Академический Документы

Профессиональный Документы

Культура Документы

00091840

Загружено:

msmsoft90Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

00091840

Загружено:

msmsoft90Авторское право:

Доступные форматы

SPE/IADC 91840

New Bit Design, Cutter Technology Extend PDC Applications to Hard Rock Drilling

Robert Clayton, Shilin Chen, and Guy Lefort, HES-Security DBS

Copyright 2005, SPE/IADC Drilling Conference

This paper was prepared for presentation at the SPE/IADC Drilling Conference held in

Amsterdam, The Netherlands, 23-25 February 2005.

This paper was selected for presentation by an SPE/IADC Program Committee following

review of information contained in an abstract submitted by the author(s). Contents of the

paper, as presented, have not been reviewed by the Society of Petroleum Engineers or the

International Association of Drilling Contractors and are subject to correction by the author(s).

The material, as presented, does not necessarily reflect any position of the SPE, IADC, their

officers, or members. Electronic reproduction, distribution, or storage of any part of this paper

for commercial purposes without the written consent of the Society of Petroleum Engineers or

the International Association of Drilling Contractors is prohibited. Permission to reproduce in

print is restricted to an abstract of not more than 300 words; illustrations may not be copied.

The abstract must contain conspicuous acknowledgment of where and by whom the paper

was presented. Write Librarian, SPE, P.O. Box 833836, Richardson, TX 75083-3836, U.S.A.,

fax 01-972-952-9435.

Abstract

An advanced series of PDC drill bits incorporating a new

highly abrasion-resistant PDC cutter has extended effective

PDC bit application to hard rock drilling. In direct offset

comparisons, the advanced series of PDC bits fitted with the

new cutters delivered significant increases in footage drilled

and rate of penetration.

To achieve an optimum match in drilling efficiency and bit

life to lower costs and mitigate risk in hard rock environments,

the series is designed using a combination of advanced

modeling capabilities and sophisticated analytical tools. These

tools allow the designs to be "customized" for specific

applications, optimizing cutting efficiency and durability

according to specific rock properties and drilling parameters.

A transitional drilling model simulation allows evaluation of

how cutting forces are affected during transitional drilling,

common in hard rock environments. The bit design is

globally balanced to optimize axial, lateral, and torsional

forces, and can be modified by adjusting features such as

profile shape, cutter rake angles, impact arrestors, and cutter

type, to optimize bit performance when drilling in hard and

transitional environments.

In addition, recognition of a third dimension of PDC

performance Thermal Mechanical Integrity (TMI) -- has

lead to development of a new PDC cutter that provides 13.5

times the abrasion resistance of the industry standard, without

sacrificing impact resistance. This improved understanding of

PDC cutter failure provides a different way of looking at the

traditional characteristics of abrasion and impact, enabling

cutter durability to be optimized in both abrasive and hard,

inter-bedded formations.

The paper discusses the science behind the advanced series

of bits, including the impact of TMI on cutter performance.

New laboratory capabilities and testing results are described,

and actual field case histories presented to demonstrate

performance improvements of these PDC bits in hard rock

applications.

Introduction

One of the greatest challenges that any PDC bit manufacturer

faces today is the extension of PDC bit application into hard

rock drilling, where impact damage, heat damage and abrasive

wear of PDC cutters limits performance. Research and

development have been focused on better understanding of

cutter/formation interaction, cutter performance, bit dynamics

and BHA dynamics.

Since the first modeling studies conducted by Sandia

Laboratories in the late 1980s, analysis of the interaction

between the cutting elements of a PDC drill bit and the

formation it is drilling has been widely investigated. One of

the predominant developments from these early investigations

was the first reliable kinematics cutter force and wear

prediction model. These models were helpful for bit

manufacturers to better understand the mechanism of

cutter/formation interaction and to design the cutter layout of a

PDC bit so load and wear of cutters over the bit face can be

balanced.

Perhaps the most significant advancements in

understanding how this interaction affects bit performance

were the result of research conducted by the Amoco Research

Center during the late 80s. 1 Laboratory tests demonstrated

that conventional PDC bits whirl backwards during drilling,

and backward whirl was a primary cause of PDC cutter

damage. This important finding led to extensive studies in bit

dynamics and drillstring dynamics. Bit dynamics models,

including BHA dynamics models were developed and were

able to repeat the backward whirl phenomenon under specific

conditions. However these dynamics models were rarely used

by bit manufacturers in the bit design process due to their

complexity and limited ability to consider the effects of cutter

layout on bit dynamics.

There were two design principles identified; namely, antiwhirl PDC bit design and force balanced PDC bit design. The

anti-whirl PDC bit design principle 1, 2 incorporated a specific

design concept, namely low friction gauge, to minimize the

effect of bit backward whirl. According to this design

principle, cutters were so arranged over the bit face so that a

net resultant radial force (around 12% of weight on bit) was

directed toward a specified portion of the bit with less friction.

www.petroman.ir

CLAYTON, SHILIN, LEFORT

Since introduction of anti-whirl technologies in the late

80s, PDC bit utilization has made significant inroads into

roller cone markets, but has consistently faltered when drilling

the traditionally more difficult insert roller cone applications,

such as hard rock. In these applications, where roller cone bits

suffer short bit life and slow ROP as well as risk loss of cones,

PDC bits typically suffer short life as a result of high impact

damage, large vibration and abrasion.

The force balanced PDC bit design principle 3 was

developed based on the understanding of PDC bit dynamics

and the mechanism of cutter/formation interaction. Unlike an

anti-whirl PDC bit, the cutters on a force balanced PDC bit

were arranged so that a net resultant radial force was

minimized or balanced. The use of tracking cutters, where

multiple cutters located within a groove, provided a restoring

force to keep the bit rotating around hole center. The design of

a force balanced PDC bit allows a higher density of cutters on

the gauge, which is usually required in hard formation drilling,

than does the anti-whirl PDC bit. The use of force balancing,

tracking cutters and asymmetrical spiraled blades improved bit

performance significantly, further expanding the range of

applications for PDC bits.

Recently, significant performance improvements have

been achieved with a new series of highly-engineered PDC bit

designs utilizing advanced cutter technology to expand the

range of PDC applications into hard rock drilling. This paper

describes several key concepts and features including global

balancing, energy balancing, transitional impact prediction

model, and the development of highly abrasion-resistant PDC

cutters based on an improved understanding of thermal cutter

failure mechanisms.

Improved Cutter/Rock Interaction Model

Advanced Cutter/Rock Interaction Model. In order to

accurately calculate the forces acting on a PDC bit, it is

necessary to have a model presenting the cutter/rock

interaction. 4-6 Such a model should be able to predict the

forces acting on a cutter, as well as the force distributions over

cutting area when the cutter is engaged with the formation.

Previous models used in either kinematics calculation or in

dynamics calculation considered only three summarized forces

on a cutter based on the engaged area: drag force, normal

force and side force. 7,8 Fig. 1. Such a model is no longer valid

with the introduction of PDC cutters with a chamfered

geometry, which significantly affects bit ROP and WOB/TOB

relationship. Furthermore, laboratory tests have found that the

orientation of PDC cutter relative to rock surface, defined by

back rake angle, side rake angle and helical motion, play a

significant role in the determination of cutting forces.

As shown in Fig. 2, a new cutter/rock interaction model is

developed in which the cutting edge is divided into three

surfaces: cutting face surface, chamfer surface and cylinder

surface. There are three forces acting on each surface, namely,

drag force, axial force and radial force. In order to accurately

calculate the engagement area of the cutter, each surface is

meshed into very small grids. In this way, the effects of cutter

orientation on the engagement area can be considered.

Depending on the cutting depth, forces on each surface may be

significantly different.

SPE/IADC 91840

Advanced cutter wear model. It is well known that cutter

wear depends on cutting force, relative speed, temperature,

cutter material properties and rock properties. Previous wear

models estimated only the wear flat without considering the

orientation of the wear flat, the actual diamond thickness, the

interface geometry of diamond layer and carbide, and abrasive

resistance.

With the new cutter/rock interaction model described

above, cutter wear can be considered three dimensionally and

all neglected factors in the previous model can be easily

considered. (Fig. 3).

Global Balancing Concept for PDC Bits

There are three forces acting on a bit: bit axial force, bit lateral

force and a bending moment. It has been believed that

balancing lateral force is very important to prevent whirl.

Previous concepts of PDC bit force balancing referred only to

lateral force balance. It was also believed that once lateral

force was balanced, bit bending moment was also balanced.

A further study on bit forces found that even a perfectly

force balanced bit may exhibit tilt motion caused by bending

moment. In fact, bit bending moment consists of two parts:

one contributed by lateral force and another contributed by

axial force distribution over bit face. Fig. 4 shows an example

of bending moment generated by uneven distribution of axial

forces over cutters.

Bit bending moment contributes not only to bit lateral

motion or whirl, but also to bit tilt motion, which has a

significant effect on bit directional control. Therefore, bending

moment balancing becomes equally important as lateral force

balancing. A PDC bit featured with both lateral force and

bending moment balanced is a "global force balanced" bit.

The design of a global force balanced PDC bit involves

adjusting the cutting structure to reduce the imbalance

numbers. The new series of bits are force balanced according

to a specific set of design criteria, which considers the

summation of cutter forces to a global lateral and axial bit

imbalance. The global lateral bit imbalance consists of the

total, radial, and drag imbalances.

Energy Balancing Concept for PDC Bits

The energy balanced concept was initially developed for roller

cone bits, where forces and rock removed by each cone

(cutter) were evenly distributed among cones. Significant

performance improvement of energy balanced roller cone bits

has been consistently observed in the field worldwide. 9

The development of an energy balanced PDC bit is based

on the fact that the amount of formation removed by each

cutter on a bit is different, and as a result, the force acting on

each cutter also differs. Furthermore, the number of cutters

differs from blade to blade, therefore, the forces acting on

each blade differ. In order to avoid overloading individual

cutters and blade, it is necessary to control the load

distributions over the cutters and blades.

An element of an efficiently running bit is a cutting

structure that evenly distributes work among the cutters during

normal drilling. Energy balancing accomplishes even

disribution by minimizing the change in work or force among

regions or zones of the cutting structure. By controlling the

www.petroman.ir

SPE/IADC 91840

NEW BIT DESIGN, CUTTER TECHNOLOGY EXTEND PDC APPLICATIONS TO HARD ROCK DRILLING

force distribution over blades and over cutters, energy

balancing reduces impact damage and uneven wear while

promoting improved ROP.

The design of an energy balanced PDC bit involves

analyzing the distribution of work and forces on a cutting

structure with the aim of controlling force distribution over

blades and cutters. As with force balancing, a specific set of

design criteria has been developed which considers the ratio of

the average change in cutter torque across zones, to the

average cutter torque over the entire region.

Transition Drilling Model

The Transition Drilling Model simulates a fixed cutter bit

drilling through a change in rock strength such as sandstone to

shale. This transitional drilling model simulation allows

evaluation of how cutting forces are affected during

transitional drilling, common in hard rock environments.

The program uses the new cutter/rock interaction model to

calculate the amount of torque per revolution each cutter

experiences through the transition layer (Fig. 4). The model

data is used in the design stage, providing the ability to easily

evaluate lateral, torsional, and axial cutter forces and work to

control impact damage, further enhancing cutter performance.

This technology gives the designer the capability to

evaluate how the cutting forces are affected when the bit is

drilling into a harder or softer rock. In effect, this technology

enables designers, during bit design phase, to identify trouble

zones where impact damage could occur while transition

drilling. Bit features such as profile shape, blade count, start of

secondary blades, cutter back rake, impact arrestor location,

can all be manipulated to improve the bits ability to drill

transitional formations. (Fig. 5).

Development of New Cutter Technology

In addition to advanced models and design tools, the new

series of bits incorporate advanced PDC cutters, developed as

a result of an improved understanding of cutter failure

mechanisms. Understanding a PDC cutters failure

characteristic is the key to understanding how to improve its

performance. Historically, abrasion and impact have been the

two characteristics observed and studied.

Abrasion refers to the mechanically generated wear that

occurs due to failure of the individual diamond crystals and/or

the diamond-to-diamond bonds within the diamond table. The

diamond failure can be a result of mechanical loading and/or

thermal degradation.

Impact wear is a mechanical failure that occurs when

forces are applied which overcome the strength of the bond

between diamond crystals and/or to the carbide of the PDC.

As a result of extensive research and development, a third

dimension of PDC cutter failure has been identified, Thermal

Mechanical Integrity (TMI). TMI failure is defined as loss

of diamond that occurs due to a combination of thermal

degradation and force, and is a measurement of the cutters

toughness as wear and thermal degradation occur.

This improved understanding of cutter failure has brought

about a different way of looking at the traditional

characteristics of abrasion and impact. Advanced testing

capabilities now enable optimization of cutter durability in

both abrasive and hard inter-bedded formations, and led to

development of a cutter more suitable for the tougher

environments of hard rock drilling. (Fig. 6).

Testing Capabilities. Finite Element Analysis (FEA),

acoustic and scanning electron microscopic (SEM) analysis,

and destructive testing (DT) are utilized to evaluate new

diamond and carbide materials, new manufacturing processes,

and new designs in order to optimize all performance aspects

of a new PDC cutter.

Finite Element Analysis (FEA) evaluates stresses that

occur between the diamond table and the carbide substrate as a

result of the differences in rate of thermal expansion between

the two materials. Significant changes in temperature can

occur during manufacturing or due to drilling temperatures

down hole. FEA images allow the residual stresses to be

analyzed under different parameters. (Fig. 7). By manipulating

the interface geometry between the diamond table and the

carbide, the stresses can be managed to optimize the cutter's

performance. (Fig. 8).

The acoustic and SEM analyses are utilized to evaluate

changes in material properties and characteristics throughout

the manufacturing process and to qualify the final product.

DT is utilized to validate the overall development for

abrasion resistance, impact resistance, and thermal mechanical

integrity in order to provide results that closely resemble cutter

failure characteristics observed in the field.

Among DT tests, the G-ratio abrasion test addresses the

diamond abrasion resistance, while heavy wear testing extends

not only into the diamond table but also into the carbide.

Extension tests the ability of the entire cutter to remove rock,

and provides the ability to test all three characteristics of PDC

failure modes: abrasion, impact and thermal degradation.

Cutter Testing Results. Laboratory testing showed the

new PDC cutters to be 20 times more abrasion-resistant than

the industry standard and 3.9 times that of industry premium

cutters, with no loss of impact resistance. (Fig. 9)

Over an 18-month period, 22 different specific cutter

iterations were developed, manufactured, and laboratory

tested. Many of these were also taken to the field for extensive

testing under actual drilling conditions. Field-testing provided

additional knowledge and drove additional insights and

improvements in the new technology cutters.

The result was a highly abrasion-resistant PDC cutter

suitable for applications in which accelerated wear typically

leads to thermal mechanical failure. This includes hard and

abrasive applications where cutting efficiency must be

maintained, and has allowed expansion of PDC applications

into Hard Rock where IADC 4 thru 7 Type Insert RC bits

currently are used.

Field Applications

The innovations incorporated into the new series of bits and

described in this paper provide a number of benefits in terms

of drilling performance. Global force balancing reduces lateral

and axial vibration to maximize ROP, while energy balancing

evenly distributes cutter forces, reducing impact damage and

uneven wear. Use of new PDC cutters with greater TMI offers

significantly increased abrasion-resistance with no loss of

impact-resistance, effectively drilling even hard rock

formations.

www.petroman.ir

CLAYTON, SHILIN, LEFORT

While specific case histories will be detailed in

forthcoming papers, the following summaries describe typical

performance to date of the new series PDC bits, designated

FM3000 with the new highly abrasion-resistant PDC

cutters, designated Z3:

Travis Peak Formation. The Travis Peak formation in the

Oak Hill field in East Texas comprises primarily very fine

grained sandstone interbedded with shale and mudstone.

Traditionally the interval could be drilled only by several

IADC 647Y to 817Y insert bits. Recent efforts of using PDC

bits to drill this section have been made with only marginal

economic improvement. 10-11

A new PDC bit designed based on the principle described

in this paper, namely, a 7-7/8 FMX753 with the advanced Z3

cutters, successfully drilled 1213 feet of at 29.6 feet/hour,

outperforming the next-best offset by 34% more footage and

7% better ROP.

The FMX753 drilled 58% more footage at a 40% higher

ROP than the average of all competitor offsets in the field,

including one offset that utilized two competitor bits. Even

when combined, those two competitor bits did not equal this

single run performance, which dropped cost per foot from a

high of $73.54 to just $19.20 per foot. (Fig. 10).

In addition, the bit was pulled in repairable condition with

a dull grade of 1-2-WT-S-X-I-CT-PR. By comparison,

competitor designs were not repairable and had an average

dull condition of 6-8-RO-N/S-X-3-BT-PR. (Fig. 11).

Almond Formation. This new technology has also

successfully drilled to TD in the Almond formation, an

extremely tough, interbedded formation at the end of a long

tough run. For this application, an FMX655 was designed with

an aggressive cutting structure incorporating the new Z3

cutters, as well as continuous spiraling along bit cutter blades

through the gage pad for optimized distribution of lateral

forces.

The bit successfully drilled the Almond formation to well

TD at an average ROP of 50 ft/hr, establishing a new ROP

performance record. In addition to achieving the best

penetration rate, the bit also resulted in the best dull condition

of any bit run in the Almond, and was pulled in re-runnable

condition.

Parkland Field Formation. In this case a 7-7/8-in.

FM3645 drilled 1162 meters in 44.5 hours to achieve the

fastest ROP in the Parkland Field to date, 26.11 m/hr. The bit

outperformed all offset bits in this application, achieving a

record average ROP of 26.11 m/hr. As a result of this

outstanding ROP performance, the customer realized

approximate savings of $31,000.

Red Rock Formation. In this case, an 8-3/4-in. FM3541

drilled significantly greater footage than all offsets, while

maintaining a competitive ROP. The FM3541 bit drilled a

total 874 meters, compared to the next-best offset performance

of 240 meters. The bit also maintained an average ROP of

5.67 m/hr to outperform the next-fastest ROP of 3.8 m/hr. As

a result, the operator saved the cost of another bit plus trip

time, for approximate total savings of $28,900.

SPE/IADC 91840

application to hard rock drilling. In direct offset comparisons,

the advanced series of PDC bits fitted with the new cutters

delivered significant increases in footage drilled and rate of

penetration.

The innovations incorporated into the new series of bits

and described in this paper provide a number of benefits in

terms of drilling performance:

Global force balancing provides maximized ROP with

reduced lateral and axial vibration.

Energy balancing evenly distributes cutter forces, reducing

impact damage and uneven wear while promoting improved

ROP.

Transition Drilling Modeling allows for faster transitioning

with reduced impacts and increased toolface stability.

New PDC cutters with greater TMI offer significantly

increased abrasion-resistance with no loss of impactresistance, effectively drilling even hard rock formations.

Designers now have the ability to easily evaluate lateral,

torsional, and axial cutter forces and work. Analysis of the

distribution of these parameters from cutter to cutter, blade to

blade, and between different bit profile segments has aided in

the discovery of features that will continue to improve overall

bit performance.

References

1. T.M. Warren, J.F. Brett and L.A. Sinor, "Development of a Whirl

Resistant Bit", SPE Drilliing Engineering, 5 (1990) 267 274.

2. T.M.Warren and L.A.Sinor, "PDC Bits: Whats Needed to Meet

Tomorrows Challenge", paper SPE 27978, presented1994.

3. G.E.Weaver, R.I.Clayton, "A New PDC Cutting Structure

Improves Bit Stabilization and Extends Application into Harder

Rock Types", paper SPE/IADC 25734, presented 1993.

4. Ortega and D. A. Glowka, "Frictional Heating and Convective

Cooling of Polycrystalline Diamond Drag Tools During Rock

Cutting", SPE Journal of Petroleum Technology, 24 (1984)

pp.121-128.

5. D.A. Glowka, and C.M. Stone, "Effects of Thermal and

Mechanical Loading on PDC Bit Life", SPE Drilling

Engineering, 1 (1986) 201-204.

6. D.A. Glowka, "Use of Single-Cutter Data in the Analysis of PDC

Bit Designs: Part 1 Development of a PDC Cutting Force

Model," SPE Journal of Petroleum Technology, 41 (1989)

pp.797-849.

7. C.J. Langeveld, "PDC Bit Dynamics", paper IADC/SPE 23867,

presented 1992.

8. J.M.Hanson, W.R.Hansen, "Dynamics Modeling of PDC Bits",

paper SPE/IADC 29401, presented 1995.

9. S. Chen, and J. Dahlem: Development and Field Applications of

Roller Cone Bits with Balanced Cutting Structure, paper SPE

71393 presented at the 2001 SPE / ATCE Annual Meeting, New

Orleans, 30 September 2001.

10. E.J.Schell, D. Phillippi, ect, New, Stable PDC Technology

Significantly Reduces Hard Rock Cost Per Foot, paper

SPE/IADC 79797 presented at the SPE/IADC Drilling

Conference held in Amsterdam, The Netherlands, Feb., 2003.

11. R. Fabian, S.Johnson, ect, Enhancements in Design Technology

and Performance of Stable PDC Bits Revolutionize Hard Rock

Drilling in East Texas Fields, Addendum to SPE/IADC Paper

No.79797, IADC/SPE 87098 presented at the IADC/SPE

Drilling Conference held in Dallas, Texas, USA, March,2004.

Conclusions

A series of PDC drill bits incorporating a new highly abrasionresistant PDC cutter has extended effective PDC bit

www.petroman.ir

SPE/IADC 91840

NEW BIT DESIGN, CUTTER TECHNOLOGY EXTEND PDC APPLICATIONS TO HARD ROCK DRILLING

Acknowledgments

The authors would to thank Halliburton and Security DBS for

permission to present this paper. Collective thanks to all the

operators, contractors and field personnel who collaborated to

make these runs possible. Special thanks go to Larry Eichman,

Robert Gum, Charlie Cogdill, Brian Davies, and Dave Herman

for their efforts on the case histories used in this paper.

www.petroman.ir

CLAYTON, SHILIN, LEFORT

Face

surface

Fig. 1 Previously used cutter/rock interaction model.

Face

surface

Cylinder

surface

Chamfer

surface

Fig. 2New cutter/rock interaction model divides cutting edge into three surfaces, each with its own force model.

Wear Profile

2.5

Cutter Tip

Exposure Line

Predicted Wear

1.5

Bit Height

0.5

-0.5

-1

-1.5

1

3

Bit Radius

Fig. 3Wear profile predicted with numerical bit model.

www.petroman.ir

SPE/IADC 91840

SPE/IADC 91840

NEW BIT DESIGN, CUTTER TECHNOLOGY EXTEND PDC APPLICATIONS TO HARD ROCK DRILLING

Axial

Axial

Fig. 4Bending moment generated by uneven distribution of axial forces over cutter

Change Percent Torque Plot

8-1/2" FM3663

Change Percent Torque Plot

8-1/2" FM2663

3.0

3.0

2.5

35

33

31

29

27

25

23

21

19

17

15

13

35

33

31

29

27

25

23

21

19

17

15

13

11

0.0

7

0.0

5

0.5

0.5

1.0

11

1.0

1.5

1.5

After

2.0

2.0

Change in Percent Torque

Before

Change in Percent Torque

2.5

Cutter #

Cutter #

Fig. 5 Cutter locations are manipulated to reduce maximum change in torque for individual cutter and to distribute change in torgue equally

over more cutters.

Fig. 6Thermal Mechanical Integrity is the third dimension of PDC cutter per formance.

www.petroman.ir

CLAYTON, SHILIN, LEFORT

Fig. 7Interface geometry between diamond layer and carbide is optimized to reduce residual stress.

Fig. 8Interface geometry of new Z3 PDC cutter.

1.6E-02

New Z3 PDC cutter

1.4E-02

Premium Cutter

Cutter Wear (in3)

1.2E-02

1.0E-02

8.0E-03

Industry Standard

6.0E-03

4.0E-03

2.0E-03

IADC "1" Wear (1/8 Diameter Worn)

0.0E+00

0

2000

4000

6000

8000

10000

Volume of Rock Removed (in3)

12000

14000

Fig. 9New cutter offers 20 times the abrasion resistance of industry standard cutters.

www.petroman.ir

SPE/IADC 91840

SPE/IADC 91840

NEW BIT DESIGN, CUTTER TECHNOLOGY EXTEND PDC APPLICATIONS TO HARD ROCK DRILLING

Offset PDC bits

New

PDC

Fig. 10Travis Peak interval drilled by new PDC bit and recent comparable offset PDC bit performance.

Fig. 11Dull condition after drilling 1213 ft of Travis Peak formation at almost 30 ft/hr, outperforming offset by 58% more footage and 40%

higher ROP.

www.petroman.ir

Вам также может понравиться

- SPE 108864 Development of A Post-Graduate Qualification Course in Telemedicine and Telepharmacy For Physicians in Offshore Oil and Gas IndustryДокумент3 страницыSPE 108864 Development of A Post-Graduate Qualification Course in Telemedicine and Telepharmacy For Physicians in Offshore Oil and Gas Industrymsmsoft90Оценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Spe 108852 MS P PDFДокумент2 страницыSpe 108852 MS P PDFmsmsoft90Оценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Spe 108554 MS P PDFДокумент3 страницыSpe 108554 MS P PDFmsmsoft90Оценок пока нет

- Reservoir Modeling For Horizontal-Well Exploitation of A Giant Heavy-Oil FieldДокумент5 страницReservoir Modeling For Horizontal-Well Exploitation of A Giant Heavy-Oil Fieldmsmsoft90Оценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- SPE 107240 4th-Generation Coiled-Tubing Manufacturing TechnologyДокумент3 страницыSPE 107240 4th-Generation Coiled-Tubing Manufacturing Technologymsmsoft90Оценок пока нет

- Determining Fracture Closure Pressure in Soft Formations Using Post-Closure Pulse TestingДокумент6 страницDetermining Fracture Closure Pressure in Soft Formations Using Post-Closure Pulse Testingmsmsoft90Оценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Analytical Theory of Coalbed Methane Recovery by Gas InjectionДокумент9 страницAnalytical Theory of Coalbed Methane Recovery by Gas Injectionmsmsoft90Оценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- SPE 87358 Technology: Catalyst For Coalgas GrowthДокумент7 страницSPE 87358 Technology: Catalyst For Coalgas Growthmsmsoft90Оценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- 00087084Документ9 страниц00087084msmsoft90Оценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Spe 101422 MS P PDFДокумент5 страницSpe 101422 MS P PDFmsmsoft90Оценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

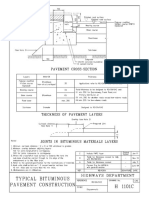

- Wearing Coat ThicknessДокумент1 страницаWearing Coat ThicknessanjanaОценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Corrosion InhibitorsДокумент355 страницCorrosion Inhibitorszaxader100% (13)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- GSTS Module-5Документ14 страницGSTS Module-5Poison PinkОценок пока нет

- (Lec6) Phase EquilibriaДокумент52 страницы(Lec6) Phase EquilibriadinurjОценок пока нет

- Cool - Ex MSDS - CompressedДокумент4 страницыCool - Ex MSDS - CompressedSofyanОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Samsung 25R MSDSДокумент8 страницSamsung 25R MSDSRais Ovadeyyanusasey AliemОценок пока нет

- Intrepid FBV15285 - Coil Damage ReportДокумент10 страницIntrepid FBV15285 - Coil Damage ReportVIKTORОценок пока нет

- Terra NovaДокумент4 страницыTerra NovaNthambi MiriamОценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- GB 8163-2008Документ14 страницGB 8163-2008hungОценок пока нет

- Hydro Power NEW - FinalДокумент84 страницыHydro Power NEW - FinalPablo ThomassetОценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Atomic Absorption & EmissionДокумент80 страницAtomic Absorption & EmissionAkshay Patil100% (1)

- Chapter 6 Assessment PDFДокумент17 страницChapter 6 Assessment PDFMichael Foster67% (3)

- FOUNDATION RCD of Footings 1 Square FTGДокумент5 страницFOUNDATION RCD of Footings 1 Square FTGChris Michelle JapinОценок пока нет

- Timer PaperДокумент5 страницTimer Paperhajjiyare2016Оценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Pneumatic Structures: The Fascination of Pneumatic Structures Begins With The Fascination of The SkyДокумент9 страницPneumatic Structures: The Fascination of Pneumatic Structures Begins With The Fascination of The SkyTangha Muklom KunchaОценок пока нет

- Welding: Krishnanand Prasad 0501213359 (04) Mechanical Engg 8 SemesterДокумент21 страницаWelding: Krishnanand Prasad 0501213359 (04) Mechanical Engg 8 SemesterSuphi YükselОценок пока нет

- SECTION 05530 Gratings Rev 1Документ17 страницSECTION 05530 Gratings Rev 1Mohsin ShaikhОценок пока нет

- (English) Translating Chemistry Word Problems (DownSub - Com)Документ4 страницы(English) Translating Chemistry Word Problems (DownSub - Com)ikhsania utamiОценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- International CataloguesДокумент18 страницInternational CataloguesHuy ThaiОценок пока нет

- Welding Visual ReportДокумент6 страницWelding Visual ReportFerdie OSОценок пока нет

- Assignment Neutralisation ReactionДокумент1 страницаAssignment Neutralisation ReactionMaridjan WiwahaОценок пока нет

- Pencetan Slide 4aДокумент59 страницPencetan Slide 4aFaradita RahmaОценок пока нет

- Brochure Alfa Laval Compabloc Ppm00033enДокумент8 страницBrochure Alfa Laval Compabloc Ppm00033enAnie EkpenyongОценок пока нет

- Staining of Tissue Pigments and DepositsДокумент4 страницыStaining of Tissue Pigments and DepositsAnonymous 8rsxG4100% (2)

- Eng SS Tec-138-702 AaДокумент34 страницыEng SS Tec-138-702 AaZorbanfrОценок пока нет

- Mechanical Properties: Issues To Address..Документ40 страницMechanical Properties: Issues To Address..Mat MatttОценок пока нет

- ReportttttttttttДокумент42 страницыReportttttttttttpradeep rОценок пока нет

- Tds - Emaco s66 CPДокумент2 страницыTds - Emaco s66 CPVenkata RaoОценок пока нет

- Deflection in BimetalДокумент4 страницыDeflection in BimetalRoisin ClearОценок пока нет

- GSE StudLiner - 09.12.2011 - Youngblood - New DesignДокумент60 страницGSE StudLiner - 09.12.2011 - Youngblood - New Designhassen gannouniОценок пока нет