Look at Industrial ROРейтинг: 2.5 из 5 звезд2.5/5 (2)

- Hmi ListДокумент1 страницаHmi ListE.C.MADHUDUDHANA REDDYОценок пока нет

- Cimplicity Machine Edition LD PLC Training 14 Sep 07Документ1 страницаCimplicity Machine Edition LD PLC Training 14 Sep 07E.C.MADHUDUDHANA REDDYОценок пока нет

- Data Overview - Sr. Project EngineerДокумент1 страницаData Overview - Sr. Project EngineerSYedZYnAleОценок пока нет

- Fittings For BoДокумент15 страницFittings For BoE.C.MADHUDUDHANA REDDYОценок пока нет

- Proposed Plan For Field Trials of Generic MPC For SH Steam Temperature Control at NTPL 2 X 500 MW TPP Site, TuticorinДокумент3 страницыProposed Plan For Field Trials of Generic MPC For SH Steam Temperature Control at NTPL 2 X 500 MW TPP Site, TuticorinE.C.MADHUDUDHANA REDDYОценок пока нет

- Scoop Control Electronics: Contrac Eas 822Документ1 страницаScoop Control Electronics: Contrac Eas 822E.C.MADHUDUDHANA REDDYОценок пока нет

- Senior Instrument Engineer Key ResponsibilitiesДокумент2 страницыSenior Instrument Engineer Key ResponsibilitiesE.C.MADHUDUDHANA REDDYОценок пока нет

- P Roposed Modification Scheme To Analyse Effluent Discharge WaterДокумент1 страницаP Roposed Modification Scheme To Analyse Effluent Discharge WaterE.C.MADHUDUDHANA REDDYОценок пока нет

- 2yoga and Naturopathy Based Treatment For 21 DiseasesДокумент37 страниц2yoga and Naturopathy Based Treatment For 21 Diseasesmuthuswamy77Оценок пока нет

- NAMUR Proximity Switches: Connection DiagramsДокумент1 страницаNAMUR Proximity Switches: Connection DiagramsE.C.MADHUDUDHANA REDDYОценок пока нет

- SL - No. Manpower Qty Type 1 C&I Engineer 1 Person in Each Shift 4 Engineer 2 C&I Supervisor 1 Person in Each Shift 4 HSKДокумент1 страницаSL - No. Manpower Qty Type 1 C&I Engineer 1 Person in Each Shift 4 Engineer 2 C&I Supervisor 1 Person in Each Shift 4 HSKE.C.MADHUDUDHANA REDDYОценок пока нет

- 771 Ma Process Clamp Meter: The Fluke 771 Is The Latest Innovative Approach To Measuring Ma Loop SignalsДокумент1 страница771 Ma Process Clamp Meter: The Fluke 771 Is The Latest Innovative Approach To Measuring Ma Loop SignalsE.C.MADHUDUDHANA REDDYОценок пока нет

- Central Electricity Regulatory CommissionДокумент2 страницыCentral Electricity Regulatory CommissionE.C.MADHUDUDHANA REDDYОценок пока нет

- ReturnДокумент1 страницаReturnE.C.MADHUDUDHANA REDDYОценок пока нет

- PushДокумент1 страницаPushE.C.MADHUDUDHANA REDDYОценок пока нет

- Zero Spped ImageДокумент1 страницаZero Spped ImageE.C.MADHUDUDHANA REDDYОценок пока нет

- Coal India Recruitment For Management Trainees 2017Документ8 страницCoal India Recruitment For Management Trainees 2017nidhi tripathi100% (1)

- Why Shri and Shrimati Does Not Mean MR and MrsДокумент2 страницыWhy Shri and Shrimati Does Not Mean MR and MrsE.C.MADHUDUDHANA REDDYОценок пока нет

- VibДокумент4 страницыVibE.C.MADHUDUDHANA REDDYОценок пока нет

- CMC (Coordinated Master Control)Документ28 страницCMC (Coordinated Master Control)Anoop Kumar Allanki100% (4)

- Zero Speed Switch JayashreeДокумент1 страницаZero Speed Switch Jayashreedilip kumarОценок пока нет

- SL. No Description UOM QTYДокумент2 страницыSL. No Description UOM QTYE.C.MADHUDUDHANA REDDYОценок пока нет

- Workshop On "Temperature Sensors & It's Calibration": Register Now Register NowДокумент1 страницаWorkshop On "Temperature Sensors & It's Calibration": Register Now Register NowE.C.MADHUDUDHANA REDDYОценок пока нет

- Grav Feeder Commng ProcedureДокумент5 страницGrav Feeder Commng ProcedureE.C.MADHUDUDHANA REDDYОценок пока нет

- Family ReliefДокумент2 страницыFamily ReliefE.C.MADHUDUDHANA REDDYОценок пока нет

- PrmaДокумент4 страницыPrmaE.C.MADHUDUDHANA REDDYОценок пока нет

- Energy EfficiencyДокумент28 страницEnergy Efficiencygajendra2010Оценок пока нет

- Turbine Efficiency Ch-8.1Документ8 страницTurbine Efficiency Ch-8.1E.C.MADHUDUDHANA REDDYОценок пока нет

- Cultural ProgrammeДокумент2 страницыCultural ProgrammeE.C.MADHUDUDHANA REDDYОценок пока нет

- Vanguard 44 - Anti Tank Helicopters PDFДокумент48 страницVanguard 44 - Anti Tank Helicopters PDFsoljenitsin250% (2)

- JIMMA Electrical&ComputerEngДокумент219 страницJIMMA Electrical&ComputerEngTewodros71% (7)

- 8 X 56 M.-SCH.: Country of Origin: ATДокумент1 страница8 X 56 M.-SCH.: Country of Origin: ATMohammed SirelkhatimОценок пока нет

- Catalogo PukangДокумент41 страницаCatalogo PukangClarita Muller LeigueОценок пока нет

- Not CE 2015 Version R Series 1t-3.5t Operating Manua 2015-08Документ151 страницаNot CE 2015 Version R Series 1t-3.5t Operating Manua 2015-08hocine gherbiОценок пока нет

- Docket - CDB Batu GajahДокумент1 страницаDocket - CDB Batu Gajahfatin rabiatul adawiyahОценок пока нет

- OsciloscopioДокумент103 страницыOsciloscopioFredy Alberto Gómez AlcázarОценок пока нет

- S-Sapfico-Satyanarayanamaterial 121212Документ183 страницыS-Sapfico-Satyanarayanamaterial 121212mpsing1133Оценок пока нет

- Ticket: Fare DetailДокумент1 страницаTicket: Fare DetailSajal NahaОценок пока нет

- BSNL BillДокумент3 страницыBSNL BillKaushik GurunathanОценок пока нет

- Linux ProgramДокумент131 страницаLinux ProgramsivashaОценок пока нет

- Final SEC Judgment As To Defendant Michael Brauser 3.6.20Документ14 страницFinal SEC Judgment As To Defendant Michael Brauser 3.6.20Teri BuhlОценок пока нет

- Electronics 11 02566Документ13 страницElectronics 11 02566卓七越Оценок пока нет

- 2010 Information ExchangeДокумент15 страниц2010 Information ExchangeAnastasia RotareanuОценок пока нет

- EC 2012 With SolutionsДокумент50 страницEC 2012 With Solutionsprabhjot singh1Оценок пока нет

- ID25bc8b496-2013 Dse English PaperДокумент2 страницыID25bc8b496-2013 Dse English PaperSimpson WainuiОценок пока нет

- 4039-Texto Del Artículo-12948-3-10-20211123Документ14 страниц4039-Texto Del Artículo-12948-3-10-20211123Ricardo ApazaОценок пока нет

- Physiol Toric Calculator: With Abulafia-Koch Regression FormulaДокумент1 страницаPhysiol Toric Calculator: With Abulafia-Koch Regression FormuladeliОценок пока нет

- Acceptable Use Policy 08 19 13 Tia HadleyДокумент2 страницыAcceptable Use Policy 08 19 13 Tia Hadleyapi-238178689Оценок пока нет

- TechBridge TCP ServiceNow Business Case - Group 6Документ9 страницTechBridge TCP ServiceNow Business Case - Group 6Takiyah Shealy100% (1)

- CandyДокумент24 страницыCandySjdb FjfbОценок пока нет

- CV Ashish PDFДокумент3 страницыCV Ashish PDFRoshan KejariwalОценок пока нет

- Session 10. Value Proposition.Документ69 страницSession 10. Value Proposition.Bibhu R. TuladharОценок пока нет

- Wordbank 15 Coffee1Документ2 страницыWordbank 15 Coffee1akbal13Оценок пока нет

- Blackbook 2Документ94 страницыBlackbook 2yogesh kumbharОценок пока нет

- How To Change Front Suspension Strut On Citroen Xsara Coupe n0 Replacement GuideДокумент25 страницHow To Change Front Suspension Strut On Citroen Xsara Coupe n0 Replacement Guidematej89Оценок пока нет

- Unit-Ii Syllabus: Basic Elements in Solid Waste ManagementДокумент14 страницUnit-Ii Syllabus: Basic Elements in Solid Waste ManagementChaitanya KadambalaОценок пока нет