Академический Документы

Профессиональный Документы

Культура Документы

(IJET-V1I2P8) Authors :L.Sarojini, P.Kayalvizhi, D.Ajay Abilash

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

(IJET-V1I2P8) Authors :L.Sarojini, P.Kayalvizhi, D.Ajay Abilash

Авторское право:

Доступные форматы

International Journal of Engineering and Techniques - Volume 1 Issue 2, Mar - Apr 2015

RESEARCH ARTICLE

OPEN ACCESS

CONTROL SYSTEM OF BIOMASS GASIFIER USING PLC

L.SAROJINI1, P.KAYALVIZHI2, D.AJAY ABILASH3

1

(Assistant professor, Department of electrical and electronics engineering, Periyar maniammai university, thanjavur)

(M.tech( Automation and control system), Department of mechanical engineering, Periyar maniammai university, thanjavur)

3

(M.tech( Automation and control system), Department of mechanical engineering, Periyar maniammai university, thanjavur)

Abstract:

India has many no of renewable energy resources. In that Biomass Gasifier plays a major role as an alternate energy

source. But it facing lot of practical problems on operation due to shortage of manpower and also several problems may

happen in these gasifiers. To overcome the above problems we go for automatic control systems in this gasifier. Therefore we

can neglect the human efforts, errors and operators of the gasifier wont get affected by the out coming gases from the

gasifiers due to this automation. The gasifier itself works according to the program which we have given. Automation is done

in the miscellaneous function, fuel feeding system and all biomass gasifier control system by using PLC (Programmable Logic

Controller). And then we develop the ladder logic program for sequence of operation in gasifier control system. In this system

the ladder logic function is programmed by using INDRALOGIC software and the hardware component of PLC is Rexroth

Bosch product.

Keywords: Programmable logic controller (PLC), Biomass gasifier, Indralogic.

I. INTRODUCTION

Biomass gasifier is an alternate source used

for power generation and thermal applications. Lots

of biomass fuels are available in rural areas. Some

of the biomass fuels are wood waste, sawdust,

briquettes, seed cakes, coconut shells, etc., These

are available at low cost. So we can generate power

at minimum cost using these fuels even though lots

of practical problems occur in the biomass gasifiers.

They are s follows i) Gasification is a involutes and

sensational process, ii) To start the process, gasifier

need at least half an hour of time, iii) Removal of

ash and tarry contents and its handling is a dirty and

time consuming process, iv) Getting the producer

gas in a proper state is difficult, v) These gasifiers

requires frequent refilling of the fuel. To overcome

the above problems automatic control system is

needed. The control system of biomass gasifier is

capable of offering a wide range of solutions to suit

these needs. These are achieved by utilizing a

variety control system like embedded system or plc

control system [1].

The embedded system is used to performing

the specific task and the hardware components of

embedded system is very low cost compare to plc.

ISSN: 2395-1303

But it has few disadvantages like it does not use in

high temperature region, Very less input/output

modules, modification of program is not possible.

For the above reasons the embedded system is not

suited for biomass gasifier control system. Hence

this paper is fully focused on control system of

biomass gasifier using PLC.

II. PLC OPERATION

PLC is a solid state digital computer used to

perform control functions in the industrial processes

such as assembly lines and machinery. It doesnt

have mouse, CD drive. Keyboard, disk drives and

monitor like PC but it has communication ports and

input/output terminals for devices. It is entirely

different from PC. PLC is designed for large no of

input/output and it has extended temperature ranges,

resistance to electrical noises and vibration. The

output of the equipment is controlled by the PLC

based on the input conditions. It has different type

of operations such as arithmetic, logical operation,

on/off operations, sequencing, timing, and counting.

In industry, PLC just replaces the control systems

and wiring connections between the devices.

Instead of connecting wires directly between the

http://www.ijetjournal.org

Page 41

International Journal of Engineering and Techniques - Volume 1 Issue 2, Mar - Apr 2015

devices, PLC provides wiring connections to them

by connecting all wiring connection to the PLC.

This is called soft wiring. PLC has memory, in that

control program is stored. It performs operations

according to the program.

PLC has many advantages over other

control systems. It is known for its flexibility, low

cost, operational speed, reliability, ease of

programming, security, and it is easy in

implementing changes and correcting errors [3].

Push button

Lights

PLC

Sensors

Motors

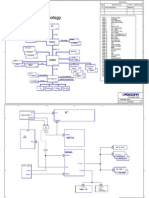

Fig.1. Typical functional components of PLC

A. Components of plc

PLC consists of the following components i)

Central processing unit ii) Memory iii) Input/output

iv) Power supply v) Programming device vi)

Programming methods

CPU is the main component of the PLC

since it is the nervous system of the controller and it

is the decision maker. It consists of microprocessor

and memory. These parts perform type of

operations listed above. In PLC, memory is used to

store data or information used for the process. It

makes decisions according to the instructions

present in the memory. They are RAM, ROM,

EPROM and EEPROM. The input/output devices

act as the interface between the controller and field

fi

equipments. Types

es of input/output devices are

analog

nalog and digital devices. I/P analog devices are

temperature and pressure sensor. Pushbuttons and

limit switchess are I/P digital devices. The analog

a

O/P devices are hydraulic and pneumatic valves.

Motor, lamp is examples for O/P devices. Internal

circuits of the PLC are supplied with the DC power.

Power is not supplied to the field devices through

power supply in larger PLC system. This can be

achieved by external current supplies for safety

purpose. For entering

ntering the desired program we need

a programming device, for this purpose PC can be

used. Each brands of PLCs has desired software

from their manufacture we can use this software in

PC and we can program in our computer. PC and

PLC can be connected throug

through communication

ports; we can edit and save our desired program in

PCs. Several methods of programming are available,

in that ladder logic is the universally accept method.

It looks like a ladder hence it is called ladder logic.

The input and output devicess are symbols. The

horizontal line is referred to as rung and otherwise

called as network. The left vertical path indicates

the power supply and right vertical line is the return

path or neutral line.

III. HARDWARE AND SOFTWARE

DESCRIPTION OF PLC IN BIOMA

BIOMASS

GASIFIER

PLCs may need to interact with people for

the purpose of configuration, alarm reporting or

everyday control. A Human--Machine Interface

(HMI) is employed for this purpose. HMIs are also

referred to as MMIs (Man Machine Interface) and

GUIs (Graphical

phical User Interface).A simple system

may use buttons and lights to interact with the user.

Text displays are available as well as graphical

touch screens. More complex systems use

programming and monitoring software installed on

a computer, with the PLC connected via a

communication interface [2].

A. Hardware

The hardware components used for the

development of this setup are Rexroth Bosch PLC,

push buttons, DC wiper motors, limit switches,

Proximity sensors, Air blower, Electronic Igniter,

Connecting wires.

es. Details of each component are

described below:

1. Rexroth Bosch PLC

The Indralogic L20 of Rexroth is a compact

PLC including a standardized I/O system on the

basis of terminal technology and is designed for

International Journal of Engineering and Techniques - Volume 1 Issue 2, Mar - Apr 2015

logic operation. Operation is only permitted in the

specified configurations and combinations of

components using the software and firmware as

specified in the relevant function descriptions.

Typical applications of Indralogic L20 are

Handling and assembly systems, Packaging

and foodstuff machine, Printing and paper

processing machines, Machine Tools. The

Indralogic L20 may only be operated under the

assembly, installation, and ambient conditions

(temperature, system of protection, humidity, EMC

requirements etc.,) [4].

y sensors

A proximity sensor is used as the input

device for sensing the level of fuel in the storage

chamber. It can detect the nearby object without

any physical contact of the sensed object. There are

no moving parts in it so it can withstand for long

duration and it has high reliability.

3. DC Wiper Motor

DC Wiper motor act as the drive system for

conveyor operation, door open close operation and

the control system of motor is achieved by

programmable logic controller (PLC).

4. Push buttons

TABLE I

SPECIFICATION OF REXROTH BOSCH PLC

Push buttons is made up of hard material or

plastic used for simple switching operation. Here it

acts as the input device and used for start and stop

operation.

5. Limit switches

Limit switch is a mechanical switch which

converts mechanical movement into electrical

signal. It is actuated by the physical contact of the

object. In this control system, limit switches are

used to control the door open close operation.

Description

Specification

Processor

ST microelectronics

ST40 with 192MHZ

Working memory

16Mbytes

DRAM

and

64kbytes

NVRAM.

Inputs

8 digital inputs (24V

DC supply)

Outputs

8 digital outputs

(24V DC supply)

Communication

Interface

Ethernet connection

or Serial RS232

interface

User memory

program

Weight

ISSN: 2395-1303

for

1Mbytes

200 grams

IV. SOFTWARE DESCRIPTION

In this paper, software used for the PLC

system is Indralogic. Here ladder logic is used as

the programming language. It is a symbolic

representation of control logic or set of instructions.

This program is to be entered in to the plc memory

for execution of real time process.

V. INTERFACING

PLC used in this system is REXROTH

BOSCH with 8 digital inputs and outputs. The input

ports are connected to the four limit switches and

three sensors. The output ports are connected to the

conveyor, blower, igniter, and motors for door

movement. PLC consists of an on delay timer using

that timing pulse can be generated in the necessary

place. The I/O port addresses are specified

according to our input/output port requirements in

the plc. While interfacing PLC must be connected

to the specified I/O devices in the appropriate port

2. address and then ladder program is created by using

Prox PLC software. Addresses are given in the program

imit must matched with those in the i/o port address

http://www.ijetjournal.org

Page 43

International Journal of Engineering and Techniques - Volume 1 Issue 2, Mar - Apr 2015

after that desired program is downloaded into the

PLC memory for real time working.

Fig. 2 Interfacing PLC

VI. RESULTS AND DISCUSSION:

After the interfacing process is done with

biomass gasifier setup, complete checking is done

for detecting errors and trials were done and the

proposed setup was successfully worked as per the

given control system.

When the push button is pressed for the first

time means, storage chamber door1 will get opened

for getting the fuel by the conveyor, if sensors

detects the predetermined level of the fuel in the

chamber,, door1 get closed and conveyor also cutoff,, then fuel get transferred into the hopper region.

Blower will automatically turn on by the control

logic and after some time delay igniter also will on.

If temperature reaches the 60 degree Celsius in the

gasifier,

ier, igniter will automatically turn off.

Whenever fuel reaches the minimum level, starting

process will happen for one more time

automatically. It is clearly seen that gasifier setup

worked successfully according to the control logic

specified in the program.

Fig.. 3 ladder diagram for biomass gasifier controls

VII. CONCLUSION

International Journal of Engineering and Techniques - Volume 1 Issue 2, Mar - Apr 2015

In this paper, the biomass gasifier was

developed with fully automatic controls. This paper

involves three stages. Stage 1: Hardware

components and software description of PLC was

studied. Stage 2: Ladder logic was developed

according to the sequence of operations in gasifier.

Stage 3: Biomass gasifier was interfaced with

Rexroth Bosch PLC hardware. The control system

of biomass gasifier was initiated with manual

switching control and other operations like

conveyor system and fuel feeding system was

automated. This system provided good stability,

high safety for operators, it overcomes manual

errors and it can operate without any human

intervention.

REFERENCES

[1] K.Sivakumar, Automation of 10 KW

Biomass Gasifier and its effectiveness on

saw dust briquettes with binder cow dung.

[2] Saurabh Sharma, Application of PLC for

Elevator Control System.

[3] Cheded, L. Al-Mulla, Ma'an, Control of a

four-level elevator system using a

programmable

logic

controller,

International

Journal

of

Electrical

Engineering Education.

[4] Rexroth indralogic L20 03VRS system

description operating and programming

guide.

ISSN: 2395-1303

http://www.ijetjournal.org

Page 45

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Bandwidth Lags Latency PDFДокумент5 страницBandwidth Lags Latency PDFBhargav Vara PrasadОценок пока нет

- Verifiable and Multi-Keyword Searchable Attribute-Based Encryption Scheme For Cloud StorageДокумент9 страницVerifiable and Multi-Keyword Searchable Attribute-Based Encryption Scheme For Cloud StorageInternational Journal of Engineering and TechniquesОценок пока нет

- Ijet V6i2p11 PDFДокумент8 страницIjet V6i2p11 PDFInternational Journal of Engineering and TechniquesОценок пока нет

- Ijet V6i2p11 PDFДокумент8 страницIjet V6i2p11 PDFInternational Journal of Engineering and TechniquesОценок пока нет

- Ijet V6i2p11Документ8 страницIjet V6i2p11International Journal of Engineering and TechniquesОценок пока нет

- Ijet V4i3p94 PDFДокумент8 страницIjet V4i3p94 PDFInternational Journal of Engineering and TechniquesОценок пока нет

- Ijet V4i3p98 PDFДокумент7 страницIjet V4i3p98 PDFInternational Journal of Engineering and TechniquesОценок пока нет

- Ijet V5i6p1Документ5 страницIjet V5i6p1International Journal of Engineering and TechniquesОценок пока нет

- Ijet V4i3p97 PDFДокумент4 страницыIjet V4i3p97 PDFInternational Journal of Engineering and TechniquesОценок пока нет

- Ijet V4i3p86 PDFДокумент5 страницIjet V4i3p86 PDFInternational Journal of Engineering and TechniquesОценок пока нет

- Ijet V4i3p96 PDFДокумент9 страницIjet V4i3p96 PDFInternational Journal of Engineering and TechniquesОценок пока нет

- Ijet V4i3p93 PDFДокумент10 страницIjet V4i3p93 PDFInternational Journal of Engineering and TechniquesОценок пока нет

- Ijet V4i3p100 PDFДокумент4 страницыIjet V4i3p100 PDFInternational Journal of Engineering and TechniquesОценок пока нет

- Ijet V4i3p101 PDFДокумент5 страницIjet V4i3p101 PDFInternational Journal of Engineering and TechniquesОценок пока нет

- Ijet V4i3p92 PDFДокумент12 страницIjet V4i3p92 PDFInternational Journal of Engineering and TechniquesОценок пока нет

- Ijet V4i3p89 PDFДокумент7 страницIjet V4i3p89 PDFInternational Journal of Engineering and TechniquesОценок пока нет

- Ijet V4i3p88 PDFДокумент7 страницIjet V4i3p88 PDFInternational Journal of Engineering and TechniquesОценок пока нет

- Ijet V4i3p95 PDFДокумент8 страницIjet V4i3p95 PDFInternational Journal of Engineering and TechniquesОценок пока нет

- Ijet V4i3p90 PDFДокумент3 страницыIjet V4i3p90 PDFInternational Journal of Engineering and TechniquesОценок пока нет

- Ijet V4i3p84 PDFДокумент7 страницIjet V4i3p84 PDFInternational Journal of Engineering and TechniquesОценок пока нет

- Ijet V4i3p72 PDFДокумент13 страницIjet V4i3p72 PDFInternational Journal of Engineering and TechniquesОценок пока нет

- Ijet V4i3p91 PDFДокумент10 страницIjet V4i3p91 PDFInternational Journal of Engineering and TechniquesОценок пока нет

- Ijet V4i3p87 PDFДокумент5 страницIjet V4i3p87 PDFInternational Journal of Engineering and TechniquesОценок пока нет

- Ijet V4i3p85 PDFДокумент7 страницIjet V4i3p85 PDFInternational Journal of Engineering and TechniquesОценок пока нет

- Ijet V4i3p79 PDFДокумент8 страницIjet V4i3p79 PDFInternational Journal of Engineering and TechniquesОценок пока нет

- Ijet V4i3p76 PDFДокумент4 страницыIjet V4i3p76 PDFInternational Journal of Engineering and TechniquesОценок пока нет

- Ijet V4i3p82 PDFДокумент7 страницIjet V4i3p82 PDFInternational Journal of Engineering and TechniquesОценок пока нет

- Ijet V4i3p83 PDFДокумент6 страницIjet V4i3p83 PDFInternational Journal of Engineering and TechniquesОценок пока нет

- Ijet V4i3p81 PDFДокумент7 страницIjet V4i3p81 PDFInternational Journal of Engineering and TechniquesОценок пока нет

- Ijet V4i3p80 PDFДокумент4 страницыIjet V4i3p80 PDFInternational Journal of Engineering and TechniquesОценок пока нет

- Ijet V4i3p70 PDFДокумент10 страницIjet V4i3p70 PDFInternational Journal of Engineering and TechniquesОценок пока нет

- Decimation PDFДокумент83 страницыDecimation PDFJose Gonzalez SapbeeОценок пока нет

- Service Manual: ONE TimeДокумент20 страницService Manual: ONE Time王军Оценок пока нет

- Power Quality Training - 30-31 Jul 2019, BrisbaneДокумент2 страницыPower Quality Training - 30-31 Jul 2019, Brisbanetosikur rahmanОценок пока нет

- LS800 CatalogДокумент11 страницLS800 CatalogZenab GeninaОценок пока нет

- Datasheet - HK Stgb14nc60kd Transistor de Ignicion para Automotriz para ECUДокумент17 страницDatasheet - HK Stgb14nc60kd Transistor de Ignicion para Automotriz para ECULuis Fernando Dorta VergaraОценок пока нет

- Physics Investigatory Project Class 12 CbseДокумент20 страницPhysics Investigatory Project Class 12 Cbsesyed50% (6)

- Baumer VeriSensC-Mount 2010-01 LRДокумент2 страницыBaumer VeriSensC-Mount 2010-01 LRpolychaetaОценок пока нет

- 20-24A EngineeringAnalysisInformationRequest 07 2019Документ5 страниц20-24A EngineeringAnalysisInformationRequest 07 2019Juan Carlos Tapia HenryОценок пока нет

- Single Instruction Stream Single Data Stream (SISD) : ClassificationsДокумент3 страницыSingle Instruction Stream Single Data Stream (SISD) : ClassificationsOLD BOYОценок пока нет

- Modulation (AM/DSB/SSB)Документ20 страницModulation (AM/DSB/SSB)Paul MalcolmОценок пока нет

- Xi4 Series Parts CatalogДокумент16 страницXi4 Series Parts Catalog2nd-levelОценок пока нет

- Mainboard Foxconn Model 741M01CДокумент40 страницMainboard Foxconn Model 741M01CHo Thanh BinhОценок пока нет

- PA in The Marching Arts PDFДокумент51 страницаPA in The Marching Arts PDFABОценок пока нет

- Garmin Wiring Diagrams - G3X - AllДокумент15 страницGarmin Wiring Diagrams - G3X - AllAviv SofferОценок пока нет

- Module 5 - Digital Techniques Electronic Instrument Systems PDFДокумент42 страницыModule 5 - Digital Techniques Electronic Instrument Systems PDFanilmathew244Оценок пока нет

- DS HighSpeedStar4 GДокумент2 страницыDS HighSpeedStar4 GKaffelОценок пока нет

- Fire c166Документ108 страницFire c166carver_uaОценок пока нет

- Ip Ip InternetДокумент6 страницIp Ip InternetbanujayantakaОценок пока нет

- Blazer Pro Series User ManualДокумент9 страницBlazer Pro Series User ManualThanh TungОценок пока нет

- HandHeld Brochure HRДокумент6 страницHandHeld Brochure HRAndrewОценок пока нет

- TempДокумент16 страницTempcaoap3847Оценок пока нет

- Erros Sonda AlpinaДокумент2 страницыErros Sonda AlpinaraphaelpessОценок пока нет

- Alteon-Tech-Spec ODS-VLДокумент3 страницыAlteon-Tech-Spec ODS-VLYo ChepoОценок пока нет

- Exams Time TableДокумент3 страницыExams Time TableManwelSciclunaОценок пока нет

- 2LAN+1POTS+WiFi Dual Mode HGU User Manual - v1.0Документ65 страниц2LAN+1POTS+WiFi Dual Mode HGU User Manual - v1.0Robert Castro SanchОценок пока нет

- UPnP DLNA White PaperДокумент25 страницUPnP DLNA White PaperVivek ChughОценок пока нет

- Power Electronics Lab ManualДокумент86 страницPower Electronics Lab ManualmadhueeОценок пока нет

- s71500 CM PTP Function Manual en-US en-USДокумент88 страницs71500 CM PTP Function Manual en-US en-USArunagiri MurugesanОценок пока нет