Академический Документы

Профессиональный Документы

Культура Документы

Grinda Simplu Rezemata

Загружено:

Saitis CatalinАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Grinda Simplu Rezemata

Загружено:

Saitis CatalinАвторское право:

Доступные форматы

Example: Simply supported primary composite beam (GB)

CALCULATION SHEET

Document Ref:

SX015a-EN-UK

Title

Example: Simply supported primary composite beam

Eurocode Ref

EN 1993-1-1, EN 1994-1-1

Made by

Laurent Narboux

Date

Nov 2006

Checked by

Charles King

Date

Nov 2006

Sheet

of

Localized resource for UK

Example: Simply supported primary composite

beam

This worked example deals with a simply supported composite beam. Two

secondary beams are connected to this primary beam.

Created on Monday, February 28, 2011

This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

6.0 m

6.0 m

3.0 m

3.0 m

9.0 m

The secondary beams are represented by two concentrated loads :

1 : Lateral restraints at the construction stage

16

Example: Simply supported primary composite beam (GB)

CALCULATION SHEET

Document Ref:

SX015a-EN-UK

Title

Example: Simply supported primary composite beam

Eurocode Ref

EN 1993-1-1, EN 1994-1-1

Made by

Laurent Narboux

Date

Nov 2006

Checked by

Charles King

Date

Nov 2006

Sheet

of

16

The beam is a UKB profile in bending about the strong axis. This example

includes :

-

the classification of the cross-section,

the calculation of the effective width of the concrete flange,

the calculation of the shear resistance of a headed stud,

the calculation of the degree of shear connection,

the calculation of the bending resistance,

the calculation of the shear resistance,

the calculation of the longitudinal shear resistance of the slab,

the calculation of the deflection at serviceability limit state.

Created on Monday, February 28, 2011

This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

This example does not include any shear buckling verification of the web.

Partial factors

G = 1.35

(permanent loads)

Q = 1.50

(variable loads)

M0 = 1.0

EN 1993-1-1

M1 = 1.0

6.1 (1)

V = 1.25

EN 1994-1-1

EN 1990

6.6.3.1

C = 1.5

EN 1992-1-1

Example: Simply supported primary composite beam (GB)

CALCULATION SHEET

Document Ref:

SX015a-EN-UK

Title

Example: Simply supported primary composite beam

Eurocode Ref

EN 1993-1-1, EN 1994-1-1

Made by

Laurent Narboux

Date

Nov 2006

Checked by

Charles King

Date

Nov 2006

Sheet

of

16

Basic data

Created on Monday, February 28, 2011

This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

Design a composite beam of a multi-storey building according to the data

given below. The supporting beams are not propped. The profiled steel

sheeting is parallel to the primary beam.

Span length :

9.00 m

Bay width :

6.00 m

Slab depth :

14 cm

Partitions :

0.75 kN/m2

Secondary beams (UKB 254x146x31) :

Imposed load :

2.50 kN/m2

Construction load :

0.75 kN/m2

Reinforced concrete density :

25 kN/m3

0.305 kN/m

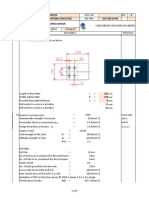

Try UKB 406x178x60 Steel grade S355

tf

Depth

ha = 406.4 mm

Width

b = 177.9 mm

Web thickness

tw = 7.9 mm

Flange thickness

tf = 12.8 mm

Fillet

r = 10.2 mm

Mass

60.1 kg/m

BS4

Corus

Advance

tw

y

y

ha

z

b

Section area

Aa = 76.5 cm2

Second moment of area /yy

Iy = 21596 cm4

Elastic section modulus /yy

Wel,y = 1062.8 cm3

Plastic section modulus /yy

Wpl.y = 1199.5 cm3

Radius of gyration /zz

iz = 3.97 cm

Modulus of elasticity of steel

Ea = 210 000 N/mm2

Example: Simply supported primary composite beam (GB)

CALCULATION SHEET

Document Ref:

SX015a-EN-UK

Title

Example: Simply supported primary composite beam

Eurocode Ref

EN 1993-1-1, EN 1994-1-1

Made by

Laurent Narboux

Date

Nov 2006

Checked by

Charles King

Date

Nov 2006

Sheet

of

16

Profiled steel sheeting

Thickness of sheet

t = 0.75 mm

Slab depth

h = 140 mm

Overall depth of the profiled steel sheeting excluding embossments

hp = 58 mm

b1 = 62 mm

b2 = 101 mm

e = 207 mm

Created on Monday, February 28, 2011

This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

Connectors

Diameter

d = 19 mm

Overall nominal height

hsc = 100 mm

Ultimate tensile strength

fu = 450 N/mm2

Number of studs

n = 74 row

(Stud at beam mid-span ignored)

b0

e

h

hsc

hp

0,5hp

b1

b2

EN 1992-1-1

Concrete class : C 25/30

Value of the compressive strength at 28 days

Secant modulus of elasticity of concrete

fck = 25 N/mm2

Ecm = 31 476 N/mm2

3.1.3

Table 3.1

Example: Simply supported primary composite beam (GB)

CALCULATION SHEET

Document Ref:

SX015a-EN-UK

Title

Example: Simply supported primary composite beam

Eurocode Ref

EN 1993-1-1, EN 1994-1-1

Made by

Laurent Narboux

Date

Nov 2006

Checked by

Charles King

Date

Nov 2006

Sheet

of

16

Permanent load :

To take into account the troughs of the profiled steel sheeting , the weight of

the slab for the secondary beams is taken as:

25 3.0 (0.14

0.106 + 0.145 0.058

) = 7.86 kN/m

2

0.207

Concentrated loads during the construction stage :

FG = (0.305 + 7.86) 6.0 = 49 kN

Permanent loads in the final stage :

The value of the concentrated loads on the primary beam is:

Created on Monday, February 28, 2011

This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

FG = (0.305 + 7.86 + 0.75 3.0) 6.0 = 62.49 kN

Self weight of the primary beam :

qG = 9.81 60.1 10-3 = 0.590 kN/m

Variable load (Imposed load) :

Concentrated loads during the construction stage :

FQ = 0.75 3.0 6.0 = 13.5 kN

Concentrated loads in the final stage:

FQ = 2.5 3.0 6.0 = 45.0 kN

ULS Combination :

G FG + Q FQ = 1.35 62.49 + 1.50 45.0 = 151.86 kN

G qG + Q qQ = 1.35 0.59 = 0.797 kN/m

Eq. (6.10) is used. In some countries, the National Annex may specify the use

of equations (6.10a) and (6.10b).

ULS Combination during the construction stage:

G FG + Q FQ = 1.35 49 + 1.50 13.5 = 86.4 kN

G qG + Q qQ = 1.35 0.59 = 0.797 kN/m

EN 1990

6.4.3.2

Example: Simply supported primary composite beam (GB)

CALCULATION SHEET

Document Ref:

SX015a-EN-UK

Title

Example: Simply supported primary composite beam

Eurocode Ref

EN 1993-1-1, EN 1994-1-1

Made by

Laurent Narboux

Date

Nov 2006

Checked by

Charles King

Date

Nov 2006

Sheet

of

16

Moment diagram

M

463.6 kNm

Maximum moment at mid span :

My,Ed = 3.0 151.86 + 0.125 0.797 9.02 = 463.6 kNm

Maximum moment at mid span (sequence of construction) :

My,Ed = 3.0 86.4 + 0.125 0.797 9.02 = 267.2 kNm

Shear force diagram

Created on Monday, February 28, 2011

This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

155.45 kN

Maximum shear force at supports :

Vz,Ed = 151.86 + 0.5 0.797 9.0 = 155.45 kN

Maximum shear force at supports (sequence of construction) :

Vz,Ed = 86.4 + 0.5 0.797 9.0 = 90.00 kN

Yield strength

Steel grade S355

EN 1993-1-1

The maximum thickness is 12.8 mm < 40 mm, so : fy = 355 N/mm2

Note :

The National Annex may impose either the values of fy from the

Table 3.1 or the values from the product standard. Does not matter in

this case.

Section classification :

The parameter is derived from the yield strength : =

Note :

235

= 0.81

f y [N/mm 2 ]

The classification is made for the non composite beam. For the

composite beam the classification is more favourable for the web.

Table 3.1

Example: Simply supported primary composite beam (GB)

CALCULATION SHEET

Document Ref:

SX015a-EN-UK

Title

Example: Simply supported primary composite beam

Eurocode Ref

EN 1993-1-1, EN 1994-1-1

Made by

Laurent Narboux

Date

Nov 2006

Checked by

Charles King

Date

Nov 2006

Sheet

of

Outstand flange : flange under uniform compression

EN 1993-1-1

c = (b tw 2 r) / 2 = (177.9 7.9 2 10.2)/2 = 74.8 mm

c/tf = 74.8 / 12.8= 5.84 < 9 = 7.29

Table 5.2

(sheet 2 of 3)

Class 1

Internal compression part :

EN 1993-1-1

c = ha 2 tf 2 r = 406.4 2 12.8 2 10.2 = 360.4 mm

c / tw = 360.4 / 7.9 = 45.62 < 72 = 58.32

16

Class 1

Table 5.2

(sheet 1 of 3)

The class of the cross-section is the highest class (i.e. the least favourable)

between the flange and the web, here : Class 1

Created on Monday, February 28, 2011

This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

So the ULS verifications should be based on the plastic resistance of the

cross-section.

Construction stage

Moment resistance

The design resistance for bending of a cross section is given by :

EN 1993-1-1

6.2.5

Mc,Rd = Mpl,Rd = Wpl,y fy / M0 = (1199.5 355 / 1.0) / 1000

Mc.Rd = 425.82 kNm

My,Ed / Mc,Rd = 267.2 / 425.82= 0.63 < 1 OK

Reduction factor for lateral torsional buckling

To determine the design buckling resistance moment of a laterally

unrestrained beam, the reduction factor for lateral torsional buckling must be

determined. The restraint provided by the steel sheet is in this case quite small

and it is neglected. The following calculation determines this factor by a

simplified method for lateral torsional buckling. This method avoids

calculating the elastic critical moment for lateral torsional buckling.

Non-dimensional slenderness

The non-dimensional slenderness may be obtained from the simplified

method for steel grade S355:

LT =

L/iz 300/3.97

=

= 0.889

85

85

See NCCI

[T1406]

Example: Simply supported primary composite beam (GB)

CALCULATION SHEET

Document Ref:

SX015a-EN-UK

Title

Example: Simply supported primary composite beam

Eurocode Ref

EN 1993-1-1, EN 1994-1-1

Made by

Laurent Narboux

Date

Nov 2006

Checked by

Charles King

Date

Nov 2006

Sheet

of

For rolled profiles, LT,0 = 0.4

16

EN 1993-1-1

Note :

The value of LT,0 may be given in the National Annex. The

recommended value is 0.4.

So

LT = 0.889 > LT,0 =0.4

6.3.2.3(1)

Reduction factor

Created on Monday, February 28, 2011

This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

For rolled sections, the reduction factor for lateral torsional buckling is EN 1993-1-1

calculated from :

6.3.2.3 (1)

LT 1.0

1

1

but

LT =

LT 2

2

2

LT + LT LT

LT

where : LT = 0.5 1 + LT LT LT,0 + LT

LT is the imperfection factor for LTB. When applying the method for rolled

profiles, the LTB curve has to be selected from the table 6.5 :

For ha/b = 406.4 / 177.9 = 2.28 > 2 Curve c (LT = 0.49)

EN 1993-1-1

Table 6.5

Table 6.3

LT,0 = 0.4 and = 0.75

Note :

The values of LT,0 and may be given in the National Annex. The

recommended values are 0.4 and 0.75 respectively.

We obtain :

LT = 0.5 [1 + 0.49 (0.889 0.4) + 0.75 (0.889)2 ] = 0.916

and :

LT =

1

0.916 + (0.916) 2 0.75 (0.889) 2

= 0.708

Then, we check : LT = 0.708 < 1.0

2

but :

LT = 0.708 < 1 / LT = 1.265

So :

LT = 0.708

Design buckling resistance moment

Mb,Rd = LT Wpl,y fy / M1

Mb,Rd = (0.708 1199500 355 / 1.0) 10-6 = 301.5 kNm

My,Ed / Mb,Rd = 267.2 / 301.5= 0.886 < 1 OK

EN 1993-1-1

6.3.2.1

Example: Simply supported primary composite beam (GB)

CALCULATION SHEET

Document Ref:

SX015a-EN-UK

Title

Example: Simply supported primary composite beam

Eurocode Ref

EN 1993-1-1, EN 1994-1-1

Made by

Laurent Narboux

Date

Nov 2006

Checked by

Charles King

Date

Nov 2006

Sheet

of

16

Shear Resistance

The shear plastic resistance depends on the shear area, which is given by:

Av,z = A 2 b tf + (tw + 2 r) tf

EN 1993-1-1

2

Av,z = 7650 2 177.9 12.8 + (7.9 + 2 10.2) 12.8 = 3458 mm

6.2.6 (3)

But not less than hw tw

conservatively taken equal to 1.0

hw tw = 1.0 380.8 7.9 = 3008 mm2

< 3458 mm2

OK

Shear plastic resistance

Created on Monday, February 28, 2011

This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

Vpl,z,Rd =

Av,z ( f y / 3 )

M0

EN 1993-1-1

=

3458 (355 / 3 ) 10 3

= 708.75 kN

1,0

6.2.6 (2)

Vz,Ed / Vpl,z,Rd = 90.00 / 708.75 = 0.127 < 1 OK

Note that the verification to shear buckling is not required when :

hw / tw 72 /

EN 1993-1-1

6.2.6 (6)

conservatively taken equal to 1.0

EN 1993-1-5

hw / tw = 380.8 / 7.9 = 48.2 < 72 0.81 / 1.0 = 58.3

5.1 (2)

No shear buckling verification required.

Interaction between bending moment and shear force

EN 1993-1-1

If Vz,Ed < Vpl,Rd / 2 then the shear force may be neglected.

So, Vz,Ed = 90.0 kN < Vpl,Rd / 2 = 708.75 / 2 = 354.4 kN

OK

6.2.8 (2)

Example: Simply supported primary composite beam (GB)

CALCULATION SHEET

Document Ref:

SX015a-EN-UK

10

Title

Example: Simply supported primary composite beam

Eurocode Ref

EN 1993-1-1, EN 1994-1-1

Made by

Laurent Narboux

Date

Nov 2006

Checked by

Charles King

Date

Nov 2006

Sheet

of

16

Final stage

Effective width of concrete flange

The effective width is constant between 0.25 L and 0.75 L, where L is the

span length. From L/4 to the closest support, the effective width decreases

linearly. The concentrated loads are located between 0.25 L and 0.75 L.

The total effective width is determined by:

EN 1994-1-1

5.4.1.2

(figure 5.1)

beff,1 = b0 + bei

b0 is the distance between the centres of the outstand shear connectors,

Created on Monday, February 28, 2011

This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

here b0 = 0 ;

bei is the value of the effective width of the concrete flange on each side of the

web and taken as bei = Le / 8 but bi = 3.0 m

beff,1 = 0 + 9.0 / 8 = 1.125 m, then beff = 2 1.125 = 2.25 m < 3.0 m

Design shear resistance of a headed stud

The shear resistance should be determined by :

0.8 f u d 2 / 4 0.29 d 2 f ck Ecm

PRd = k l Min

;

V

V

EN 1994-1-1

6.6.3.1

hsc / d = 100 / 19 = 5.26 > 4, so = 1

Reduction factor (kl)

For sheeting with ribs parallel to the supporting beam, the reduction factor for

shear resistance is calculated by :

EN 1994-1-1

b h

6.6.4.1

kl = 0.6 0 sc 1 but 1

hp hp

Where : nr = 1

hp = 58 mm

hsc = 100 mm

b0 = 82 mm

So,

k l = 0.6

82 100

- 1 = 0.614 1

58 58

OK

Example: Simply supported primary composite beam (GB)

CALCULATION SHEET

Document Ref:

SX015a-EN-UK

Title

Example: Simply supported primary composite beam

Eurocode Ref

EN 1993-1-1, EN 1994-1-1

Made by

Laurent Narboux

Date

Nov 2006

Checked by

Charles King

Date

Nov 2006

Sheet

11

of

16

0.8 450 19 2 / 4 0.29 1 19 2 25 31476

.10 3

PRd = 0.614 Min

;

1

.

25

1

.

25

= 0.614 Min 81.66 kN ; 74.29 kN

PRd = 45.61 kN

Degree of shear connection

The degree of shear connection is defined by :

Created on Monday, February 28, 2011

This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

Where :

EN 1994-1-1

Nc

N c,f

6.2.1.3 (3)

Nc is the design value of the compressive normal force in the

concrete flange

Nc,f is the design value of the compressive normal force in the

concrete flange with full shear connection

At the load location:

The compressive normal force in the concrete flange represents the force for

full connection.

Ac is the cross-sectional area of concrete, so at the load location:

Ac = beff hc

with

hc = h - hp = 140 58 = 82 mm

Ac = 2250 82 = 184500 mm2

So,

N c,f = 0.85 Ac f cd = 0.85 Ac

f ck

= 0,85 184500

25

10

1.5

-3

= 2614 kN

Since the maximum moment is nearly reached at the load location, the studs

should be placed between the support and the concentrated load. However

studs should also be placed between the concentrated loads.

3,0 m

1,5 m

e1

e2

31 studs spaced at e1 = 95 mm and 6 studs spaced at e2 = 220 mm

Example: Simply supported primary composite beam (GB)

CALCULATION SHEET

Document Ref:

SX015a-EN-UK

Title

Example: Simply supported primary composite beam

Eurocode Ref

EN 1993-1-1, EN 1994-1-1

Made by

Laurent Narboux

Date

Nov 2006

Checked by

Charles King

Date

Nov 2006

Sheet

12

of

16

So, the resistance of the shear connectors limits the normal force to not more

than:

N c = n PRd = 31 45.61 = 1414 KN

So,

N c 1414

=

= 0.541

N c, f 2614

The ratio is less than 1.0 so the connection is partial.

Verification of bending resistance

Minimum degree of shear connection

Created on Monday, February 28, 2011

This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

The minimum degree of shear connection for a steel section with equal

flanges is given by :

355

(0.75 - 0.03Le ) with Le 25

f

y

min = 1 -

EN 1994-1-1

6.6.1.2

Le is the distance in sagging bending between points of zero bending moment

in metres, for our example : Le = 9.0 m

So,

min = 1 (355 / 355) (0.75 0.03 9.0) = 0.520

Then,

min = 0.520 < = 0.541 OK

Plastic Resistance Moment at the load location

The design value of the normal force in the structural steel section is given

by :

N pl,a = Aa f y / M0 = 76500 355 10

-3

/ 1.0 = 2716 kN

So, N pl,a > N c = N c,f = 0.541 2614 = 1414kN

With the ductile shear connectors and the cross-section of the steel beam in

Class 1, the resistance moment of the critical cross-section of the beam MRd at

the load location is calculated by means of rigid-plastic theory except that a

reduced value of the compressive force in the concrete flange Nc is used in

place of the force Ncf.

Here, the plastic stress distribution is given below:

EN 1994-1-1

6.2.1.2 and

6.2.1.3

Example: Simply supported primary composite beam (GB)

CALCULATION SHEET

Document Ref:

SX015a-EN-UK

13

Title

Example: Simply supported primary composite beam

Eurocode Ref

EN 1993-1-1, EN 1994-1-1

Made by

Laurent Narboux

Date

Nov 2006

Checked by

Charles King

Date

Nov 2006

Sheet

of

16

Nc= Nc,f= 1403 kN

hp

797 kN

MRd

hn

Na= 2201 kN

The position of the plastic neutral axis is : hn = 396 mm

Created on Monday, February 28, 2011

This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

Then the design bending resistance of the composite cross-section is :

MRd = 690.5 kNm

So,

My,Ed / MRd = 463.6 / 690.5 = 0.67 < 1 OK

EN 1994-1-1

Shear Resistance

The shear plastic resistance is the same as for steel beam alone.

So,

6.2.2.2

Vpl,z,Rd = 708.75 kN

Vz,Ed / Vpl,z,Rd = 155.45/ 708.75 = 0.22 < 1 OK

Interaction between bending moment and shear force

EN 1993-1-1

If Vz,Ed < Vpl,Rd / 2 then the shear force may be neglected.

So, Vz,Ed = 155.45 kN < Vpl,Rd / 2 = 708.75 / 2 = 354.38 kN

OK

6.2.8 (2)

Longitudinal Shear Resistance of the Slab

The plastic longitudinal shear stresses is given by :

vEd =

Fd

hf x

Where x = 9.0 / 2 = 4.5 m

EN 1992-1-1

6.2.4

(figure 6.7

Example: Simply supported primary composite beam (GB)

CALCULATION SHEET

Document Ref:

SX015a-EN-UK

14

Title

Example: Simply supported primary composite beam

Eurocode Ref

EN 1993-1-1, EN 1994-1-1

Made by

Laurent Narboux

Date

Nov 2006

Checked by

Charles King

Date

Nov 2006

Sheet

of

The value for x is half the distance between the section where the moment is

zero and the section where the moment is a maximum, and we have two areas

for the shear resistance.

Fd = Nc / 2 = 1414 / 2 = 707 kN

hf = h - hp = 140 58 = 82 mm

vEd

Fd

707 103

= 1.92 N/mm2

=

=

hf x 82 4500

To prevent crushing of the compression struts in the concrete flange, the

following condition should be satisfied :

Created on Monday, February 28, 2011

This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

vEd < f cd sin f cos f with = 0.6 [1 f ck / 250] and f = 45

25 25

vEd < 0.6 1

0,5 = 4.5 N/mm2

250 1.5

OK

The following inequality should be satisfied for the transverse reinforcement :

Asf fyd / sf vEd hf / cot f where fyd = 500 / 1.15 = 435 N/mm2

Assume the spacing of the bars sf = 200 mm and there is no contribution from

the profiled steel sheeting

Asf

1.92 82 200

= 72.4 mm2

435 1.0

We can take 10 mm diameter bars (78.5 mm2) at 200 mm cross-centres could

be used for this design.

Serviceability Limit State verifications

Formula for the calculation of the deflection due to G + Q :

wG =

wQ =

5 qG L4

a (3L2 4a 2 )

+

FG

384 E I y

24 E I y

a (3L2 4a 2 )

FQ

24 E I y

So, w = wG + wQ

16

Example: Simply supported primary composite beam (GB)

CALCULATION SHEET

Document Ref:

SX015a-EN-UK

Title

Example: Simply supported primary composite beam

Eurocode Ref

EN 1993-1-1, EN 1994-1-1

Made by

Laurent Narboux

Date

Nov 2006

Checked by

Charles King

Date

Nov 2006

Sheet

15

of

16

Construction stage

SLS Combination during the construction stage :

FG = 49.0 kN

EN 1990

FQ = 13.5 kN

qG = 0.59 kN/m

6.5.3

Deflection during the construction stage :

Iy is the second moment of area of the steel beam.

Created on Monday, February 28, 2011

This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

wG =

5 0.59 90004

3000 (3 90002 - 4 30002 )

+

49000

384 210000 21596 10 4

24 210000 21596 10 4

wG = 1.4 + 28.0 = 29.4 mm

3000 (3 90002 - 4 30002 )

wQ =

13500 = 7.7 mm

24 210000 21596 10 4

So, w = wG + wQ = 29.4 + 7.7 = 37.1 mm

The deflection under (G+Q) is L/243

Final stage

SLS Combination

FG = 62.49 kN

EN 1990

FQ = 45.00 kN

6.5.3

qG = 0.59 kN/m

Deflection at the final stage :

Iy depends on the modular ratio (n) depending on the type of loading. By

simplification, we can take :

n0 = Ea / Ecm = 210000 / 31476 = 6.67 for short-term effects (Q)

EN 1994-1-1

So Iy = 77881 cm at mid span

And n = 3Ea / Ecm = 20.01 for permanent loads (G)

So Iy = 60297 cm4

7.2.1

Example: Simply supported primary composite beam (GB)

CALCULATION SHEET

Note :

Document Ref:

SX015a-EN-UK

Title

Example: Simply supported primary composite beam

Eurocode Ref

EN 1993-1-1, EN 1994-1-1

Made by

Laurent Narboux

Date

Nov 2006

Checked by

Charles King

Date

Nov 2006

Sheet

16

of

16

It may be used for both short-term and long-term loading, a EN 1994-1-1

nominal modular ratio (n) corresponding to an effective modulus of

5.4.2.2 (11)

elasticity for concrete Ec,eff taken as Ecm / 2.

wG = 29.4 mm

wpartitions =

wQ =

3000 (3 9000 2 - 4 3000 2 )

13500 = 2.8mm

24 210000 60297 10 4

3000 (3 90002 - 4 3000 2 )

45000 = 7.1 mm

24 210000 77881 10 4

So, w = wG + wpartitions + wQ = 29.4 + 2.8 + 7.1 = 39.3 mm

Created on Monday, February 28, 2011

This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

The deflection under (G + Q) is L/229

Note 1 : The limits of deflection should be specified by the client. The

National Annex may specify some limits. Here the result may be

considered as fully satisfactory.

Note 2 : Concerning vibrations, the National Annex may specify limits EN 1993-1-1

concerning the frequency. Here the total deflection is low and the

7.2.3

mass fairly high and by experience there is no problem of vibration.

Example: Simply supported primary composite beam (GB)

Example: Simply supported primary composite beam

SX015a-EN-UK

Quality Record

RESOURCE TITLE

Example: Simply supported primary composite beam

Reference

SX015a-EN-GB

Created on Monday, February 28, 2011

This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

LOCALISED RESOURCE DOCUMENT

Name

Company

Date

Created by

Laurent Narboux

SCI

Oct 2006

Technical content checked by

Charles King

SCI

Oct 2006

Editorial content checked by

D C Iles

SCI

19/2/07

Вам также может понравиться

- Seismic BehaviorДокумент13 страницSeismic BehaviorSaitis CatalinОценок пока нет

- 1672 PDFДокумент8 страниц1672 PDFPartha Arpita SahaОценок пока нет

- Strain XДокумент221 страницаStrain XSaitis CatalinОценок пока нет

- Detaliul A Scara 1:5: Universitatea Tehnica Din Cluj-Napoca Facultatea de ConstructiiДокумент1 страницаDetaliul A Scara 1:5: Universitatea Tehnica Din Cluj-Napoca Facultatea de ConstructiiSaitis CatalinОценок пока нет

- Dimensions: ZKKE 16t X 20000mmДокумент1 страницаDimensions: ZKKE 16t X 20000mmSaitis CatalinОценок пока нет

- Macara Turn Liebherr Turmdrehkran 90 ECДокумент1 страницаMacara Turn Liebherr Turmdrehkran 90 ECSaitis CatalinОценок пока нет

- Sectiunea B-B Scara 1:2: Universitatea Tehnica Din Cluj-Napoca Facultatea de ConstructiiДокумент1 страницаSectiunea B-B Scara 1:2: Universitatea Tehnica Din Cluj-Napoca Facultatea de ConstructiiSaitis CatalinОценок пока нет

- Detaliul A Scara 1:5: Universitatea Tehnica Din Cluj-Napoca Facultatea de ConstructiiДокумент1 страницаDetaliul A Scara 1:5: Universitatea Tehnica Din Cluj-Napoca Facultatea de ConstructiiSaitis CatalinОценок пока нет

- Loads and ForcesДокумент1 страницаLoads and ForcesSaitis CatalinОценок пока нет

- Sectiune A AДокумент1 страницаSectiune A ASaitis CatalinОценок пока нет

- Sectiunea B-B Scara 1:2: Universitatea Tehnica Din Cluj-Napoca Facultatea de ConstructiiДокумент1 страницаSectiunea B-B Scara 1:2: Universitatea Tehnica Din Cluj-Napoca Facultatea de ConstructiiSaitis CatalinОценок пока нет

- Sectiunea B-B Scara 1:2: Universitatea Tehnica Din Cluj-Napoca Facultatea de ConstructiiДокумент1 страницаSectiunea B-B Scara 1:2: Universitatea Tehnica Din Cluj-Napoca Facultatea de ConstructiiSaitis CatalinОценок пока нет

- Detalii 1Документ1 страницаDetalii 1Saitis CatalinОценок пока нет

- Plan SapaturaДокумент1 страницаPlan SapaturaSaitis CatalinОценок пока нет

- RacordareДокумент1 страницаRacordareSaitis CatalinОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Chapterwise Question bank-DSR-22502Документ5 страницChapterwise Question bank-DSR-22502soumyasonawane100% (1)

- Lug Analysis - MechaniCalcДокумент31 страницаLug Analysis - MechaniCalcmuhammad hadiОценок пока нет

- Experimental investigation of soil-cement columns for ground improvementДокумент8 страницExperimental investigation of soil-cement columns for ground improvementCristina Andreea BitirОценок пока нет

- Emm MCQ of All Six UnitДокумент121 страницаEmm MCQ of All Six UnitSantosh100% (2)

- The Nature and Cause of Earthquakes ExplainedДокумент47 страницThe Nature and Cause of Earthquakes ExplainedEngr Waqar AsmatОценок пока нет

- Awc TR12 1510Документ36 страницAwc TR12 1510Jelean NavalОценок пока нет

- Deflection of Beams and Trusses 1Документ9 страницDeflection of Beams and Trusses 1nickxnickОценок пока нет

- Theories of Mechanical FailureДокумент11 страницTheories of Mechanical FailureRavi PalaskarОценок пока нет

- Piepline Thickness CalculationДокумент6 страницPiepline Thickness CalculationAneeq NaufalОценок пока нет

- Aprelim Exam Review MD 1st Sem 22 - 23Документ2 страницыAprelim Exam Review MD 1st Sem 22 - 23Rex OabelОценок пока нет

- Stone Column Design and Construction TechniquesДокумент210 страницStone Column Design and Construction TechniquesGeorge Christodoulidis100% (2)

- Strut-and-Tie Model For Shear Behavior in Deep Beams and Pile Caps Failing in Diagonal SplittingДокумент7 страницStrut-and-Tie Model For Shear Behavior in Deep Beams and Pile Caps Failing in Diagonal SplittingRamadanОценок пока нет

- New Manasa M.tech Project JournalДокумент11 страницNew Manasa M.tech Project JournalkavyaОценок пока нет

- ANALYSIS OF PIPELINE STRESS IN GEOTHERMAL PIPING SYSTEMДокумент15 страницANALYSIS OF PIPELINE STRESS IN GEOTHERMAL PIPING SYSTEMAbdul Haris SiregarОценок пока нет

- Structural Modeling of Cold-Formed Steel Portal Frames by Zhang and Rasmussen 2015Документ11 страницStructural Modeling of Cold-Formed Steel Portal Frames by Zhang and Rasmussen 2015fahmi aballiОценок пока нет

- Tutorial 30 Slope Angle OptimizationДокумент13 страницTutorial 30 Slope Angle OptimizationPratibha SinghОценок пока нет

- Lec 67Документ8 страницLec 67Kaushal KumarОценок пока нет

- T Beam SOFISTIKДокумент8 страницT Beam SOFISTIKMarija DocevskaОценок пока нет

- Strap Footing Sample PDFДокумент6 страницStrap Footing Sample PDFRegan Tandukar44% (9)

- Chapter 2 Stress and Strain - Axial LoadingДокумент43 страницыChapter 2 Stress and Strain - Axial Loadingtaymar18Оценок пока нет

- 6 - Soil Data in Orcaflex-Y.T.kimДокумент9 страниц6 - Soil Data in Orcaflex-Y.T.kimYoungtae KimОценок пока нет

- ICEEDM2016-Final (31juli2016) Yudha Lesmana FIniteДокумент35 страницICEEDM2016-Final (31juli2016) Yudha Lesmana FIniteMangisi Haryanto ParapatОценок пока нет

- ASTM D 2899 - 01 Establishing Allowable Stresses For Round Timber PilesДокумент6 страницASTM D 2899 - 01 Establishing Allowable Stresses For Round Timber Pilesalin2005Оценок пока нет

- Connection Surge Bin Supp Beam1Документ5 страницConnection Surge Bin Supp Beam1Venkatesh HebbarОценок пока нет

- Report of Experiment 3Документ10 страницReport of Experiment 3laura sageОценок пока нет

- Rules of MixtureДокумент33 страницыRules of Mixtureperlan1234100% (1)

- Som Paper PDFДокумент3 страницыSom Paper PDFsahil borichaОценок пока нет

- Stress: Engr. Estanislao M. Pialago Jr. PMEДокумент16 страницStress: Engr. Estanislao M. Pialago Jr. PMEBrianОценок пока нет

- CH 6Документ25 страницCH 6Bill WilliamsОценок пока нет

- Underground Circular Tank R2 Sump WellДокумент14 страницUnderground Circular Tank R2 Sump Wellsurendra_panga100% (1)