Академический Документы

Профессиональный Документы

Культура Документы

Lessons Learned From Wall Failure - Ts1097

Загружено:

18926119Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Lessons Learned From Wall Failure - Ts1097

Загружено:

18926119Авторское право:

Доступные форматы

LESSONS

LEARNED FROM

WALL FAILURE

TECH SHEET #1097

PAGE 1

What started out to be a typical site in need of a retaining wall, provided us with a wealth of information on how reinforced soil structures perform under less than optimum conditions. Picture a change in elevation of approximately 13 ft

(4.0 m), between the side yard of a residential building and street adjacent to the property. A perfect project for Allan

Block, and on the surface a typical retaining site. So goes the story that is seen in hundreds of towns around the world.

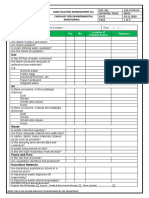

This particular retaining wall was designed by a professional engineer from the residence in need of site work. The

design called for a three degree wall with grid lengths of 6 ft (1.8 m) at a maximum spacing of 4 courses for an exposed

wall height of approximately 12 ft (3.7 m). A driveway was located at one end of the wall and a gradual slope to the residence located approximately 50 ft (15.2 m) from the back of the wall. A soils report was not obtained but experience

indicated that this was a typical clay soil for the area. Little information is available on the method of construction, except

that soils were placed in the infill zone in 2 ft (0.61 m) lifts with little if any compaction achieved. The following sequence

of events outlines what transpired after the wall was completed.

Heavy rain from the adjacent property saturated the fill area behind the wall.

Settlement, averaging 8 in. (20.3 cm), extending approximately 9 ft (2.8 m)

behind the wall was experienced because of the lack of water management

and the resulting saturation of the soil. Surface water runoff from several lots

simply followed a pre-existing grade and stopped at the back of the wall. A

drainage outlet was not incorporated into the design.

During the construction care was taken to route down spouts from the

house gutters through two, 4 in. (10.2 cm) rigid plastic pipes.

Subsequent to the settlement the rigid plastic drain pipes broke directly

behind the wall. It can be assumed that during the settlement the

geogrid directly behind the wall experienced unanticipated loading, and

possible damage, caused by the soil consolidation.

During frequent rain falls that followed, the settlement area turned into a

ponding area, holding water runoff. This inability for the site to effectively

drain water away from the soil resulted in constant saturation of the soil.

Continuing rain fall resulted in an internal stability failure. A localized slip

plane materialized, caused by a build up of hydrostatic pressure and by a

reduction in strength of the soil. These conditions undoubtedly created a

bulge in the wall at approximately 4 ft (1.2 m) above grade.

LESSONS LEARNED Cont.

TECH SHEET #1097

PAGE 2

With no way of determining what happened next, we can speculate that after

an undetermined amount of bulging, shear lips failed at approximately 2 ft

(0.61 m) above grade and the geogrid sheared behind the wall at the top

three layers of grid. At each layer of grid that failed, a length of approximately

10 in. (25.4 cm) sheared away from the rest of the reinforcement mat.

An internal failure plane, following a log spiral configuration, resulted and a

section of wall approximately 8 ft (2.4 m) high by 50 ft (15.2 m) long collapsed onto the street below.

In addition to the conditions described it was determined that two of the layers of geogrid had been installed with the machine direction parallel to the

face of the wall.

Now what lessons have been learned from this failure. First we need to

summarize what went wrong.

1.

2.

3.

Water was not diverted away from the wall.

Proper compaction was not achieved.

Grid was improperly installed.

Due to these conditions we have reaffirmed the several design assumptions and characteristics of Allan Block retaining walls. In particular we proved, in the field, the rock lock grid connection is in fact a positive connection. We also clearly were able to see that a failure plane follows a log spiral profile and that increased grid lengths at the top of the wall in

no way would have increased the stability of this wall. As is the case in all retaining wall projects compaction is essential.

The design used on this wall did not follow the guidelines that we use on a day in day out basis and by taking into account

the incorrect placement of the grid design calculations indicate that a failure could be expected. This project presented a

snapshot of real life and allowed us to take our nose out of the text books for a few moments and gain a perspective that

can only be seen in real life.

Allan Block Corporation 5300 Edina Industrial Blvd., #100, Edina, MN 952-835-5309 952-835-0013 - Fax Copyright 1997

US Patents #4,909,010 & 5,484,236 Canadian Patent #2,012,286 & 2,133,675 Australian Patent #682,394

Taiwan Patent #NI-090824 Intl. & Other Patents Pending Internet address allanblock.com

Вам также может понравиться

- Terramesh Retaining Wall Failure Forensic Report - IstinatДокумент2 страницыTerramesh Retaining Wall Failure Forensic Report - IstinataygunbayramОценок пока нет

- Retaining Wall BayuДокумент5 страницRetaining Wall BayurionovОценок пока нет

- 1689 ReportДокумент6 страниц1689 ReportAmin AminiОценок пока нет

- PDHLibrary-Forensics - Sinkhole Damage To BuildingДокумент9 страницPDHLibrary-Forensics - Sinkhole Damage To BuildingPDHLibraryОценок пока нет

- 2011 03 Mccowan Kivela PDFДокумент11 страниц2011 03 Mccowan Kivela PDFNaveen Karki100% (1)

- Inspection: Sample Inspection Report: Inspector: John Brown Info@propertyinspector - Co.zaДокумент14 страницInspection: Sample Inspection Report: Inspector: John Brown Info@propertyinspector - Co.zaWalid SonjiОценок пока нет

- UnderpinningДокумент58 страницUnderpinningZoeyHakim100% (1)

- 13256-006 2 Watson Street Structural Assessment Report - HT Rev (NA) 2017.11.04 PDFДокумент9 страниц13256-006 2 Watson Street Structural Assessment Report - HT Rev (NA) 2017.11.04 PDFHowell TungolОценок пока нет

- Joint Free Slabs On Grade An Innovative Approach WorkingДокумент6 страницJoint Free Slabs On Grade An Innovative Approach Workingmehdi_hoseineeОценок пока нет

- TCH Seminar Cavity WallДокумент30 страницTCH Seminar Cavity WallSachin AbhiramОценок пока нет

- G.Adithya PGPCPM-06 5801713140129: Earth WorksДокумент11 страницG.Adithya PGPCPM-06 5801713140129: Earth WorksadithyОценок пока нет

- Support of Deep Excavation in Soft Clay A Case History StudyДокумент8 страницSupport of Deep Excavation in Soft Clay A Case History StudyAlfredo A LopezОценок пока нет

- Structure Structure: Magazine MagazineДокумент4 страницыStructure Structure: Magazine MagazinershaghayanОценок пока нет

- 07-02-157 Practical Soil Nail Wall Design and Constructability IssuesДокумент11 страниц07-02-157 Practical Soil Nail Wall Design and Constructability Issuesben indrawanОценок пока нет

- Retaining Wall Modular Unit Reinforced Earth Tensar Geogrid Re InforcementДокумент15 страницRetaining Wall Modular Unit Reinforced Earth Tensar Geogrid Re InforcementAnonymous 1TTYYaОценок пока нет

- Case Studies of Some Concrete Structural Failures ICEДокумент96 страницCase Studies of Some Concrete Structural Failures ICEAhmed Nurul100% (1)

- Building Defects and RemediesДокумент22 страницыBuilding Defects and Remediesruksar100% (1)

- Deep Basement ExcavationДокумент4 страницыDeep Basement Excavationmypenta2008Оценок пока нет

- Parametric Study On Analysis and Design of Permanently Anchored Secant Pile Wall For Earthquake LoadingДокумент16 страницParametric Study On Analysis and Design of Permanently Anchored Secant Pile Wall For Earthquake LoadingInternational Journal of computational Engineering research (IJCER)Оценок пока нет

- Failures During and After Construction - tcm45-340882Документ6 страницFailures During and After Construction - tcm45-340882Uvie M. PtwolanОценок пока нет

- How To Prevent Cracks in Buildings: General Measures For Protection of Cracks.Документ10 страницHow To Prevent Cracks in Buildings: General Measures For Protection of Cracks.Cimpureanu FlorinОценок пока нет

- The Modern Bricklayer - A Practical Work on Bricklaying in all its Branches - Volume III: With Special Selections on Tiling and Slating, Specifications Estimating, EtcОт EverandThe Modern Bricklayer - A Practical Work on Bricklaying in all its Branches - Volume III: With Special Selections on Tiling and Slating, Specifications Estimating, EtcРейтинг: 5 из 5 звезд5/5 (1)

- Construction Defects and Remedies PresentationДокумент14 страницConstruction Defects and Remedies PresentationShobhit Agarwal79% (14)

- Diaphragm Wall DesignДокумент18 страницDiaphragm Wall DesignJosé Chávez100% (3)

- Walls Over CompДокумент6 страницWalls Over CompMiguel ÑañezОценок пока нет

- Soil Nailing Case Histories and Developments: A. D. BARLEY, Contracts Director, Keller ColcreteДокумент15 страницSoil Nailing Case Histories and Developments: A. D. BARLEY, Contracts Director, Keller ColcreteLaura SilviОценок пока нет

- Masonry Failures: Neil R. Baer, P.EДокумент8 страницMasonry Failures: Neil R. Baer, P.EVenkatesh ArunaОценок пока нет

- Evaluation and Retrofitting of Buildings Damaged Due To Jabalpur (India) Earthquake of May 22Nd 1997Документ8 страницEvaluation and Retrofitting of Buildings Damaged Due To Jabalpur (India) Earthquake of May 22Nd 1997Ashish BhartiОценок пока нет

- Wall Detailing in Radaition FalloutДокумент9 страницWall Detailing in Radaition FallouthammedОценок пока нет

- Earth WorkДокумент4 страницыEarth WorkNurali MamenОценок пока нет

- Building Defects and RemediesДокумент24 страницыBuilding Defects and RemediesAbhimanyu Bhardwaj87% (15)

- Assignment 3 (Infill Wall)Документ6 страницAssignment 3 (Infill Wall)Mahmoud AlbhaisiОценок пока нет

- Construction of Footings and Flooring SystemsДокумент24 страницыConstruction of Footings and Flooring SystemsAlbert LiuОценок пока нет

- Abstract:: A Case Study - Installation of Cut-Off Wall in Seyrantepe Dam ProjectДокумент7 страницAbstract:: A Case Study - Installation of Cut-Off Wall in Seyrantepe Dam ProjectsertackcdgОценок пока нет

- Cracks in Residential Basement WallДокумент2 страницыCracks in Residential Basement WallaaОценок пока нет

- Paperno 77Документ14 страницPaperno 77sertackcdgОценок пока нет

- Case Study of Failure of A RДокумент4 страницыCase Study of Failure of A RPriya AggarwalОценок пока нет

- Deep Excavation Techniques Deep Excavation Techniques: Presented byДокумент31 страницаDeep Excavation Techniques Deep Excavation Techniques: Presented byRizwan Khurram100% (1)

- Sheet Pile Retaining Walls Design and Construction in A Brown Fields Environment Amir Holakoo KBRДокумент6 страницSheet Pile Retaining Walls Design and Construction in A Brown Fields Environment Amir Holakoo KBREng mohammadОценок пока нет

- Retaining Wall Failures PDFДокумент3 страницыRetaining Wall Failures PDFrockingjoe100% (1)

- Diaphragm Wall ConstructionДокумент14 страницDiaphragm Wall ConstructionAkshay Kumar Sahoo100% (5)

- Nicoll Highway IncidentДокумент8 страницNicoll Highway IncidentAnonymous PeeXLtNsMpОценок пока нет

- Trouble Free Foundations For Expansive SoilsДокумент8 страницTrouble Free Foundations For Expansive SoilsGregorius FilipusОценок пока нет

- Diagonal CracksДокумент18 страницDiagonal CracksNaveen Kumar Nil100% (1)

- GE441 Lecture6 2Документ19 страницGE441 Lecture6 2sebastian9033Оценок пока нет

- Slope Stabilisation by Soil Nails and Replacement by Anchored Bored Pile Wall For Area Development Ground Engineering February 2002Документ4 страницыSlope Stabilisation by Soil Nails and Replacement by Anchored Bored Pile Wall For Area Development Ground Engineering February 2002Kenny CasillaОценок пока нет

- Repair RehabilitationДокумент16 страницRepair RehabilitationbaburshahmandozaiОценок пока нет

- Basement and Retaining WallsДокумент42 страницыBasement and Retaining WallsSamata Mahajan0% (1)

- 9 UnderpinningДокумент12 страниц9 UnderpinningTadiwanashe MangwiroОценок пока нет

- Muhammad Fathullah Bin MD YazidДокумент7 страницMuhammad Fathullah Bin MD YazidPathul FathulОценок пока нет

- Basement Floor Lowering Info Sheet For ClientsДокумент6 страницBasement Floor Lowering Info Sheet For Clientshahaer77Оценок пока нет

- BackfillingДокумент3 страницыBackfillingAjay SastryОценок пока нет

- Repairs and Maintenance of RCC Framed StructuresДокумент36 страницRepairs and Maintenance of RCC Framed StructuresSagarKanadeОценок пока нет

- Soil Nail Wall - Soil Nailing - Deep ExcavationДокумент7 страницSoil Nail Wall - Soil Nailing - Deep ExcavationAlok Mehta0% (1)

- Digital Assignment - Ii Advanced Foundation Design: Soil Nailing and Anchoring, Design Aspects and Case StudiesДокумент14 страницDigital Assignment - Ii Advanced Foundation Design: Soil Nailing and Anchoring, Design Aspects and Case StudiesSANTHOSH KUMAR VОценок пока нет

- Collapse of A Reiinforced Soil Segmental Retainign WallДокумент9 страницCollapse of A Reiinforced Soil Segmental Retainign WallrfingeОценок пока нет

- Cut and Cover Tunnels - Waterproof Magazine Winter 2012 PDFДокумент5 страницCut and Cover Tunnels - Waterproof Magazine Winter 2012 PDFfethi42Оценок пока нет

- BCM-V U2 Part-B 19-07-2021Документ55 страницBCM-V U2 Part-B 19-07-2021hyperloop707 designОценок пока нет

- Engineer's Report: Seismic Performance Evaluation and Tire Construction AnalysisОт EverandEngineer's Report: Seismic Performance Evaluation and Tire Construction AnalysisОценок пока нет

- Achievers Focusing SystemДокумент0 страницAchievers Focusing SystemHashim AdilОценок пока нет

- Frequently Asked Questions : Return To: BlogsДокумент15 страницFrequently Asked Questions : Return To: Blogs18926119Оценок пока нет

- TerraceДокумент2 страницыTerrace18926119Оценок пока нет

- Lighting Criteria StandardsДокумент19 страницLighting Criteria Standards18926119Оценок пока нет

- Real Estate Appraisal: Chapter 1: Introduction To AppraisalДокумент4 страницыReal Estate Appraisal: Chapter 1: Introduction To Appraisal18926119Оценок пока нет

- Toilet - FluidMaster - How It WorksДокумент1 страницаToilet - FluidMaster - How It Works18926119Оценок пока нет

- Business Plan: Outline of AДокумент7 страницBusiness Plan: Outline of A18926119Оценок пока нет

- Markandeya Purana, Books VII, VIII: Rev. B. Hale WorthamДокумент22 страницыMarkandeya Purana, Books VII, VIII: Rev. B. Hale Wortham18926119Оценок пока нет

- Lighting Fundamentals: IlluminationДокумент28 страницLighting Fundamentals: IlluminationSixto VadilloОценок пока нет

- Retaining Wall GlossaryДокумент1 страницаRetaining Wall Glossary18926119Оценок пока нет

- Post Exercise Carbohydrates PDFДокумент5 страницPost Exercise Carbohydrates PDFAndy DragomirОценок пока нет

- Summer Action Plan 2023Документ2 страницыSummer Action Plan 2023SivaPrasad KattaОценок пока нет

- Grade 3-6 Weather, Water, AirДокумент8 страницGrade 3-6 Weather, Water, AirMis GloriaОценок пока нет

- Water Resources in India - WikipediaДокумент13 страницWater Resources in India - WikipediaSanjukta SahooОценок пока нет

- Water Resources in Egypt Future Challege PDFДокумент14 страницWater Resources in Egypt Future Challege PDFMohamed SolimanОценок пока нет

- Good Day Everyone!: Reporters: Harry Quinto Michaela Carmona Mar Nisperos Missy SalaumДокумент8 страницGood Day Everyone!: Reporters: Harry Quinto Michaela Carmona Mar Nisperos Missy SalaumAriam SorepsinОценок пока нет

- Hse-07-Fr-02 Checklist For Environmental MonitoringДокумент2 страницыHse-07-Fr-02 Checklist For Environmental MonitoringSalah S. Barih100% (5)

- Desalination: H. Bhandary, Chidambaram Sabarathinam, A. Al-Khalid TДокумент13 страницDesalination: H. Bhandary, Chidambaram Sabarathinam, A. Al-Khalid TBrigita de BrillarОценок пока нет

- Brexil Mix (Agritrade) SDSДокумент12 страницBrexil Mix (Agritrade) SDSRОценок пока нет

- Other Processes Include:: Septic TankДокумент16 страницOther Processes Include:: Septic TankrajeshОценок пока нет

- CSA 4H Manual (E-Copy)Документ82 страницыCSA 4H Manual (E-Copy)Steve Maximay100% (2)

- 50 Đề Thi Vào 10 Môn Anh Tỉnh Thanh Hóa Có Đáp Án MÃ ĐỀ 008Документ3 страницы50 Đề Thi Vào 10 Môn Anh Tỉnh Thanh Hóa Có Đáp Án MÃ ĐỀ 008Anh Lê Thị VânОценок пока нет

- State of Florida Department of Transportation Drainage Handbook Exfiltration SystemsДокумент94 страницыState of Florida Department of Transportation Drainage Handbook Exfiltration SystemsBimantoro GalihОценок пока нет

- Isobond: SBR Bonding AdmixtureДокумент3 страницыIsobond: SBR Bonding AdmixtureHussain MarzooqОценок пока нет

- Assignment No 3Документ1 страницаAssignment No 3Trisha Mae AspuriaОценок пока нет

- Lakasa Sand InterceptorДокумент1 страницаLakasa Sand InterceptorIswadi Bin ZulkarnainОценок пока нет

- Aquaponics Fact Sheet PDFДокумент1 страницаAquaponics Fact Sheet PDFSofiene RouisОценок пока нет

- WSP Costs: Case Study in Sana'a, YemenДокумент17 страницWSP Costs: Case Study in Sana'a, YemenVichekaОценок пока нет

- Nature-Based Solutions For Resilient Ecosystems and SocietiesДокумент31 страницаNature-Based Solutions For Resilient Ecosystems and SocietiesPWD USU Ganjil 2021Оценок пока нет

- Laudato SiДокумент7 страницLaudato SiCzarina Louise NavarroОценок пока нет

- 2023 MATE ROV Competition Briefing 5Документ11 страниц2023 MATE ROV Competition Briefing 5Omar MedhatОценок пока нет

- RRWH Short Course For YemenДокумент102 страницыRRWH Short Course For YemenKatia PipiliОценок пока нет

- ORF OccasionalPaper 317 BlueGreenInfrastructureДокумент38 страницORF OccasionalPaper 317 BlueGreenInfrastructureMd IbrahimОценок пока нет

- Earth Life Science Quarter 1 Module 1 PDFДокумент41 страницаEarth Life Science Quarter 1 Module 1 PDFNicka MaalaОценок пока нет

- # 1.urban Water Management in Cities Historical, Current and Future RegimesДокумент9 страниц# 1.urban Water Management in Cities Historical, Current and Future RegimesMINALACHEW TAYEОценок пока нет

- Module 3 Experiment Group Answers Inserted Envi Sci FinalДокумент6 страницModule 3 Experiment Group Answers Inserted Envi Sci FinalJillian Kaye OsinОценок пока нет

- Modified Cluster System Approach To WastДокумент10 страницModified Cluster System Approach To WastGraziella NavacciОценок пока нет

- Shallow Wells ManualДокумент17 страницShallow Wells ManualFleming Mwijukye100% (1)

- Multiple Choice Questions: Primary Production and Energy FlowДокумент10 страницMultiple Choice Questions: Primary Production and Energy FlowAmaniОценок пока нет

- MSDS DR-665.02Документ5 страницMSDS DR-665.02I Gede AnggaОценок пока нет

- Mizoram IntroductionДокумент88 страницMizoram IntroductionwhitesnipeОценок пока нет