Академический Документы

Профессиональный Документы

Культура Документы

European Patent Specification F01D 11/00, F16J 15/34,: Printed by Jouve, 75001 PARIS (FR)

Загружено:

shamsИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

European Patent Specification F01D 11/00, F16J 15/34,: Printed by Jouve, 75001 PARIS (FR)

Загружено:

shamsАвторское право:

Доступные форматы

Europisches Patentamt

(19)

European Patent Office

*EP000818607B1*

Office europen des brevets

(11)

EP 0 818 607 B1

EUROPEAN PATENT SPECIFICATION

(12)

(45) Date of publication and mention

of the grant of the patent:

16.06.2004 Bulletin 2004/25

(51) Int Cl.7:

F01D 11/00, F16J 15/34,

F16J 15/44

(21) Application number: 97300846.9

(22) Date of filing: 10.02.1997

(54) Gas turbine with carbon seal containment barrier system

Gasturbine mit Verunreinigungssperrsystem fr Kohlenstoffdichtung

Turbine gaz avec barrire contre la contamination pour garniture tanche en carbone

(84) Designated Contracting States:

DE FR GB

(30) Priority: 09.02.1996 US 599028

(43) Date of publication of application:

14.01.1998 Bulletin 1998/03

(73) Proprietor: Rolls-Royce Corporation

Indianapolis, IN 46206-0420 (US)

(72) Inventors:

EP 0 818 607 B1

Smith, Joseph C.

Plainfield, Indiana 46168 (US)

Bowman, Mark E.

New Palestine, Indiana 46163 (US)

Black, Joseph D.

Brownsburg, Indiana 46112 (US)

(74) Representative: Holmes, Matthew Peter et al

MARKS & CLERK,

Sussex House,

83-85 Mosley Street

Manchester M2 3LG (GB)

(56) References cited:

US-A- 2 992 842

US-A- 5 301 957

US-A- 4 969 652

Note: Within nine months from the publication of the mention of the grant of the European patent, any person may give

notice to the European Patent Ofce of opposition to the European patent granted. Notice of opposition shall be led in

a written reasoned statement. It shall not be deemed to have been led until the opposition fee has been paid. (Art.

99(1) European Patent Convention).

Printed by Jouve, 75001 PARIS (FR)

EP 0 818 607 B1

Description

BACKGROUND OF THE INVENTION

[0001] The present invention relates generally to the

design and construction of seal systems useful in a gas

turbine engine. More particularly, the present invention

has one application with a carbon seal system for preventing the contamination of the carbon seal system. Although the invention was developed for use in a gas turbine engine, certain applications may be outside of this

field.

[0002] It is well known that a gas turbine engine integrates a compressor and a turbine having components

that rotate at extremely high speeds relative to each other, and across which there are pressure differentials that

make the provision of seals for minimizing fluid leakage

very important. Prior designers of seal systems have

generally used a sealing device consisting of a plurality

of arcuate carbon material segments arranged to form

a stationary carbon ring that forms a rubbing interface

with a rotating seal runner.

[0003] The rubbing interface between the rotating

seal runner and the carbon ring minimizes or prevents

the leakage of fluid through the seal, however if the heat

generated by the rubbing interface is not adequately dissipated the resulting fluid leakage at the seal interface

may become excessive. The carbon seal system requires the precise geometric fit between the stationary

carbon ring and the rotating seal runner to ensure that

the intimate rubbing interface is obtained between the

mating components. The rubbing interface between the

mating components is critical to the performance of the

seal, and certain tolerances associated with the seal

components are measured in millionths of an inch. In

order to maintain the precision geometric fit between the

mating components of the rubbing interface, prior designers of carbon seal systems have typically utilized a

fluid cooling medium to extract excessive heat from the

seal runner.

[0004] A conventional technique utilized by designers

of gas turbine engines to minimize the flow of cooling

fluid onto the carbon seal is to use an integral windback

in the seal housing. Persons of ordinary skill in the art

will realize that a windback is generally used to pump

oil away from the carbon seal, thereby evacuating the

oil from the seal. A common limitation associated with

windback systems is that as the oil is being evacuated

away from the carbon seal, a vacuum is formed which

can result in solid oil being pulled back into the seal and

fluid leak occurs. Fluid leakage across the carbon seal

is detrimental to the function of the engine, causing

problems ranging from a hazardous condition to contamination of the aircraft environmental system. Contamination of the aircraft environmental system may result in an air-oil mist being discharged into the cockpit

or passenger compartment of the aircraft, thereby rendering the environment unfriendly to pilots and passen-

10

15

20

25

30

35

40

45

50

55

gers.

[0005] Examples of known carbon seal arrangements

for gas-turbine engines are disclosed in US Patents

Nos. 4,969,652 and 5,301,957. Both of these patents

disclose sealing arrangement comprising a carbon seal

ring mounted to the turbine housing and forming a fluid

tight seal with a seal runner which rotates with the turbine shaft. The seal arrangement disclosed in US

5,301,957 has all of the features of the characterising

portion of claims 1 and 23 of the present application.

[0006] Even with a variety of earlier designs there remains a need for an improved carbon seal contaminant

barrier system. The present invention satisfies this need

in a novel and unobvious way.

[0007] According to a first embodiment of the present

invention there is provided a gas turbine engine comprising:

a mechanical housing within said gas turbine engine;

a shaft rotatably mounted within said housing;

a first sealing element coupled to said housing;

a second sealing element connected to said shaft,

said second sealing element arranged adjacent to

said first sealing element to form a substantially fluid

tight seal therebetween;

a third sealing element positioned adjacent said

second sealing element; characterised by:

a baffle spaced from said third sealing element

and positioned around said second sealing element.

[0008] According to a second embodiment of the

present invention there is provided a gas turbine engine

comprising:

a mechanical housing within said gas turbine engine;

a shaft rotatably mounted within said housing;

a first sealing element coupled to said housing;

a second sealing element connected to said shaft,

said second sealing element arranged adjacent to

said first sealing element to form rubbing interface

therebetween;

a third sealing element arranged adjacent said first

sealing element to form a rubbing interface with said

second sealing element, said third sealing element

wiping the outer surface of said second sealing element to reduce the flow of a liquid to said first sealing element; characterised by:

a passageway around said second sealing element and in fluid communication with said

third element said passageway having a narrowed portion for calming the flow of liquid prior

to impingement upon said third sealing element.

EP 0 818 607 B1

[0009] One object of one embodiment of the present

invention is to provide an improved carbon seal containment barrier system for a gas turbine engine.

[0010] Related objects and advantages of the present

invention will be apparent from the following description.

BRIEF DESCRIPTION OF THE DRAWINGS

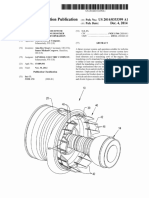

[0011] FIG. 1 is a side elevational view of a gas turbine

engine utilizing one form of the present invention therein.

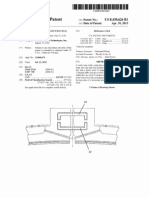

[0012] FIG. 2 is a fragmentary side elevational view

in full section of the FIG. 1 gas turbine engine having a

carbon seal contaminant barrier system according to

one embodiment of the present invention.

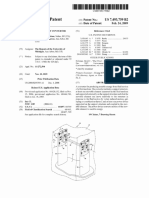

[0013] FIG. 3 is a fragmentary side elevational view

in full section of the FIG. 1 gas turbine engine having a

carbon seal contaminant barrier according to another

embodiment of the present invention.

[0014] FIG. 4 is an end view of a baffle comprising a

portion of the carbon seal contaminant barrier of FIG. 3.

[0015] FIG. 5 is a side elevational view in full section

of the FIG. 4 baffle.

[0016] FIG. 6 is an enlarged perspective view of a portion of the carbon sealing ring with pressurized fluid discharge aperture therein comprising a portion of the carbon seal contaminant barrier system.

10

15

20

25

DESCRIPTION OF THE PREFERRED EMBODIMENT

30

[0017] For the purposes of promoting an understanding of the principles of the invention, reference will now

be made to the embodiment illustrated in the drawings

and specific language will be used to describe the same.

It will nevertheless be understood that no limitation of

the scope of the invention is thereby intended, such alterations and further modifications in the illustrated device, and such further applications of the principles of

the invention as illustrated therein being contemplated

as would normally occur to one skilled in the art to which

the invention relates.

[0018] Referring to FIG. 1, there is illustrated a gas

turbine engine 10 which includes a compressor 11, a

combustor 12 and a power turbine 13. Three components have been integrated together to produce an aircraft flight propulsion engine. One aircraft engine of this

general type is model AE 2100 that is produced by Allison Engine Company, Inc. of Indianapolis, Indiana. It is

important to realize that there are a multitude of ways in

which the components can be linked together. Additional compressors and turbines could be added with intercoolers connected between the compressors and reheat combustion chambers could be added between the

turbines. Further, a gas turbine engine is equally well

suited to be used for industrial applications.

Historically, there has been wide spread application of

industrial gas turbine engines, such as pumping sets for

gas and oil transmission lines, electricity generation and

35

40

45

50

55

naval propulsion.

[0019] With reference to FIG. 2, there is illustrated a

fragmentary view in full section of gas turbine engine 10.

A tubular shaft 15 is rotatably mounted within the gas

turbine engine 10 about a longitudinal axis y of the engine 10. The shaft 15 is supported on a plurality of bearings (16) (only one illustrated) that are disposed between the shaft 15 and a rigid housing 17 that forms a

portion of the engine 10. One of the plurality of bearings

is a bearing 16 that is coupled to the mechanical housing

17. A volume defined between the shaft 15 and the mechanical housing 17 is sump 18 in which bearing 16 is

disposed.

[0020] The sump 18 functions as a reservoir for cooling fluid that is utilized to cool and lubricate the mechanical components of the gas turbine engine 10 such as

bearing 16. In the preferred embodiment annular barriers (not illustrated) are attached to the front and rear of

the mechanical housing to close the sump 18. Further,

a plurality of seals are disposed between mechanical

housing 17 and shaft 15 that is rotatably mounted within

mechanical housing 17. One of the plurality of seals is

sealing arrangement 21. In the preferred embodiment

the sealing arrangement 21 is a carbon seal system that

includes a stationary component and a rotating component.

[0021] The stationary component of the sealing arrangement 21 has a first sealing element 22 that is coupled to the mechanical housing 17. While the rotating

component of the sealing arrangement 21 has a second

sealing element 23 that is mechanically connected to

the rotating shaft 15. It is well known that the rotating

component of this sealing arrangement is known as a

seal runner, and that the stationary component is known

as a circumferential carbon seal. It is understood that

other types of primary seals could also be used.

[0022] In the preferred embodiment the first sealing

element 22 is positioned axially concentric with and radially outward from the second sealing element 23. Further, in the preferred embodiment the sealing elements

22 and 23 are arranged adjacent to each other to form

a rubbing interface therebetween. A first cylindrical surface 25 is formed on the radially inward side of the first

sealing element 22, and a second cylindrical surface 26

is formed on the radially outward side of the second

sealing element 23. At least a portion of the cylindrical

surfaces 25 and 26 are maintained in rubbing contact to

form a fluid tight seal at the rubbing interface 27.

[0023] A lubrication system, which normally provides

cooling fluid under pressure to lubricate and cool the

moving parts of the engine, such as the bearing 16 and

the second sealing element 23 delivers its fluid through

a nozzle 28. The cooling fluid is pressurized by a pump

(not illustrated) to a pressure of about 207 kPa (about

30 pounds per square inch gage), and delivered through

nozzle 28 with sufficient kinetic energy to traverse the

passageway 30 formed along shaft 15. The passageway 30 provides a pathway for the axial flow of cooling

EP 0 818 607 B1

fluid to a substantially solid planar surface 31 that forms

a portion of the second sealing element 23. This planar

surface 31 prevents any further axial flow of the cooling

fluid and helps direct the fluid to flow in a substantially

radial direction. In the preferred embodiment, a plurality

of openings 39 are formed on one end of the passageway 30 to allow the discharge of cooling lubricants. In

the preferred embodiment the cooling fluid is an engine

oil having a viscosity suited for the high temperatures

associated with a gas turbine engine 10. Other types of

fluid lubrication systems may be employed and the specific disclosure of the preferred embodiment is not intended to limit the types of lubrication systems which

may be used in furtherance of the present invention.

[0024] In the preferred embodiment a circumferential

channel 33 is formed on the radially inward surface 23a

of the second sealing element 23. The radially inward

surface 23a defines an outwardly sloping surface that is

axially concentric with the first sealing element 22 and

the second sealing element 23. This outwardly sloping

surface preferably has a slope of about two degrees as

measured from a reference line parallel to the central

axis Y of the gas turbine engine 10.

[0025] The circumferential channel 33 extends uninterrupted around the second sealing element 23. The

channel 33 is designed and constructed for receiving

cooling fluid therein that has been released through the

plurality of openings 39 in passageway 30. As the cooling fluid exits the openings 39 of passageway 30 it is

thrown radially outward by centrifugal forces during normal engine operation. As the cooling fluid is received

into channel 33 it flows circumferentially through the

channel until the channel is full. When the channel 33 is

full of fluid it allows the cooling fluid to escape at a plurality of points along its length. The cooling fluid is evenly

distributed on the radially inward surface 23a of the second sealing element 23 and provides for substantially

uniform dissipation of thermal energy therefrom. Further

details regarding a circumferential flow channel, such

as flow channel 33 are disclosed in commonly owned

U.S. Patent Application Serial No. 08/309,081.

[0026] The second sealing element 23 has an external portion 8 extending a further distance from the first

sealing element 22 than the channel 33 is located from

the first sealing element 22. External portion 8 is designed to minimize the volume of oil that engages the

first sealing element 22. In the preferred embodiment

the first sealing element 22 includes a carbon sealing

element. The carbon sealing element defines an annular ring that is formed from a plurality of arcuate carbon

material segments arranged in an abutting relationship.

[0027] In one form of the present invention a windback

40 is positioned radially outward from the second sealing element 23 and adjacent the first sealing element

22. Windbacks are generally known to those skilled in

the art, however, windback 40 has been designed and

manufactured such that there is only one thread 41. The

windback 40 is utilized to assist in preventing the im-

10

15

20

25

30

35

40

45

50

55

pingement of oil onto the first sealing element 22. Further, a fluid contaminant flow barrier 43 is disposed between the housing 17 and the rotating seal runner 23.

In the preferred embodiment the fluid contaminant flow

barrier 43 is an annular baffle spaced radially from seal

runner 23. In the preferred embodiment, the baffle 43 is

formed of sheet metal. Baffle 43 (illustrated in FIGS. 5

and 6) is connected to the mechanical housing 17 and

prevented from rotation relative to the housing by an anti-rotation mechanism.

[0028] With reference to FIG. 3, there is illustrated a

fragmentary side elevational view in section of a gas turbine engine having another embodiment of the carbon

seal contaminant barrier system. FIGS. 2 and 3 are substantially identical with like numbers representing like

features and distinctions therebetween will be discussed hereinafter. The fluid contaminant flow barrier

43 is positioned within the mechanical housing 17 by an

interference fit. The fluid flow barrier 43 being radially

spaced from seal runner 23 so as to eliminate contact

between the seal runner 23 and the stationary barrier

43. An annular fluid seal 50 is disposed between the mechanical housing 17 and the outer cylindrical surface

23b of seal runner 23. In the preferred embodiment the

fluid seal 50 is a lip seal having a L-shaped lip and made

of TEFLON impregnated with carbon graphite. TEFLON is a registered trademark of E.I. DuPont De Nemours and Company of Wilmington, DE. Other annular

fluid seal designs are contemplated herein, such as a

hydrodynamic lip and alternative material choices such

as TEFLON filled with glass/moly and TEFLON filled

with EKONOL. EKONOL is a trademark of Furon of

Los Alamitos, CA. Other lip seals designs may be employed and the specific disclosure of lip seal 50 is not

intended to limit the types of lip seals which may be used

in furtherance of the present invention. However, it is

understood that the lip seal must have the characteristics required to operate in the present environment. The

lip 50a of the lip seal 50 rides on the outer cylindrical

surface 23b of the seal runner 23 and wipes away solid

oil that comes in contact therewith.

[0029] In the preferred embodiment a pressurized gas

is discharged from the compressor through tubular shaft

15, aperture 100, aperture 101 in labryinth seal 102, and

is delivered via a passageway adjacent to the face 53k

of carbon sealing element 53. The discharge of the pressurized gas assists in preventing the impingement of

contaminants on the carbon sealing element 53. In the

preferred embodiment the gaseous fluid is air. Further,

the discharge of the pressurized gas acts on the lip seal

50 in order to reduce the load associated with the lip

seal 50 contacting the rotating seal runner 23. It is understood that as the engine speed increases, the pressurized gaseous supply increases. The corresponding

reduction in the load associated with the lip seal 50 that

is transferred to seal runner 23 decreases the incidence

of the seals burning in a high speed rotary device such

as a gas turbine engine 10. The pressurized gas also

EP 0 818 607 B1

functions to blow contaminants away from the seal, and

more particularly to blow oil away from the seal.

[0030] In the preferred embodiment pressurized gas

from the compressor flows into a plurality of circumferential channels 110 formed on the planar face 111 of the

arcuate carbon members 105. The gaseous flow from

the compressor passes along the channels 110 formed

on the individual carbon arcuate members 105 and is

blocked from exiting the respective flow channel 110 by

the adjoining arcuate carbon member and the mechanical housing 17. The planar surface 111 of the arcuate

members 105 are in contact with an internal surface of

the mechanical housing 17 and creates a fluid tight seal.

A passageway 115 is formed across the planar sealing

surface 111 at each of the respective joints where the

respective arcuate carbon members 105 abut. The

three passageways 115 allow the pressurized gas to

flow between the respective abutting ends 120 and 121

of the members 105 and be discharged from the carbon

ring adjacent surface 23b of the sealing element 23. Further, it is understood that in another embodiment of the

present invention the carbon sealing element does not

have apertures associated therewith for the pressurized

discharge of gas adjacent the face of the carbon seal.

Carbon sealing elements of this general type are now

available from Stein Seal of Philadelphia, Pa. However,

the utilization of pressurized gas to reduce the drag on

lip seal 50 has been found to enhance the life of the seal.

[0031] In the preferred embodiment, the circumferential carbon seal 53 is formed of three arcuate carbon

members 105 (only 2 illustrated) that interlock and are

assembled between the mechanical housing 17 and the

shaft 15. A circumferential tensioning spring 106 is utilized to provide a compressive force to the plurality of

arcuate carbon member 105 to position them adjacent

and in rubbing interface with the rotating shaft 15.

[0032] The fluid contaminant barrier 43 functions as

a bulk head to prevent excited fluid from sump 18 from

directly impinging onto the lip seal 50. As the lubricant

passes through the narrowed annular opening 125 it is

calmed as it is discharged into an annular cavity 61. Annular cavity 61 is defined by lip seal 50, baffle 43, and

the rotating shaft 15. The lubricant having been discharged into cavity 61 assists in cooling and lubricating

the lip 50a of lip seal 50, thereby helping to prevent deterioration of lip seal due to the high surface speeds inherent in a gas turbine engine.

[0033] With reference to FIGS. 4 and 5, there is illustrated the preferred embodiment of fluid contaminant

barrier 43. In the preferred embodiment fluid contaminant barrier 43 is a baffle with a central aperture disposed around sealing element 23, and a fluid drain aperture 75 which allows any fluid retained within cavity

61 to drain into the sump 18 after the gas turbine engine

is shut down. In the preferred embodiment the fluid

drainage is a gravity fed process. Further, the baffle 43

has an anti-rotation mechanism comprising a slot 76

that receives a pin (not illustrated) therein. The pin (not

10

15

20

25

30

35

illustrated) is connected to the housing 17 and engages

the anti-rotation slot 76 to prevent baffle 43 from rotating. In the preferred embodiment the baffle 43 defines

a annular ring having a first end 130 with a larger outside

diameter d1 and a second end 131 with a smaller outside diameter d2 that are connected by a tapered cylindrical surface.

[0034] Alternate forms of the present invention are

contemplated herein and are deployable in different environments within a sump 18 located near a carbon seal.

The two general classes of environment are classified

as an air-oil mist environment and a solid oil environment. Owing to the characteristics of these two environments, each environment may require different methods

to optimize the contaminant barrier sealing system,

however there is no limitation intended that a specific

contaminant barrier system design can only work in a

specific class of environment.

[0035] With reference to FIGS. 1-6, there will be illustrated examples of carbon seal contaminant barrier systems. In a sump environment having substantially only

air-oil mist there may be no need for the entire combination of baffle, lip seal and carbon seal with pressurized

air discharge. In the air-oil mist environment utilizing a

contaminant barrier system without the baffle allows the

air-oil mist to directly impinge upon the lip seal and cool

the seal. Further, there are situations when there is not

present in the sump a sufficient volume of air-oil mist to

warrant the combination of the baffle, lip seal, and carbon seal with pressurized gaseous discharge; and deployment thereof may starve the lip seal of required

cooling fluid and cause a premature deterioration of the

lip seal. However, in a solid oil environment the combination of a carbon seal with pressurized gaseous discharge, fluid contaminant barrier, and a lip seal may be

required. It is understood that these combinations are

not be construed as limitations and are just examples of

carbon seal contaminant barrier systems that can be utilized to enhance the gas turbine engine.

40

Claims

1.

A gas turbine engine (10) comprising:

45

50

55

a mechanical housing (17) within said gas turbine engine (10);

a shaft (15) rotatably mounted within said housing;

a first sealing element (22;53) coupled to said

housing (17);

a second sealing element (23) connected to

said shaft (15), said second sealing element

(23) arranged adjacent to said first sealing element (22;53) to form a substantially fluid tight

seal therebetween;

a third sealing element (40;50) positioned adjacent said second sealing element (23);

EP 0 818 607 B1

characterised by a baffle (43) spaced from

said third sealing element (40;50) and positioned

around said second sealing element (23).

2.

A gas turbine engine according to claim 1, wherein

said first sealing element (22;53) is a carbon seal

and said second sealing element (23) is a seal runner, and further wherein said third sealing element

(40;50) contacts said seal runner (23).

10

3.

A gas turbine engine according to claim 2, wherein

said seal runner (23) has a circumferential cooling

channel (33) formed therearound.

4.

A gas turbine engine according to claim 2 or claim

3, wherein said carbon seal (22;53) and said seal

runner (23) are axially concentric, and wherein said

seal runner (23) and said carbon seal (22;53) each

have a cylindrical surface disposed adjacent each

other for forming said substantially fluid tight seal.

5.

15

20

25

A gas turbine engine according to claim 5, wherein

said carbon seal (22;53) has a channel (110) formed

therein for fluid flow.

7.

A gas turbine engine according to claim 6, wherein

said channel (110) is formed substantially circumferential.

8.

A gas turbine engine according to claim 6 or claim

7, wherein said carbon seal (22;53) has a radially

extending path for allowing the discharge of pressurized gas to the outer surface of said seal runner

(23).

9.

A gas turbine engine according to claim 8, wherein

said carbon seal (22;53) is defined by a plurality of

arcuate adjoining members (105) and wherein said

radially extending path is formed between a pair of

said plurality of arcuate adjoining members (105).

14. A gas turbine engine according to any one of claims

10 to 13, which further includes means

(15,100,101) for discharging pressurized gas

against said lip seal (50) for reducing the load on

said shaft (15).

15. A gas turbine engine according to claim 1, wherein

said third sealing element is a windback (40).

17. A gas turbine engine according to any preceding

claim, wherein said third sealing element (40;50) is

for substantially reducing the flow of a contaminant

to said first sealing element (22;53) and wherein

said baffle (43) is connected to said housing (17)

and positioned radially from said second sealing element (23) for reducing the impingement of the contaminant on said third sealing element (40;50).

35

18. A gas turbine engine according to any preceding

claim, which further includes an annular radial passageway between said baffle (43) and said second

sealing element (23) leading to an annular cavity

(61) disposed around said second sealing element

(23), said annular radial passageway being smaller

than said annular cavity (61).

40

19. A gas turbine engine according to claim 18 when

dependent on any one of claims 10 to 14, wherein

said annular cavity (61) retains fluids to cool said lip

seal (50).

45

20. A gas turbine engine according to claim 18 or 19,

wherein said baffle (43) has an opening (75) therein

for allowing fluid drainage from said annular cavity

(61).

30

10. A gas turbine engine according to any preceding

claim, wherein said third sealing element is a lip seal

(50).

11. A gas turbine engine according to claim 10 when

dependant on any one of claims 2 to 9, wherein a

portion (50a) of said lip seal (50) rides on the outer

surface of said seal runner (23) to wipe contaminants away.

13. A gas turbine engine according to claim 11 or claim

12, wherein said baffle (43) is spaced axially from

said lip seal (50) and radially from said seal runner

(23) and wherein said baffle (43) acts to minimise

the direct impingement of excited fluid on said lip

seal (50).

16. A gas turbine engine according to claim 15, wherein

said windback (40) has only one thread (41).

A gas turbine engine according to any one of claims

2 to 4, wherein said carbon seal (22;53) is defined

by an arcuate carbon ring.

6.

10

50

55

12. A gas tubine engine according to claim 11, wherein

said lip seal (50) has an L shaped portion.

21. A gas turbine engine according to claim 20, wherein

said baffle (43) is sheet metal, and said opening

(75) permits the drainage of fluid from said annular

cavity (61) during the shut down of said gas turbine

engine (10).

22. A gas turbine engine according to any preceding

claim, wherein said baffle (43) is formed of sheet

metal and has anti-rotation means (76) for preventing rotation of the baffle (43) relative to said housing

(17).

11

EP 0 818 607 B1

23. A gas turbine engine (10) comprising:

a mechanical housing (17) within said gas turbine engine (10);

a shaft rotatably (15) mounted within said housing (17);

a first sealing element (22;53) coupled to said

housing (17);

a second sealing element (23) connected to

said shaft (15), said second sealing element

(23) arranged adjacent to said first sealing element (22;53) to form a rubbing interface therebetween;

a third sealing element (40;50) arranged adjacent said first sealing element (22;53) to form

a rubbing interface with said second sealing element (23), said third sealing element (40;50)

wiping the outer surface of said second sealing

element (23) to reduce the flow of a liquid to

said first sealing element (22;53);

characterised by a passageway (18, 125,

61) around said second sealing element (23) and in

fluid communication with said third element (40;50)

said passageway having a narrowed portion for

calming the flow of liquid prior to impingement upon

said third sealing element (40;50).

Dichtungselement (22; 53)

ein zweites, mit der Welle (15) verbundenes,

Dichtungselement (23), wobei das zweite Dichtungselement (23) angrenzend an das erste

Dichtungselement (22; 53) angeordnet wird,

um zwischen denselben eine wesentlich fluiddichte Dichtung zu bilden,

ein drittes, angrenzend an das zweite Dichtungselement (23) angeordnetes, Dichtungselement (40; 50),

10

gekennzeichnet durch ein mit Zwischenraum zu dem dritten Dichtungselement (40; 50) angeordnetes und um das zweite Dichtungselement

(23) angeordnetes Leitblech (43).

15

2.

Gasturbinentriebwerk nach Anspruch 1, bei dem

das erste Dichtungselement (22; 53) eine Kohledichtung ist und das zweite Dichtungselement (23)

ein Dichtungslaufrad ist, und bei dem auerdem

das dritte Dichtungselement (40; 50) das Dichtungslaufrad (23) berhrt.

3.

Gasturbinentriebwerk nach Anspruch 2, bei dem

das Dichtungslaufrad (23) einen um dasselbe geformten umlaufenden Khlungskanal (33) hat.

4.

Gasturbinentriebwerk nach Anspruch 2 oder Anspruch 3, bei dem die Kohledichtung (22; 53) und

das Dichtungslaufrad (23) in Axialrichtung konzentrisch sind, und bei dem das Dichtungslaufrad (23)

und die Kohledichtung (22; 53) jeweils eine aneinander angrenzend angeordnete zylindrische Flche haben, um die wesentlich fluiddichte Dichtung

zu bilden.

5.

Gasturbinentriebwerk nach einem der Ansprche 2

bis 4, bei dem die Kohledichtung (22; 53) durch einen bogenfrmigen Kohlering definiert wird.

6.

Gasturbinentriebwerk nach Anspruch 5, bei dem

die Kohledichtung (22; 53) einen in derselben geformten Kanal (110) fr einen Fluidstrom hat.

7.

Gasturbinentriebwerk nach Anspruch 6, bei dem

der Kanal (110) wesentlich umlaufend geformt wird.

8.

Gasturbinentriebwerk nach Anspruch 6 oder Anspruch 7, bei dem die Kohledichtung (22; 53) eine

in Radialrichtung verlaufende Bahn hat, um das

Ausstrmen von unter Druck gesetztem Gas zur

Auenflche des Dichtungslaufrads (23) zu ermglichen.

9.

Gasturbinentriebwerk nach Anspruch 8, bei dem

die Kohledichtung (22; 53) durch eine Vielzahl von

20

25

24. A gas turbine engine according to claim 23, wherein

said third sealing element is a lip seal (50).

30

25. A gas turbine engine according to claim 24, wherein

said lip seal (50) has pressurized gas discharged

thereagainst for reducing said lip seal's load on said

shaft (15).

35

26. A gas turbine engine according to claim 23, wherein

said third sealing element is a windback (40).

27. A gas turbine engine according to any one of claims

23 to 26, wherein said first sealing element (22;53)

is a carbon seal and said second sealing element

(23) is a seal runner, said carbon sealing element

(22;53) and said seal runner (23) being axially concentric.

40

45

Patentansprche

1.

Gasturbinentriebwerk (10), das folgendes umfat:

50

ein Maschinengehuse (17) innerhalb des

Gasturbinentriebwerks (10),

eine drehbar innerhalb des Gehuses angebrachte Welle (15),

12

55

ein erstes, an das Gehuse (17) gekoppeltes,

13

EP 0 818 607 B1

bogenfrmigen aneinanderstoenden Elementen

(105) definiert wird, und bei dem die in Radialrichtung verlaufende Bahn zwischen einem Paar der

Vielzahl von bogenfrmigen aneinanderstoenden

Elementen (105) gebildet wird.

(23) einschliet, der zu einem um das zweite Dichtungselement (23) angeordneten ringfrmigen

Hohlraum (61) fhrt, wobei der ringfrmige Durchgang in Radialrichtung kleiner ist als der ringfrmige

Hohlraum (61).

10

19. Gasturbinentriebwerk nach Anspruch 18, wenn von

einem der Ansprche 10 bis 14 abhngig, bei dem

der ringfrmige Hohlraum (61) Fluids zurckhlt,

um die Lippendichtung (50) zu khlen.

15

20. Gasturbinentriebwerk nach Anspruch 18 oder 19,

bei dem das Leitblech (43) eine ffnung (75) in

demselben hat, um einen Fluidabflu aus dem ringfrmigen Hohlraum (61) zu ermglichen.

10. Gasturbinentriebwerk nach einem der vorhergehenden Ansprche, bei dem das dritte Dichtelement eine Lippendichtung (50) ist.

11. Gasturbinentriebwerk nach Anspruch 10, wenn von

einem der Ansprche 2 bis 9 abhngig, bei dem ein

Abschnitt (50a) der Lippendichtung (50) auf der Auenflche des Dichtungslaufrads (23) luft, um Verunreinigungen wegzuwischen.

12. Gasturbinentriebwerk nach Anspruch 11, bei dem

die Lippendichtung (50) einen L-frmigen Abschnitt

hat.

20

13. Gasturbinentriebwerk nach Anspruch 11 oder Anspruch 12, bei dem das Leitblech (43) mit Zwischenraum in Axialrichtung zu der Lippendichtung

(50) und in Radialrichtung zu dem Dichtungslaufrad

(23) angeordnet wird, und bei dem das Leitblech

(43) wirksam ist, um das unmittelbare Auftreffen

von angeregtem Fluid auf die Lippendichtung (50)

auf ein Minimum zu verringern.

14

25

21. Gasturbinentriebwerk nach Anspruch 20, bei dem

das Leitblech (43) aus Blech ist und die ffnung

(75) whrend des Abschaltens des Gasturbinentriebwerks (10) den Abflu von Fluid aus dem ringfrmigen Hohlraum (61) ermglicht.

22. Gasturbinentriebwerk nach einem der vorhergehenden Ansprche, bei dem das Leitblech (43) aus

Blech hergestellt wird und Rotationsverhinderungsmittel (76) hat, um ein Drehen des Leitblechs (43)

im Verhltnis zum Gehuse (17) zu verhindern.

23. Gasturbinentriebwerk (10), das folgendes umfat:

14. Gasturbinentriebwerk nach einem der Ansprche

10 bis 13, das auerdem Mittel (15, 100, 101) einschliet, um unter Druck gesetztes Gas gegen die

Lippendichtung (50) auszustoen, um die Belastung der Welle (15) zu verringern.

30

ein Maschinengehuse (17) innerhalb des

Gasturbinentriebwerks (10),

35

15. Gasturbinentriebwerk nach Anspruch 1, bei dem

das dritte Dichtungselement eine Windback-Labyrinthdichtung (40) ist.

16. Gasturbinentriebwerk nach Anspruch 15, bei dem

die Windback-Labyrinthdichtung (40) nur eine Windung hat.

17. Gasturbinentriebwerk nach einem der vorhergehenden Ansprche, bei dem das dritte Dichtungselement (40; 50) dazu dient, den Strom einer Verunreinigung zu dem ersten Dichtungselement (22;

53) wesentlich zu verringern, und bei dem das Leitblech (43) mit dem Gehuse (17) verbunden und in

Radialrichtung von dem zweiten Dichtungselement

(23) angeordnet wird, um das Auftreffen der Verunreinigung auf das dritte Dichtungselement (40; 50)

zu verringern.

18. Gasturbinentriebwerk nach einem der vorhergehenden Ansprche, das auerdem einen ringfrmigen Durchgang in Radialrichtung zwischen dem

Leitblech (43) und dem zweiten Dichtungselement

eine drehbar innerhalb des Gehuses (17) angebrachte Welle (15),

ein erstes, an das Gehuse (17) gekoppeltes,

Dichtungselement (22; 53)

40

45

50

55

ein zweites, mit der Welle (15) verbundenes,

Dichtungselement (23), wobei das zweite Dichtungselement (23) angrenzend an das erste

Dichtungselement (22; 53) angeordnet wird,

um zwischen denselben eine Reibgrenzflche

zu bilden,

ein drittes, angrenzend an das zweite Dichtungselement (23) angeordnetes, Dichtungselement (40; 50), um eine Reibgrenzflche mit

dem zweiten Dichtungselement (23) zu bilden,

wobei das dritte Dichtungselement (40; 50) die

Auenflche des zweiten Dichtungselements

(23) abwischt, um den Strom einer Flssigkeit

zu dem ersten Dichtungselement (22; 53) zu

verringern,

gekennzeichnet durch einen Durchgang

(18, 125, 61) um das zweite Dichtungselement (23)

15

EP 0 818 607 B1

und in Fluidverbindung mit dem dritten Element (40;

50), wobei der Durchgang einen verengten Abschnitt hat, um den Flssigkeitsstrom vor dem Auftreffen auf das dritte Dichtungselement (40; 50) zu

beruhigen.

2.

Moteur turbine gaz selon la revendication 1,

dans lequel ledit premier lment d'tanchit (22;

53) est une garniture d'tanchit en carbone et ledit deuxime lment d'tanchit (23) est une roue

mobile d'tanchit, et en outre dans lequel ledit

troisime lment d'tanchit (40; 50) contacte ladite roue mobile d'tanchit (23).

3.

Moteur turbine gaz selon la revendication 2,

dans lequel ladite roue mobile d'tanchit (23)

comporte, forme autour de celle-ci, une gorge de

refroidissement circonfrentielle (33).

4.

Moteur turbine gaz selon la revendication 2 ou

la revendication 3, dans lequel ladite garniture

d'tanchit en carbone (22; 53) et ladite roue mobile d'tanchit (23) sont axialement concentriques, et dans lequel ladite roue mobile d'tanchit

(23) et ladite garniture d'tanchit en carbone (22;

53) prsentent chacune une surface cylindrique

dispose proximit l'une de l'autre pour former ledit joint d'tanchit sensiblement tanche aux fluides.

25

5.

Moteur turbine gaz selon l'une quelconque des

revendications 2 4, dans lequel ladite garniture

d'tanchit en carbone (22; 53) est dfinie par une

bague en carbone arque.

30

6.

Moteur turbine gaz selon la revendication 5,

dans lequel ladite garniture d'tanchit en carbone

(22; 53) comporte une gorge (110) forme en son

sein pour l'coulement de fluide.

35

7.

Moteur turbine gaz selon la revendication 6,

dans lequel ladite gorge (110) est de forme sensiblement circonfrentielle.

8.

Moteur turbine gaz selon la revendication 6 ou

la revendication 7, dans lequel ladite garniture

d'tanchit en carbone (22; 53) comporte un chemin s'tendant radialement pour permettre la dcharge de gaz sous pression vers la surface extrieure de ladite roue mobile d'tanchit (23).

9.

Moteur turbine gaz selon la revendication 8,

dans lequel ladite garniture d'tanchit en carbone

(22; 53) est dfinie par une pluralit d'lments attenants arqus (105) et dans lequel ledit chemin

s'tendant radialement est form entre une paire de

ladite pluralit d'lments attenants arqus (105).

24. Gasturbinentriebwerk nach Anspruch 23, bei dem

das dritte Dichtungselement eine Lippendichtung

(50) ist.

10

25. Gasturbinentriebwerk nach Anspruch 24, bei dem

die Lippendichtung (50) einen Aussto von unter

Druck gesetztem Gas gegen dieselbe hat, um die

Belastung der Welle (15) durch die Lippendichtung

zu verringern.

15

26. Gasturbinentriebwerk nach Anspruch 23, bei dem

das dritte Dichtungselement eine Windback-Labyrinthdichtung (40) ist.

20

27. Gasturbinentriebwerk nach einem der Ansprche

23 bis 26, bei dem das erste Dichtungselement (22;

53) eine Kohledichtung ist und das zweite Dichtungselement (23) ein Dichtungslaufrad ist, wobei

das Kohledichtungselement (22; 53) und das Dichtungslaufrad (23) in Axialrichtung konzentrisch

sind.

Revendications

1.

Moteur turbine gaz (10) comprenant:

un carter mcanique (17) l'intrieur dudit moteur turbine gaz (10);

un arbre (15) mont mobile en rotation l'intrieur dudit carter;

un premier lment d'tanchit (22; 53) coupl audit carter (17);

un deuxime lment d'tanchit (23) raccord audit arbre (15), ledit deuxime lment

d'tanchit (23) tant dispos adjacent audit

premier lment d'tanchit (22; 53) pour former entre eux un joint d'tanchit sensiblement tanche aux fluides;

un troisime lment d'tanchit (40; 50) positionn adjacent audit deuxime lment

d'tanchit (23);

caractris par une chicane (43) espace

dudit troisime lment d'tanchit (40; 50) et positionne autour dudit deuxime lment d'tanchit (23).

16

40

45

50

55

10. Moteur turbine gaz selon l'une quelconque des

revendications prcdentes, dans lequel ledit troisime lment d'tanchit est un joint lvre (50).

11. Moteur turbine gaz selon la revendication 10

lorsqu'elle dpend de l'une quelconque des reven-

17

EP 0 818 607 B1

19, dans lequel ladite chicane (43) comporte en son

sein une ouverture (75) pour permettre la vidange

du fluide de ladite cavit annulaire (61).

dications 2 9, dans lequel une partie (50a) dudit

joint lvre (50) chevauche la surface extrieure

de ladite roue mobile d'tanchit (23) pour liminer

les contaminants par essuyage.

5

12. Moteur turbine gaz selon la revendication 11,

dans lequel ledit joint lvre (50) comporte une partie en forme de L.

13. Moteur turbine gaz selon la revendication 11 ou

la revendication 12, dans lequel ladite chicane (43)

est espace axialement dudit joint lvre (50) et

radialement de ladite roue mobile d'tanchit (23),

et dans lequel ladite chicane (43) agit de faon

minimiser l'incidence directe du fluide excit sur ledit joint lvre (50).

18

21. Moteur turbine gaz selon la revendication 20,

dans lequel ladite chicane (43) est en tle, et ladite

ouverture (75) permet la vidange du fluide de ladite

cavit annulaire (61) pendant l'arrt dudit moteur

turbine gaz (10).

10

15

22. Moteur turbine gaz selon l'une quelconque des

revendications prcdentes, dans lequel ladite chicane (43) est en tle et comporte des moyens antirotation (76) pour empcher la rotation de la chicane (43) par rapport audit carter (17).

23. Moteur turbine gaz (10) comprenant:

14. Moteur turbine gaz selon l'une quelconque des

revendications 10 13, qui comprend en outre des

moyens (15, 100, 101) pour dcharger un gaz sous

pression contre ledit joint lvre (50) afin de rduire

la charge sur ledit arbre (15).

20

15. Moteur turbine gaz selon la revendication 1,

dans lequel ledit troisime lment d'tanchit est

un joint de refoulement (40).

25

16. Moteur turbine gaz selon la revendication 15,

dans lequel ledit joint de refoulement (40) ne possde qu'un seul filet (41).

17. Moteur turbine gaz selon l'une quelconque des

revendications prcdentes, dans lequel ledit troisime lment d'tanchit (40; 50) est destin

rduire sensiblement l'coulement d'un contaminant vers ledit premier lment d'tanchit (22;

53), et dans lequel ladite chicane (43) est raccorde

audit carter (17) et est positionne radialement par

rapport audit deuxime lment d'tanchit (23)

pour rduire l'incidence du contaminant sur ledit

troisime lment d'tanchit (40; 50).

18. Moteur turbine gaz selon l'une quelconque des

revendications prcdentes, qui comprend en outre

un passage annulaire radial entre ladite chicane

(43) et ledit deuxime lment d'tanchit (23)

menant une cavit annulaire (61) dispose autour

dudit deuxime lment d'tanchit (23), ledit passage annulaire radial tant plus petit que ladite cavit annulaire (61).

19. Moteur turbine gaz selon la revendication 18,

lorsqu'elle dpend de l'une quelconque des revendications 10 14, dans lequel ladite cavit annulaire (61) retient les fluides pour refroidir ledit joint

lvre (50).

un carter mcanique (17) l'intrieur dudit moteur turbine gaz (10);

un arbre (15) mont mobile en rotation l'intrieur dudit carter (17);

30

35

40

45

50

un premier lment d'tanchit (22; 53) coupl audit carter (17);

un deuxime lment d'tanchit (23) raccord audit arbre (15), ledit deuxime lment

d'tanchit (23) tant dispos adjacent audit

premier lment d'tanchit (22; 53) pour former entre eux une interface de frottement;

un troisime lment d'tanchit (40; 50) dispos adjacent audit premier lment d'tanchit (22; 53) pour former une interface de

frottement avec ledit deuxime lment d'tanchit (23), ledit troisime lment d'tanchit

(40; 50) essuyant la surface extrieure dudit

deuxime lment d'tanchit (23) pour rduire l'coulement d'un liquide vers ledit premier lment d'tanchit (22; 53);

caractris par un passage (18, 125, 61)

autour dudit deuxime lment d'tanchit (23) et

en communication de fluide avec ledit troisime lment (40; 50), ledit passage comportant une partie

rtrcie pour calmer l'coulement de liquide avant

l'incidence sur ledit troisime lment d'tanchit

(40; 50).

24. Moteur turbine gaz selon la revendication 23,

dans lequel ledit troisime lment d'tanchit est

un joint lvre (50).

55

25. Moteur turbine gaz selon la revendication 24,

dans lequel un gaz sous pression est dcharg contre ledit joint lvre (50) pour rduire la charge du

20. Moteur turbine gaz selon la revendication 18 ou

10

19

EP 0 818 607 B1

joint lvre sur ledit arbre (15).

26. Moteur turbine gaz selon la revendication 23,

dans lequel ledit troisime lment d'tanchit est

un joint de refoulement (40).

27. Moteur turbine gaz selon l'une quelconque des

revendications 23 26, dans lequel ledit premier

lment d'tanchit (22; 53) est une garniture

d'tanchit en carbone et ledit deuxime lment

d'tanchit (23) est une roue mobile d'tanchit,

ledit lment d'tanchit en carbone (22; 53) et ladite roue mobile d'tanchit (23) tant axialement

concentriques.

10

15

20

25

30

35

40

45

50

55

11

20

EP 0 818 607 B1

12

EP 0 818 607 B1

13

EP 0 818 607 B1

14

EP 0 818 607 B1

15

EP 0 818 607 B1

16

Вам также может понравиться

- A Practical Guide to Piping and Valves for the Oil and Gas IndustryОт EverandA Practical Guide to Piping and Valves for the Oil and Gas IndustryРейтинг: 5 из 5 звезд5/5 (3)

- Thomas Ogle Gas Saver Carburetor PatentДокумент11 страницThomas Ogle Gas Saver Carburetor Patentfatihy73Оценок пока нет

- ASTM D 3385 - 94-2003 - Infiltration Rate of Soils in Field Using Double-Ring PDFДокумент8 страницASTM D 3385 - 94-2003 - Infiltration Rate of Soils in Field Using Double-Ring PDFMartin Daniel Palacios Quevedo100% (1)

- Cast and Crew Release FormДокумент1 страницаCast and Crew Release FormTin AngusОценок пока нет

- Audit of Intangibles Consolidated PDFДокумент29 страницAudit of Intangibles Consolidated PDFRosemarie VillanuevaОценок пока нет

- El Piano PDFДокумент45 страницEl Piano PDFRichard EnglandОценок пока нет

- The Patrician, Vol. IДокумент418 страницThe Patrician, Vol. ILuca BarducciОценок пока нет

- William Hofeldt: in The Company of AngelsДокумент10 страницWilliam Hofeldt: in The Company of AngelsValentina RiveraОценок пока нет

- European Patent Specification: Turbine Engine With An Abradable SealДокумент10 страницEuropean Patent Specification: Turbine Engine With An Abradable SealshamsОценок пока нет

- European Patent Specification F01D 11/00: Printed by Jouve, 75001 PARIS (FR)Документ10 страницEuropean Patent Specification F01D 11/00: Printed by Jouve, 75001 PARIS (FR)shamsОценок пока нет

- United States Patent: Arness Et A) - (10) Patent N0.: (45) Date of PatentДокумент12 страницUnited States Patent: Arness Et A) - (10) Patent N0.: (45) Date of PatentshamsОценок пока нет

- TEPZZ - 4 885B - T: European Patent SpecificationДокумент10 страницTEPZZ - 4 885B - T: European Patent SpecificationshamsОценок пока нет

- European Patent Application: Method of Manufacturing A Spar CapДокумент11 страницEuropean Patent Application: Method of Manufacturing A Spar CapBrenoLucenaОценок пока нет

- 11 Composite ImpellerДокумент79 страниц11 Composite ImpellerNithin LouisОценок пока нет

- CarburettorsДокумент13 страницCarburettorslopezramon2111Оценок пока нет

- Docket No. 57975EДокумент14 страницDocket No. 57975EAngelo da CruzОценок пока нет

- Us 3407511Документ5 страницUs 3407511AhmadmartakОценок пока нет

- Patent eДокумент5 страницPatent eDaniel OliveiraОценок пока нет

- Gicc Us8631660Документ9 страницGicc Us8631660Ricardo RamsesОценок пока нет

- Modern Blast Furnace (BF) and Converter (Bof) Gas Cleaning - A Report of State-Of-The-Art TechnologyДокумент11 страницModern Blast Furnace (BF) and Converter (Bof) Gas Cleaning - A Report of State-Of-The-Art TechnologycvfОценок пока нет

- United States Patent (10) Patent No.: US 8,251,371 B2Документ4 страницыUnited States Patent (10) Patent No.: US 8,251,371 B2shamsОценок пока нет

- References Cited The Tip 8f The Blade 1ils Rotatabge, Abfotuht LgnglixtltdinlflДокумент11 страницReferences Cited The Tip 8f The Blade 1ils Rotatabge, Abfotuht LgnglixtltdinlflRubén Gutiérrez AmoОценок пока нет

- TEPZZ - 6Z768B - T: European Patent SpecificationДокумент23 страницыTEPZZ - 6Z768B - T: European Patent Specificationzweisteine777Оценок пока нет

- Patent Application Publication (10) Pub. No.: US 2014/0260215 A1Документ23 страницыPatent Application Publication (10) Pub. No.: US 2014/0260215 A1Bala RajuОценок пока нет

- articolROMAT2012rev6 ENGLДокумент4 страницыarticolROMAT2012rev6 ENGLIonita TaviОценок пока нет

- European Patent Application C25D 7/00, C25D 3/04,: Chrome Plated Engine ValveДокумент10 страницEuropean Patent Application C25D 7/00, C25D 3/04,: Chrome Plated Engine ValveMasum RavaniОценок пока нет

- Directive 009: Casing Cementing Minimum Requirements: July 1990Документ17 страницDirective 009: Casing Cementing Minimum Requirements: July 1990smithyry2014Оценок пока нет

- EP21160517NWB1Документ16 страницEP21160517NWB1frank saruhanОценок пока нет

- EP3138697B1Документ22 страницыEP3138697B1keyupequauce-2083Оценок пока нет

- Nemesgáz Motor Patent US20110113772 PDFДокумент12 страницNemesgáz Motor Patent US20110113772 PDFGergely HollóОценок пока нет

- IRE - 21 TURBOFAN ENGINE DESIGN - Group - 2Документ52 страницыIRE - 21 TURBOFAN ENGINE DESIGN - Group - 2Mr. Jaykumar JoshiОценок пока нет

- Dry Gas Seal1Документ8 страницDry Gas Seal1anshug1016100% (1)

- Lean Combustion Technology For Internal Combustion Engines: A ReviewДокумент4 страницыLean Combustion Technology For Internal Combustion Engines: A ReviewNitin NaveenОценок пока нет

- United States Patent: (12) (10) Patent N0.: US 7,377,754 B2Документ23 страницыUnited States Patent: (12) (10) Patent N0.: US 7,377,754 B2Selvaraji MuthuОценок пока нет

- Biffi Hydraulic ActuatorsДокумент28 страницBiffi Hydraulic ActuatorsMuthu Kumar RОценок пока нет

- A Review of Free-Piston Engine History and Applications.Документ16 страницA Review of Free-Piston Engine History and Applications.Thulasi RamОценок пока нет

- United States Patent (191: Hodgkins (45) Date of Patent: Oct. 21, 1986Документ10 страницUnited States Patent (191: Hodgkins (45) Date of Patent: Oct. 21, 1986nbnbОценок пока нет

- Ep2784324a1 - ImpДокумент29 страницEp2784324a1 - ImpSharad KokateОценок пока нет

- Spe163887 PDFДокумент11 страницSpe163887 PDFCarlos Ulises LeonidasОценок пока нет

- European Patent Specification: Rotating Proprotor Arrangement For A Tiltrotor AircraftДокумент23 страницыEuropean Patent Specification: Rotating Proprotor Arrangement For A Tiltrotor AircraftgorgiОценок пока нет

- Bifrm 0023 enДокумент0 страницBifrm 0023 enMario Rivera AlonsoОценок пока нет

- US7383809B2 失效Документ8 страницUS7383809B2 失效Steven CHENОценок пока нет

- IN - 202221004737 - A Supreme LPGДокумент28 страницIN - 202221004737 - A Supreme LPGkkОценок пока нет

- AluminumДокумент12 страницAluminummousaОценок пока нет

- European Patent Specification B64C 27/32: Printed by Jouve, 75001 PARIS (FR)Документ12 страницEuropean Patent Specification B64C 27/32: Printed by Jouve, 75001 PARIS (FR)Amir BahramiОценок пока нет

- Cardone Industries Et. Al. v. BBB IndustriesДокумент22 страницыCardone Industries Et. Al. v. BBB IndustriesPriorSmartОценок пока нет

- 70 Ijmperdapr201870Документ8 страниц70 Ijmperdapr201870TJPRC PublicationsОценок пока нет

- Steam Feed and Effect of Steam-Thermal Tire PyrolysisДокумент6 страницSteam Feed and Effect of Steam-Thermal Tire PyrolysisWonde BogОценок пока нет

- United Patent: StatesДокумент11 страницUnited Patent: Statesmick.pride81Оценок пока нет

- Air Cleaner For Internal Combustion EngineДокумент6 страницAir Cleaner For Internal Combustion EngineSirDeparnieux100% (1)

- Wo - 2020 - 242557 - A1 - Cement Slurries, Cured Cement and Methods of MakingДокумент39 страницWo - 2020 - 242557 - A1 - Cement Slurries, Cured Cement and Methods of MakingGabriel MartinsОценок пока нет

- Lagrangian SourceДокумент7 страницLagrangian SourceAnonymous caJfG6Оценок пока нет

- Bypass SystemsДокумент17 страницBypass SystemsNael100% (1)

- Thrust Reverser GEДокумент14 страницThrust Reverser GEMarco Raneo PezzanoОценок пока нет

- Characterization of The Ring Pack Lubricant and Its EnvironmentДокумент10 страницCharacterization of The Ring Pack Lubricant and Its EnvironmentAvinash Gamit100% (1)

- United States: (12) Patent Application Publication (10) Pub. No.: US 2013/0108418 A1Документ5 страницUnited States: (12) Patent Application Publication (10) Pub. No.: US 2013/0108418 A1shamsОценок пока нет

- Me 52500 Combustion Term Projectabstract: PengyuanguoДокумент3 страницыMe 52500 Combustion Term Projectabstract: PengyuanguoReshad ChowdhuryОценок пока нет

- United States Patent (19) 4,671,227: Hollerweger Et A1. Jun. 9, 1987Документ17 страницUnited States Patent (19) 4,671,227: Hollerweger Et A1. Jun. 9, 1987marcglebОценок пока нет

- Hyd Damper g3 m3dДокумент16 страницHyd Damper g3 m3dmailbkraoОценок пока нет

- FINAL Salient Tech Features - DGP - 2x20 MWДокумент11 страницFINAL Salient Tech Features - DGP - 2x20 MWNaresh BalujaОценок пока нет

- Two Stroke RotaryДокумент8 страницTwo Stroke RotaryslipsittinОценок пока нет

- 2002 Mega-Capacity Urea PlantsДокумент15 страниц2002 Mega-Capacity Urea PlantsEnrique CastañedaОценок пока нет

- TEPZZ - 6 48B - T: European Patent SpecificationДокумент13 страницTEPZZ - 6 48B - T: European Patent SpecificationshamsОценок пока нет

- Nickel and Cobalt MaterialsДокумент2 страницыNickel and Cobalt MaterialsshamsОценок пока нет

- Advanced NDTEquipmentsДокумент4 страницыAdvanced NDTEquipmentsshamsОценок пока нет

- June 23, 1925.: F . I: ZacherДокумент3 страницыJune 23, 1925.: F . I: ZachershamsОценок пока нет

- Microturbine Energy SystemsДокумент16 страницMicroturbine Energy SystemsshamsОценок пока нет

- Gas Turbine Blade CoatingsДокумент1 страницаGas Turbine Blade CoatingsshamsОценок пока нет

- European Patent Application: A Seal in A Gas Turbine and A Method of Manufacturing A SealДокумент3 страницыEuropean Patent Application: A Seal in A Gas Turbine and A Method of Manufacturing A SealshamsОценок пока нет

- European Patent Specification F01D 11/00, F01D 5/26: Printed by Jouve, 75001 PARIS (FR)Документ13 страницEuropean Patent Specification F01D 11/00, F01D 5/26: Printed by Jouve, 75001 PARIS (FR)shamsОценок пока нет

- Gas Turbine Compressor Washing State of The Art - Field ExperiencesДокумент8 страницGas Turbine Compressor Washing State of The Art - Field Experiencesshams100% (1)

- United States: (12) Patent Application Publication (10) Pub. No.: US 2013/0108418 A1Документ5 страницUnited States: (12) Patent Application Publication (10) Pub. No.: US 2013/0108418 A1shamsОценок пока нет

- Ulllted States Patent (10) Patent N0.: US 8,430,626 B1Документ9 страницUlllted States Patent (10) Patent N0.: US 8,430,626 B1shamsОценок пока нет

- Tepzz 7Z 58B - T: European Patent SpecificationДокумент17 страницTepzz 7Z 58B - T: European Patent SpecificationshamsОценок пока нет

- United States Patent (10) Patent No.: US 8,251,371 B2Документ4 страницыUnited States Patent (10) Patent No.: US 8,251,371 B2shamsОценок пока нет

- Welding and Weld Repair of Single Crystal Gas Turbine Alloys PDFДокумент8 страницWelding and Weld Repair of Single Crystal Gas Turbine Alloys PDFshamsОценок пока нет

- Improved Power Plant PerformanceДокумент3 страницыImproved Power Plant Performanceshams100% (1)

- Dev ExpressДокумент9 страницDev ExpressamgalanОценок пока нет

- Prelim Midterm Exams Proel2Документ11 страницPrelim Midterm Exams Proel2james VillanuevaОценок пока нет

- Chaos in A Double Pendulum: Troy Shinbrot Celso Grebogi Jack Wisdom James A. YorkeДокумент10 страницChaos in A Double Pendulum: Troy Shinbrot Celso Grebogi Jack Wisdom James A. Yorkedomenico123Оценок пока нет

- Pros and COnsДокумент17 страницPros and COnsj3r1c0d5Оценок пока нет

- Free Drawing Book For Kids Cartooning With Letters Numbers Words PDFДокумент34 страницыFree Drawing Book For Kids Cartooning With Letters Numbers Words PDFநாகராசன் சண்முகம்83% (6)

- Cyclone4 HandbookДокумент490 страницCyclone4 HandbookatalincОценок пока нет

- Fluid Motion Energy ConverterДокумент16 страницFluid Motion Energy ConverterAlberto TeodoroОценок пока нет

- United States Patent (19) : Johnson, JRДокумент4 страницыUnited States Patent (19) : Johnson, JRrancang pabrikОценок пока нет

- Blood Pressure ChartДокумент8 страницBlood Pressure ChartmrusdiantoОценок пока нет

- B.3.4 Design Calculations For Snap-Fit Joints, FarbigДокумент18 страницB.3.4 Design Calculations For Snap-Fit Joints, FarbigpchannagoudarОценок пока нет

- Lenz V Universal Music CorpДокумент16 страницLenz V Universal Music CorpJorel Andrew FlautaОценок пока нет

- SaprodgdeДокумент6 страницSaprodgdeA MahmoodОценок пока нет

- Harmonic Trading: Establishing The 4 Main Types of Harmonic PatternsДокумент17 страницHarmonic Trading: Establishing The 4 Main Types of Harmonic PatternsMancusoMartin100% (1)

- In The United States District Court For The District of DelawareДокумент31 страницаIn The United States District Court For The District of DelawareYCSTBlogОценок пока нет

- Synthetic Division Practice Problems 1Документ1 страницаSynthetic Division Practice Problems 1Tine AquinoОценок пока нет

- Winter Vocabulary Esl Matching Exercise Worksheet For KidsДокумент2 страницыWinter Vocabulary Esl Matching Exercise Worksheet For KidsSusi ToscanoОценок пока нет

- FCL01Документ11 страницFCL01quemasda quiensoyОценок пока нет

- Co Tiong Sa Co Tiong Sa v. Director of Patentsv. Director of PatentsДокумент2 страницыCo Tiong Sa Co Tiong Sa v. Director of Patentsv. Director of PatentsNenzo Cruz100% (1)

- Astm e 1135 - 12Документ6 страницAstm e 1135 - 12Martin Chimenti - ARO SAОценок пока нет

- RTD Microchip AN687A - Pt100Документ8 страницRTD Microchip AN687A - Pt100ge_bdОценок пока нет

- Fundamentals of Machine Component Design 5th Edition Juvinall Solutions ManualДокумент36 страницFundamentals of Machine Component Design 5th Edition Juvinall Solutions Manualadelaidethaoj8w3100% (32)

- Test For Footwear and Footwear Materials - : Methods ofДокумент8 страницTest For Footwear and Footwear Materials - : Methods ofhemantp1170Оценок пока нет

- ASTM C 289 ASR Aggregates Chemical MethodДокумент7 страницASTM C 289 ASR Aggregates Chemical Methodsattiric100% (1)

- Full Download Essentials of Comparative Politics 5th Edition Oneil Test BankДокумент35 страницFull Download Essentials of Comparative Politics 5th Edition Oneil Test Banksearcher.forwardsg4f052100% (25)