Академический Документы

Профессиональный Документы

Культура Документы

Cyclone Blockage Clearing

Загружено:

AnGahBasHaАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Cyclone Blockage Clearing

Загружено:

AnGahBasHaАвторское право:

Доступные форматы

Guidance to Prevent Hot Meal Burns

Published December 2005

CONTENTS

1. Scope of this guidance

2. Hazards and Risks

3. Reducing Personnel

Exposure

- Kiln Feed Chemistry

- Reducing Cyclone Blockages

- Alarm Systems & Automatic

Shutoff

- Static Cleaning Systems

1. Scope of this guidance

This document focuses on the hazards and associated risks of

working in dry process pre-heater towers and on the areas

under/around grate or cross bar cooling systems; posed by hot

meal (the mixture of raw feed materials used in cement

manufacture). Consequently, procedures for clearing and hot

working in pre-heater towers systems and coolers, should be

modified to take account of its recommendations. Only the

tasks, which involve exposure to hot meal where there is the

potential for personal injury, have been evaluated.

Further recommendations are made to establish better control

over hot meal and reduce the risk of hot meal incidents. This

guidance is intended for use at UK cement kilns.

4. Normal cleaning &

system maintenance

5. Major Blockages

6. Personnel Training

7. Completion of preheater tower work

8. Personal Protective

Equipment

9. Effects and Treatment

of Burns

Hot meal in kiln

10.Heat Stress

11.Legal Context

12.Personal Protective

Equipment Catalogue

2nd Edition: December 2005: I. Gibson

2. Hazards and Risks

Hazards are caused by blockages and accidental releases of hot

cement meal at temperatures that may be up to 900oC or more.

The hot meal can flow like a liquid and consequently escape

through any unsealed parts of the clinker manufacturing

environment.

1

Guidance to prevent hot meal burns

December 2005

Risks occur when employees are exposed to hot

meal, typically during unblocking, maintenance and

cleaning activities. Incidents involving hot meal

burns have caused death and injury in the cement

industry as some of the following reports

demonstrate.

When the access door for the enclosed conveyor

was opened, hot clinker spilled into standing water

generating a steam outburst that burned the victim.

The victim died from his injuries a week later.

Incident 3

A team of workers were freeing a jammed drag

chain that removed dust from a filter. A hatch in the

kiln was opened to remove a build-up of dust which

was believed to be causing the problem.

Incident 1

Three employees were in the process of repairing

an air leak around an external access door on a

cement kiln. Two of them were on a scaffold and

had removed the access door of the kiln to replace

the seal. A blockage in the pre-heater broke loose

sending 900 degree centigrade material into the kiln

and out the access door opening.

This filled the building with very hot dust although

no one was hurt at that stage. When the dust had

cleared, it was assumed that it had all come out but

a further dust fall occurred as the hatch was being

replaced.

The hot material knocked one of the victims off the

scaffold. He fell 25 feet landing face down in hot

material that had accumulated on the ground and

died instantly from sustained injuries. Another

employee suffered third degree burns over 90 per

cent of his body and died two weeks later. The third

employee suffered third degree burns to his feet.

One employee was burned on his face, neck, ear,

chest and hand and also suffered scratches to the

surface of his eyes. Another employee was burned

on the face, neck and ear.

Incident 4

During a routine inspection a cap became detached

from a maintenance point, causing hot raw material

to spill out onto the second floor of the pre-heater

tower. The spillage was mainly contained within the

pre-heater tower, but as a precaution, because of the

presence of oxy-acetylene canisters in the area, the

fire brigade was called to the site.

Incident 2

A process operator with 29 years experience was

seriously injured when clearing a blockage inside a

cement clinker drag conveyor located in a tunnel.

Fatal accident site

2nd Edition: December 2005: I. Gibson

Guidance to prevent hot meal burns

December 2005

3. Reducing Personnel Exposure

During breakdown or blockage and normal

cleaning activities, personal exposure to hot meal

may sometimes be unavoidable. However, this

exposure should be for the shortest duration

possible, to a minimum number of personnel (but

always more then one) and at the lowest

temperature possible.

The Management of Health and Safety at Work

Regulations 1999 include duties on employers to

assess risks and where necessary take action to

safeguard health and safety. The regulations

require employers to carry out a suitable and

sufficient assessment of the risks for all work

activities for the purpose of deciding what

measures are necessary for safety. A hierarchy of

control measures is set out that has legal status.

The risks associated with clearing blockages should

be reduced by

Local/task specific risk assessments should be the

norm in addition to area specific risk assessments.

It is important that the recommendations made in

this document are considered as part of the overall

risk assessment. This will allow any health and

safety conflicts that might arise from the

recommendations, e.g. because of a higher priority

risk, to be resolved at the local level.

Ultimately companies and sites are responsible for

the nature and scope of the controls that need to be

implemented based on their health and safety

policy and in particular the site specific risk

assessment.

Normal cleaning / coating removal

2nd Edition: December 2005: I. Gibson

Risk assessment

Proper management systems,

Safe working procedures, such as permits to

work.

Effective supervision

Trained and competent personnel

Good communications

The use of Suitable & Approved Personal

Protective Equipment

The cement process is particularly prone to the

formation of build-ups in the pre-heater where the

kiln feed contains relatively high levels of sulphur

and low levels of alkalis.

The raw meal passing into the kiln as kiln feed and

the fuel fired in the kiln contain some compounds

which volatilise or dissociate when they encounter

the high temperatures in the kiln burning zone.

In this state these compounds travel back up the

kiln system with the kiln exhaust gases until they

reach a part of the kiln or pre-heater system where

the temperature is below the melting point of the

compound. At this point they will condense and

form a strong glue, which can bind meal together

and form build-up.

It is only in response to particular circumstances

that personal exposure to the hot environment will

be required. It is under these conditions where the

potential for injury is greatest. There are usually

two reasons for personnel exposure to the internal

heat of the pre-heater tower:

Breakdown or blockage

Automatic clearing systems

Kiln Feed Chemistry

If the requirement for personnel to be exposed to

hot meal is removed, then the risk of injury from

hot meal is largely removed. Personnel exposure to

hot meal during normal operations of the kiln

system is negligible; physical and managerial

control measures should be in place that prevent

direct contact between operators and the internal

heat of the kiln systems. Provided these control

measures are adhered to, the probability of injury is

very low. The main priorities should be to prevent

blockages occurring in the first place and to reduce

the size of blockages by early detection.

In order to minimise build-up in the kiln and preheater it is therefore important to minimise the

burning zone temperature. The burning zone

temperature will largely be determined by how easy

it is to burn the kiln feed mix to achieve the

3

Guidance to prevent hot meal burns

December 2005

target free-lime level. The ease of burning of kiln

feed is determined by its chemical composition and

fineness which determines the combinability; the

ability of the kiln feed to be combined into the

clinker minerals.

Alarm Systems & Automatic Shut Off

Normal system operating conditions should be

established sufficiently to allow key alarm

parameters to be set for hot meal blockages. When

these parameters are reached, audible and visual

alarms should sound in all vulnerable areas such as

coolers, clinker transport and pre-heater or cooler

sample points to warn personnel.

Key kiln feed chemistry features to control preheater build-up include:

Minimising the combinability temperature of

the kiln feed by tightly controlling kiln feed

chemistry and raw mill product residues on

target.

Where control systems allow, a kiln feed control

loop should be established that

Ensuring that there is sufficient oxygen in the

kiln to eliminate spikes at the kiln inlet and

pre-heater exit. Typically, this means that

the kiln exit oxygen concentration should be

maintained at between 3 and 4% V/V

(volume of oxygen as % of total volume).

operates the alarms detailed above

shuts off the kiln feed system

should a number of pre-determined parameters be

reached.

Static Cleaning Systems

Setting up appropriate communication

systems that inform other process staff of any

increased risk of blockages.

Static cleaning systems fitted on UK cement works,

generally come in two types:

A fitted blaster or air cannon type system.

Fitted to a known and identified point within

the system that attracts build-ups. Most can

be discharged manually and some are

discharged by an automatic system, the

timing of which is set as result of experience.

A movable system (e.g. CardoxTM), which

can be fitted, used and then removed.

Reducing Cyclone Blockages

Reliable methods of monitoring flow through the

pre-heater tower cyclone system represent best

practice. Accurate diagnosis of a failure in a

cyclone outlet can prevent large build-ups of

material in the blocked cyclone. This may be

achieved by alerting the kiln controller to the

problem (e.g. by sounding an alarm) or by

automated removal of the kiln feed.

Both of these systems have clear benefits in that

their efficient use can prevent personnel exposure

to hot meal by removing build-ups before they

result in blockages. In some cases they can also

remove blockages without the need for internal

intervention.

Reducing the amount of hot meal within a blocked

system reduces the volume of material personnel

are exposed to if internal intervention is required.

Reduced volume also has the advantage of

generally reducing the overall exposure time and

furthermore it can reduce the time the precalciner

is shut down to allow unblocking.

Operators should clearly identify points of build up

in the pre-heater system and other areas. Static

cleaning systems should then be installed to control

the build up at these points. Operators should be

trained and competent in their use, particularly on

movable systems as vessels may have to be charged

and connections made to the system.

Suitable nucleic, isotopic probes or similar devices

that provide real time flow indication and early

blockage reporting should be installed on all

cyclonic towers.

2nd Edition: December 2005: I. Gibson

Guidance to prevent hot meal burns

December 2005

4. Normal Cleaning & System

Maintenance

Restrict Access to Work Area

Access to the work area should be prevented for

those not directly involved with the task. This can

be done using a mixture of physical barriers and

visual and audible alarms.

Routine cleaning of some areas in the hot system

may be required on an ongoing basis. Production

personnel usually carry this out as part of the tasks

undertaken during the shift.

For example:

The task is normally carried out with the system in

production and as such under suction. There is

however the potential for the discharge of hot

material from the system if suction is lost.

In all instances looked at by the Working Group

this task was planned and assessed as to risk; tasks

were the subject of a safe system of work or

procedure, which detailed the control measures in

place when under taking this task.

A method of ascertaining the extent and

position of the build up or blockage

A method of removing the build up or

blockage.

Details of the tools to be used and their

storage and maintenance.

Ensure all effected floors are isolated by the

use of lockable physical barriers.

Isolation of all static cleaning devices such as air

cannon or blasters is essential while personnel

access is available to the process. This is to protect

employees from a number of hazards including

exposure to high pressure air, exposure to hot

material dislodged by the air cannon/blasters and

potential discharge of material from the system

caused by loss of suction.

Written safe working procedures should be readily

available to the operatives. These procedures

should at the least consider:

A method of starting the job

Ensure access is denied to all areas (both

local and remote) affected by the task with

the use of lockable physical barriers.

Other Issues

Written Safe Working Procedures

The working area should be clean and secure.

Water should not be allowed to accumulate where

it can come into contact with hot materials, as

contact can cause a steam outburst that can cause

severe injuries.

There should be good access and egress from

inspection doors and rodding points.

A method of putting the system back into

operation.

Trained and Competent Personnel

Employees should be above the level of the

blockage they are clearing and rodding holes

should be downward facing.

Trained and competent operatives must be used at

all times. Operatives should only be deemed to be

trained after a comprehensive training program and

assessment by competent persons. Sufficient back

up should be available to cover employees who

may be away from work, on holiday or sick.

There should be good dedicated communications

with other workers involved in the cleaning and

with the control room. Only Suitable &

Approved personal protective equipment should

be provided. (This subject is explored in another

section of this report.)

The numbers of personnel directly involved in the

task must be kept to a minimum.

2nd Edition: December 2005: I. Gibson

Guidance to prevent hot meal burns

December 2005

5. Major Blockages

by site personnel. The numbers of personnel

directly involved in the task must be kept to a

minimum.

In these circumstances the potential for contact

with hot meal is dramatically increased, but as

stated elsewhere this contact should be kept to the

absolute minimum. Where major blockages occur

plants are taken off line and work can be

undertaken at a measured pace in a more planned

environment. The use of professional contractors

can also be explored.

Restrict Access to Work Area

Access to the work area should be prevented for

those not directly involved with the task. This can

done using a mixture of physical barriers and visual

and audible alarms. For example:

If there is concern as to whether the blockage is

minor or major, a precautionary approach should

be taken and the approach for major blockages

should be implemented.

Once blockages are removed, the system needs to

be brought back into production quickly and

efficiently. All access points into the system should

be resealed and closed. All equipment used to

remove the blockage should then be returned to

storage. A full investigation into the reasons for the

blockage should be undertaken and any lessons

that would prevent a reoccurrence should be learnt.

A method of ascertaining the extent and

position of the build up or blockage

A method of removing the build up or

blockage.

Details of the tools to be used and their

storage and maintenance.

A method of putting the system back into

operation.

Ensure all affected floors are isolated by the

use of lockable physical barriers.

Visual and audible alarms must be installed

in all areas (both local and remote) affected

by the task. Operation of these warning

systems must be guaranteed by regular

testing.

The working area should be clean and secure.

Water should not be allowed to accumulate where

it can come into contact with hot materials. There

should be good access and egress from inspection

doors and rodding points.

Employees should be above the level of the

blockage they are clearing and rodding holes

should be downward facing.

Trained and Competent Personnel

Trained and competent operatives must be used at

all times. Operatives should only be deemed to be

trained after a comprehensive training program and

assessment by competent persons. Any contractors

used to carry out this work must be experienced in

the task, fully aware of the hazards and supervised

2nd Edition: December 2005: I. Gibson

Isolation of all static cleaning devices such as air

cannon or blasters is essential while personnel

access is available to the process. This is to protect

employees from a number of hazards including

exposure to high pressure air, exposure to hot

material dislodged by the air cannon/blasters and

potential discharge of material from the system

caused by loss of suction.

Written safe working procedures should be readily

available to the operatives. These procedures

should at the least consider:

A method of starting the job

Ensure access is denied to all areas (both

local and remote) affected by the task with

the use of lockable physical barriers.

Other Issues

Written Safe Working Procedures

The use of any tower lifts should be limited to

those directly involved in the task.

There should be good dedicated communications

with other workers involved in the cleaning and

with the control room. Only Suitable &

6

Guidance to prevent hot meal burns

December 2005

Approved personal protective equipment should

be provided. (This subject is explored in another

section of this report.)

instruction and training on anything which may

affect their health and safety. This needs to take

account of the risks of the activities of all parties.

Furthermore, all parties need to exchange clear

information about the risks arising from their

operations, including relevant safety rules and

procedures, and procedures for dealing with

emergencies. The information should include

details of any risks that other parties could not be

reasonably expected to know and must be specific

to the work.

Use of Contractors (source: HSE publication Use

of Contractors: a joint responsibility)

Cement companies and their contractors have

general health and safety responsibilities to protect

each other, their workforce, visitors and members

of the public. Similarly if the contractor employs

subcontractors to carry out some or all of the work,

all parties will have some health and safety

responsibilities; the extent of which will depend on

the circumstances. All parties most co-operate to

ensure that health and safety is properly managed.

There must be co-operation and co-ordination

between all parties involved and liaison meetings

should be set up. The workforce must be consulted

and they should be part of the liaison arrangements.

Contractors must be effectively managed and

supervised. The more impact the contractors work

could have on health and safety, the greater the

management and supervisory responsibility.

Responsibilities also increase where the cement

company knows more about the health & safety

implications of the contracted work than the

contractor. The nature of control should be agreed

before any work commences.

The health and safety implications of the blockage

clearance need to be considered. This will involve

selecting a suitable contractor, a risk assessment,

determining what instruction and training is

required, how co-operation and co-ordination

between all parties can be achieved, how the

workforce is to be consulted and the level of

management and supervision required.

Cement companies will need to satisfy themselves

that contractors are competent to do the job safely

and without risks to health and safety. HSE suggest

asking contractors about their experience, H&S

policies and practices, recent H&S performance,

qualifications and skills, subcontractor selection

procedure, provision of H&S training and

supervision, arrangements for consulting the

workforce, any independent assessment of their

competence, membership of relevant trade or

professional bodies and whether they hold a

passport in H&S training. A decision can then be

made on how much evidence needs to be sought to

support what prospective contractors have said.

How the work will be carried out and the

precautions that need to be taken may need to be

agreed with the contractor. Relevant issues include

The cement company will then need to agree the

risk assessment with the contractor and the

preventative and protective steps that will apply

when the work is in progress. If subcontractors are

involved they should also be part of the discussion

and agreement.

Employees must be provided with information,

2nd Edition: December 2005: I. Gibson

What equipment should or should not be

worked on/used

PPE to be used and who will provide it

Working procedures, including any permits to

work

The number of people needed to do the job

Accident reporting & safekeeping of records/

plans.

Checks will be required to ensure the risk

assessment is up to date and that control measures

are working. Periodic checks will be necessary on

the contractors performance to see if work is being

done as agreed. Accidents and near misses should

be investigated and lessons learnt. Any failure to

meet requirements should be put right or the

contractor should be stopped from working on the

job until requirements can be met.

Guidance to prevent hot meal burns

December 2005

6. Personnel Training

Ensuring all poke holes, covers and doors are

closed and sealed.

A trained and competent workforce is less likely to

suffer accidents or incidents when confronted with

a situation involving hot meal and hot meal

systems.

Cordoning off and securing any remaining

hot meal (erect warning signs as required).

Checking any affected area for fire.

Returning all equipment to safe and secure

storage.

Communicating that the blockage is clear and

removing or deactivating any warning signs

or signals.

Reinstating any static cleaning devices and

test.

Reviewing the incident to determine probable

cause, drawing out the lessons to learn,

debriefing the team.

Ensuring that all investigations of this type of

incident are communicated to all employees

and other interested parties. (It should be

remembered that all cement manufacturers

share the same problems and can only benefit

from each others experiences).

All personnel involved in the production process

should be trained to prevent blockages and build up

occurring. The training should also extend to

dealing with blockages and build ups safely when

they occur. This should include training in the use

of Personal Protective Equipment.

The desirability of early warnings of blockages and

the importance of kiln control/kiln feed chemistry

have been explained under item 3. Reducing

Personnel Exposure. Methods of communication

need to be set up to alert other process staff of

potential hazards and to correct the kiln feed before

blockages occur.

Where kiln systems have not yet been fitted with

automatic monitoring devices, the kiln system

should still be monitored closely for temperature

and pressure variations, which could indicate a

blockage and the system, shut down for

investigation. Kiln operators must be able to

recognise the early warning signs and understand

the importance of a quick response.

8. Personal Protective Equipment

Under the hierarchy of control measures Personal

Protective Equipment (PPE) is the last control

measure to be considered. However the type and

effectiveness of the PPE provided for both

breakdown or blockage and normal cleaning /

coating removal is vitally important.

7. Completion of Pre-heater Tower

Work

The requirement to undertake risk assessments

under the Management of Health and Safety at

Work Regulations 1999 is set out under 3.

Reducing Personnel Exposure. It will be necessary

to ensure that these risk assessments are also

compatible with the Personal Protective Equipment

Regulations 1992 (as amended) and/or for specific

legislation if applicable (e.g. COSHH, confined

spaces etc); where PPE is selected.

As with all jobs carried out on the hot meal system,

the final completion of the work must be planned

and carried out correctly.

A procedure should be established for the orderly

completion of pre-heater tower work which should

include:

Confirmation that blockage is clear using

appropriate methods.

The kiln system is hot externally as well as

2nd Edition: December 2005: I. Gibson

Guidance to prevent hot meal burns

December 2005

internally, so persons working on the system will

need to be protected at all times while working on

the system itself or in areas with a potential for hot

meal burns or other thermal burns. To this end a

manual of the PPE in use at various sites has been

compiled.

Use water from a shower, a hose, a sink or

whatever water source is closest. Hold the

burn under cool running water and seek

medical advice.

Most of us will experience at least one

painful burn in our working lives,

remembering this simple, effective first aid

treatment is an easy way to relieve the

discomfort of a burn and prevent lasting burn

damage.

PPE provided to employees must be appropriate to

the hazard encountered and take into account the

ergonomics of the individual/task/environment. It

should fit correctly and be compatible with any

other PPE worn. It must comply with relevant

legislation and be marked to CE or equivalent

standard. Appropriate storage should be provided

for PPE that protects it from damage. PPE should

be properly maintained and any defects should be

reported. Employees should be trained and

instructed in the use of PPE.

Alkali Burns

Cement and other powders within the

manufacturing process are alkali substances and as

a result may cause burns. If these powders come

into contact with the skin and reacts with sweat or

other sources of moisture, then a reaction can occur

which releases heat. Typically the victim does not

know for hours that a burn has occurred, as it is

often a painless process under clothing.

9. Effects and Treatment of Burns

Misconceptions over the classification of burns and

their correct treatment were found amongst front

line employees at a number of sites visited by the

Working Group that prepared this guidance

document. Consequently, the following section

was compiled with assistance from Dr Moinmen of

Selly Oak Burns Unit.

If the agent is left on an unprotected part of the

body for any period of time this can cause the fat in

the skin to turn in to a substance which will burn

and can penetrate the tissue. The severity of the

injury is generally measured by the duration of

exposure. Raw meal burns may often lead to fullthickness skin loss, and destroy ectodermal

elements such as hair follicles, sweat glands and

nerve endings.

Thermal Burns

When a burn occurs not all the damage happens at

once. Because the body holds heat, the burning

process can last for several minutes to several days

or even longer in the case of serious burns. These

burns can also lead to the loss off hair follicles,

sweat glands, and nerve endings and may lead to

skin grafts. Immediate treatment has been found

to decrease the degree and depth of the burn.

First aid for alkali burns:

1. While protecting yourself, brush off dry

particles from the victims skin.

2. Wash with soapy water and rinse for at least

20 minutes, remember that heat is released

when alkalis are mixed with water, so it is

really important to irrigate for at least 20

minutes.

For this purpose, emergency showers must be

installed in all areas where there is a risk of

exposure to the hot feed system.

3. Do not attempt to identify specific

neutralising agents when you should be

irrigating the burn area.

First aid for thermal burns:

Speed is the most important single factor in

burn treatment. The more quickly you cool

down the burn the better your chances of

reducing its effects.

2nd Edition: December 2005: I. Gibson

4. Seek medical attention.

Guidance to prevent hot meal burns

December 2005

10. Heat Stress

all work activities for the purpose of deciding what

measures are necessary for safety.

HSE have produced guidance on heat stress risk

assessments and on what can be done to avoid heat

stress occurring;

A hierarchy of control measures is set out that has

legal status. Schedule 1 of the regulations sets out

the following principles of prevention;

Control temperature

Provide mechanical aids

(a)

avoiding risks;

Regulate exposure time

(b)

evaluating the risks which cannot be avoided;

Prevent dehydration

(c)

combating the risks at source;

Provide specialised PPE

(d)

Provide training

Allow acclimatisation

Identify employees who are susceptible

Health Monitoring

adapting the work to the individual,

especially as regards the design of

workplaces, the choice of work equipment

and the choice of working and production

methods, with a view, in particular, to

alleviating monotonous work and work at a

predetermined work-rate and to reducing

their effect on health;

(e)

adapting to technical progress;

(f)

replacing the dangerous by

dangerous or the less dangerous;

(g)

developing a coherent overall prevention

policy which covers technology, organisation

of work, working conditions, social

relationships and the influence of factors

relating to the working environment;

(h)

giving collective protective measures priority

over individual protective measures; and

(i)

giving appropriate instructions to employees.

The HSE guidance should be followed where

appropriate. The guidance can be obtained from the

HSE website: www.hse.gov.uk/pubns/geis1.pdf

11. Legal Context

Health and Safety at Work Act Section 2

Employers duty of care is set out in section 2 of the

Act. Particular obligations include:

Providing and maintaining plant and systems

of work that are safe and without risks to

health.

non-

Local/task specific risk assessments should be the

norm in addition to area specific risk assessments.

It is important

that the Working Group

recommendations are considered as part of the

overall risk assessment. This will allow any health

and safety conflicts that might arise from the

recommendations, e.g. because of a higher priority

risk, to be resolved at the local level.

Providing such information, instruction,

training and supervision to ensure that

employees can carry out their jobs safely.

The Health and Safety at Work Regulations

detailed below are generally more explicit than the

Health and Safety at Work Act.

Ultimately companies and sites are responsible for

the nature and scope of the controls that need to be

implemented based on their health and safety

policy and in particular the site specific risk

assessment.

Management of Health and Safety at Work

Regulations 1999

The regulations require employers to carry out a

suitable and sufficient assessment of the risks for

2nd Edition: December 2005: I. Gibson

the

10

Guidance to prevent hot meal burns

December 2005

This guidance focuses on hot meal and there may

be other hazards associated with clearing and hot

working in pre-heater towers systems and coolers;

these hazards may be subject to other legislation.

Examples include the Confined Space Regulations

1997, COSHH, the Provision & Use of Work

Equipment Regulations 1998 and the Work at

Height Regulations 2005. Risk assessments should

take account of all relevant legislation

Further Reading: Management of Health and

Safety at Work Regulations 1999: Approved code

of practice and guidance L21 HSE Books ISBN 0

7176 2488 9.

Personal Protective Equipment Regulations

1992 (as amended)

The main requirement is that PPE should be

supplied and used at work wherever there is a

health and safety risk that cannot be controlled in

any other way.

The regulations also set out requirements relating

to assessment, training (including regular checks

that PPE is used correctly), maintenance (including

storage) and the requirement to use CE marked

equipment (when supplied after 1995).

Further Reading:

Personal Protective Equipment Regulations 1992:

Approved code of practice and guidance L21 HSE

Books ISBN 0 7176 2488 9.

A short guide to the Personal Protective

Equipment Regulations 1992-IND(G) 174

www.hse.gov.uk/pubns/ppeindex.htm

Disclaimer

All advice or information from the British Cement Association (BCA) is intended for those who will evaluate the significance

and limitations of its contents and take responsibility for its use and application. No liability (including that for negligence) for

any loss resulting from such advice or information is accepted. Readers should note that all BCA publications are subject to

revision from time to time and should therefore ensure that they are in possession of the latest version. Advice should be taken

from a competent person before taking or refraining from any action as a result of the comments in this guide which is intended

as a brief introduction to the subject.

2nd Edition: December 2005: I. Gibson

11

Guidance to prevent hot meal burns

December 2005

12. Personal Protective Equipment Catalogue

The following photographs have been compiled to

illustrate the various types of PPE currently being

used during high temperature cleaning operations

at different cement works.

On each page details are given of a contact who

will:

- provide supplier and manufacturer details

- give advice about the suitability of the

equipment for certain conditions

- explain the benefits or drawbacks of particular

items.

Responsibility for equipment selection lies with the

employer and must be based on a specific risk

assessment.

2nd Edition: December 2005: I. Gibson

12

Guidance to prevent hot meal burns

December 2005

CASTLE CEMENT: CLITHEROE WORKS

Contact: Chris Fish

Tel: 01200 414 320

E-mail: chris.fish@castlecement.com

An airflow helmet with combined front and back apron. During

operation the helmet is attached to an airline which feeds a constant

flow of filtered fresh air from a special low pressure compressor.

The TST firemans suit is available in heavy duty (left) or light

duty (right). Both have zip fronts and Velcro seals.

2nd Edition: December 2005: I. Gibson

13

Guidance to prevent hot meal burns

December 2005

Cleaning specialists Powerclean UK Ltd. use the above PPE when

clearing pre-heater blockages, and believe the equipment provides

excellent full body protection, whilst allowing good manoeuvrability.

To ensure good communications between members of the cleaning

team, a three way radio link is fitted inside the helmet.

2nd Edition: December 2005: I. Gibson

14

Guidance to prevent hot meal burns

December 2005

LAFARGE CEMENT DIVISION:

Contact: Richard Harrhy Tel: 01446 752371 E-mail: : richard.harrhy@Lafargecement.co.uk

Detachable Visor

Gallet Helmet (MSA Scotland)

Nomex Snood Hood (Arco)

2nd Edition: December 2005: I. Gibson

Neptune Kevlar 18 Sleeve

(Protec Manchester)

15

Guidance to prevent hot meal burns

December 2005

LAFARGE CEMENT DIVISION: CAULDON CEMENT WORKS (below)

Contact: Ian Dawson

Tel: 01538 309 418

E-mail: ian.dawson@lafargecement.co.uk

Gallet helmet with neck cover

Kevlar sleeve

LAFARGE CEMENT DIVISION: CAULDON CEMENT WORKS (below)

Contact: Richard Harrhy Tel: 01446 752371 E-mail: richard.harrhy@Lafargecement.co.uk

Neptune Kevlar gloves (Protec Manchester)

2nd Edition: December 2005: I. Gibson

16

Guidance to prevent hot meal burns

December 2005

LAFARGE CEMENT DIVISION: CAULDON CEMENT WORKS (below)

Contact: Ian Dawson

Tel: 01538 309 418

Nomex balaclava

2nd Edition: December 2005: I. Gibson

E-mail: ian.dawson@lafargecement.co.uk

Gallet helmet with neck cover

17

Guidance to prevent hot meal burns

December 2005

BUXTON LIME INDUSTRIES: TUNSTEAD QUARRY CEMENT WORKS (below)

Contact: Paul Downes

Tel: 01298 76 8246 E-mail: paul.downes@tarmac.co.uk

The design of this suit is very similar to the silver suit, with double Velcro seal

down the front.

2nd Edition: December 2005: I. Gibson

18

Guidance to prevent hot meal burns

December 2005

CASTLE CEMENT: CLITHEROE WORKS

Contact: Chris Fish

Tel: 01200 414 320

E-mail: chris.fish@castlecement.com

Aluminised one piece suit with zip fastener

and studded seal.

2nd Edition: December 2005: I. Gibson

19

Вам также может понравиться

- Sop - Pre-Heater Cyclone Blockage ClearingДокумент18 страницSop - Pre-Heater Cyclone Blockage ClearingVisnu Sankar100% (2)

- Hot Meal Burns Guidance 2nd Edition December 2005 PDFДокумент19 страницHot Meal Burns Guidance 2nd Edition December 2005 PDFSuad BushiОценок пока нет

- Preheater BLOДокумент24 страницыPreheater BLOSanth Raul100% (1)

- 7holcim PDFДокумент41 страница7holcim PDFbulentbulut100% (2)

- Rotary Kiln Reconditioning Tyre and Roller GrindingДокумент8 страницRotary Kiln Reconditioning Tyre and Roller GrindingTiago CamposОценок пока нет

- Cement Mill ReportДокумент13 страницCement Mill ReportYhaneОценок пока нет

- PS05 - PS ReportsДокумент9 страницPS05 - PS Reportssaji kumarОценок пока нет

- Cooler ETA Vs Grate JG (Документ39 страницCooler ETA Vs Grate JG (NaelОценок пока нет

- Kiln Mechanics - (1.4) - ''Quizz Practices''Документ7 страницKiln Mechanics - (1.4) - ''Quizz Practices''Diego AlejandroОценок пока нет

- Kiln Control UnicemfinalДокумент26 страницKiln Control UnicemfinalOUSSAMA LAKHILI100% (1)

- 08 M Roller Lube Mill Greas SysДокумент16 страниц08 M Roller Lube Mill Greas SysDavid Vilca MamaniОценок пока нет

- TiraxunidanrawmillДокумент4 страницыTiraxunidanrawmillsreejilmenon4724Оценок пока нет

- Clinker Coolers Part 1 & 2 96dpiДокумент246 страницClinker Coolers Part 1 & 2 96dpigustavo50% (2)

- 24 00 RP and BM Operation EДокумент9 страниц24 00 RP and BM Operation EDiego AlejandroОценок пока нет

- How To Ensure Safety For Castable MixingДокумент4 страницыHow To Ensure Safety For Castable MixingNaelОценок пока нет

- PR RFR P07 27 v1-0 How To Ensure Safety For Cyclone Lining WorkДокумент6 страницPR RFR P07 27 v1-0 How To Ensure Safety For Cyclone Lining WorkJuan Nacimba NacimbaОценок пока нет

- Pre Calci NerДокумент61 страницаPre Calci NerJoko Dewoto100% (2)

- Unwanted False Air in Cement Plants Can Be A Big Problem and Has To Be Taken SeriouslyДокумент5 страницUnwanted False Air in Cement Plants Can Be A Big Problem and Has To Be Taken SeriouslyharyantoaditОценок пока нет

- Session 1 - Advancement Technologies in Pyro-ProcessingДокумент85 страницSession 1 - Advancement Technologies in Pyro-Processingmahendra sen100% (1)

- Kiln Inlet Lamella Seal FLSДокумент2 страницыKiln Inlet Lamella Seal FLSamir100% (3)

- 3 Rollers Skewing - AДокумент9 страниц3 Rollers Skewing - AFurqan ShabbirОценок пока нет

- Training For Tensioning Hydraulic System MPS MillsДокумент69 страницTraining For Tensioning Hydraulic System MPS MillsImam SampoernoОценок пока нет

- Atox 20 Coal Mill Critical Interlock SheetДокумент6 страницAtox 20 Coal Mill Critical Interlock SheetValipireddy NagarjunОценок пока нет

- Case Study - Maintenance ManagementДокумент27 страницCase Study - Maintenance ManagementDuke Maher SalemОценок пока нет

- Hot Kiln SurveyДокумент2 страницыHot Kiln SurveyHenok Moges KassahunОценок пока нет

- Ball Mill Training - Walk-By Inspections (Tuesday) : Objective of The WorkshopДокумент2 страницыBall Mill Training - Walk-By Inspections (Tuesday) : Objective of The WorkshopDiego AlejandroОценок пока нет

- Phillips Kiln Kiln Alignment Gebhart 2006Документ36 страницPhillips Kiln Kiln Alignment Gebhart 2006mustaf100% (2)

- Operation of The Kiln Line: TrainingДокумент32 страницыOperation of The Kiln Line: TraininglafecapoОценок пока нет

- PR RFR P07-31 How To Perform TrialsДокумент3 страницыPR RFR P07-31 How To Perform TrialsJuan Nacimba NacimbaОценок пока нет

- Thermal & Chemical - Kilb 2015Документ37 страницThermal & Chemical - Kilb 2015Moud SaklyОценок пока нет

- Unique Fan Vibration ProblemsДокумент4 страницыUnique Fan Vibration ProblemsSafrin SangiaОценок пока нет

- Kilns Khaled PDFДокумент16 страницKilns Khaled PDFbulentbulut100% (1)

- Kiln Mechanics - (2.3) - ''Quizz Photos''Документ7 страницKiln Mechanics - (2.3) - ''Quizz Photos''Diego AlejandroОценок пока нет

- MHR21924 CMC Chapter CCДокумент48 страницMHR21924 CMC Chapter CCDede KaladriОценок пока нет

- Clinker Cooler OperationДокумент5 страницClinker Cooler OperationJCSОценок пока нет

- Co Processing Cement KilnsДокумент10 страницCo Processing Cement Kilnshanhccid0% (1)

- Alkali Bypass MaintencnceДокумент15 страницAlkali Bypass MaintencnceJCS100% (1)

- Bag Filters Types, Working Principles & Daily Maintenance - INFINITY FOR CEMENT EQUIPMENT PDFДокумент14 страницBag Filters Types, Working Principles & Daily Maintenance - INFINITY FOR CEMENT EQUIPMENT PDFRICARDOALEXBORGES100% (2)

- PG 1591-1634 Chap5-RawMealHomogenization TextДокумент44 страницыPG 1591-1634 Chap5-RawMealHomogenization TextMKPashaPasha100% (3)

- 273Документ75 страниц273LabroufiAbdelouahedОценок пока нет

- Firing: Vii - CombustionДокумент207 страницFiring: Vii - CombustionMustafa RamadanОценок пока нет

- Cement Mill Ball Mill TestingДокумент30 страницCement Mill Ball Mill Testingzementhead100% (2)

- Ball Mill InspectionДокумент9 страницBall Mill InspectionmahantmtechОценок пока нет

- 08 Rp-Trouble ShootingДокумент26 страниц08 Rp-Trouble Shootingaff bearОценок пока нет

- Type of SurfaceДокумент31 страницаType of SurfaceD N SHARMAОценок пока нет

- Kiln Inlet Risk AssessmentДокумент2 страницыKiln Inlet Risk AssessmentmunatsiОценок пока нет

- Cement Division Technical Training Tools: 090519 Technicaltrainingtools DescriptionДокумент6 страницCement Division Technical Training Tools: 090519 Technicaltrainingtools Descriptionrupesh soniОценок пока нет

- Cecil Module 5 Lesson 70 Red Spots On Kiln Shell PDFДокумент38 страницCecil Module 5 Lesson 70 Red Spots On Kiln Shell PDFbulentbulut100% (1)

- 3 SOP For Cleaning of Clinker Cooler DischargeДокумент3 страницы3 SOP For Cleaning of Clinker Cooler DischargekakaОценок пока нет

- Combined PDF Courses Outlines A&E 2011Документ47 страницCombined PDF Courses Outlines A&E 2011emad sabriОценок пока нет

- Cement Milling I Blue Circle PDFДокумент24 страницыCement Milling I Blue Circle PDFIrshad HussainОценок пока нет

- 26 00 Special Cases and Experiences EДокумент9 страниц26 00 Special Cases and Experiences EDiego AlejandroОценок пока нет

- Repair and Maintenance: CoolerДокумент61 страницаRepair and Maintenance: CoolerYhaneОценок пока нет

- ETA Inspection and Maintanance - ETA 10+15 - Rev - 09 - 09Документ66 страницETA Inspection and Maintanance - ETA 10+15 - Rev - 09 - 09serkalemtОценок пока нет

- MillOpBasics OperationДокумент36 страницMillOpBasics OperationIrshad HussainОценок пока нет

- 10 Golden Rules For Clinker Burning - INFINITY FOR CEMENT EQUIPMENT PDFДокумент15 страниц10 Golden Rules For Clinker Burning - INFINITY FOR CEMENT EQUIPMENT PDFNahro AdnanОценок пока нет

- CH-13 Boiler SafetyДокумент10 страницCH-13 Boiler SafetyRavi ShankarОценок пока нет

- Accident Incident InvestigationДокумент2 страницыAccident Incident InvestigationKhawarizmi JaferyОценок пока нет

- Duhok Polytechnic University College of Technical Engineering Department of PetrochemicalДокумент17 страницDuhok Polytechnic University College of Technical Engineering Department of PetrochemicalDll ZarОценок пока нет

- Boiler Operators SafetyДокумент7 страницBoiler Operators SafetyTrainer 01Оценок пока нет

- Coal CV 6000Документ4 страницыCoal CV 6000AnGahBasHaОценок пока нет

- Audit Report Form - For 1 StarsДокумент3 страницыAudit Report Form - For 1 StarsAnGahBasHaОценок пока нет

- Coal CV 6000Документ2 страницыCoal CV 6000AnGahBasHaОценок пока нет

- Coal CV 6000Документ2 страницыCoal CV 6000AnGahBasHaОценок пока нет

- Conversion m3h To Nm3h UpdateДокумент1 страницаConversion m3h To Nm3h UpdateAnGahBasHaОценок пока нет

- Impact of MoistureДокумент2 страницыImpact of MoistureAnGahBasHaОценок пока нет

- Tyre Ash AbsorbtionДокумент6 страницTyre Ash AbsorbtionAnGahBasHaОценок пока нет

- Preheat ProcessДокумент42 страницыPreheat ProcessAnGahBasHaОценок пока нет

- Ventilation Lecture 8 PH Alleen LezenДокумент27 страницVentilation Lecture 8 PH Alleen LezenIppiОценок пока нет

- Temperature Measurements With Thermocouples: How-To Guide: Document Type NI Supported Publish DateДокумент6 страницTemperature Measurements With Thermocouples: How-To Guide: Document Type NI Supported Publish DateDilip PatelОценок пока нет

- Temperature Measurements With ThermocouplesДокумент2 страницыTemperature Measurements With ThermocouplesAnGahBasHaОценок пока нет

- Muh 26 1 8 0010 7Документ12 страницMuh 26 1 8 0010 7AnGahBasHaОценок пока нет

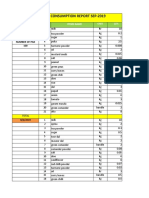

- Water Consumption UpdateДокумент5 страницWater Consumption UpdateAnGahBasHaОценок пока нет

- Glossario de CementoДокумент16 страницGlossario de CementoCarlos LoyagaОценок пока нет

- Table Plant AirДокумент4 страницыTable Plant AirAnGahBasHaОценок пока нет

- ATOX Coal MillДокумент8 страницATOX Coal MillAnwar AliОценок пока нет

- Relations Between Coal Properties and Spontaneous Combustion ParametersДокумент6 страницRelations Between Coal Properties and Spontaneous Combustion ParametersZia Ru'ya HilalОценок пока нет

- V 106 N 03 P 199Документ6 страницV 106 N 03 P 199AnGahBasHaОценок пока нет

- Table Plant AirДокумент4 страницыTable Plant AirAnGahBasHaОценок пока нет

- It'S All in The Bag: by John B Johnson, Flsmidth Aft, UsaДокумент3 страницыIt'S All in The Bag: by John B Johnson, Flsmidth Aft, UsaAnGahBasHaОценок пока нет

- It'S All in The Bag: by John B Johnson, Flsmidth Aft, UsaДокумент3 страницыIt'S All in The Bag: by John B Johnson, Flsmidth Aft, UsaAnGahBasHaОценок пока нет

- It'S All in The Bag: by John B Johnson, Flsmidth Aft, UsaДокумент3 страницыIt'S All in The Bag: by John B Johnson, Flsmidth Aft, UsaAnGahBasHaОценок пока нет

- Preheat ProcessДокумент42 страницыPreheat ProcessAnGahBasHaОценок пока нет

- Cement Milling (Training)Документ3 страницыCement Milling (Training)AnGahBasHaОценок пока нет

- Preheat ProcessДокумент42 страницыPreheat ProcessAnGahBasHaОценок пока нет

- Preheat ProcessДокумент42 страницыPreheat ProcessAnGahBasHaОценок пока нет

- Rule of ThumbДокумент5 страницRule of ThumbAnGahBasHa100% (1)

- CER - Shree CementsДокумент3 страницыCER - Shree CementsHuyentrang NguyenОценок пока нет

- Acute Renal Failure in The Intensive Care Unit: Steven D. Weisbord, M.D., M.Sc. and Paul M. Palevsky, M.DДокумент12 страницAcute Renal Failure in The Intensive Care Unit: Steven D. Weisbord, M.D., M.Sc. and Paul M. Palevsky, M.Dkerm6991Оценок пока нет

- Study Notes On Isomers and Alkyl HalidesДокумент3 страницыStudy Notes On Isomers and Alkyl HalidesChristian Josef AvelinoОценок пока нет

- Chapter 2 and 3 ImmunologyДокумент16 страницChapter 2 and 3 ImmunologyRevathyОценок пока нет

- Crime Data Analysis 1Документ2 страницыCrime Data Analysis 1kenny laroseОценок пока нет

- Senior Project RiceberryДокумент76 страницSenior Project RiceberryIttisak PrommaОценок пока нет

- Feature: SFP Optical Module 1 .25G Double Optical Fiber 20kmДокумент2 страницыFeature: SFP Optical Module 1 .25G Double Optical Fiber 20kmDaniel Eduardo RodriguezОценок пока нет

- 6Документ2 страницы6Min Hsuan HsianОценок пока нет

- Multi-Wing Engineering GuideДокумент7 страницMulti-Wing Engineering Guidea_salehiОценок пока нет

- Pioneer PDP 5071 5070pu Arp 3354Документ219 страницPioneer PDP 5071 5070pu Arp 3354Dan Prewitt100% (1)

- Basics of Fire SprinklerДокумент21 страницаBasics of Fire SprinklerLeo_1982Оценок пока нет

- Neopuff PDFДокумент4 страницыNeopuff PDFoechimОценок пока нет

- Gendec - Inbound HS-HTNДокумент1 страницаGendec - Inbound HS-HTNKhalidОценок пока нет

- Riber 6-s1 SP s17-097 336-344Документ9 страницRiber 6-s1 SP s17-097 336-344ᎷᏒ'ᏴᎬᎪᏚᎢ ᎷᏒ'ᏴᎬᎪᏚᎢОценок пока нет

- Assignment - Lab Accidents and PrecautionsДокумент6 страницAssignment - Lab Accidents and PrecautionsAnchu AvinashОценок пока нет

- Analysis of Pure Copper - A Comparison of Analytical MethodsДокумент12 страницAnalysis of Pure Copper - A Comparison of Analytical Methodsban bekasОценок пока нет

- D6228 - 10Документ8 страницD6228 - 10POSSDОценок пока нет

- Ec Declaration of Conformity: W1/35 KEV KIRK - Protective Gloves - Cathegory IIДокумент3 страницыEc Declaration of Conformity: W1/35 KEV KIRK - Protective Gloves - Cathegory IICrystal HooverОценок пока нет

- Project Management A Technicians Guide Staples TOCДокумент5 страницProject Management A Technicians Guide Staples TOCAnonymous NwnJNO0% (3)

- Dr. Sajjad Hussain Sumrra Isomerism (CHEM-305) Inorganic Chemistry-IIДокумент48 страницDr. Sajjad Hussain Sumrra Isomerism (CHEM-305) Inorganic Chemistry-IITanya DilshadОценок пока нет

- Meat Plant FeasabilityДокумент115 страницMeat Plant FeasabilityCh WaqasОценок пока нет

- AFMAN91-201 NewДокумент458 страницAFMAN91-201 NewbombtechОценок пока нет

- Daily Staff Food Consumption Reports Sep-2019Документ4 страницыDaily Staff Food Consumption Reports Sep-2019Manjit RawatОценок пока нет

- Lesson 1 - Intro To Highway EngineeringДокумент15 страницLesson 1 - Intro To Highway EngineeringSaoirseОценок пока нет

- PPR Soft Copy Ayurvedic OkДокумент168 страницPPR Soft Copy Ayurvedic OkKetan KathaneОценок пока нет

- S ELITE Nina Authors Certain Ivey This Reproduce Western Material Management Gupta Names Do OntarioДокумент15 страницS ELITE Nina Authors Certain Ivey This Reproduce Western Material Management Gupta Names Do Ontariocarlos menaОценок пока нет

- Covid-19 Mitigation PlanДокумент8 страницCovid-19 Mitigation PlanEkum EdunghuОценок пока нет

- Case Report CMV RetinitisДокумент27 страницCase Report CMV RetinitistaniamaulaniОценок пока нет

- Service Manual: Multifunction Electrical Tester CalibratorДокумент106 страницService Manual: Multifunction Electrical Tester CalibratorJuan Carlos Ferrer OrtizОценок пока нет

- Employee Final SettlementДокумент1 страницаEmployee Final SettlementZeeshan Mirza0% (1)

- Feeder BrochureДокумент12 страницFeeder BrochureThupten Gedun Kelvin OngОценок пока нет