Академический Документы

Профессиональный Документы

Культура Документы

Starch Had Lost Its Inherent Granule Characteristics (Morphology, Crystalline Structure and Integrity)

Загружено:

Philipe MongetОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Starch Had Lost Its Inherent Granule Characteristics (Morphology, Crystalline Structure and Integrity)

Загружено:

Philipe MongetАвторское право:

Доступные форматы

Innovative Food Science & Emerging Technologies 12 (2011) 586593

Title: The effect of ball milling treatment on structure and porosity of maize starch granule

Authors: Tian Yi Liu, Ying Ma, Shi Feng Yu, John Shi, Sophia Xue

1. Introduction:

- Starch is the main storage carbohydrate of plants, 80% of the world market for starch, application in food and

industry are affected by its structure, such as relative crystallinity, the ratio of amylose to amylopectin, surface

morphology of starch granule and the particle diameters of granules.

- Several physical technologies, such as high pressure, pulsed electric fields, ultrasound, microwave, gamma

irradiation and heat-moisture treatment, to achieve particular structure and technological properties, such as

solubility, viscosity properties in solution, swelling and pasting properties, and digestibility.

- Ball milling treatment, as a cost-lowering and environmental-friendly physically modified method, has been used

to decrease effectively relative crystallinity and increase solubility and digestibility of starch. Ratio of pore volume

to granule volume, plays an important role in such phenomena as sorption, thermal conductivity, water diffusivity

and also influences their mechanical and textural properties.

- The objective is to precisely understand the variation of crystalline structure, to demonstrate the development of

central cavity and to elucidate pore and surface characteristics of starch during ball milling treatment through Xray diffraction, Fourier transforms infrared, 13C CP/MAS NMR, scanning electron microscope, transmission

electron microscope, laser diffraction analysis and method of nitrogen absorption analysis.

2. Materials & Methods:

- A QM-DK low temperature planetary ball mill, 500 rpm for different times (1, 2 and 3 h). The starch samples and

five times weight ceramic balls.

- The X-ray diffraction analysis was performed using a Rigaku D/max-2500 V diffractometer, The FTIR spectra of

starches with different milling times were recorded on Avatar 360, High-resolution solid-state 13C CP/MAS

experiments were conducted using Bruker 300 ultrashieldTM.

- Scanning electron microscope (SEM), Laser diffraction analysis: Malvern Mastersizer, Transmission electron

microscope (TEM), Pore size distribution: surface area basing on BET adsorption isotherm. The pore size

distribution was obtained applying the iterative method of Barret, Joyner and Hallendy (BJH).

3. Results:

- The X-ray diffraction patterns (Fig 1), all the diffraction peaks at 2 h and 3 h almost disappeared, reflected the

decrease of crystallinity, which was the result of the transition from polycrystalline state to amorphous state ( table

2). Destruction of crystalline area and promotion of the amorphous area in the starch granules.

- (Fig 2.)the intensities of bands at 3382 cm1 and 1018 cm1 in the treated starch spectra were increased with

the increase of milling time, and the band (1047 cm1) was almost resolved at 1 h ball milling treatment, at the

same time, the amplitude of band (995 cm1) was decreased with the milling time.

- 13C CP/MAS NMR (Fig 3), shifts in peaks. his resolution of triplet peak was believed to decrease of double helix

content in ball milled starches

- (Fig 4) Significant changes in the internal structure of the granule. For 2 h the integrity and granule periphery still

remained.

- milling treatment from 0 to 2 h was growth process of the particle size, and particle size decreases occurred with

longer milling time (3 h). Fig 6: starch had lost its inherent granule characteristics (morphology,

crystalline structure and integrity). Fig 7: Hysteresis loop of ball milled starch (2 h) was larger than that of

untreated starch.

- SBET or the VBJH and DBJH were increased. It was indicated that mesopores and macropores existed in the

inner of starch granules beside microspores on the surface of granules. (2 h) gave a wider pore diameter

distribution (1355 nm), whereas untreated maize starch showed a narrow distribution of pore diameters (1035

nm)

4. Conclusion

- Decrease in double helix content and crystalline component of maize starch. Meanwhile, span and median

diameter, special surface area (SBET), cumulative volume (VBJH) and average diameter pores (DBJH) of starch

granules increased rapidly.

- increase greatly the porosity of starch, which indicated that ball milling treatment can induce the adsorptive capacity

of starches.

Вам также может понравиться

- Beam Tutorial 1Документ23 страницыBeam Tutorial 1aikalessОценок пока нет

- Case 9Документ2 страницыCase 9Chechaa PerezОценок пока нет

- Dispersion - Strengthened Nanocrystalline Copper: of Achievements in Materials and Manufacturing EngineeringДокумент8 страницDispersion - Strengthened Nanocrystalline Copper: of Achievements in Materials and Manufacturing EngineeringbinkinОценок пока нет

- 2016 - P&C - Modeling The Impacts of Petrophysical PropertiesДокумент9 страниц2016 - P&C - Modeling The Impacts of Petrophysical PropertiesBandy HavanaОценок пока нет

- Surface Analyses of Pyrolysed Rice Husk Using Scanning Force MicrosДокумент4 страницыSurface Analyses of Pyrolysed Rice Husk Using Scanning Force MicrosNorman IskandarОценок пока нет

- Is There An Optimal Grain Size For Creep Resistance in Ni-Based Disk Superalloys?Документ17 страницIs There An Optimal Grain Size For Creep Resistance in Ni-Based Disk Superalloys?Usman NaseemОценок пока нет

- Articulo Cereales Almidon 1Документ9 страницArticulo Cereales Almidon 1Nahin RodriguezОценок пока нет

- EPL 0002593 ArticleДокумент7 страницEPL 0002593 Articlesus023Оценок пока нет

- Crystalline Structure in Starch: Denis - Lourdin@Документ30 страницCrystalline Structure in Starch: Denis - Lourdin@aliafzalch89Оценок пока нет

- A Method of Proppant Pack Permeability AssessmentДокумент10 страницA Method of Proppant Pack Permeability Assessmentsmithyry2014Оценок пока нет

- Using TEM and SEM To Unveil The Role of Nanoclays in Polymer BlendsДокумент6 страницUsing TEM and SEM To Unveil The Role of Nanoclays in Polymer BlendsMuhamad Fahri NurzamsiОценок пока нет

- Mechanical Alloying Cu in Ga Se - USA Setembro 99Документ5 страницMechanical Alloying Cu in Ga Se - USA Setembro 99Fabricio FaitaОценок пока нет

- Plasticization Effect of Triacetin On Structure and Properties of Starch Ester FilmДокумент8 страницPlasticization Effect of Triacetin On Structure and Properties of Starch Ester FilmNanik HendrawatiОценок пока нет

- Particle Size Distribution of Different Grinding SystemsДокумент29 страницParticle Size Distribution of Different Grinding SystemsTsakalakis G. Konstantinos100% (1)

- Graphite Particle Reduction Process Using High Energy MillingДокумент4 страницыGraphite Particle Reduction Process Using High Energy Millingsaleem saleemОценок пока нет

- Pengujian Gel Clarity Jafari 2024Документ17 страницPengujian Gel Clarity Jafari 2024marijuana.hesОценок пока нет

- Cobalt Ferrite Nanoparticles For Biomedical Applications-2020-06-23-10-55Документ18 страницCobalt Ferrite Nanoparticles For Biomedical Applications-2020-06-23-10-55Karina EndoОценок пока нет

- Grain Boundary and Intragranular Deformations During High Temperature Creep of A PM Nickel-Based SuperalloyДокумент8 страницGrain Boundary and Intragranular Deformations During High Temperature Creep of A PM Nickel-Based SuperalloynaderbahramiОценок пока нет

- 10 1016@j Ceramint 2007 02 012 PDFДокумент7 страниц10 1016@j Ceramint 2007 02 012 PDFlami75Оценок пока нет

- ZHANG-2003 - Al3Ti Prepared PDFДокумент7 страницZHANG-2003 - Al3Ti Prepared PDFSofiane TaaneОценок пока нет

- Assignment 1 PT FA19 CHE 083Документ3 страницыAssignment 1 PT FA19 CHE 083Maryam FatimaОценок пока нет

- 10 1016@j Ceramint 2007 02 012 PDFДокумент7 страниц10 1016@j Ceramint 2007 02 012 PDFlami75Оценок пока нет

- Preparation of Resin/nano Fillers Mixture For Composites: A Case StudyДокумент11 страницPreparation of Resin/nano Fillers Mixture For Composites: A Case StudyNiranjan HugarОценок пока нет

- Technical Report On Magnesium SuperplasticityДокумент22 страницыTechnical Report On Magnesium Superplasticityashvani0% (1)

- Chemorheology and Properties of Epoxy-Layered Silicate NanocompositesДокумент8 страницChemorheology and Properties of Epoxy-Layered Silicate NanocompositesrenebarreiroОценок пока нет

- Characterization of Ancient MortarsДокумент4 страницыCharacterization of Ancient MortarsdenisedefeoОценок пока нет

- Revie Article Laser2Документ10 страницRevie Article Laser2MUA MAОценок пока нет

- Investigation The Calcite HydrophobisationДокумент10 страницInvestigation The Calcite HydrophobisationDaniel L. FrandsenОценок пока нет

- Adsorption of Starch, Amylose, Amylopectin and Glucose Monomer and Their Effect On The Flotation of Hematite and QuartzДокумент6 страницAdsorption of Starch, Amylose, Amylopectin and Glucose Monomer and Their Effect On The Flotation of Hematite and QuartzDiego VeneuОценок пока нет

- Diez 1993Документ8 страницDiez 1993Simanchal KarОценок пока нет

- Pu Clay Foam MacoskoДокумент9 страницPu Clay Foam MacoskoUfuk ErkenОценок пока нет

- Development and Properties of Polycaprolactone/ Hydroxyapatite Composite BiomaterialsДокумент5 страницDevelopment and Properties of Polycaprolactone/ Hydroxyapatite Composite BiomaterialsAnna SlotoschОценок пока нет

- 2931 14102 1 PBДокумент9 страниц2931 14102 1 PByasin AhmedОценок пока нет

- The Application of High Chrome Grinding Media at MMG Century Mine For Improved Grinding Media Consumption and Metallurgy PerformanceДокумент15 страницThe Application of High Chrome Grinding Media at MMG Century Mine For Improved Grinding Media Consumption and Metallurgy PerformanceYaser Mohamed Abas100% (1)

- A Comparative Study On Antibacterial Properties of Mgo Nanoparticles Prepared Under Different Calcination TemperatureДокумент7 страницA Comparative Study On Antibacterial Properties of Mgo Nanoparticles Prepared Under Different Calcination TemperatureAmir ChaNdiaОценок пока нет

- Use of Acoustic Energy in Sand Casting oДокумент4 страницыUse of Acoustic Energy in Sand Casting oMuhammad MujtabaОценок пока нет

- Grinding Kinetics ofДокумент10 страницGrinding Kinetics ofirinaОценок пока нет

- Optimization of The Mechanical Properties of Polypropylene-Based Nanocomposite Via The Addition of A Combination of OrganoclaysДокумент11 страницOptimization of The Mechanical Properties of Polypropylene-Based Nanocomposite Via The Addition of A Combination of OrganoclaysLaysFitaroniОценок пока нет

- Synthesis and Their Texture Characteristics of Mesoporous Silica Gel As Surfactant Supporting RutinДокумент7 страницSynthesis and Their Texture Characteristics of Mesoporous Silica Gel As Surfactant Supporting RutinCentral Asian StudiesОценок пока нет

- Reuse of Eggshell Waste and Recycled Glass in TheДокумент12 страницReuse of Eggshell Waste and Recycled Glass in TheJohn Michael EcaranОценок пока нет

- Scanning Electron Microscopy (SEM) Methods For Dental EnamelДокумент16 страницScanning Electron Microscopy (SEM) Methods For Dental EnamelAna CondeОценок пока нет

- Drying Shrinkag1Документ11 страницDrying Shrinkag1Navneet KaurОценок пока нет

- Beneciation of Elazg-Kefdag Chromite by Multi Gravity SeparatorДокумент3 страницыBeneciation of Elazg-Kefdag Chromite by Multi Gravity SeparatorMohammad Rizwan KhanОценок пока нет

- Liu 2014Документ6 страницLiu 2014SadieОценок пока нет

- Processing and Properties of Fine-Grained Transparent Mgal O CeramicsДокумент4 страницыProcessing and Properties of Fine-Grained Transparent Mgal O CeramicsadeelumerОценок пока нет

- Lightweight Materials Obtained by Utilization of Agricultural WasteДокумент4 страницыLightweight Materials Obtained by Utilization of Agricultural WasteabdullmalikОценок пока нет

- Properties of Porous Silica Glasses Prepared Via Sol Gel ProcessДокумент5 страницProperties of Porous Silica Glasses Prepared Via Sol Gel ProcessCaro CuadrasОценок пока нет

- Preparation of MgO Added Iron Ore Pellets and EffeДокумент13 страницPreparation of MgO Added Iron Ore Pellets and EffePSS PrasadОценок пока нет

- Ultrasonics - Sonochemistry: Yuliana Monroy, Sandra Rivero, María A. GarcíaДокумент10 страницUltrasonics - Sonochemistry: Yuliana Monroy, Sandra Rivero, María A. GarcíaNguyễn Thị VươngОценок пока нет

- Mineral Processing Laboratory ManualДокумент43 страницыMineral Processing Laboratory Manualalnemangi100% (1)

- Effect of A Novel Sintering Process On Mechanical Properties of Hydroxyapatite Ceramics PDFДокумент5 страницEffect of A Novel Sintering Process On Mechanical Properties of Hydroxyapatite Ceramics PDFfishvalОценок пока нет

- Okuyama 2006, Preparation of Functional Nanostructured Particles by Spray DryingДокумент25 страницOkuyama 2006, Preparation of Functional Nanostructured Particles by Spray DryingzakiyyayulandariОценок пока нет

- Geometallurgy-A Route To More Resilient Mine Operations: MineralsДокумент34 страницыGeometallurgy-A Route To More Resilient Mine Operations: MineralschoqolloОценок пока нет

- Mechanical Behavior of An Altered Reservoir Limestone: Multi-Scale and Core Analysis ApproachesДокумент12 страницMechanical Behavior of An Altered Reservoir Limestone: Multi-Scale and Core Analysis ApproachesRosa K Chang HОценок пока нет

- Crystallinity Cellulose FormulaДокумент7 страницCrystallinity Cellulose Formulaetnomuz2003Оценок пока нет

- Shirdel2014 Article MicrostructuralEvolutionDuringДокумент9 страницShirdel2014 Article MicrostructuralEvolutionDuringKlaus AdlerОценок пока нет

- Jolina A. Padunan Bscere 3-AДокумент3 страницыJolina A. Padunan Bscere 3-Apadunanjolina4Оценок пока нет

- Image Analysis of Pearlite Spheroidization Based On The Morphological Characterization of Cementite ParticlesДокумент9 страницImage Analysis of Pearlite Spheroidization Based On The Morphological Characterization of Cementite ParticlesaminsuhadiОценок пока нет

- Natural ScienceДокумент15 страницNatural Sciencelamia97Оценок пока нет

- Cellulose Nanocrystals: Properties, Production and ApplicationsОт EverandCellulose Nanocrystals: Properties, Production and ApplicationsОценок пока нет

- Geological Carbon Storage: Subsurface Seals and Caprock IntegrityОт EverandGeological Carbon Storage: Subsurface Seals and Caprock IntegrityStéphanie VialleОценок пока нет

- Cellulose Science and Technology: Chemistry, Analysis, and ApplicationsОт EverandCellulose Science and Technology: Chemistry, Analysis, and ApplicationsThomas RosenauОценок пока нет

- LeroyДокумент1 страницаLeroyPhilipe MongetОценок пока нет

- Biodiesel Production Through The Use of Different Sources in The UK ObjectivesДокумент5 страницBiodiesel Production Through The Use of Different Sources in The UK ObjectivesPhilipe MongetОценок пока нет

- Innovation in Meat IndustryДокумент1 страницаInnovation in Meat IndustryPhilipe MongetОценок пока нет

- WeblinkДокумент1 страницаWeblinkPhilipe MongetОценок пока нет

- Nature 08637Документ6 страницNature 08637Philipe MongetОценок пока нет

- Tipos Concavos y MantosДокумент22 страницыTipos Concavos y MantosJose Luis Atao SantiagoОценок пока нет

- 6066 T6 Aircraft Aluminum Alloy Sheet SuppliersДокумент12 страниц6066 T6 Aircraft Aluminum Alloy Sheet Supplierssanghvi overseas incОценок пока нет

- Description and Instructions For Water Leakage DetectorДокумент3 страницыDescription and Instructions For Water Leakage Detectorsaurabhjerps231221Оценок пока нет

- Strategic MGMT Ch-3Документ30 страницStrategic MGMT Ch-3Desu MekonnenОценок пока нет

- Marine BoilerДокумент30 страницMarine BoilerCarloОценок пока нет

- Effect of Operating Conditions On COP of VCRДокумент9 страницEffect of Operating Conditions On COP of VCRSatheesh ChandranОценок пока нет

- AP Hercules AfДокумент1 страницаAP Hercules AfSami KahtaniОценок пока нет

- 3M™ Wrap Film Series 1380: Application On Substrates With RecessesДокумент9 страниц3M™ Wrap Film Series 1380: Application On Substrates With RecessesAnonymous OCKxWxsjlОценок пока нет

- 9452K6Документ2 страницы9452K6Thiago NandiОценок пока нет

- Lighting: Tef 2440 Obstruction Light Low Intensity, Type AДокумент2 страницыLighting: Tef 2440 Obstruction Light Low Intensity, Type Apramod_tryОценок пока нет

- Residual Strength A N D Crack Propagation Tests O N C-130 Airplane Center Wings With Service-Imposed Fatigue DamageДокумент69 страницResidual Strength A N D Crack Propagation Tests O N C-130 Airplane Center Wings With Service-Imposed Fatigue DamagemilindshettiОценок пока нет

- Multipower Cha K 726-P÷36012-P CLB 41.7Документ40 страницMultipower Cha K 726-P÷36012-P CLB 41.7Xavi Tendre100% (1)

- HSE Guide For Hot Tapping Part 1-13Документ4 страницыHSE Guide For Hot Tapping Part 1-13abhisheknharanghat100% (1)

- Ce 326 Principles of Environmental Engineering: SPRING 2010Документ2 страницыCe 326 Principles of Environmental Engineering: SPRING 2010Jorge Gomez RamirezОценок пока нет

- MaterialogyДокумент181 страницаMaterialogyrajraj3550Оценок пока нет

- Hoja Técnica Lanco 1890 CДокумент2 страницыHoja Técnica Lanco 1890 CBryan GavilanezОценок пока нет

- Pressure and Temperature Chart of Ammonia - I NH Sub 3 Sub IДокумент4 страницыPressure and Temperature Chart of Ammonia - I NH Sub 3 Sub Inishant361Оценок пока нет

- Roper 3611-22 GHB PumpsДокумент1 страницаRoper 3611-22 GHB PumpsDark CenobiteОценок пока нет

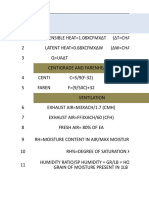

- All Formulas HvacДокумент11 страницAll Formulas HvacrockОценок пока нет

- Bimbar InflatableДокумент36 страницBimbar InflatableMelissa MorganОценок пока нет

- CLASS - X CHEMISTRY Important QuestionsДокумент17 страницCLASS - X CHEMISTRY Important Questionsvt654009Оценок пока нет

- Permissible Crack Width ExplanationДокумент4 страницыPermissible Crack Width ExplanationAntony John VianyОценок пока нет

- Non-Cycling Refrigerated Dryer 200-800 SCFMДокумент24 страницыNon-Cycling Refrigerated Dryer 200-800 SCFMCarlos Jiménez100% (1)

- Identifying Toyota HiluxДокумент4 страницыIdentifying Toyota Hiluxtoaster es100% (1)

- RS-540SH-7520|MABUCHI MOTOR CO., LTD. Product SearchДокумент2 страницыRS-540SH-7520|MABUCHI MOTOR CO., LTD. Product Searchjoroma58Оценок пока нет

- Section 13 (Masonry) - Qcs 2010Документ36 страницSection 13 (Masonry) - Qcs 2010gendy350% (2)

- Led LCD TV: Service ManualДокумент60 страницLed LCD TV: Service ManualFrank VillaОценок пока нет

- HP Transformer OilsДокумент2 страницыHP Transformer OilsNoble Jose KunhiparaОценок пока нет