Академический Документы

Профессиональный Документы

Культура Документы

Water Testing-January 2010

Загружено:

lalindaОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Water Testing-January 2010

Загружено:

lalindaАвторское право:

Доступные форматы

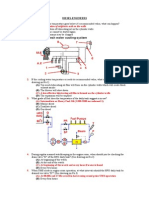

INSTITUTE OF ENGINEERING TECHNOLOGY - KATUNAYAKE

1.1.4 WATER TESTING AND TREATMENT

It is important to control the hydrogen ion concentration of water to

minimize corrosion as it makes water acidic when the PH value is low

(discussed in the previous lecture see notes.)

Chemical additives can be added to condition the water in order to

reduce the acidity ie hydrogen ion concentration and hence the ph

value. Acids lower PH value alkalis increase ph value.

To give alkalinity to water the most common additives used are. Sodium

hydroxide caustic soda or sodium carbonate and Ca(OH)2

It is been studied in oxygen must be present to accomplish the formation

of metal oxide therefore it is very important to reduce the amount of

oxygen in the water whether it is a cooling water system or boiler water

oxygen comes mainly from the air and de aeration can be achieved by

mechanically or chemically or a combination of both.

Mechanical method may be accomplished by using an air ejector in the

system.

Chemicals used for oxygen scavenging and deaerating the water, are

usually sodium sulphite or hydrazine.

Sodium Sulphite + Oxygen

Sodium sulphate

2Na2SO3 + O2

2Na2SO4

When added to boiler water the sodium sulphate which is formed

remains in solution under normal conditions causing no problems.

(Increase boiler water density disadvantage)

Use of Hydrazine solution (60% hydrazine 40% water approximately)

Hydrazine + Oxygen

Water + Nitrogen

N 2 H 4 + O2

2H2O + N2

Advantage of using hydrazine does not increase boiler water density.

(Hydrazene reacts with any metal oxide therefore a controlled excess is

beneficial)

Marine Engineering Department

Page 1 of 19

INSTITUTE OF ENGINEERING TECHNOLOGY - KATUNAYAKE

It is important to know the salts presenting natural water

and

evaporated as it is widely used for cooling of man machinery and as

make up feed for low pressure boilers.

The salts dissolved in natural water are metallic salts of sodium,

Magenesium, Calcium.

The standard method of measuring the metallic salt content parts per

million or P.P.M.

FRESH WATER SAMPLE ANALYSIS

SALT

SYMBOL

P.P.M.

Sodium Chloride

Na Cl

50

Sodium Nitrite

Na NO3

35

Magnesium Sulphate

Mg SO4

30

Calcium Sulphate

Ca SO4

90

Calcium Carbonate

Ca CO3

200

Marine Engineering Department

Page 2 of 19

INSTITUTE OF ENGINEERING TECHNOLOGY - KATUNAYAKE

ANALYSIS OF SEAWATER

Average sea water contains approximately 32,000 p.p.m. of total

dissolved solids.

Salt

Chemical

Symbol

Sodium chloride

Approximate %

of total dissolved

solids

p.p.m.

79

25,000

Nacl

Magnesium Chloride

Mg Cl2

10

3,000

Magnesium Sulphate

Mg SO4

2,000

Calcium Sulphate

Calcium Bicarbonate

Ca SO4

Ca (HCO3)2

Less than 1

1,200

200

HARDNESS SALTS

Alkaline Hardness salts are

Hydroxides

Carbonates

Calcium

of

Magnesium

Bicarbonates

Bicarbonates of calcium and magnesium are called temporary

hardness. Because they are decomposed by heating or boiling the

water boiling they liberate carbon dioxide CO2 and leave the

carbonates.

Calcium Bicarbonate.

Ca[HCO3]2

Marine Engineering Department

Page 3 of 19

INSTITUTE OF ENGINEERING TECHNOLOGY - KATUNAYAKE

Calcium carbonate

Calcium carbonate + Carbon dioxide + water

Calcium carbonate has a low solubility and solubility decreased as temp

increase it can therefore form scale.

Non Alkaline or permanent hardness salts are the chlorides, Sulphates,

Nitrates due to these salts is not removed by boiling or heating the salts

can be removed by chemical treatment.

Total hardness is therefore is the sum of alkaline and non alkaline

hardness.

SCALE FORMATION AND SLUDGE FORMATION

Steam bubble is formed upon the heating surface the plate under the bubble

overheats as it is insulated momentarily from the water.

The water containing salts is in contact with the periphery of the bubble. If the

salts are those which decrease in solubility as temperature increases.

Bubble

Periphery of

bubble overheats

Overheating

Moment

insulation

from water

They are deposited in the form of

a crystal ring. This is because the

water is supersaturated locally

with the salts.

When the bubble bursts the

water comes in contact with the

plate overheated plate, local

overheating occurs and more

salts are deposited.

Therefore salts whose solubility decrease with increase of temp are those

which form scale upon heating surfaces and sludge upon the cooling surfaces.

Marine Engineering Department

Page 4 of 19

INSTITUTE OF ENGINEERING TECHNOLOGY - KATUNAYAKE

Salts whose solubility increase with increase in temp do not

normally form scale upon heating surfaces. But sludge may be

formed if their saturation point is reached.

EFFECTS OF USING SEA WATER AS BOILER FEED WATER

As studied earlier sea water contains following. Dissolved solids, ie

sodium Chloride - Nacl, Magnesium Chloride Mg Cl 2, Magnesium

Sulphate, Calcium Sulphate, Calcium Bicarbonate Ca(HCO3).

Sodium Chloride (NaCl)

Heavy concentrations Solubility Variable

-

Cause foaming and priming

Increase of temp and Pressure

Solution Of Each Salt Is Variance With Tem

Some chlorides some not of solution

2Na Cl2 + Mg SO4

Mg Cl2 + Na2SO4

Mg Cl2 insoluble under normal boiler conditions.

Mg Cl + 2H2O

Mg (OH)2

HCL

Mg (OH)2 + 2H Cl

Low Solubility

can deposit and form scale

Can cause corrosion

2 HCL + Fe

Fe CL2 + H2

Fe Cl2 + 2 H2O

Fe (OH)2 + 2HCl

Marine Engineering Department

Page 5 of 19

INSTITUTE OF ENGINEERING TECHNOLOGY - KATUNAYAKE

Corrosive Cycle continues

Magnesium Sulphate (Mg SO4)

Soluble under normal boiler conditions

If density too high

Nacl + Mg SO4

Deposit form scale

Mg Cl2 + Na SO4

Calcium Sulphate (Ca SO4)

Most dangerous -

Forms scale - Tenacious & Hard

Effects heat transfer - Failure of heating surface.

Calcium bicarbonate (CaHCO3)

Decomposes when heated

Ca(HCO3)2

CaCO3 -

CaCO3

+ CO2 +H2O

Has low solubility decreases with increase of temp can form scale

(soft and porous) not be bad as CaSo4 when heat transfer is

concerned.

Fresh water as boiler feed water

It is better than using sea water as the dissolved salts are much less than in

sea water chance of forming and priming reduced hardness salts will cause

scale formation to a lesser much degree than sea water. (Most low pressure

boilers use fresh water for their feed).

Distilled water as feed water

Obviously very much less dissolved solids (must for high pressure boilers. With

high evaporation rates etc.)

Marine Engineering Department

Page 6 of 19

INSTITUTE OF ENGINEERING TECHNOLOGY - KATUNAYAKE

(Blowing down of boiler regularly)

THE PRINCIPAL OBJECTS OF BOILER WATER TREATMENT

(1).

To prevent scale formation in boiler and feed system.

(a). Using distilled water (B) Precipitating all scale forming salts

into the non adhering sludge.

(2).

To prevent corrosion in the boiler and feed system by maintaining

the boiler water in an alkaline condition and free from dissolved

gases.

(3).

To control the sludge formation and prevent carry over with steam.

(4).

To prevent foreign matter entering the boiler oil, waste, mill scale,

iron oxide, copper particles sand, weld spatter.

Before pre commissioning clean well

Watch the drains

Do not allow corrosion in condensate system.

PHOSPHATE

TREATMENT

3CaCO3

3Na2CO3

2Na3PO4

Marine Engineering Department

Ca3(PO4)

+

Page 7 of 19

INSTITUTE OF ENGINEERING TECHNOLOGY - KATUNAYAKE

Calcium Carbonate + Tri Sodium phosphate

3CaSO4

+2Na3PO4

Calcium sulphate + Tri Sodium phosphate

3CaCl2

+ 2Na3PO4

Calcium Chloride + Tri Sodium phosphate

Mg SO4

+2Na3PO4

Calcium sulphate + Tri Sodium phosphate

Calcium

Phosphate

Sodium

carbonate

Ca3(PO4)2 +

Calcium

Phosphate

3Na2SO4

+

Sodium

sulphate

Ca3(PO4)2 +

6NaCl

Calcium

Phosphate

+

Sodium

chloride

Mg3(PO4)2 +

3Na2SO4

Magnesium +

Sodium

Phosphate

Sulphate

By using in sodium phosphates sodium carbonate is formed. Due to the sneak

down of the sodium carbonate sodium hydroxide is essentially formed and their

makes the water moderately alkaline.

Tri Sodium phosphate is directly add to the boiler since they are guide to

react and could form scale in the feed water system.

Marine Engineering Department

Page 8 of 19

INSTITUTE OF ENGINEERING TECHNOLOGY - KATUNAYAKE

Other phosphate Sodium Hecata phosphate

Sodium Phosphate

Di Sodium phosphate Poured directly into

Tri sodium phosphate the BLR.

Due to the calcium removal by the phosphate the tendency for these silicate

present at the water to form scale is greatly reduced. They tend to remain in

solution.

Phosphate treatment is suitable for low as well as high pressure boilers.

LIME

AND SODA TREATMENT.

Internal softening : Traditionally this is achieved by Injecting lime - Ca(OH)2

and soda

Soda may be in the form of Na2 Co3 or caustic soda NaOH

Lime react with temperarory hardnes salt

Soda react with permanent hardness salt.

These chemicals are used in conjunction with the suitable coagulants such

as starch and tannin to condition the sludge finaly to form a flocculent flock.

Sodium aluminate is used to remove the traces of oil from the boiler if

such contamionation has taken place.

.

The density gives an idea of the total dissolved solids.

An electric salinometer may also be used.

The range of scales are,

TYPE OF BOILER

WATER TUBE

PRESSURE

SCOTCH VERTICA

upto

17.5-31.5 31.5-42

~

17.5 bar

bar

bar

PPM

PPM

PPM

PPM

PPM

42-60

60-84

bar

bar

PPM

PPM,

ALKAIANITY TO

PHINOPTHALIN

ENOLF IN FHA-

Marine Engineering Department

Page 9 of 19

INSTITUTE OF ENGINEERING TECHNOLOGY - KATUNAYAKE

300-700 300-500 150-300 150-300 100-150 50-100

50-H

CAUSTIC

ALKALINITY

150-500

150-400

75-200

100-250

50-1.00

40-60

40-60

3000

INO

300

150

I50

50

30

7000

3000

1500

1000

500

500

300

50-100

50-100

50-100

50-100

20-50

0.1-1.0

0.1-1.0

10-50

20-30

CHLORIDES

(MAX.)

DISOLVED

SOLIDS (MAX.)

HARDNESS(MAX.)

SULPHITE

or

HYDRAZINE

PHOSPHATE

30-70

30-50

BOILER WATER TESTS

Boiler water should be regularly tested and the treatment of the boiler water

should be conducted according to the results obtained from the tests.

For low pressure boilers such as the multitubular Scotch, verti cal Cochran or

thimble tube, salinometer and litmus papers are still frequently used as

testing equipment.

Salinometer

The range of the scale is normally from 0 to -J~ and when the salinometer is

floating in pure water at 93C which has a relative density at that

temperature of unity, the salinometer reading is zero. When the

salinometer is floating in solutions of common salt at 93C the salinometer

reading is -A7 (approx. 32,000 p.p.m.) when the relative density of the

solution is 1.025. (The relative density of salt water at 93C is

approximately 1.025 or- on the salinometer.)

Marine Engineering Department

Page 10 of 19

INSTITUTE OF ENGINEERING TECHNOLOGY - KATUNAYAKE

If sea water is used as make up feed for low pressure boilers it is

recommended that the boiler density should be maintained as close as

possible to A- (approx. 125,000 p.p.m.). This would be attained by resorting

to blow down. The use of sea water as make up feed for boilers should be

avoided as far as possible, but if it has to be used a certain amount of

protection for the boiler can be provided by using soda ash.

Litmus Papers

These are used to ascertain the degree of acidity or alkalinity of the water. A

litmus paper when inserted into a sample of boiler water may change colour,

turning blue if the water is alkaline, or red if the water is acidic. The degree of

colouration is a very rough indication of the pH value of the boiler water.

For accurate testing of the boiler water, the foregoing salinometer and litmus

paper methods are inadequate. Table 4.9 gives recommended values for low

and high pressure boilers, to ascertain whether these values are being

maintained, more refined testing methods are used.

Alkalinity

Tests for alkalinity are as follows:

(1) Alkalinity to Phenolphthalein

Take 100 ml sample of boiler water,

add N/ 50 sulphuric acid to clear the sample.

Calculation: ml of N/ 50 acid used x 10 = P-P- In- CaCO3

Phenolphthalein is less alkaline than hydroxides or carbonates, and when it is

added to a sample containing hydroxides and or carbonates it will turn pink in

colour. The acid used after this colouration will first neutralise the

hydroxides, forming salts, it %~ III then react with the carbonate molecules

present forming bicarbonate molecules. Bicarbonate molecules are less

alkaline than phenolphthalein, hence, the pink colouration will disappear

once all the hydroxides and carbonates have been dealt with by the acid. One

bicarbonate molecule is formed from two carbonate molecules, hence in the

test the quantity of acid used is a measure the alkalinity due to the

hydroxides (caustic) present and half the carbonates.

(2).

Total alkalinity

Take alkalinity to phenolphthalein sample,

Marine Engineering Department

Page 11 of 19

INSTITUTE OF ENGINEERING TECHNOLOGY - KATUNAYAKE

add 10 drops of methyl-orange, result yellow colouration, add N 50

sulphuric acid until pink

Calculation: ml of N / 50 acid used for both tests x 10 = p.p.m. CaCO3.

(3) Caustic Alkalinity

Take 100 ml sample of boiler water,

add 10 ml of barium chloride,

add 10 drops of phenolphthalein, result pink colouration, add N; 50

sulphuric acid to clear the sample.

Calculation: ml of N / 50 acid used x 10 = p.p.m. CaCO3.

In this test barium chloride is first added to the boiler water sample in order

to precipitate all the carbonates which are present. The test is then carried out

as for the alkalinity to phenolphthalein test but in this case only the hydroxides

(caustic) will be measured.

Chloride Test

Take alkalinity to phenolphthalein sample,

add 2 ml of sulphuric acid,

add 20 drops of potassium chromate indicator,

add N / 35.5 silver nitrate solution until a brown colouration

results.

Calculation: ml of N / 35.5 solution used x 10 = p.p.m. C1

or ml of N / 50 silver nitrate solution used x 10 = p. p.m. Ca CO3

Sulphite Test

Take 100 ml of boiler water sample,

add 2 ml of sulphuric acid,

add 1 ml of starch solution

add potassium iodide-iodate solution until sample is blue in colour

Calculation: ml of iodide-iodate solution used x 12.5 = p.p.m.

Na2SO3.

Marine Engineering Department

Page 12 of 19

INSTITUTE OF ENGINEERING TECHNOLOGY - KATUNAYAKE

Phosphate Test

Take 50 ml of hot water sample,

add 4 grams of potassium nitrate crystals, put 25 ml

of the above into a test tube,

stand test tube in a water bath at 38 to 40C, add 5 ml

of ammonium molybdate reagent.

A sample of boiler water which contains sodium phosphates

and dissolved potassium nitrate will turn cloudy when ammonium

molybdate is added. This reaction to produce a cloudiness in the

sample is quicker the larger the quantity of phosphates present.

If the cloudiness does not result until after five minutes have

elapsed, the phosphate reserve in the boiler water is too low

(below- 20 p.p.m.). If the cloudiness results before two minutes

have elapsed, the phosphate reserve is too high (above 70

p.p.m.). It will be appreciated that the sample of boiler water

must be hot in order to dissolve the crystals.

Hardness Test

Take 100 ml of boiler water sample,

add 0.2 ml at a time, standard soap solution,

shake vigorously after each addition of soap until a lather

persists for at least five minutes.

Calculation: ml of soap solution used x 10= p.p.m. CaCO3

equivalent.

pH Value

A boiler water's pH value can be obtained by three basic methods.

(1) Litmus papers.

(2) Colourl metrically.

(3) Electrolytically.

The litmus paper method has already been described but the test does not

give a very accurate pH result, indicating merely if the water is acidic or

alkaline. Tests (2) and (3) however give a reasonably accurate pH value

Total Dissolved Solids

These are ascertained by use of a hydrometer or electrical conductivity

meter.

Hydrometer: vdrometer: Usually graduated in grains per imperial gallon (to convert

grains per imperial gallon to p.p.m. multiply by 14.3). Care must be taken

Marine Engineering Department

Page 13 of 19

INSTITUTE OF ENGINEERING TECHNOLOGY - KATUNAYAKE

when using the hydrometer to account for the water meniscus and to

ascertain accurately the temperature of the sample. Temperature correction

tables for the hydrometer are usually supplied with it.

Conductivity Meter: A portable, battery operated, electrical conductivity

meter is used in this test. The removable conductivity cell is washed out and

filled with a treated boiler water sample (treatment consists of cooling to

15 to 20 C, adding phenolphthalein and removing pink colouration

with acid). The filled cell is plugged into the meter, its temperature

checked and the temperature control set to correspond. A range switch is set

to approximate range of reading expected, then a central control is operated

until 'null' balance of the electrical bridge circuit (the cell forms one

resistance) is achieved. Position of the central control indicates the

total dissolved solids in the water usually in p.p.m. but it may be

conductivity in micromhos (to convert; p.. p.m. total dissolved solids =

conductivity in micromhos x 0.7)

WATER SIDE ATTACK IN DIESEL ENGINES.

Great importance is attached to the need for water treatment and it is

recommended that specialist advice is always taken to protect engine from

Marine Engineering Department

Page 14 of 19

INSTITUTE OF ENGINEERING TECHNOLOGY - KATUNAYAKE

damage that can be caused by the use of untreated water in engine spaces,

where damage has occurred but is only correct water treatment can be

expected to arrest it. For modem large slow speed two stroke engine the

builder recommend to use evaporated water. Evaporated water has a l o w

salinity,

w h i c h c a n p ro v i d e t h e l i n e r s u r f a c e w i t h a protective

coating.

Cast iron cylinder liners and jackets are subjected to the following forms of

attack.

I.

Corrosive attack

2. Galvanic attack

3. Cavitations erosion

4. Velocity erosion or impingement attack

Corrosive attack

This results from the use of unsuitable coolant and/or the incorrect application

of the water treatment. The presence of free or dissolved oxygen will

accelerate the attack. The pH value of coolant is of particular importance,

acidic waters with pH below seven will attack ferrous metals and

alkaline waters with pH above 9 will attack aluminum alloy. Presence of

free carbon dioxide can also cause this form of attack. CO2 is released when

dissolved by carbonate are heated above 710C.

Galvanic action

This occurs between dissimilar metals unsuitable water conditions.

Cavitations erosion.

It is the result of vibration of the cylinder liner wall. This cause the

collapse of small air or vapor bubbles and subjects the wall to localize

hydraulic hammering. This form of attack is usually confined to the thrust

face of the cylinder wall. Attention must be paid to over come the cause

of abnormal vibration excessive piston slap may also cause this attack.

Marine Engineering Department

Page 15 of 19

INSTITUTE OF ENGINEERING TECHNOLOGY - KATUNAYAKE

Velocity erosion

This can result from excessive coolant velocity created by restriction in

the water system. This is aggregated by the presence of abrasive particals.

Cylinder heads

Corrosion of the cylinder head water spaces will invariably result from

untreated Water. The resulting reduction in material section can result in

fatigue cracking allowing leakage of water into the combustion space

cylinder head cracking can also be caused by local overheating due either

to the deposition of scale, loss or reduction of water circulation or retention

of air in the coolant passages in the head.

It is essential that water treatment be employed in all engine cooling

system as soon as the engine goes into service. Some inhibitors provide

chemical protection and pH control while others deposit a protective film

on the waterside surfaces. Some inhibitors contains anti-freeze chemicals

like sodium benzoate or sodium nitrate.

The instruction supplied with an inhibitor must be strictly adhered to

particularly in respect to dosage/ strength. The presence of chlorides in

the water can greatly aggravate corrosion. Normally the maximum limit

of 250-300 ppm should be observed and better if it is less than 100 ppm.

Mechanical consideration.

If piston or ring clearances are allowed to become excessive increased

vibration of the cylinder walls may result in acceleration of cavitations attack.

Hard water

Hard water contains salts in solution and when heated these salts come out

of solution to forma hard deposit of scale in the jackets and cylinder heads in

the engine.

Control of acidity and alkalinity

Sodium benzoate and sodium nitrite both these compounds have good

corrosion inhibiting properties. But their efficiency is very much improved

when employed in combination/. They form an invisible film of insoluble

products on the surface.

Marine Engineering Department

Page 16 of 19

INSTITUTE OF ENGINEERING TECHNOLOGY - KATUNAYAKE

Sodium Nitrite and sodium silicate

Here sodium nitrite provides protection of cast iron and steel and sodium

silicate prevents attack on soldered joints.

Soluble oils:

This is a special anticorrosion oil which is completely immulsifiable in water

and acts as a corrosion inhibitor. When introducing soluble oil to an engine

already in service it is very essential to ensure that all rubber hoses are

nitrite lined and other rubber joints and seals in contact with the coolant are

of nitrite rubber.

Recommendation for scale and corrosion control in diesel engine

cooling system;

Present practice is to reduce the risk of scale formation and corrosion attack in

cooling systems using a combination of acceptable quality cooling water

and a suitable corrosion inhibitor. If hard water is Used calcium scale

deposits, which can accumulate and act as an insulator, which may

cause overheating resulting in excessive cylinder liner wear and possible

fracture corrosion may also cause serious damage to cylinder jackets,

piping, pumps etc. The water used in the engine should not have hardness

contain as calcium carbonate above 100 ppm and the chloride contain or

the sulphate contain should not exceed 50 ppm.

There are three corrosion inhibitors, which are suitahle.1br engines.

1. Nitrite Borate

2. Chromates

3. Soluble oils.

Nitrite borate has the following advantages.

n Effective inhibitor with no increase in corrosion caused by, over or under

treatment.

n Dosage concentration easily determined by simple test.

n It is safe to handle, will not cause skin deceases.

n Approved for diesel engines when water is used as a heat source in fresh

Marine Engineering Department

Page 17 of 19

INSTITUTE OF ENGINEERING TECHNOLOGY - KATUNAYAKE

water generators.

n Acts as pH buffer against leakage of combustion gases in to the cooling

water.

The disadvantages are.

This mixture cannot be used in galvanized pipe work or if sacrificial zinc

anodes are fitted. Also it attacks soft solders.

Chromatic has the following advantage

n Very effective inhibitor.

n Concentration easily determined by color

n Can be used in presence of zinc coating or sacrificial anodes.

The disadvantages are

n Must be handle with caution to avoid skin contact.

n

n

n

n

Low concentration will promote pitting attack

Can not be used if the engine water is used in a freshwater generator

Poisonous, therefore care must be taken when dumping

Foes not act as pH buffer.

Soluble oils has the.f6flowing advantages.

n Safe to handle

n Approved for engines where water is used in fresh water generators.

n Reduce cavitations effects

n Gives good protection on clean metal surfaces.

The disadvantages are.

n If water quality is not good, the emulsion can loose stability and oil gets

separated out.

n The system must keep absolutely clean.

Marine Engineering Department

Page 18 of 19

INSTITUTE OF ENGINEERING TECHNOLOGY - KATUNAYAKE

n Tendency to form beat insulating layers of solid substances with

separated oil acting as bonding agent.

n High concentration can cause overheating.

n Foaming may take place if water has very low hardness.

Marine Engineering Department

Page 19 of 19

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- British MallardДокумент42 страницыBritish MallardlalindaОценок пока нет

- Electricity For EngineersДокумент15 страницElectricity For Engineerslalinda100% (3)

- AutomationДокумент57 страницAutomationlalinda100% (4)

- Diesel EngineersДокумент18 страницDiesel EngineerslalindaОценок пока нет

- Meo Class IV Orals Ques Bank - Mumbai MMDДокумент66 страницMeo Class IV Orals Ques Bank - Mumbai MMDlalindaОценок пока нет

- Corrosion - February 2010Документ15 страницCorrosion - February 2010lalindaОценок пока нет

- Solas For TankerДокумент25 страницSolas For TankerlalindaОценок пока нет

- Cu Carry Over To BoilerДокумент8 страницCu Carry Over To BoilerlalindaОценок пока нет

- Introduction To Fuels and Lubricants - Feb 2010Документ14 страницIntroduction To Fuels and Lubricants - Feb 2010lalindaОценок пока нет

- Solas For TankerДокумент25 страницSolas For TankerlalindaОценок пока нет

- 2010 MMEP Res HydraulicsДокумент5 страниц2010 MMEP Res HydraulicslalindaОценок пока нет

- AR-5061/AR-5061u ADSL2+ Ethernet Router User Manual: Version A1.0, March 18, 2009Документ86 страницAR-5061/AR-5061u ADSL2+ Ethernet Router User Manual: Version A1.0, March 18, 2009lalindaОценок пока нет

- AVRДокумент3 страницыAVRlalindaОценок пока нет

- Alpha Lubricator System OperationДокумент190 страницAlpha Lubricator System Operationlalinda67% (3)

- International Construction Consortium and State Engineering OnДокумент3 страницыInternational Construction Consortium and State Engineering OnlalindaОценок пока нет

- Air Coolers: Air Cooler Grid Type Water SeparatorДокумент1 страницаAir Coolers: Air Cooler Grid Type Water Separatorherobpo13373Оценок пока нет

- Air CompressorsДокумент7 страницAir Compressorsherobpo13373Оценок пока нет

- Air Starting SystemsДокумент9 страницAir Starting SystemslalindaОценок пока нет

- SOLAS Emergency Power Requirements CH 2 Sec 2Документ8 страницSOLAS Emergency Power Requirements CH 2 Sec 2lalinda100% (1)

- Electrical Work ShopДокумент5 страницElectrical Work ShoplalindaОценок пока нет

- 07 Fitting ShopДокумент9 страниц07 Fitting ShoplalindaОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- JLL India - India's Green FootprintДокумент9 страницJLL India - India's Green FootprintVulcanmindОценок пока нет

- Katalog Per-Eko enДокумент13 страницKatalog Per-Eko enapi-246705026Оценок пока нет

- Hydraulic Lab Manual 2017Документ48 страницHydraulic Lab Manual 2017Muhammad AdilОценок пока нет

- Earth Science 11 Water ResourcesДокумент4 страницыEarth Science 11 Water ResourcesKhristine Khate Odiaman MendezОценок пока нет

- Methods of Precooling Fruits, Vegetables, and Cut Flowers: Product RequirementsДокумент10 страницMethods of Precooling Fruits, Vegetables, and Cut Flowers: Product RequirementsFlorin OnucОценок пока нет

- Humidification and Evaporative Cooling SystemsДокумент106 страницHumidification and Evaporative Cooling Systemsسامح الجاسمОценок пока нет

- HYDRO 2023 PamphletДокумент2 страницыHYDRO 2023 PamphletBhargava ReddyОценок пока нет

- A Short History of WaterДокумент10 страницA Short History of WatermnettorgОценок пока нет

- Renewable Energy: Bilal Lamrani, FR Ederic Kuznik, Abdeslam DraouiДокумент16 страницRenewable Energy: Bilal Lamrani, FR Ederic Kuznik, Abdeslam DraouiSenhaji AllalОценок пока нет

- User Manual All JET-TECH ModelsДокумент32 страницыUser Manual All JET-TECH ModelsAllen ZhangОценок пока нет

- Mechanical Seals Mechanical Seals For Pumps Pusher Seals M7NДокумент6 страницMechanical Seals Mechanical Seals For Pumps Pusher Seals M7NVolodymyrОценок пока нет

- Flottec F150 Frother MSDS r04Документ6 страницFlottec F150 Frother MSDS r04Jo An MeMeОценок пока нет

- Protecting Machinery Spaces From Fire: Hi-Fog Total Flooding SystemsДокумент4 страницыProtecting Machinery Spaces From Fire: Hi-Fog Total Flooding SystemsAdvenser GroupОценок пока нет

- Water Quality of Pasig RiverДокумент8 страницWater Quality of Pasig RiverManna PintoОценок пока нет

- Is 7784 1 1993 PDFДокумент18 страницIs 7784 1 1993 PDFkalli2rfdfОценок пока нет

- ScriptДокумент6 страницScriptapi-384935219Оценок пока нет

- 〈2021〉 MICROBIAL ENUMERATION TESTS-NUTRITIONAL AND DIETARY SUPPLEMENTSДокумент5 страниц〈2021〉 MICROBIAL ENUMERATION TESTS-NUTRITIONAL AND DIETARY SUPPLEMENTSehsan050628Оценок пока нет

- Labuan Bajo Trip PricelistДокумент10 страницLabuan Bajo Trip PricelistValentinus Findy AjiОценок пока нет

- Is 12786 1989 PDFДокумент22 страницыIs 12786 1989 PDFMurali Somasundharam100% (1)

- June 2015 (v1) QP - Paper 1 CIE Biology IGCSEДокумент16 страницJune 2015 (v1) QP - Paper 1 CIE Biology IGCSEMariana TorresОценок пока нет

- BASF CAT-003091 SorbeadAir TechArticle A4 04Документ4 страницыBASF CAT-003091 SorbeadAir TechArticle A4 04Amir RahbariОценок пока нет

- Global Actiflo Ref Sorting List (June 2010) PDFДокумент16 страницGlobal Actiflo Ref Sorting List (June 2010) PDFtkortiz24Оценок пока нет

- Water Report FULL 8 8 19 PDFДокумент104 страницыWater Report FULL 8 8 19 PDFSamantha SomersОценок пока нет

- DEE Module 5.3 AllДокумент55 страницDEE Module 5.3 AllVusi MabuzaОценок пока нет

- Hargreaves USSEC Wastewater Treatment Tech - Compatibility ModeДокумент10 страницHargreaves USSEC Wastewater Treatment Tech - Compatibility ModeDiel MichОценок пока нет

- Corrosion Under Insulation JMДокумент8 страницCorrosion Under Insulation JMgems_gce074325Оценок пока нет

- 14 Amazing Ways To Cleanse Your Kidneys at Home - My Health Tips PDFДокумент9 страниц14 Amazing Ways To Cleanse Your Kidneys at Home - My Health Tips PDFRAGHAVENDRA100% (1)

- Sectionc Climatology (A) Distinguish Between Weather and Climate (B) Explain How Any Two Elements of Weather Are Measured at A Weather StationДокумент39 страницSectionc Climatology (A) Distinguish Between Weather and Climate (B) Explain How Any Two Elements of Weather Are Measured at A Weather Stationkalule elvisОценок пока нет

- Food Supply Chain Using Green Technology-Prasad EditДокумент12 страницFood Supply Chain Using Green Technology-Prasad EditRajendiraperasad ManiamОценок пока нет

- Bộ Đề Thi Thử 2019 Tiếng Anh Lovebook - Đề Số 21.Документ17 страницBộ Đề Thi Thử 2019 Tiếng Anh Lovebook - Đề Số 21.vvctriОценок пока нет