Академический Документы

Профессиональный Документы

Культура Документы

Valvula de Diluvio Watts 100d-b

Загружено:

Luis Carlos Figueroa PintoАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Valvula de Diluvio Watts 100d-b

Загружено:

Luis Carlos Figueroa PintoАвторское право:

Доступные форматы

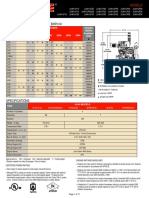

TECHNICAL BULLETIN

MODEL 100D-B

Deluge Valve- Electronically Actuated

UL Listed

Function

Opens on demand to provide water flow to the fire protection sprinkler system.

Pilot system can be hydraulically, pneumatically, or manually operated.

Opening of valve is by electrical signal to solenoid or by manual opening.

Features

The WATTS ACV 100D-B deluge valve meets all requirements for UL Listed,

fire protection service. The design and features incorporated into the

WATTS ACV valve assure dependable performance and long life.

Specifications

100D-B

5

Air/Hydraulic Pressure Line

TO

ATMOSPHERE

2

TO

ATMOSPHERE

TO

ATMOSPHERE

3

Y

FC

FLOW

1

Body and Cover: Ductile Iron - ASTM A536 Fusion Bonded Epoxy Coated

Cast Steel - ASTM A216 WCB Fusion Bonded Epoxy Coated

Seat (trim): Stainless Steel AISI 316 (CF8M) -Xylan Coated

Internals: (stem, seat seal retainer, retainer plate and seat):

Stainless Steel AISI 303 or 316

Diaphragm washers: Ductile Iron- ASTM A536 Fusion Bonded Epoxy Coated (6" & 8")

Steel- ASTM A36 Fusion Bonded Epoxy Coated (4" & 10")

Stem: Stainless Steel AISI 303 - Xylan Coated

Spring: Stainless Steel AISI 302

Elastomers: BUNA- N

100M Pneumatic/Hydraulic Control:

Body & Cover- Bronze -ASTM B61 or Stainless Steel AISI 316 (CF8M)

Seat & Stem-Stainless Steel AISI 316

Elastomers- BUNA-N

Solenoid: Brass or Stainless Steel/ Explosion Proof-Nema 4,7,9

Flow Direction Shown: Under the Seat

COMPONENTS

1 - Main Valve - Deluge

2 - 100M (Pneumatic/Hydraulic Control)

3 - Fixed Orifice Restriction

CLOSES VALVE

4 - Ball Valve

OPENS VALVE

5 - 3-Way Solenoid

FC - Flow-Clean Strainer

Control Tubing: Copper or Stainless Steel

Fittings: Brass,Stainless Steel

2" NPT drain ports provide test and drainage

10

UL

UL

UL

UL

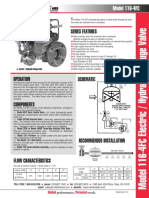

Operation

Figure 100D-B Deluge Valve is controlled by a 3-way direct-acting solenoid which controls the position of the Fig. 100M

Pnematic/Hydraulic pilot.

When the solenoid is de-enegerized, ports 1 and 3 are connected (port 2 is blocked). Pressure is routed to the cover

of the pneumatic/hydraulic control. The pneumatic/hydraulic control closes, closing the main valve.

When the solenoid is energized, port 1 and 2 are connected (port 3 is blocked). The cover of the pneumatic/hydraulic

control is vented. The control opens, opening the main valve.

An isolation ball valve in the control circuit provides a manual by-pass/ override of the pneumatic/hydraulic control.

Opening the ball valve will open the main valve. This ball valve is to be CLOSED during normal operation.

8550 Hansen Road . Houston, TX 77075 . Telephone 713.943.0688 . Fax 713.944.9445 www.wattsacv.com

ACV 100D-B TECHNICAL BULLETIN

DIMENSIONS

INSTALLATION

(TYPICAL)

DETECTION

CONTROL PANEL

Field Installed

Control Line

`'`'`

`'`'`'

'`'`'`'`'`

`'`'

'`'`'

`'`'`'

`'`'

SUPPLY

`'`'`

`'`'`'

'`'`'`'`'`

`'`'

'`'`'

`'`'`'

`'`'

DELUGE VALVE

`'`'

`'`'`'

`'`'

'`'`'

'`'`'`'`'`

`'`'`'

`'`'`

`'`'

`'`'`'

`'`'

'`'`'

'`'`'`'`'`

`'`'`'

`'`'`

`'`'`

`'`'`'

'`'`'`'`'`

`'`'

'`'`'

`'`'`'

`'`'

`'`'`

`'`'`'

'`'`'`'`'`

`'`'

'`'`'

`'`'`'

`'`'

NOTE:

Avoid mounting valve in

vertical discharge position

(valve stem horizontal orcover pointed side ways).

Valves mounted in this

position may not perform

as tested and approved.

STEM

ST

EM

TO FIRE

PROTECTION

SYSTEM

INSTALLATION/ START-UP

Start-up of a deluge valve requires that proper procedures

be followed:

- Clear the line of slag and other debris.

- Close upstream system isolation valve, if so equipped.

- Install the valve so that the FLOW ARROW marked

on the valve body matches the flow through the line.

- Ensure that the manual by-pass isolation ball valve

is closed.

- Connect actuating air/hydraulic pressure source to

port 3 of the solenoid control.

STEP 1 Energize the solenoid to check actuation and to

confirm connection to power source.

STEP 2 De-energize the solenoid for initial valve filling.

STEP 5 Partially open the manual ball valve to vent

air trapped in the cover chamber. Close

when fluid begins to vent. Caution: Do not

remove or loosen top cover plug while valve

is under pressure.

STEP 6 Energize the solenoid. This will vent the

pneumatic/hydraulic control cover chamber,

causing the main valve to open.

STEP 7 De-energize the solenoid. This will pressure the

pneumatic/hydraulic control cover chamber,

causing the main valve to close.

STEP 4 Open manual by-pass ball valve to ensure that

the main valve opens. MANUAL BY-PASS BALL

VALVE MUST BE CLOSED DURING NORMAL

OPERATION OF VALVE.

STEP 3 Activate the air/hydraulic pressure source.

STEP 4 Pressure the line, opening the upstream isolation

valve slowly.

*Where difficulty in performance is experienced, WATTSACV or an authorized representative shall be contacted if any

field adjustment is to be made.

8550 Hansen Road . Houston, TX 77075 . Telephone 713.943.0688 . Fax 713.944.9445 www.wattsacv.com

Вам также может понравиться

- Solid Bore Discharge Formula & Flow Testing GuidelinesДокумент1 страницаSolid Bore Discharge Formula & Flow Testing GuidelinesDiego Francisco Ancajima CuevaОценок пока нет

- Firetrol - Data Sheet - Mod. FTA550FДокумент11 страницFiretrol - Data Sheet - Mod. FTA550FRolan PonceОценок пока нет

- R03 RELA-EOL End-Of-Line RelayДокумент2 страницыR03 RELA-EOL End-Of-Line RelayAngela Peralta100% (1)

- Manual de Diseño Ecaro 25Документ110 страницManual de Diseño Ecaro 25Jose Gregorio Prada RodriguezОценок пока нет

- Ansul: Vehicle Fire Suppression Systems Parts ListДокумент2 страницыAnsul: Vehicle Fire Suppression Systems Parts ListPau MundacaОценок пока нет

- Ficha Tecnica Motor DP6H-UFAA88Документ9 страницFicha Tecnica Motor DP6H-UFAA88SYA33% (3)

- C0108031 O&M Manual y Curva Fabricante PDFДокумент127 страницC0108031 O&M Manual y Curva Fabricante PDFcesar100% (1)

- TF20G 2000GPM DieselДокумент1 страницаTF20G 2000GPM DieselKarim Tarek100% (1)

- Parts Illustration - JU6 - Tier 3Документ37 страницParts Illustration - JU6 - Tier 3Franklin Gustavo Zagaceta Bautista100% (1)

- Installation & Maintenance of Foam ChambersДокумент5 страницInstallation & Maintenance of Foam ChambersvivicastedoОценок пока нет

- FMM - 4-20ma I56-2991-002Документ2 страницыFMM - 4-20ma I56-2991-002Elias RangelОценок пока нет

- Panel de Control XLS200Документ2 страницыPanel de Control XLS200Carlos AlbertoОценок пока нет

- Safety Precautions For Scott Air-Pak CylindersДокумент2 страницыSafety Precautions For Scott Air-Pak CylindersDario Yañez CОценок пока нет

- Wa 800 Catalogo Komatsu CargadorДокумент12 страницWa 800 Catalogo Komatsu CargadorElvis Eberth Huanca MachacaОценок пока нет

- Model 878752 Suppression System Abort Station Installation InstructionsДокумент2 страницыModel 878752 Suppression System Abort Station Installation InstructionsAlexander TiopanОценок пока нет

- Fitflow Supplies 500GPM Pump DatasheetДокумент2 страницыFitflow Supplies 500GPM Pump DatasheetRonni LBОценок пока нет

- Lede Valve - Compuerta BridadaДокумент1 страницаLede Valve - Compuerta Bridadajhoger2012Оценок пока нет

- Detector Fike 63-1053Документ2 страницыDetector Fike 63-1053Hugo Bermeo CarrionОценок пока нет

- Master Actuation Pack-FikeДокумент2 страницыMaster Actuation Pack-Fikepaloale2180% (5)

- Battery Specification Sheet - C131885Документ1 страницаBattery Specification Sheet - C131885Ricardo BarrosОценок пока нет

- Clarke JU6H Specification SheetДокумент2 страницыClarke JU6H Specification Sheetabhayundale100% (1)

- DATA SHEET FIRE PEERLESS ELECTRICO 75HP-220V-MOD-4AEF10C (500 GPM at 150P...Документ20 страницDATA SHEET FIRE PEERLESS ELECTRICO 75HP-220V-MOD-4AEF10C (500 GPM at 150P...LUIS SOTELO50% (2)

- ChemetronДокумент82 страницыChemetrongto_indoОценок пока нет

- Ju4h Uf14Документ11 страницJu4h Uf14Ahmed Salah Abd EL-WahedОценок пока нет

- Cheetah Xi DatasheetДокумент26 страницCheetah Xi DatasheetJM CEОценок пока нет

- BH-90a User Manual - Portable Single Gas DetectorДокумент12 страницBH-90a User Manual - Portable Single Gas DetectorJose GarciaОценок пока нет

- Maintenance Schedule Checklist: Check and Correct As NecessaryДокумент1 страницаMaintenance Schedule Checklist: Check and Correct As NecessaryLeonardo RamirezОценок пока нет

- Clarke INSTALLATION & OPERATION DATAДокумент12 страницClarke INSTALLATION & OPERATION DATAInam Haq100% (1)

- Simplex Fire Alarm Model Number To Data SheetДокумент24 страницыSimplex Fire Alarm Model Number To Data SheetAntonio Carlos Müller100% (1)

- Chemetron Micro 1 Ev Chemetronics Fire SystemsДокумент34 страницыChemetron Micro 1 Ev Chemetronics Fire SystemsIrwan Ramdani100% (1)

- 06 791 1 - Rev2 PDFДокумент94 страницы06 791 1 - Rev2 PDFMaria Ignacia VasquezОценок пока нет

- JU4H-UF34 ProposalДокумент12 страницJU4H-UF34 ProposalUmmeОценок пока нет

- Pyro-Chem Manual PDFДокумент109 страницPyro-Chem Manual PDFKevin Tsui100% (4)

- Hi-T Pigalert IOM ManualДокумент14 страницHi-T Pigalert IOM ManualRaghОценок пока нет

- SPP Pumps - Tf15h - Dp6h-Ufaa50 - DrawingДокумент1 страницаSPP Pumps - Tf15h - Dp6h-Ufaa50 - Drawingroger cuipalОценок пока нет

- FMDS0326Документ15 страницFMDS0326Story LoveОценок пока нет

- ClarkeДокумент11 страницClarkeJuan Carlos100% (2)

- Gas Cartridge ActuatorДокумент2 страницыGas Cartridge ActuatorJavier Guillermo Nuñez Valdivia0% (1)

- CDR-UCN - L (Mech Seal)Документ31 страницаCDR-UCN - L (Mech Seal)Sandi AslanОценок пока нет

- Ty6236 Esfr k14 ColganteДокумент4 страницыTy6236 Esfr k14 ColganteRaúl Antonio MacíasОценок пока нет

- 06 369 CheetahXi 50 Install Manual Rev 6Документ76 страниц06 369 CheetahXi 50 Install Manual Rev 6victor sagastumeОценок пока нет

- Manual Cheetah XIДокумент158 страницManual Cheetah XIart159357100% (3)

- TutorialДокумент4 страницыTutorialyeyi11100% (1)

- X Ls 200 System SpecificationsДокумент4 страницыX Ls 200 System SpecificationsCarlos AlbertoОценок пока нет

- Installation, Operation and Maintenance Manual for Modular Dry Chemical Vehicle Fire Suppression SystemsДокумент93 страницыInstallation, Operation and Maintenance Manual for Modular Dry Chemical Vehicle Fire Suppression SystemsWalid RzigОценок пока нет

- F40 61 ESE 4x3x13FM Electric SubmittalДокумент1 страницаF40 61 ESE 4x3x13FM Electric Submittalwili_ab8040Оценок пока нет

- Catalogo-Valvulas DewitДокумент126 страницCatalogo-Valvulas Dewitfrankie636850% (2)

- Foam Agent Field ManualДокумент11 страницFoam Agent Field Manualnap_carino100% (1)

- Busqueda API 521Документ2 страницыBusqueda API 521bogginocОценок пока нет

- Foam Liquid Concentrates - Ul Product Iq SolbergДокумент15 страницFoam Liquid Concentrates - Ul Product Iq SolbergLuis Alberto Serrano MesaОценок пока нет

- Toma Chemetron Serie 500Документ4 страницыToma Chemetron Serie 500ricardo velascoОценок пока нет

- C06-018rev6 CO2 Design ManualДокумент178 страницC06-018rev6 CO2 Design Manualcmarinvzla100% (1)

- Electri RelifДокумент18 страницElectri Relifsuleman247Оценок пока нет

- 08-Conv Valves Product InfoДокумент18 страниц08-Conv Valves Product Infoakrk777Оценок пока нет

- Model A Deluge Valve Features and OperationДокумент4 страницыModel A Deluge Valve Features and OperationmanbkkОценок пока нет

- On - Off ValveДокумент5 страницOn - Off Valvekresimir.mikoc9765Оценок пока нет

- Automatic Rapping SystemДокумент8 страницAutomatic Rapping SystemAnonymous j0aO95fgОценок пока нет

- Deluge Valve Technical Data SheetДокумент14 страницDeluge Valve Technical Data SheetSiddharth GupteОценок пока нет

- Hoja de Datos - 116-4FCДокумент2 страницыHoja de Datos - 116-4FCHenry Garavito RamirezОценок пока нет

- ACV 113-6RFP Specification SheetДокумент4 страницыACV 113-6RFP Specification SheetWattsОценок пока нет

- Data Sheet: Photoelectric Smoke DetectorДокумент2 страницыData Sheet: Photoelectric Smoke DetectorLuis Carlos Figueroa PintoОценок пока нет

- Agent Release Module: EOL - End of Line ResistorДокумент2 страницыAgent Release Module: EOL - End of Line ResistorLuis Carlos Figueroa PintoОценок пока нет

- PDFДокумент7 страницPDFJose JohnОценок пока нет

- Integra32 Harware ManualДокумент26 страницIntegra32 Harware Manuallcfigueroa1987Оценок пока нет

- PDFДокумент7 страницPDFJose JohnОценок пока нет

- Gram A Tic AДокумент1 страницаGram A Tic ALuis Carlos Figueroa PintoОценок пока нет

- ACRONYM LISTДокумент2 страницыACRONYM LISTLuis Carlos Figueroa PintoОценок пока нет

- 1.0 PurposeДокумент2 страницы1.0 PurposeLuis Carlos Figueroa PintoОценок пока нет

- Vikas KumarДокумент4 страницыVikas Kumarsanju sharmaОценок пока нет

- Assignment On Uber: Going Global From Day One: Course Name: International Business Course Code: BUS 606 Section: AДокумент5 страницAssignment On Uber: Going Global From Day One: Course Name: International Business Course Code: BUS 606 Section: AIqbal JoyОценок пока нет

- Your First ProgramДокумент7 страницYour First ProgramJosephat MugumbaОценок пока нет

- Compro Saj 2023 - 22052023Документ58 страницCompro Saj 2023 - 22052023Ahmad FauziОценок пока нет

- Abinash Master SeminarДокумент51 страницаAbinash Master SeminarAGRICULTURE BOYОценок пока нет

- Report on internship at JDS TransformersДокумент50 страницReport on internship at JDS TransformersSachinОценок пока нет

- History of CFD Work in IndiaДокумент10 страницHistory of CFD Work in IndiajoemonjacobОценок пока нет

- Cat Marine Engine ProgramДокумент4 страницыCat Marine Engine ProgramRobert BeddingfieldОценок пока нет

- BCH102 Unit - III: Physiology Topic: BloodДокумент18 страницBCH102 Unit - III: Physiology Topic: Blooddivya vajpayeeОценок пока нет

- Metrology-Lab-Manual 3 Year 1semДокумент41 страницаMetrology-Lab-Manual 3 Year 1semBHARATH Chandra100% (1)

- BRP-1 Final Report Borjan Private LimitedДокумент38 страницBRP-1 Final Report Borjan Private LimitedArsalan IqbalОценок пока нет

- Chapter 16 Magnetic Fields: Electricity and MagnetismДокумент11 страницChapter 16 Magnetic Fields: Electricity and MagnetismeltytanОценок пока нет

- FOOD PRESERVATION CHART FOR CANNING LOW-ACID & ACID FOODSДокумент2 страницыFOOD PRESERVATION CHART FOR CANNING LOW-ACID & ACID FOODSjhОценок пока нет

- The Global Commitment 2021 Progress ReportДокумент39 страницThe Global Commitment 2021 Progress ReportComunicarSe-ArchivoОценок пока нет

- IDENTIFICATION. Identify The Following Questions Being Asked. (2 Points Each)Документ5 страницIDENTIFICATION. Identify The Following Questions Being Asked. (2 Points Each)Myla Rose AcobaОценок пока нет

- Rajan 2013Документ12 страницRajan 2013TheNourEldenОценок пока нет

- Ihp MicroДокумент13 страницIhp MicroTejas HambirОценок пока нет

- The Journey of HIV 1 Non-Nucleoside Reverse TranscriptaseДокумент33 страницыThe Journey of HIV 1 Non-Nucleoside Reverse TranscriptaseAnkit Kumar SinghОценок пока нет

- ExtraДокумент3 страницыExtraaman100% (1)

- Energy Engineering and Management For Building SystemДокумент288 страницEnergy Engineering and Management For Building SystemJivan BadaghaОценок пока нет

- NSL Hollow Core Slabs 12jul16 - 2016 Edition PDFДокумент24 страницыNSL Hollow Core Slabs 12jul16 - 2016 Edition PDFjohnkoh9950% (2)

- Certification Shop Test 3Документ13 страницCertification Shop Test 3sanyam dhawanОценок пока нет

- Ras Tanura Informatin-مهدیДокумент9 страницRas Tanura Informatin-مهدیxtrooz abiОценок пока нет

- Book ReviewДокумент4 страницыBook ReviewṬhanuama BiateОценок пока нет

- Chartering Terms ExplainedДокумент49 страницChartering Terms Explainedbrett1856Оценок пока нет

- Nissan Skyline RB Engine Oil Control ModsДокумент1 страницаNissan Skyline RB Engine Oil Control Modsbyrnesvictim100% (1)

- Sachin KotianДокумент4 страницыSachin Kotianapi-3699646Оценок пока нет

- Emc SCADA PresentationДокумент36 страницEmc SCADA Presentationerode els erodeОценок пока нет

- The Long Suffering of Frederic ChopinДокумент7 страницThe Long Suffering of Frederic ChopinDaniel CiobanuОценок пока нет

- ACS560 Drives (0.75 To 160 KW, 1.0 To 215 HP) : Hardware ManualДокумент164 страницыACS560 Drives (0.75 To 160 KW, 1.0 To 215 HP) : Hardware ManualNutan PowerОценок пока нет