Академический Документы

Профессиональный Документы

Культура Документы

GE Portascan Portable Bladder Scanner - Service Manual

Загружено:

Ruslan SergeevАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

GE Portascan Portable Bladder Scanner - Service Manual

Загружено:

Ruslan SergeevАвторское право:

Доступные форматы

GE Healthcare

Portascan

Portable Bladder Scanner

Service Manual

Portascan Service and Assembly Manual

MAN-004-049

Issue 1

Table of Contents

� Section 1

Service Information

� Chapter 1. Introduction

About this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

� Chapter 2. Warnings and Precautions

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1

1

� Chapter 3. Technical Specifications of the Scanner

General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Acoustic Output information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2

2

� Chapter 4. Connector overview

Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Main board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ETX Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3

3

3

� Chapter 5. Planned Maintenance

Handling and Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Handling and Care probes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Agents and procedures that may damage the probes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4

4

4

� Chapter 6. Unit Disassembly

Images . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

� Chapter 7. Faults and Solutions

Screen Related . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Probe Related . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Keypad Related . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Software Related . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7

7

7

7

Chapter 8. Parts list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

� Chapter 9. ESD

What is ESD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preventing ESD damage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ESD safe workshop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ESD safe field service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9

9

9

9

�Circuit Diagrams

Diagram 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagram 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagram 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10

11

�Appendix 1

Testing of Final Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mediwatch UK Ltd

Cosford Lane, Rugby CV21 1QN

Phone +44 1788 547888 Fax +44 1788 536434

12

Mediwatch Service Department

Service Documentation

Table of Figures

� Figure 1

Portascan Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

� Figure 2

Mainboard Top View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

� Figure 3

ETX Board Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

� Figure 4

Portascan Top View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

� Figure 5

Portascan complete. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

� Figure 6

Battery release & removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

� Figure 7

Unscrew 4 screws ... & remove cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

� Figure 8

Battery Pack & PCB Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

� Figure 9

Back Panel with release screws arrowed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

� Figure 10

Note location of long screw. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

� Figure 11

Probe connector lock nut. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

� Figure 12

Use special Lemo wrench to loosen probe connector nut. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

� Figure 13

Cut or remove security sticker then hinge top away to separate case. . . . . . . . . . . . . . . . . . . . . . . . . .

� Figure 14

The bottom case and handle grip can be placed to one side. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

� Figure 15

Two screws hold the main assembly in place. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

� Figure 16

Lift main board peeling away earth strap & disconnect plugs/skts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

� Figure 17

Note location of sounder & fan ... and display inverter board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

� Figure 18

Carefully turn over main panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

� Figure 19

Shielding removed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3

3

3

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

Mediwatch Service Department

Service Documentation

Table of Figures

� Figure 20

Probe interface panel set. ... Remove screws to separate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

� Figure 21

Separate ribbon connector, or carefully hinge probe interface boards . . . . . . . . . . . . . . . . . . . . . . . . . .

� Figure 22

... to reveal ETX Heatsink screws. Retain Heatsink from other side. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

� Figure 23

The compact flash can now be removed, reprogrammed & replaced. . . . . . . . . . . . . . . . . . . . . . . . . . .

� Figure 24

RAM can also be accessed if necessary. (Observe E.S.D. precautions) . . . . . . . . . . . . . . . . . . . . . . . . . . .

� Figure 25

Thermal Printer PCB and location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

� Figure 26

5

6

6

6

6

6

Paper roll installed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

�Dual Frequency prove & connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

�Rear panel connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

�Bottom case label. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

�Keypad membrane. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mediwatch Service Department

Service Documentation

Section 1

About this manual

Chapter 1. Introduction

This service manual can be used to service the Portascan at board level. The manual explains the functioning of the boards by

means of functional block diagrams and photographs while connections can be checked at the connector overview.

Preventative and corrective maintenance is also included as are circuit diagrams.

Warnings

Chapter 2. Warnings and Precautions

�

A probe may only be connected to or disconnected from the scanner while the instrument is switched off. Ignoring

this may cause severe damage to your scanner and/or probe.

To avoid a risk of explosion the equipment must not be operated in the presence of flammable anaesthetics.

To avoid a risk of electric shock do not open the equipment. Refer servicing to qualified personnel only.

Be careful not to place the patient into contact with the ultrasound equipment or other devices. If the ultrasound

equipment or other devices are defective, there is a risk of electrical shock.

For continued protection against fire hazard, replace fuses only with the same type and rating.

The use of non-Mediwatch Plc components with this scanner may result in damage to Mediwatch Plc components.

To prevent hazards; refer to your local requirements for adequate electrical installation in case of class 1 type BF

equipment.

Do not subject the equipment to excessive shock, for example, when moving the equipment. If the equipment is

repeatedly subjected to excessive shock, mechanical parts may be damaged.

Assembly operations, extensions, re-adjustments, modifications or repairs must be carried out by authorized persons.

The electrical installation of the relevant room must comply with the IEC requirements.

The product must be used in accordance with the instructions for use.

Precautions

�

Cleaning the probe is done by first removing the ultrasound coupling gel with a soft tissue and then gently wipe the

probe dry using a new tissue or dry cloth.

When more cleaning is required only a mild detergent or hand-soap may be used together with some water and a

soft tissue cloth.

To avoid possible damage, the probe cable must not be coiled to a diameter of less than 9 cm (3.5 inch).

Although there is no danger to a patient with an implantable pulse generator (IPG); ultrasonic scanning equipment

could cause mechanical damage to the IPG if used directly over the device's implant site.

Do not use the equipment in locations subject to intense electric or magnetic fields (near transformers, for

example). If the equipment is used in such locations, the monitor will be adversely affected.

Do not use the equipment near devices generating high frequencies (such as medical telemeters and cordless

telephones). If used near such devices, the equipment may malfunction or adversely affect such devices.

To guarantee proper unit operation; do not operate the scanner in an environment with a temperature in excess of

35 C. If the equipment is used in a small room, the room temperature may rise. Proper ventilation must be

provided.

Avoid installation near a heater or in direct sunlight.

For correct image geometry, only monitors properly adjusted by the manufacturer may be used on the scanner.

Inspect the probe carefully after a drop. A dangerous situation may arise due to damaged insulation of the probe

surface.

To prevent damage to mechanical probes due to excessive heat, a warning mechanism has been built into the system.

Mediwatch Service Department

Service Documentation

Section 1

Chapter 3. Technical Specifications of the Scanner

General Specifications:

Power Input

10 - 13.5 Vdc

Power Consumption

12 VA

Scanning Method

Mechanical Sector

Display Modes

B - mode

Probe Frequency

3.5/5.0 MHz

Max Image Depth

20 cm

Scan Converter

Full Digital 512 x 512 x 8

Bladder Volume

0 -1500 ml

Accuracy

0 - 699 ml 20%, 20ml

(whichever is700 ml - 1500ml 25% 25ml greater)

Accuracy is based upon usage as per instructions and scanning a tissue equivalent phantom

Display Format

8 inch colour TFT LCD 640 x 480 pixels

Battery

12 Volt rechargeable at least 1.5 Hrs continuous operation

from full charge.

Dimensions

WxDxH = 16 x13 x 13 cm

Weight

2540g without battery and probe3220g with battery and probe

Enclosure Leakage and Earth Leakage Current

Within specification for Class II type BF according to

EN 60601 - 1

Environmental Operating Conditions

Temperature 8 - 40C Humidity up to 90% (20C)

General Storage Conditions

Temperature 0 - 50C

Standards

EN 60601 - 1 & Class II, Type BF handheld equipment

Acoustic Output information for the 3.5/5.0 MHz Mechanical sector (410047):

Parameter:

Mode

B W o max.

P_

1spt

System settings

(MPa)

(mW.cm2)

1.2

2.8

5.0HMz

Min. scan angle

Min. scan depth

53.8

(mm)

(KHz)

2.4

1708

1p

(mm)

Wpb6 (_1_)

Prr

Srr

(Hz)

Output Beam Dimensions

Area

(mm)

,<

()

Fawf

Acoustic power up fraction

(%)

Maximum Power

(mW)

lob

(mW/cm)

Power up mode

Initialisation mode

Acoustic output freeze

L tt

(mm)

Lts

(mm)

Inclusive modes

2.8

520.6

(mm),

19.35

(MHz)

3.2

0

2.6

0.6

B

B

YES

7.29

CONTACT

B

Mediwatch Service Department

Service Documentation

Section 1

Chapter 4. Connector overview

Connections:

Backlight

LCD Display

Repairable Parts

Ultrasonic Probe

Serviceable by Module Only

Composite USB

Converter

Backlight

Inverter

Motherboard

Probe

Board 1

Probe Board 2

ETX Board With Dimm &

Flash Memory

7 Way Keypad

External Peripherals

Printer

Removable Battery Pack

Universal DC Supply

(Applied Only When

Charging Removed

Battery Pack)

Battery Charge

Control

Battery

A.C. Mains

Figure 1. Portascan Block Diagram

Main Board:

EXT Board:

See Main Board Schematic for further details

DRAM

of connector Pin assignments.

CPU

Geode GX1

BIOS

12C

Setup

Data

Hard Disk

Interface

LCD

JLI

Connector X3

12C

NDA

Floppy

LTP

CRT

Connector X1

CF Socket

sec. master

1028aseT

Ethernet

Controller

PCI BUS

Companion

Chip

CS5530A

USB0

USB1

Sound

Codec

Converter

ISA BUS

Connector X2

Connector X4

flash

memory

Figure 2. Mainboard Top View

Mouse

KeyCOM1

COM2

Figure 3. ETX Board Block Diagram

Mediwatch Service Department

Service Documentation

Section 1

Chapter 5. Planned Maintenance

Handling and Care

Although the scanner is produced with the utmost care and only the highest quality components are used, maintenance will be

necessary from time to time to ensure trouble-free operation.

�

Remove loose dust from the exterior with a soft cloth or a dry brush. A solution of water with a mild detergent may

be used, but not freely applied. Avoid aggressive cleaners.

Check the ventilation fans of the unit for proper operation.

Handling and Care probes

Basic precautions probes

Always follow these basic precautions:

�

Inspect the probe daily for cracks and other damage.

DO NOT use a probe that has been cracked or damaged.

DO NOT use a probe that has been dropped or struck against another object until it is inspected by a service

engineer.

Avoid pinching or kinking the probe cable. If the probe housing becomes cracked or broken or if there are cuts or

openings in the probe cable the electrical safety of the probe could be compromised.

Disconnect the probe from the scanner before cleaning and disinfection. Make sure to switch the system off before

disconnecting or connecting the probe.

To prevent hazards; refer to your local requirements for adequate electrical installation in case of class 1 type BF

Agents and procedures that may damage the probes.

Some agents and procedures damage probes. Use of any of the following procedures or products WILL VOID your probe

warranty.

Agents that contain the following chemicals are known to damage the probe:

�

Acetone

Methanol

Denatured ethyl alcohol

Mineral oil

Iodine

Any lotions or gels containing perfume. Check with the ultrasound gel manufacturer regarding gel contents. If you

have additional questions, please contact your representative.

The following procedures are known to damage probes:

�

�

Autoclaving

Soaking the probe in chlorine bleach

General probe cleaning

Cleaning the probe is done by first removing the ultrasound coupling gel with a soft tissue and then gently wiping the probe

dry using a new tissue or dry cloth. When more cleaning is required only a mild detergent or hand-soap may be used

together with some water and a soft tissue cloth.

Mediwatch Service Department

Service Documentation

Section 1

Chapter 6. Unit Disassembly

Figure 4. Portascan Top View

Figure 7. Unscrew 4 screws

Figure 10. Note location of

long screw

Figure 6. Battery release & removal

Figure 5. Portascan complete

Figure 8.

& remove cover

Figure 11.

Figure 12.

Probe connector

lock nut

Battery Pack &

PCB Board

Cut or remove security sticker then hinge top away

to separate case

Figure 14. The bottom case and

handle grip can be placed to one

side

Figure 16.

Lift main board peeling away earth strap &

disconnect plugs/skts.

Figure 17.

Figure 18.

Carefully turn

over main panel.

Figure 20.

Back Panel with

release screws arrowed

Use special Lemo wrench to loosen probe

connector nut

Figure 13.

Figure 19. Shielding removed

Figure 9.

Figure 15. Two screws hold the

main assembly in place

Note location of sounder & fan and display

inverter board

Probe interface panel set. Remove screws to

separate

Mediwatch Service Department

Service Documentation

Section 1

Chapter 6. Unit Disassembly - continued

Figure 21.

Separate ribbon connector, or carefully hinge probe

interface boards

Figure 23.

The compact flash can now be removed,

reprogrammed & replaced

Figure 24.

Figure 25.

The compact flash can now be removed,

reprogrammed & replaced

Figure 26.

24 RAM can also

be accessed if necessary

(Observe E.S.D. precautions)

LCD mounting brackets &

screws

Bottom case label

Keypad membrane

Dual frequency probe &

connector

Figure 22.

to reveal ETX

Heatsink screws

Rear panel connections

Retain Heatsink from other side

24 RAM can also be accessed if necessary

(Observe E.S.D. precautions)

Mediwatch Service Department

Service Documentation

Section 1

Chapter 7. Faults and Solutions

Screen Related

LCD blank, can be caused by loose connector at rear of display panel or faulty display.

LCD poor contrast or dark due to failure of inverter board P/N C-00049.

Probe Related

Probe knocking: generally caused by one or more broken wires at the back of probe socket.

Probe not scanning, error message probe too hot: Probe or probe interface board

Keypad Related

Led failure, internal led becomes detached possibly due to operator, replace keypad.

No response from keypad. Due either to connector failure or to short caused by poor etching of the keypad ribbon cable.

Reconnect or replace keypad

Software Related

On the rare occasion that Windows 98SE crashes, the display will freeze and keypad will be inactive. In this situation the

system will automatically shut down after 15 seconds. DO NOT remove the battery pack until this has happened. Removing

the battery pack before complete shutdown could cause the following problems:

Unit boots into windows safe mode, connect external keyboard and follow screen prompts, if problem is not resolved after

two or three reboot attempts then unit requires the compact flash to be reprogrammed.

Fatal exception error, run scandisk to establish integrity of compact flash using the ETX test assembly. If flash disk fails then

replace and reprogram with latest version.

Boot error message writing to drive c, treat as per fatal exception error.

Mediwatch Service Department

Service Documentation

Section 1

Chapter 8. Parts List

Parts Description

Mediwatch Code

Battery Cells

PSA00020

Battery Gold Contacts

PSA00021

Battery Pack

PA00141B

Battery Pack Case (Lower)

C00052A

Battery Pack Case (Upper)

C00051A

Battery PCB

PSA00052

Fan

C00068

Flash Memory 256Mb

C00169

Flexi-Links (Interface PCB-pair)

PSA00065

Frame Grabber PCB

C00165

Motherboard PCB

PSA 00042

ETX PCB

C00148

SDRAM 256Mb

C00168B

Interface PCB

PA00143A

Inverter Cable

C00049

Screening Cans

PSA00062

Keyboard Membrane

PSA00182

LCD Backlight Inverter

C00048

LCD Bracket(Bottom)

PSA00015

LCD Bracket(Top)

PSA00014

LCD Data Cable

PSA00017

LCD Screen

C00047

Lid

PSA00006A

Magnet Contact

PSA00061

Magnet Support Plates

PSA00060

Handle Soft Grip

PSA00011

Magnet(Print Lid)

C00216

Main Case(Lower)

C00037A

Main Case(Upper)

C00036A

Main Printer Lid

C00040A

Printer Bowl

C00041A

Printer Pcb Assy.

PSA00045

Probe 3.5/5.0Mhz

PA00143

Probe Connector Location Washer

PSA00072

Probe Connector Mounting Ring

PSA00064A

Battery Charger

PA00142B

Speaker

C00067

Thermal Print Unit

C00057

Mediwatch Service Department

Service Documentation

Section 1

Chapter 9. ESD

What is ESD

Electro Static Discharge (ESD) is the transmission of electro static charges between two bodies with a potential difference. This

transmission can be achieved by direct contact or by an inducted electrostatic field. Electro static discharges are not always

noticed by operators, because ESD is:

�

sensed at 3,500 Volt

audible at 4,500 Volt

visible at 5,000 Volt

Components and integrated circuits are more sensitive than operators and might be damaged by lower voltage discharges.

Component Type

ESD sensitivity in Volts

V-MOS

30-1800

mosFET

100-200

EPROM

100

JFET

140-7000

OP-AMP

190-2500

C-MOS

250-3000

Schottky Diodes

300-2000

Bipolar Transistors

380-7000

ECL

500-1500

SCR

680-1000

Schottky

TTL 1000-2500

Preventing ESD damage

Use electro static sensitive parts only in an ESD safe workshop.

�

Use ESD safe packing material.

Remove all static chargeable materials (plastics) from the workshop.

Wear ESD safe clothing.

Always check wrist strap and other ESD equipment before use.

Be grounded.

BE AWARE.

ESD safe workshop

To be sure that there is no potential difference between body, boards and work surface, the work surface should be made of

electrostatic dissipative rubber. The work surface should be connected to a central ground point. The engineer, handling the

boards should also be connected to the central ground point, either through wrist strap or heal strap (and conductive floor).

ESD safe field service

To enable ESD field safe service an ESD field service kit has to be used whenhandling boards.

This ESD field service kit should be connected to a central ground point and the service engineer should be connected to the

ESD field service kit through a wrist strap.

Handle boards only on this ESD field service kit and pack in ESD safe packing material.

More information about ESD precautions

All precautions against ESD damage are described in the CECC 00015/I regulations, composed by the CECC - Cenelec

electronic Components Committee.

Mediwatch Service Department

Service Documentation

Section 1

Circuit Diagrams

10

Mediwatch Service Department

Service Documentation

Section 1

Circuit Diagrams

11

Mediwatch Service Department

Service Documentation

Section 1

Appendix 1

Testing of Final Assembly

Scanner Serial No:

Interface Board Serial No:

Probe Serial No:

Instructions:

Pass / fail:

Insert a charged 'test' battery pack and check that it fits securely.

Ensure that the printer door opens and closes smoothly and that the magnetic latch holds the door

securely when the door is closed.

Restrain paper and shake unit and ensure that there are no loose parts inside.

Unplug the probe from the unit by pulling on the release ring on the plug and ensure that

there is no damage to the connector on the unit or the probe plug. Plug the probe in and check

that it clicks securely in place.

Plug a standard PC keyboard into the appropriate socket on the back of the unit. Switch the unit

on by pressing the red power button & wait for the unit to start up.

Hold down 'Alt'& 'Shift'& 'Control' then press 'W' very briefly to disable the Interface board

watchdog timer. Switch off by pressing the red button and wait for the unit to power down.

Remove the keyboard and switch the unit back on by pressing the red button. Wait for the unit

to start up.

Press the display brightness button several times and ensure that the display brightness toggles

between its high and low setting.

Press the menu button and check that the menu options are displayed.

Using the "UP", "DOWN" menu buttons select the "Date/Time" option and then press the

"SELECT" button. Press the "SELECT" button again to select the "Set Date" option. Check that the

correct date is displayed. If the incorrect date is displayed then set the correct date by using the

"UP", "DOWN" and "TAB" menu buttons and lock the setting by pressing the "SELECT" button.

Press the menu button. Using the "UP", "DOWN" menu buttons select the "Date/Time" option and

then press the "SELECT" button. Press the "DOWN" button and then the "SELECT" button to select

the "Set Time" option. Check that the correct time is displayed. If the incorrect time is displayed

then set the correct time by using the "UP", "DOWN" and "TAB" menu buttons and lock the setting

by pressing the "SELECT" button.

Press the menu button. Using the "UP", "DOWN" menu buttons select the "Set Probe Frequency"

option and then press the "SELECT" button. Press the "DOWN" button and then the "SELECT"

button to select the "5Mhz" option. The unit will switch to 5Mhz operation and "5Mhz" will be

displayed at the top of the display.

Press the green button to start scanning.

Align the probe on a phantom bladder so the largest section of the phantom can be seen

on the display. Press the magnification button repeatedly so that the unit cycles through all

levels of magnification then set the magnification so that the phantom fills the display but does

not overlap the edges of the scan sector.

Press the green scan button to record the reading. Check that the reading is within tolerance

(+ or - 10% of indicated phantom volume).

Press the print button to obtain a hard copy of the result.

Press the sagittal scan button and rotate the probe 90 degrees from the position of the first

scan and obtain the largest section and press the sagittal scan button again to obtain the reading.

12

Mediwatch Service Department

Service Documentation

Section 1

Appendix 1

Testing of Final Assembly - continued

Instructions:

Pass / fail:

Press the print button to obtain a hard copy of the result.

Press the menu button. Using the "UP", "DOWN" menu buttons select the "Set Probe Frequency"

option and then press the "SELECT" button. Press the "DOWN" button and then the "SELECT"

button to select the "3.5Mhz" option. The unit will switch to 3.5Mhz operation and "3.5Mhz" will be

displayed at the top of the display.

Press the green button to start scanning.

Align the probe on a phantom bladder so the largest section of the phantom can be seen

on the display. Press the magnification button repeatedly so that the unit cycles through all levels

of magnification then set the magnification so that the phantom fills the display but dose not

overlap the edges of the scan sector.

Press the print button to obtain a hard copy of the result.

Press the sagittal scan button and rotate the probe 90 degrees from the position of the first

scan and obtain the largest section and press the sagittal scan button again to obtain the reading.

Press the print button to obtain a hard copy of the result.

On the printed results record in the field "Patient Name" the serial number of the unit that is

being inspected.

Open the printer door and raise the print head and remove the paper. Feed the paper back into

the printer until the end appears from the front paper slot and re-engage the print head.

Press the print button. The last recorded image should be printed.

Leave the unit sitting for 5 minutes in which time the display should have shut down. (If the unit

is left for longer than 7 minutes the unit will switch off and the test will need to be repeated in

order to proceed to the next step).

Press any function button to reactivate the display.

Press the red power button. The unit will now shutdown and switch off. Remove the battery pack.

Fit the top cover with protective polythene.

Ensure that the top cover opens and closes smoothly and that the latch holds the cover securely

in place when closed. Ensure that the friction latch holds it from falling forward when fully opened.

Check that the Power drawn by the Battery when the unit is powered down is less than 10mA.

This Bladder scanner has PASSED/FAILED the above Test Procedure.

(Delete as appropriate)

Signed: ________________.

Date: ____/____/________

13

Mediwatch Service Department

Service Documentation

Visit us online at:

www.gehealthcare.com

2005 General Electric

Company

All Rights Reserved

GE and GE Monogram are

trademarksof General Electric

Company.

GE Medical Systems, a General

Electric company, going to

market as GE Healthcare.

Windows CE is either a

registered Trade Mark or a Trade

Mark of Microsoft Corporation in

the United States and/or other

countries.

General Electric Company

reserves the right to make

changes in specifications and

features shown herein, or

discontinue the product

described at any time without

notice or obligation.

Portascan manufactured by:

Mediwatch (UK) Ltd.

Swift House

Cosford Lane

Rugby

Warwickshire

CV21 1QN

For more than 100 years, scientists and industry leaders

have relied on General Electric for technology, services and

productivity solutions. So no matter what challenges your

healthcare system faces you can always count on GE

to help deliver the highest quality services and support.

For details, please contact your GE Service Sales Team.

GE Healthcare

Building 4B, 21 South Street

Rydalmere, NSW 2116

Australia

Phone: 1800 223 615

www.gehealthcare.com

Вам также может понравиться

- GE Logiq-200 - Service ManualДокумент183 страницыGE Logiq-200 - Service ManualRuslan SergeevОценок пока нет

- Honeywell Galaxy g2 Installation Programming Manual PDFДокумент148 страницHoneywell Galaxy g2 Installation Programming Manual PDFluis mariano Alda100% (1)

- Liebert NXa Users ManualДокумент132 страницыLiebert NXa Users ManualWaqqaskhan50% (2)

- JUMO DICON Touch PDFДокумент192 страницыJUMO DICON Touch PDFJevgenij ChupinОценок пока нет

- 4247 L03 ServiceДокумент231 страница4247 L03 ServicerendangenakОценок пока нет

- DP-3000 R59770374 03 Service PDFДокумент377 страницDP-3000 R59770374 03 Service PDFAlmaz CinemaОценок пока нет

- Installation Manual Exit Device RFIDДокумент33 страницыInstallation Manual Exit Device RFIDla costa la costaОценок пока нет

- Case 580f Tractor Loader Backhoe Operators ManualДокумент8 страницCase 580f Tractor Loader Backhoe Operators Manualأكرم تيجي100% (1)

- Eaton Power Distribution Product GuideДокумент477 страницEaton Power Distribution Product GuideRodrigo Alonso Rosales OrtegaОценок пока нет

- Volvo Excavator Parts Catalog EC380DДокумент1 492 страницыVolvo Excavator Parts Catalog EC380DUsman gani67% (3)

- GE Portascan Portable Bladder Scanner - Service ManualДокумент18 страницGE Portascan Portable Bladder Scanner - Service ManualHarold MartinezОценок пока нет

- MM12822 Rev 9-07Документ68 страницMM12822 Rev 9-07Beltazor HellboyОценок пока нет

- High Precision Automotive Unipolar Hall Effect Switch TLE4964-1MДокумент27 страницHigh Precision Automotive Unipolar Hall Effect Switch TLE4964-1MDhashana MoorthyОценок пока нет

- 4472.751.101 Repair Instructions AV-110 & AV-133Документ138 страниц4472.751.101 Repair Instructions AV-110 & AV-133Paweł DakiniewiczОценок пока нет

- Sli-23198 Rev0Документ56 страницSli-23198 Rev0Andrey GurevichОценок пока нет

- Alcatel Lucent RRH60 21C Site Specification V02.01 Dec10Документ45 страницAlcatel Lucent RRH60 21C Site Specification V02.01 Dec10Hamid QaziiОценок пока нет

- Liebert Gxt4 230V, 5000-10,000VA: User ManualДокумент56 страницLiebert Gxt4 230V, 5000-10,000VA: User ManualEmerson Müller Juarez AvilaОценок пока нет

- RxControl ManualДокумент77 страницRxControl ManualMoni ZaОценок пока нет

- Microcommander Installation Manual: Mm12793 Rev.B 8/02Документ112 страницMicrocommander Installation Manual: Mm12793 Rev.B 8/02Jb100% (1)

- A9110E UBTS CommissioningДокумент74 страницыA9110E UBTS CommissioningNguyen Nam PhongОценок пока нет

- Ascent Trainer Service Manual Matrix Fitness 24756Документ61 страницаAscent Trainer Service Manual Matrix Fitness 24756Nathan TapscottОценок пока нет

- Liebert GXT3 10kVA Tower Model SLI 23442 REV3!05!12 ManualДокумент44 страницыLiebert GXT3 10kVA Tower Model SLI 23442 REV3!05!12 ManualMianWaqarОценок пока нет

- Barco RLM g5 PDFДокумент114 страницBarco RLM g5 PDFRainer AdelsbergerОценок пока нет

- MFS 9130 Hardware DescriptionДокумент112 страницMFS 9130 Hardware DescriptionYasser AlqadhiОценок пока нет

- Manual de Servicio Epson TM-U220Документ96 страницManual de Servicio Epson TM-U220Angel Eduardo Alvarez Rodriguez100% (1)

- 30 41 t5xx Series Manaul en Us UslДокумент250 страниц30 41 t5xx Series Manaul en Us UslHeryanto MarioОценок пока нет

- C1621MBДокумент40 страницC1621MBTRAINING PLC IO ROBOTICS AND AUTOMATIONОценок пока нет

- Celitron Operacion InglesДокумент85 страницCelitron Operacion InglesLeonel Losada CardozoОценок пока нет

- FLIR t559845 EngДокумент198 страницFLIR t559845 EngMike WrightОценок пока нет

- 9130 BSC HW DescriptionДокумент138 страниц9130 BSC HW DescriptionrajaОценок пока нет

- Liebert Gxt4 UPS 120V/208V 500VA-3000VA: User ManualДокумент56 страницLiebert Gxt4 UPS 120V/208V 500VA-3000VA: User ManualJuan BaltasarОценок пока нет

- Ilite 6/8/10/12 Display: Service ManualДокумент82 страницыIlite 6/8/10/12 Display: Service ManualtioinoОценок пока нет

- Rice Lake 520 Manual Técnico PDFДокумент98 страницRice Lake 520 Manual Técnico PDFproyectosdicome2Оценок пока нет

- TEK TDS 3000 Series ServiceДокумент140 страницTEK TDS 3000 Series Servicelolo406Оценок пока нет

- Nihon-Kohden TEC-9110,9130 ECG Monitor - Service Manual PDFДокумент143 страницыNihon-Kohden TEC-9110,9130 ECG Monitor - Service Manual PDFAnonymous EABpniBОценок пока нет

- Grid-Tie Transformerless Solar Inverter: Rpi M50A Operation and Installation ManualДокумент76 страницGrid-Tie Transformerless Solar Inverter: Rpi M50A Operation and Installation ManualLars MaesОценок пока нет

- Homnewei stt25dДокумент40 страницHomnewei stt25djhon padronОценок пока нет

- Tektronix - Service ManualДокумент140 страницTektronix - Service ManualNathan T Nesbitt100% (1)

- Rexa Manual x2 Iom 10-2014Документ294 страницыRexa Manual x2 Iom 10-2014AH100% (1)

- CAS ER New - PlusService Manual - 070703 - OIMLДокумент86 страницCAS ER New - PlusService Manual - 070703 - OIMLRpetrovichОценок пока нет

- Ob VKS10 V1.01 08.2020 enДокумент99 страницOb VKS10 V1.01 08.2020 enquang.an185Оценок пока нет

- AN2586 Application Note: STM32F10xxx Hardware Development: Getting StartedДокумент28 страницAN2586 Application Note: STM32F10xxx Hardware Development: Getting StartedRouaissi RidhaОценок пока нет

- EMC110006E 5 EGSV3 CACR-xx-EExVxx-00 UsersManual PDFДокумент64 страницыEMC110006E 5 EGSV3 CACR-xx-EExVxx-00 UsersManual PDFLautaro AyoroaОценок пока нет

- JUMO VariTRON 500 Operating ManualДокумент110 страницJUMO VariTRON 500 Operating ManualNatiqОценок пока нет

- IQ Plus 710: Discontinued ProductДокумент84 страницыIQ Plus 710: Discontinued ProductAlfonso CepedaОценок пока нет

- M250HV ManualДокумент96 страницM250HV ManualRoshan ChhetriОценок пока нет

- Grid-Tie Transformerless Solar Inverter: M70A / M50A Operation and Installation ManualДокумент88 страницGrid-Tie Transformerless Solar Inverter: M70A / M50A Operation and Installation ManualABCDОценок пока нет

- Cardio Aid200 Artema Service Manual PDFДокумент152 страницыCardio Aid200 Artema Service Manual PDFarshad209Оценок пока нет

- EZ-SCREEN SLS Safety Light Curtain In-Struction ManualДокумент114 страницEZ-SCREEN SLS Safety Light Curtain In-Struction Manualhector danielОценок пока нет

- Evita 4Документ216 страницEvita 4Mohamed Abdulaal100% (1)

- Evlunic Ac-Wallbox Mba en Rev-C AbbДокумент65 страницEvlunic Ac-Wallbox Mba en Rev-C AbbDiego MaldonadoОценок пока нет

- PMCL 400 Series MonitorДокумент24 страницыPMCL 400 Series Monitornestkwt1Оценок пока нет

- User Manual 39276Документ44 страницыUser Manual 39276Matias MiroОценок пока нет

- Smt8x Technical Manual Letripp IIДокумент18 страницSmt8x Technical Manual Letripp IIIgroufaNaguibОценок пока нет

- ArduinoДокумент58 страницArduinoLalo RSОценок пока нет

- Cardio-Aid 200 PDFДокумент7 страницCardio-Aid 200 PDFSERGIO PEREZОценок пока нет

- Manual Nxe 10 - 30 KvaДокумент80 страницManual Nxe 10 - 30 Kvaanon_760637530Оценок пока нет

- Common Building Block (CBB) Battery Pack For Notebooks: Design Guide April 2007 Revision 1.1Документ56 страницCommon Building Block (CBB) Battery Pack For Notebooks: Design Guide April 2007 Revision 1.1spotОценок пока нет

- AVy Lift Eng - 2 PDFДокумент223 страницыAVy Lift Eng - 2 PDFKaian elevatorОценок пока нет

- Emerson UPSДокумент88 страницEmerson UPSserkalemtОценок пока нет

- GE LOGIQ 400 - Service ManualДокумент502 страницыGE LOGIQ 400 - Service ManualRuslan SergeevОценок пока нет

- Aloka SSD-5500 - Service ManualДокумент672 страницыAloka SSD-5500 - Service ManualRuslan Sergeev100% (1)

- ATL Ultramark 9HDI - Service ManualДокумент966 страницATL Ultramark 9HDI - Service ManualRuslan SergeevОценок пока нет

- GE Logiq-100 - Service ManualДокумент141 страницаGE Logiq-100 - Service ManualLuis Fernando Garcia SОценок пока нет

- Crossmax Elite 29 2017 FRONTДокумент2 страницыCrossmax Elite 29 2017 FRONTlcesserОценок пока нет

- Compal La-5893p r0.1 Schematics PDFДокумент57 страницCompal La-5893p r0.1 Schematics PDFАлекс ХомичОценок пока нет

- TK10 Madoneservice 062309Документ27 страницTK10 Madoneservice 062309depuy01Оценок пока нет

- Pa 31 - Pa 31 300 325 - smv1994 PDFДокумент1 106 страницPa 31 - Pa 31 300 325 - smv1994 PDFJosue MedinaОценок пока нет

- Computer JSS 1 First - ThirdДокумент117 страницComputer JSS 1 First - ThirdJames100% (2)

- 1234 - 36 - 38 Manual Rev Feb 09 PDFДокумент134 страницы1234 - 36 - 38 Manual Rev Feb 09 PDFPedro NetoОценок пока нет

- bss65, bss65r Zetex L1 PDFДокумент2 страницыbss65, bss65r Zetex L1 PDFuzenhoОценок пока нет

- Chapter I Designing Approval: S.N Item Description Unit QuantityДокумент22 страницыChapter I Designing Approval: S.N Item Description Unit QuantityJavaid ahmed turkОценок пока нет

- PIR Sensor Based Security System, Circuit Diagram, Working, ApplicationsДокумент13 страницPIR Sensor Based Security System, Circuit Diagram, Working, ApplicationsAlan A. TorresОценок пока нет

- Engine Valve Lash - Inspect/Adjust: Controlli e RegistrazioniДокумент4 страницыEngine Valve Lash - Inspect/Adjust: Controlli e RegistrazionijamcaОценок пока нет

- Electro Motion Machine Tools Stock ListДокумент13 страницElectro Motion Machine Tools Stock ListElectro Motion UK (Export) LtdОценок пока нет

- Bd9397efv e PDFДокумент30 страницBd9397efv e PDFshafiuddin7326Оценок пока нет

- ATX Power Supply Pinout TablesДокумент4 страницыATX Power Supply Pinout TablesElectrical EEEОценок пока нет

- Reddot R9757 (Rh40e) - 1Документ8 страницReddot R9757 (Rh40e) - 1Rodny Romero0% (1)

- Manual PLC ZelioДокумент16 страницManual PLC ZelioAlexander FelizОценок пока нет

- 3 - 1 - SimbologiaДокумент2 страницы3 - 1 - SimbologiaRenan Verolli Dal'AvaОценок пока нет

- 737-300/400/500 MAINTENANCE TRAINING MANUAL Main Hydraulic Systems - Reservoir Pressurization System - Component LocationsДокумент11 страниц737-300/400/500 MAINTENANCE TRAINING MANUAL Main Hydraulic Systems - Reservoir Pressurization System - Component LocationsBYRON PAUL YANEZ BOMBONОценок пока нет

- TISP4360H3BJ Overvoltage Protector SeriesДокумент14 страницTISP4360H3BJ Overvoltage Protector SeriesIgor PОценок пока нет

- SERVICE MANUAL - Jordans ManualsДокумент36 страницSERVICE MANUAL - Jordans ManualsNirmal NepalОценок пока нет

- Milliohm Meter YF-508 Ctds PDFДокумент1 страницаMilliohm Meter YF-508 Ctds PDFristanintanОценок пока нет

- 1966 Ford Mustang Breaker Points and Condenser Removal and InstallationДокумент4 страницы1966 Ford Mustang Breaker Points and Condenser Removal and InstallationOxgardОценок пока нет

- Electricity Lesson PlanДокумент2 страницыElectricity Lesson Planramel gedorОценок пока нет

- Zapi FC2086 Codes PDFДокумент8 страницZapi FC2086 Codes PDFGabriel BravoОценок пока нет

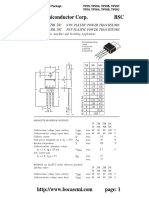

- Boca Semiconductor Corp. BSC: Continental Device India LimitedДокумент3 страницыBoca Semiconductor Corp. BSC: Continental Device India LimitedNadia Ayelen GonzalezОценок пока нет

- Air Caster Rigging - ACRS2016 WEBДокумент2 страницыAir Caster Rigging - ACRS2016 WEBTri EplengОценок пока нет

- Winpower Murphy Asm150 Micro Controller PDFДокумент4 страницыWinpower Murphy Asm150 Micro Controller PDFAbdul KhaliqОценок пока нет

- Manual Furadeira Radial Rd3050x16Документ56 страницManual Furadeira Radial Rd3050x16rbocca123Оценок пока нет